ELMED SPG10 User manual

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: info@elmed.it

http://www.elmed.it

36·36·288

V6.2LM Service-Instruction (16.12.2015)

English

SPG10

Sprayer Computer

Instructions

Microprocessor control system

for agricultural sprayers

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

2

The

SPG10

Control Unit

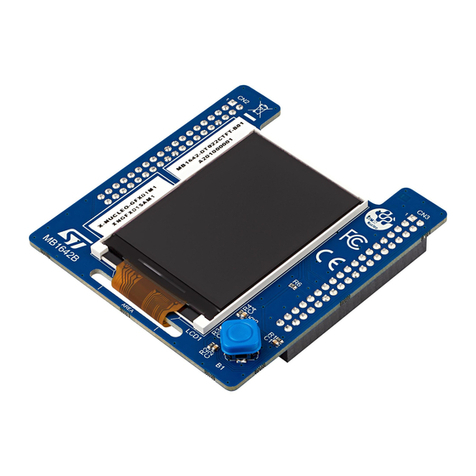

The SPG10 sprayer computer is used in fruit and vine cultivation. It is used as a control and

regulation device for agricultural sprayers that are designed for use with tractors.

In combination with the SPG20 control module and all the connected sensors, the SPG10

offers a tightly controlled spraying system for modern agriculture. There are clear economic

and environmental strengths to the spraying system. The regulation aspect guarantees

constant pressure through the sprayer valves and so it is easy to accurately meter the quantity

of product applied and to spray the required amount.

The system consists of an operating unit (SPG10), the control module (SPG20), one valve

actuator and various sensors. The operating unit has a clear Touch Monitor and it is fitted

directly in the tractor cab. The control module is attached to the sprayer tank and it is

connected to all the components of the sprayer control system. The measured nozzle pressure

and tank volume values are provided by a pressure sensor and a volume sensor and

transmitted to the control module.

Technical Data:

Display

Size

3.5 inches

Resolution:

320×240 pixels (black & white)

Backlight white LED; 7.0 cd/m² (type)

Touch screen

Input pin 10÷70 g

Finger 20÷80 g

Connections Mains supply: 12V DC power supply and RS485 serial interface

Serial interface: USB

Connections to

Volume sensor:

IDS03 spray and water resistant IP64

the SPG-20

Alternate motor for pump:

±12V statistically with overload protection

control unit

Pressure sensor

Up to 0÷60bar with 4÷20mA output signal

Speed sensor

2 wire Inductive sensor (NAMUR)

Flow sensor

Valve outlets for max. 8

nozzle rings and 1

supplementary relay

For motor or magnet valves (max. 8A per outlet)

Dimensions (SPG10 without plug):

(H × B × T) 104mm × 124mm × 45mm

Power consumption (SPG10 and SPG20

with all valves switched off):

270mA @ 12V DC

CE mark

CEE 89/336 EMC Directive

CEE 73/23 Low Voltage Directive

WEEE (en) ; RAEE (it)

Disposal of electrical and

electronic equipment

This device complies with the WEEE directive

regarding the proper disposal of electrical and

electronic equipment. Disposal in household waste

is prohibited. May cause environmental damage

and health problems. The unit must be disposed of

by a municipal waste disposal service (e.g. recycling

centre)

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

3

Safety information

WARNING! The following safety information aims to preserve the personal safety of the

user and protect the equipment and working environment from possible damage.

General

• Do not attempt to repair the device yourself if you have not received appropriate training.

Always fully comply with all installation instructions.

• Improper use of or interference with the device may result in damage to the device, fire or

other hazards. In addition, guarantee and warranty claims will be invalidated.

• Do not insert any objects in component apertures. This may damage the device by short-

circuiting the internal components.

• The device is protected against condensation and atmospheric moisture by a protective

lacquer. Nevertheless, deterioration of the lacquer may cause the device to be damaged due

to condensation. For this reason, if you enter a room with strongly fluctuating temperatures or

atmospheric humidity, please wait until the moisture has evaporated before starting up the

device.

Power supply

• Ensure that the polarity is correct before starting up the device.

The correct polarity for the connecting wires is shown in the wiring

diagram.

• Check the operating voltage! When the motor is running and all of

the nozzle rings are switched on, the operating voltage must be over 13V. It is possible to

display the voltage in the display area (

chapter 1.1).

• Protect the connecting wires: do not use the lead for pulling out the plug or carrying the

device. Make sure that the connecting wires do not come into contact with heat or sharp edges.

Damaged connecting wires may cause fire, short circuits and electric shocks.

Cleaning

• Do not use chemical solvents for cleaning, as these may damage the

plastic surface. You should also not use a pressure washer for cleaning. Any

water penetration could result in damage to the device.

• Clean the display with a soft, clean cloth and water. Moisten the cloth with

water and wipe the screen evenly in one direction from top to bottom. Quickly

remove any remaining moisture from the display and keep it dry. Over the long

term, moisture may damage the display. Do not use conventional window

cleaner for cleaning the display.

Assembly

• The SPG20 control unit that is fitted to the tank must be fitted in such a way that the cable

grommets point downwards to make it harder for water to penetrate.

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

4

Contents

Safety information................................................................................................................................... 3

1

The Main Window .......................................................................................................................... 6

1.1

Display area .............................................................................................................................. 6

1.2

Nozzle rings .............................................................................................................................. 7

1.2.1

Nozzle ring selection ......................................................................................................... 7

1.2.2

Switching on the left/right-hand nozzle rings ................................................................... 8

1.2.3

Fan cover ........................................................................................................................... 8

1.2.4

Sectors in multi-row sprayers ........................................................................................... 8

1.3

Main switch .............................................................................................................................. 8

1.4

Setting the pressure manually................................................................................................... 9

1.5

Setting the pressure automatically ............................................................................................ 9

1.5.1

Setting the nominal pressure without a spray programme: ............................................... 9

1.5.2

Setting the pressure with a spray programme: .................................................................. 9

1.6

The alarm list .......................................................................................................................... 10

2

Settings ...........................................................................................................................................11

2.1

Settings in semi-automatic mode (½Auto) ............................................................................. 12

3

Spray Management ....................................................................................................................... 13

Creating a spray programme ......................................................................................................... 13

3.1

Field ........................................................................................................................................ 14

3.2

Spray programmes .................................................................................................................. 15

3.2.1

Page 1: (Programme and field selection) ........................................................................ 15

3.2.2

Page 2: (Programme settings) ......................................................................................... 16

3.2.2.1

Standard option ........................................................................................................ 16

3.2.2.2

SBR South Tyrol Option ..................................................................................... 17

3.2.3

Page 3: (Selecting the chemical/product) ........................................................................ 18

3.2.4

Spray Programme Management ...................................................................................... 18

3.3

Chemicals/Products ................................................................................................................ 20

3.4

Statistics.................................................................................................................................. 20

3.5

Starting/stopping spraying ...................................................................................................... 21

21

1.1.1

Recording spray programmes and free memory ............................................................. 21

4

System Setup ................................................................................................................................. 22

4.1

Language ................................................................................................................................ 22

4.2

Alarm ...................................................................................................................................... 22

4.3

Content display (fast / slow) ................................................................................................... 22

4.4

Date and Time ........................................................................................................................ 23

4.5

Operating hours ...................................................................................................................... 23

5

Display Settings ............................................................................................................................ 23

5.1

Contrast .................................................................................................................................. 23

5.2

Backlight ................................................................................................................................ 24

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

5

5.3

Display test ............................................................................................................................. 24

6

Setup.............................................................................................................................................. 24

6.1

Impulses per 100mt ................................................................................................................ 24

6.2

Tank name .............................................................................................................................. 24

6.3

Beep if alarm? ........................................................................................................................ 24

6.4

Pressure display to one decimal place .................................................................................... 24

6.5

Standby after X minutes ......................................................................................................... 25

6.6

Level sensor adjustment ......................................................................................................... 25

6.7

Minimum pressure limit (pressure control) ............................................................................ 25

6.8

Minimum speed (km/h) .......................................................................................................... 26

6.9

Pressure losses in percent ....................................................................................................... 26

6.10

Flow rate impulses/litre .......................................................................................................... 26

6.11

Control with flow meter ......................................................................................................... 26

7

Service menu ................................................................................................................................. 27

Login 27

7.1

Setup SPG20........................................................................................................................... 27

7.2

Factory settings (default settings)........................................................................................... 28

7.3

Display calibration ................................................................................................................. 28

7.4

Number of nozzle rings .......................................................................................................... 29

7.5

Current display ....................................................................................................................... 29

8

Content ......................................................................................................................................... 29

8.1

Directory ................................................................................................................................. 29

8.2

Assignment ............................................................................................................................. 29

9

Dosing ........................................................................................................................................... 30

9.1

Accept “set” analogue value ................................................................................................... 30

9.2

Increase content incrementally ............................................................................................... 30

9.3

Edit content manually “+/- litre” ............................................................................................ 30

9.4

Dosing menu........................................................................................................................... 31

9.4.1

Change increment value .................................................................................................. 31

9.4.2

Save table ........................................................................................................................ 31

9.4.3

Edit table ......................................................................................................................... 31

9.4.4

Load table ........................................................................................................................ 32

10

Exchanging data with a PC ....................................................................................................... 32

11

IDS03 Volume Sensor ............................................................................................................... 32

11.1 Instructions on installing the volume sensor ............................................................................. 32

12

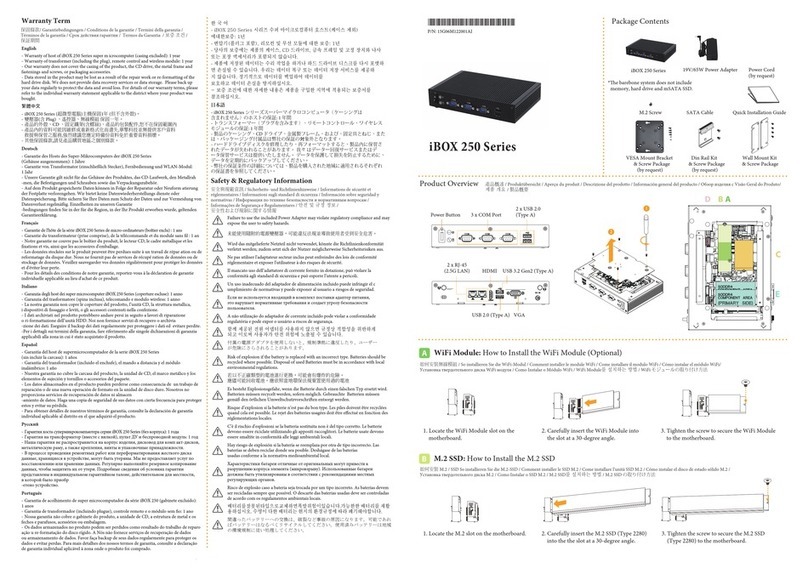

Wiring diagram ......................................................................................................................... 33

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

6

1

The Main Window

The main window appears after switching the computer

on (Fig. 1).

The main window consists of the button area around the

sides and the display area in the middle of the screen.

At the top of the screen there is also a status area. This

displays the current spray programme (three dashes (“--

-“) mean that no spray programme is active).

1.1 Display area

The display area shows – in big bold figures – the

pressure (above) and various measures available for selection (e.g. content, distance, speed,

etc.) (below).

The top of the display area only shows the pressure:

Pressure: The current pressure is shown at the top of the display

area in bar. This area is also used for setting the pressure either

manually or automatically. The current pressure regulation mode

is indicated in the top left-hand corner of this display area by

either “auto” or “man”. ( See chapter 1.4 „Setting the pressure manually“ or chapter

1.5 “Setting the pressure automatically”).

In the bottom part of the display area it is possible to select various measured values (content,

distance, speed etc.) (by clicking in the middle of the screen):

Content in litres: The content of the spray tank in litres. The

display speed can be adjusted in Settings (

Chapter 4.3) (fast

when filling, slow during travel).

Distance [m]/[km]: This is the distance travelled since

commencing spraying*. Below 1km the distance will be given in

meters (m), then only in km. Periods during which the nozzle

rings are closed are not counted. The recording ends with the

conclusion of the spray programme. (See also chapter 3.5 “Starting/stopping

spraying”).

Speed [km/h]: The current speed in km/h. This also appears in

smaller text above all the other measured variables selected (on

the right).

l/ha: The amount of spray (converted to litres per hectare) currently being applied.

l/min.: The current output in litres per minutes.

If a flow meter is in use, then a ring appears above the measured

quantity, which flashes when receiving a signal from the flow meter.

Fig. 1: Main window with 4 nozzle rings

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

7

Amount [l]: The total amount of spray in litres that has been applied since the start of

the current spraying operation*.

Area [ha]: Area covered since the start of the spraying operation in hectares*.

Voltage [V]: The supply voltage (battery voltage). In addition, an

alarm is triggered as soon as the voltage falls too low.

*

A new spraying operation starts when a new spray programme starts or by resetting the counter in semi-

automatic mode (→ chapter 2.1)

In the button area there are buttons for the nozzle rings, the menu button, the button for the

main switch, the button for switching between manual and automatic pressure control, and

optionally the switch symbol for the fan cover:

Nozzle rings

Menu

Fan cover

Main switch

Pressure control

to

or

The individual functions of these buttons are described in the following chapters.

1.2 Nozzle rings

On the right and left side of the display there are numbered buttons for the

nozzle rings. Depending on the number of nozzle rings that can be switched

on there may be 2, 4, 6 or 8 buttons.

The buttons on the left-hand side correspond to the nozzle rings on the left side of the

sprayer. Likewise the lower buttons correspond to the lower nozzle rings.

1.2.1

Nozzle ring selection

The nozzle rings are selected by pressing the corresponding button. The nozzle rings

selected are highlighted with a circle. Individual rings can be deselected by pressing the

relevant button again (circle disappears):

Nozzle ring selected Nozzle ring not selected

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

8

1.2.2

Switching on the left/right-hand nozzle

rings

By pressing in the left or right-hand area of the

content display (highlighted in blue in Fig. 2), or by

using the left/right button (on top of the device), the

right or left nozzle rings can be turned on or off

individually. If one side is turned on, this will be

shown with a solid dot (circled in red in Fig. 2).

Note: The nozzle rings can only be switch on/off

when the main switch (→ chapter 1.3) has been

deactivated.

Nozzle ring on

Nozzle ring off

Notes: In the case of prolonged inactivity (about 5 min. without speed, pressure and in

absence of any keys being operated on the display), all valves are switched off

automatically for safety reasons and in order to reduce power consumption (nozzle rings

and suction). Even the display illumination is turned off. The same applies to the IDS03

volume sensor (if in place).

1.2.3

Fan cover

The two switch symbols for switching the left and right-hand fan covers on and off

can be operated either manually or automatically (see also chapter 2 "Cover").

In the case of sprayers without the relevant covers, these buttons are not available.

1.2.4

Sectors in multi-row sprayers

With multi-row sprayers the individual sectors are switched on and off with the nozzle ring

buttons described above, and not the nozzle rings. In the case of tunnel sprayers, the left

and right sides of a sector are always turned on at the same time, even if you just click on

one of the two sides.

1.3 Main switch

All nozzle rings are switched off or on again with the main switch (press on the

corresponding symbol or with the middle button on the top of the device).

Main switch on, Main switch off

(=nozzle rings off) (=nozzle rings on)

Fig. 2: Switching on left/right-hand nozzle

rings

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

9

1.4 Setting the pressure manually

In order to control the pressure manually, the manual control

needs to be activated (“Man.” is displayed at the top left-

hand edge of the pressure display, see Fig. 3). Otherwise

this must first be switched to manual control mode

with the pressure control button.

The pressure can be reduced and increased by pressing the left or right-hand side of the

pressure gauge (down or up arrows, highlighted in blue in Fig. 3).

Briefly pressing the button reduces or increases the pressure gradually. Holding the arrows

increases or reduces the pressure continuously.

1.5 Setting the pressure automatically

Activate the automatic pressure gauge with the

pressure control button. The word “Auto” will

appear top left in the display

(see Fig. 4).

The pressure will now be regulated automatically to the

given set-point or the nominal pressure required by the spray

programme.

1.5.1

Setting the nominal pressure without a spray programme:

Press in the middle of the pressure display. A

window opens in which the nominal pressure can

be set (fig. 5).

The value can be increased or decreased

gradually using the plus and minus buttons.

Alternatively, you can also set the pressure

directly by sliding your finger on the bar.

Then press the OK button to accept the revised

nominal pressure value.

Notes: When using the automatic pressure

control, i.e. without an active spray programme,

it is very important to adhere precisely to the

correct speed of travel. Otherwise, at too high a

speed too little or at too low a speed too much spray will be applied per hectare. ( More

information on working without a spray programme can be found in chapter 2.1 “Settings

in semi-automatic mode (½Auto)”).

1.5.2

Setting the pressure with a spray programme:

When the pressure is set with an active spray programme, the nominal pressure setting

described above is ignored! The pressure is regulated solely by the spray programme, so

that the volume of spray applied per hectare – even if the speed is not adhered to

exactly – remains constant.

(See “Setting the pressure automatically” chapter3.5).

Fig. 3: Manual pressure setting

Fig. 4: Automatic pressure

setting

Fig. 5: Nominal pressure settings

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

10

1.6 The alarm list

The alarm list can be displayed by pressing on the

top edge of the screen (on "bar" or above, see Fig.

6). All active alarms are shown in this list (Fig. 7).

The following errors may be shown:

Battery voltage too low

Ensure that the sprayer computer is being

operated with sufficient voltage (between 12 and

14V DC). Unpredictable errors may occur if the

voltage is too low. The power may also be

interrupted if there is a poor connection between

the power supply cable and the port (e.g. due to

dirt or rust).

SPG10

+

SPG20

versions not compatible!

If this error occurs, then one of the devices has an

out-of-date software version and needs to be

updated.

Pressure out of range!

This error message appears if the pressure

deviates for a long period of time from the nominal

pressure. This may happen, for example, if

nozzles are blocked or if the nominal pressure has been set incorrectly.

Pressure sensor error!

The pressure sensor is defective or not connected. Check the pressure sensor or its

connections.

Tank volume table error!

The tank volume table is needed to determine the volume of the sprayer tank. This error

message appears if the tank volume table is damaged or no table has been assigned to

the system yet. This error can be resolved by selecting a new table in the service menu.

Volume sensor error!

The volume sensor is defective or not connected.

Speed out of range!

The speed of travel is too high or too low to guarantee the required sprayer output. The

nominal speed is specified in the spray programme. The maximum permitted speed

deviation may be adjusted in System setup under "Alarm" (chapter 4.2 “Alarm”).

Off-line, no connection!

It has not been possible to establish communication with the SPG20 control module. For

example, due to a missing or faulty connection to the control module.

Overcurrent has occurred

The amount of current absorbed by the pressure control motor has reached the maximum

value permitted. The motor will be switched off immediately until the error has been

resolved. If this error occurs often, please contact the customer service. The overcurrent

parameters can only be adjusted in the Service menu.

Fig. 6: Opening the alarm list

Fig. 7: The alarm list

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

11

2

Settings

Press the menu button to open the “setup” menu.

The status indicator that indicates the name of the

active spray programme is located in the bottom part

of the screen (Fig. 8). If no programme has been

started, “----” is displayed.

Pressing the “spraying” button opens the

spray management menu, where new or

modified spray programmes can be set up or edited.

Fields or chemicals/products can be displayed,

edited or added (→ chapter 3).

Clicking the “setup” button opens System setup, where you can change date, time and

language (→ chapter 4).

ON/OFF button: This button is used to switch a supplementary relay on or off.

Devices such as a stirrer, nozzle lighting etc. can be connected to this relay.

The label for this button can be freely selected (depending on the function assigned to it) and

can be changed in the service menu. (→ chapter 7.1)

Cover: This button is used to switch the fan cover control to automatic (the inverse of

the symbol is shown and the word "auto" appears in brackets).

If at least one nozzle ring is switched on on one side in automatic mode, then the

corresponding fan cover for this side is automatically switched on.

Fig. 8: Settings

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

12

2.1 Settings in semi-automatic mode

(½Auto)

If no active spray programme is running, so is the

semi-automatic mode automatically active. It

allows to work without a spray-program. In order

to display all measurements correctly in the

display area, the following settings need to be

made:

Number of nozzles

The number of nozzles for each nozzle ring is

shown separately in the top part of the screen

(order is clockwise, starting with the bottom

left nozzle ring).

To adjust the number of nozzles, press this

top area and a window will open (Fig. 10),

where the position of the nozzle rings with the

number of nozzles is displayed in graphic

form (bottom left to bottom right). Press one

of the nozzle rings (=selection fields) to define

a new number of nozzles.

Row width

Enter the row width in meters.

l/ha (optional)

The quantity in litres per hectare to be applied.

If the check box in the “l/ha” window is checked, then by clicking on the Sprayer output

field (a small distance from the check box), the desired quantity can be entered using

the number keypad. With this setting, it is also possible in semi-automatic mode to

regulate the pressure in the event of changes to the speed of travel.

km/h

The target speed of the sprayer during spraying is entered here in km/h. (Small

deviations in speed are taken into consideration as the vehicle is moving and

compensated for automatically).

Note: When the speed limiter function is active, then the value entered here (minus 0.2

km/h) is used as the threshold value. (For more information see Setup → chapter 6.8

“Minimum speed”)

Pressure in Bar:

The working pressure calculated by the programme is displayed.

The value cannot be adjusted. If you wish to change the pressure, the above-mentioned

parameters must be changed.

Nozzle type

The type of nozzle used (ATR or ISO) can be selected in the corresponding selection

box (under “Nozzles, right”, Fig. 9). The nozzle colour can be chosen in the preceding

field.

Fig. 10: Selecting the number of nozzles

Fig. 9: Settings for semi-automatic mode

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

13

The distance, content and area buttons

The three buttons for “Dist. = 0”, “Liter = 0” and “Area = 0”, can be used to reset the

counters for the display in the main window for distance, amount (litres) and area to 0

(see also chapter 1.1 → distance [m]/kmh], content [l] and area [ha]). Useful before

starting a new spraying operation without a spray programme.

Notes: Spraying operations are not recorded in semi-automatic mode and are therefore also

not available for statistical purposes or for evaluation on the PC.

3

Spray Management

Spray programmes can be created and edited in

Spray Management. These are required for starting

a spraying operation in automatic mode. A spray

programme is started using the Start button in the

"Setup" menu (see also chapter “3.5

Starting/stopping spraying”). The fields and

chemicals/products involved can be managed here

too. Moreover, the spraying operations recorded to

date can be viewed in the statistics.

Creating a spray programme

1. Set up a field (→ chapter 3.1) in the Field Management menu.

2. In the Spray programme menu (→ chapter 3.2) press on the pencil button. This will

enable you to access the “Spray programme management” menu (→ chapter 3.1.4) where

you can create a new spray programme.

3. Once you have returned to the Spray programme menu, you will be able to select the

desired programme and allocate it to a field (see → chapter 3.1.1)

4. As soon as the desired programme has been allocated to a field, you can proceed with

programming the spray programme. ( → chapter 3.1.2).

5. Save the programme with the “save” button.

Summary:

- Field (→ chapter 3.1)

- Spray programmes (→ chapter 3.2)

- Page 1: (Programme and field selection) (→ chapter 3.2.1)

- Page 2: (Programme settings) (→ chapter 3.2.2)

- Page 3: (Selecting the chemical/product) (→ chapter 3.2.3)

- Chemicals/Products (→ chapter 3.3)

- Statistics (→ chapter 3.4)

Fig. 11: Spray management

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

14

3.1 Field

The “Field management” menu (accessed

via spray management) is where all of

the fields that are needed for creating the

spray programmes can be created and

edited. Fields can also be edited on the PC

using the SPG10 software.

Field selection

The name of the field is displayed in the top part of

the screen. Pressing on this area opens a selection

window where another (existing) field can be

selected. Alternatively, you can switch between fields

with the arrow keys.

Editing parameters

Simply press one of the five lines (area, row width, plant height, variety or info). The data to

be amended can be amended with the input window now opened.

Area (m²)

Enter the field size in square meters here.

Row width

Enter the row width in meters here.

Plant height

Enter the plant height, also in meters.

Variety

All the varieties planted in the field can be entered here.

Info

Any text/note of your choice can be entered in the information line.

Create a new field

As soon as you click on the “New” button a new field is created with the name “New”.

Change field name

One press of this button opens the input field where the name can be changed.

Delete field

Press the delete button to delete a field. If the confirmation prompt is confirmed with

OK, the field will be irrevocably deleted.

Fig. 12: Field management

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

15

3.2 Spray programmes

Existing programmes can be viewed or edited

in the “spray programmes” menu, and new

spray programmes can also be created or even

deleted. In general, it is recommended just to change

little things. The programmes can be managed much

more comfortably on the PC, with the help of the

SPG10 software.

The “spray programmes” menu consists of 3 pages,

which can be scrolled through with the next and back

arrows. They are described individually in the

following 3 sub-sections:

3.2.1

Page 1: (Programme and field

selection)

First of all the programme to be viewed or edited

must be selected in the programme box (Fig. 13, top

left). To do this press on the relevant area. A list

appears. (Fig. 14), where you can choose the desired

programme. Confirm with the OK button. (If you wish

to apply a new programme, create it first, see

chapter 3.2.4).

Each programme is assigned a field which is

displayed in the field area (Fig. 13, top right). Press

in the relevant area to select another field. (To edit

fields or create new ones see chapter 3.2.4). The

most important parameters of the field selected are

shown under the two selection areas. (Fig. 13):

variety, row width, plant height.

Below are those values that can be calculated using the selected field and settings on page 2

and 3:

Water application in litres required for the spraying operation

The expected water output in

“litres per minute” and in

“litres per hectare”

And the necessary working pressure in bar

If 3 stars () also appear in the “working pressure” line, this means that the

recommended nozzles have not been selected for this pressure (nozzle selection

chapter 3.1.2).

Please make sure that all your changes are saved by pressing the “save” button.

Fig. 13: Spray programmes - page 1

Fig. 14: Drop-down list

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

16

3.2.2

Page 2: (Programme settings)

Depending on the device settings, for the second page there are two different input options

(standard and SBR). Which of the two options are applicable can be ascertained from the

parameters to be entered:

Standard option (

chapter 3.2.2.1)

with the following inputs: area, application quantity and speed. (see Fig. 15)

SBR South Tyrol option (

chapter 3.2.2.2)

with the following inputs: area, concentration, water required and speed. (see Fig. 17)

3.2.2.1

Standard option

The window with the “standard option” programme

settings only appears if the check-box for

“Calculation by SBR South Tyrol option” is disabled

in the Service menu ( chapter 7.1). Otherwise

please follow the instructions in the next chapter (

3.2.2.2).

The following parameter can be set:

Number of nozzles

The number of nozzles in each ring is shown

individually in the top part of the screen (in

clockwise order, starting with the bottom left

ring).

To adapt the number of nozzles press this top

area and a window will open (Fig. 16), where

the position of the nozzle rings with the

number of nozzles are shown in graphic form

(bottom left to bottom right). Press one of the

nozzle rings (=selection fields) to define a new

number of nozzles.

In the case of multi-row sprayers, just the number

of nozzles per sector needs to be indicated.

Area

The area to be worked is taken from the data for the assigned field. It can be adjusted

individually here.

Application rate

The amount in litres per hectare to be applied.

Fig. 16: Selecting the number of nozzles

Fig. 15: Spray programmes - page 2

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

17

Speed

This is where the recommended speed that should be adhered to when driving with the

sprayer is displayed in km/h. (Small deviations in speed are taken into consideration as

the vehicle is moving and compensated for automatically).

Note: When the speed limiter function is active, then the value entered here (minus 0.2

km/h) is used as the threshold value. (For more information see Setup → chapter 6.8

“Minimum speed”)

Nozzle-type

The type of nozzle used (ATR or ISO) can be selected in the corresponding selection

area (Fig. 15). The nozzle colour can be chosen in the neighbouring area. The

recommended nozzle colour indicated beneath is determined using the spray

programme settings.

3.2.2.2

SBR South Tyrol Option

The window with the “SBR South Tyro option”

programme settings only appears, if the check-box

for the “Calculation by SBR South Tyrol option” is

activated in the Service menu ( chapter 7.1).

Otherwise follow the instructions in the previous

chapter ( 3.2.2.1).

The following parameters can be set:

Number of nozzles

The number of nozzles in each ring is shown

individually in the top part of the screen (in

clockwise order, starting with the bottom left

ring).

To adapt the number of nozzles press this top

area and a window will open (Fig. 18), where

the position of the nozzle rings with the

number of nozzles are shown in graphic form

(bottom left to bottom right). Press one of the

nozzle rings (=selection fields) to define a new

number of nozzles.

In the case of multi-row sprayers, just the

number of nozzles per sector needs to be

indicated.

Area

The area to be worked is taken from the data for the assigned field. It can be adjusted

individually here.

Concentration

The spray concentration can be set here (1 to 30).

Fig. 17: Spray programmes - page 2

Fig. 18: Selecting the number of nozzles

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

18

Water application deviation in percent

Depending on the existing plant system it may be necessarily to adapt the water

application rate. Enter the deviation in percentage points (-50 to +50%).

Plant systems with recommended deviation:

0% = single row 30% = bed planting

10% = double row -10% = palms

20% = triple row

Speed

This is where the recommended speed that should be adhered to when driving with the

sprayer is displayed in km/h. (Small deviations in speed are taken into consideration as

the vehicle is moving and compensated for automatically).

Note: When the speed limiter function is active, then the value entered here (minus 0.2

km/h) is used as the threshold value. (For more information see Setup → chapter 6.8

“Minimum speed”)

Nozzle-type

The type of nozzle used (ATR or ISO) can be selected in the corresponding selection

area (Fig. 15). The nozzle colour can be chosen in the neighbouring area. The

recommended nozzle colour indicated beneath is determined using the spray

programme settings.

3.2.3

Page 3: (Selecting the chemical/product)

The chemicals/products used for the spraying operation

are entered on the last page.

Up to 5 chemicals/products may be selected. For each

chemical/product used the required (= max.

recommended) quantity per hectolitre is displayed in

grams alongside (may be amended by pressing on the

corresponding number). The final number is the

absolute quantity necessary for the field to be worked.

3.2.4

Spray Programme Management

To delete, copy or create programmes press

the button for managing the spray

programmes the “spray programmes” menu

(in the middle of the button area, Fig. 13 & 15 or 17 &

19). A new window opens (Fig. 20) with the following

four buttons:

Fig. 19: Spray programme – page 3

Fig. 20: Spray programme management

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

19

Create new programme

Press this button to create a new programme.

A name is suggested for the new programme in the window that now opens. This can

be amended by pressing on it.

The new programme is then saved with the “save” button.

Edit programme name

Select the programme whose name you wish to change. The name can be changed

in the field below. Since every spray programme is assigned to a field and at least one

chemical/product, it is recommended that the names should be chosen so that the

field and type of spraying operation can be recognized, e.g. “Home meadow scab

treatment”.

Copy programme

The programme to be copied is selected in

the “source” box in this window (Fig. 21) and

the programme to be overwritten is selected

in the “target” box. The programme in the

target box is overwritten by pressing the

arrow key. If you do not wish to overwrite an

existing programme, simply create a new

programme with the “new” button.

Delete programme

Any programme selected in the list can

be deleted with the “delete” button. Once

the confirmation prompt has been confirmed with OK the programme will be

irretrievably deleted.

Fig. 21: Copy programme

Mitterweg 25 – Via di Mezzo ai Piani 25

I

-

39100 Bozen

-

Bolzano

Tel.:

0471 977236

-

Fax:976525

e-mail: in[email protected]

http://www.elmed.it

20

3.3 Chemicals/Products

The individual chemicals/products can be

displayed and edited in Chemical/Product

Management. A chemical/product can be selected

using the selection window or with the two arrow

keys.

The maximum amount per hectolitre in

grams that should not be exceeded for this

chemical/product appears under the

chemical/product selection. The maximum

value can be adjusted by pressing this line.

The waiting period in days is safe period of

time between treatments prescribed under

integrated plant protection. This value is solely

for information purposes and can also be amended by pressing on it.

Create new chemical/product

A new chemical/product with the name “New” is created by pressing the “New”

button.

Change name of chemical/product

The edit button opens the input field where the name can be changed.

Delete chemical/product

A chemical/product can be deleted with the delete button (after confirmation

prompt).

3.4 Statistics

The statistics section is where the recorded spraying

operations are stored and remain until they are

transferred to the PC or deleted individually using the

delete button.

One spraying operation is displayed per window. The

next or previous spraying operation can be displayed

using the arrow keys. The total number of all spraying

operations recorded is shown in the status bar (top

right).

The date indicated for each spraying operation

corresponds to the date on which the spray

programme started.

Delete individual records

Individual records can be deleted using the delete button. After the confirmation

prompt, they will be irrevocably deleted and can thus no longer be transferred to the

PC.

Fig. 22: Chemical/product management

Fig. 23: Statistics

Table of contents