6 0620A Roto-Jet I

SAFETY (CONT.)

9. Use the Right Cleaning Device. Do not use a cleaning device or attachment to do a job for which it

is not recommended. Refer to the Elliott E-100 catalog for all optional equipment. Do not alter the

machine or cleaning device, this will void the warranty on the product.

10. Use Proper Accessories. Use Elliott accessories only. Be sure accessories are properly installed

and maintained. Do not defeat a guard or other safety device when installing an accessory or

attachment.

11. Check for Damaged Parts. Inspect guards and other parts before use. Check for misalignment,

binding of moving parts, improper mounting, broken parts or any other conditions that may affect

operation. If abnormal noise or vibration occurs, turn the machine off immediately and have the

problem corrected before further use. Do not use a damaged machine. Tag damaged machines “Do

Not Use” until repaired. A guard or other damaged part should be properly repaired or replaced by

an Elliott service facility. For all repairs, insist on only identical replacement parts.

12. Remove All Wrenches. Check that all accessory wrenches are removed from the system before

turning it on.

13. Guard Against Electric Shock. Hold the exshaft by the insulated nonmetal casing surfaces. Inspect

and test the Ground Fault Circuit Interrupter (GFCI) prior to each new use of the machine to ensure

its proper operation. For more information refer to the “Electrical” section.

14. Avoid Accidental Starting. Be sure your machine is turned off before plugging it in. Do not use a

machine if the foot switch control does not turn the machine on and off. NEVER USE ANY OBJECT

TO HOLD THE FOOT SWITCH IN THE “ON” POSITION.

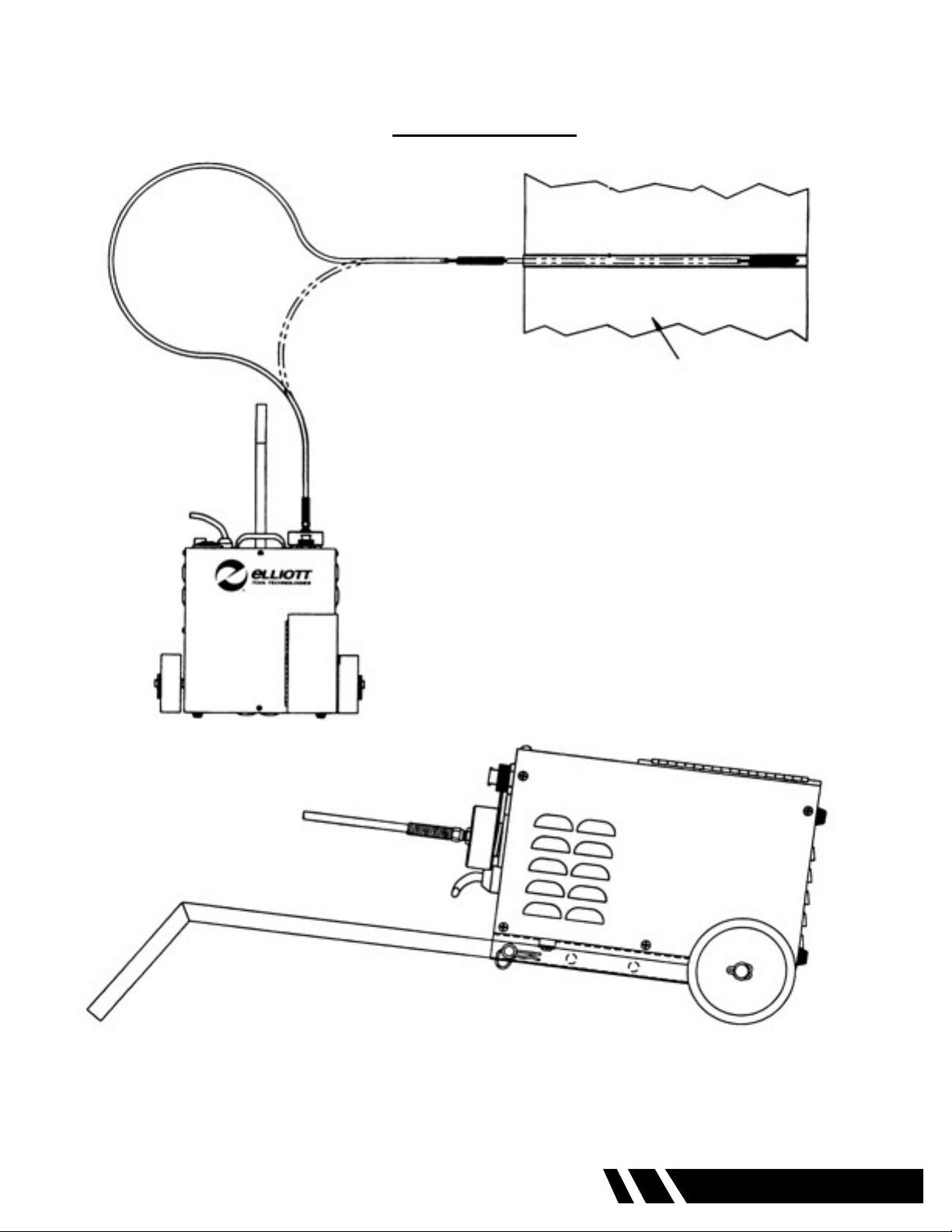

15. Do Not Force the Flexshaft. Your Elliott Roto-Jet™ will perform best at the rate for which it was

designed. Excessive force only causes operator fatigue, increased exshaft wear, shaft or break

away coupling failure.

16. Keep Hands Away from All Moving Parts.

17. Do Not Abuse Cord. Never carry your machine or foot switch by its cord. Never unplug the machine

by yanking the cord from the outlet. Pull the plug rather than the cord to reduce the risk of damage.

Keep the cord away from heat, oil, sharp objects, cutting edges and moving parts.

18. Do Not Overreach - Maintain Control. Keep proper footing and balance at all times.

19. Stay Alert. Watch what you are doing, and use common sense. DO NOT use a machine when you

are tired, distracted or under the inuence of drugs, alcohol or any medication causing decreased

control.

20. Unplug Machine when it is not in use, before changing accessories or performing recommended

maintenance.

21. Maintain Machine Carefully. Keep handles dry, clean and free from oil and grease. Follow

instructions for lubricating and changing accessories. For more information see “Maintenance”

section. Periodically inspect the machine cord and extension cords for damage. Have damaged

parts repaired or replaced by an Elliott service facility.

22. Store Idle Machines. When not is use, store your machine in a dry, heated, secured place. For more

information see “Maintenance” section.