ELMED ISOTEST 4S User manual

Operation manual ISOTEST 4S / 4Splus Page 1

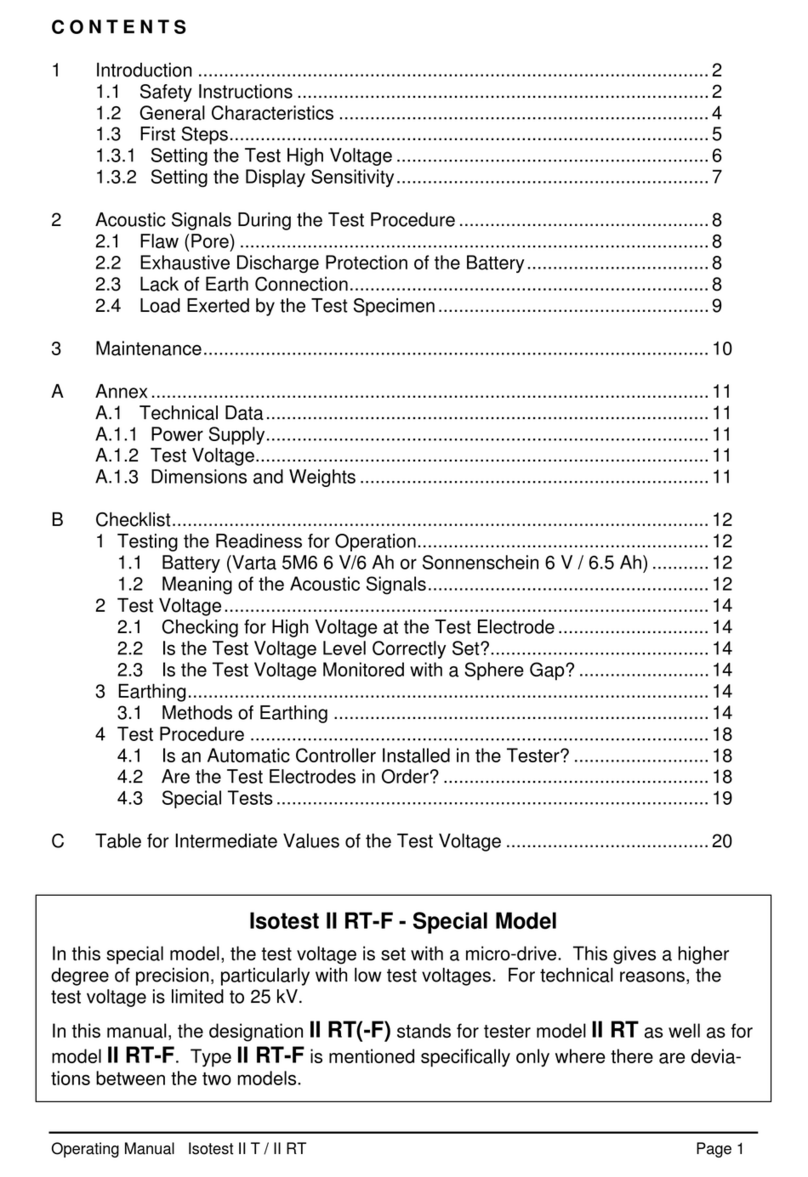

TABLE OF CONTENTS

Product description.............................................................3

1. Proper Use ........................................................................................3

2. Design................................................................................................4

3. Functional description.....................................................................6

4. Technical data...................................................................................8

5. Performance characteristics...........................................................9

EC Conformity Declaration...............................................10

General safety information ...............................................11

1. User's Responsibility.....................................................................11

2. Explanation of safety symbols being used in this manual........12

3. Basic safety measures...................................................................13

4. Operator requirements ..................................................................14

5. Special hazards ..............................................................................15

Grounding ..........................................................................16

1. Direct grounding.............................................................................16

2. Special grounding methods..........................................................18

Testing plastic material .................................................................18

3. Indirect grounding through the soil .............................................19

4. Capacitive grounding.....................................................................19

Safety button......................................................................22

1. Functional description of the single-stage safety button

(standard version)..............................................................................22

2. Function of the double-stage safety button (optional version).22

Startup................................................................................25

Page 2 Operation manual ISOTEST 4S / 4Splus

Check the settings and modify, if required..................... 27

1. Turn the ISOTEST®test equipment on......................................... 28

2. Operating mode of the safety button...........................................28

3. Filter settings..................................................................................28

Changing the operating mode of the safety button ....... 29

Changing Filter Settings................................................... 29

Error messages and troubleshooting (Checklist) .......... 30

Repair................................................................................. 33

1. Storage............................................................................................33

2. Maintenance.................................................................................... 33

3. Inspections/Calibration .................................................................33

4. Repairs ............................................................................................ 34

Additional information...................................................... 35

1. Definitions of terms .......................................................................35

2. Rechargeable battery.....................................................................38

3. Battery chargers............................................................................. 38

4. Extension bars................................................................................ 42

Overview of controls......................................................... 44

Operation manual ISOTEST 4S / 4Splus Page 3

Product description

1. Proper Use

ELMED ISOTEST®test equipment has been exclusively designed for

mobile testing of non-porosity of non-conducting or semiconducting

materials, especially insulation, and may only be used for this purpose.

-The equipment is not designed to be used for the stationary

continuous operation.

-Other use than described above is prohibited.

Please note that

operating the equipment in explosion-hazard environments is

strictly forbidden.

Proper use extends on reading these operating instructions as well as

meeting all relevant requirements, especially safety regulations.

Furthermore, all inspection and maintenance should be performed within

the specified time intervals.

During the operation of ISOTEST®test equipment, radio equipment

or radio services may be affected by radio interference. In these

cases, the equipment must not be used. The equipment should

always be turned on only for a minimum period of time.

ISOTEST®test equipment may only be operated by trained personnel.

If ISOTEST®test equipment is not used as described above, safe

operation cannot be guaranteed.

The manufacturer does not assume any liability for injuries of persons or

damage to equipment if the test equipment is not properly used.

These operating instructions apply to all units of the following series:

ISOTEST 4S and 4Splus

Page 4 Operation manual ISOTEST 4S / 4Splus

2. Design

All ELMED ISOTEST®test equipment is designed for maximum safety.

The units are designed and manufactured according to acknowledged

safety rules and the current state of art.

The high safety standards guarantee that personal is protected from

electric shock hazards. Potential hazards resulting from pulse

voltages in the ISOTEST®are clearly below the allowable limits of

IEC 479-1 and IEC 479-2.

The basic construction of all ISOTEST®test equipment is very similar with

respect to the components being used:

Enclosures Rugged polystyrene enclosure with

separate compartment for

rechargeable batteries

Carrying Case A leather carrying case with

shoulder and carrying belt as well

as transparent pouch with user

guide

Power Supply Easily replaceable lead-acid

accumulator (maintenance-free)

Lithium battery

Deep discharge protection of

rechargeable battery Acoustic alarm by piezo buzzer

when the operating voltage falls

below its allowable minimum plus

warning indication by LED and

automatic partial shut-off after 1

minute

Operation Rotary Switches

Voltage Generation (test voltage) Processor-controlled switching

power supply with high-voltage

transformer

Adjustable Test Voltage (with limits) Spherical spark gap with stepping-

motor control and continuous zero

calibration or electronic spark gap

Adjustable Test Voltage Rotary Switches

Indication Of Test Voltage Values on membrane-switch front

panel

Operation manual ISOTEST 4S / 4Splus Page 5

Test Voltage Regulation Load-dependent, processor-

controlled electronic adjustment

(continuous)

Load Matching Freely selectable filter adjustment

for optimum matching to individual

test conditions

Adjustable Load Matching Rotary Switches

Evaluation Of Voids Integral Evaluation Process

Void Indication

Acoustic by piezo buzzer, visual by

LED

Safety Button (single-stage) Switch-on of test voltage

Safety Button (double-stage)

(optional)* Switch-on of test voltage

Selectable emergency shut-down

funkction

Maintenance LED Indicators

Maintenance and repair of the test equipment may only be

performed by qualified personnel authorized by ELMED.

Special care should be taken when opening the unit because

metal parts may become accessible that carry voltages

considerably higher than the unit's supply voltage.

* Holiday detectors – optionally equipped with the double-stage

safety button - are marked with an instruction plate above the

safety button on the handle

Safety Button (single-stage)

Safety Button (double-stage)

Page 6 Operation manual ISOTEST 4S / 4Splus

3. Functional description

By using a high-voltage tester, even the smallest voids can safely be

detected. Voids can be pinholes, cracks or weak spots.

Depending on the grounding method employed, the following tests can be

performed:

Recognition of voids in non-conducting or semiconducting coatings

on electrically conductive carrier material.

Areas of application, e.g.,:

Systems for protection of pipelines

Coatings applied by the

manufacturer

(internal and external)

Coatings applied in the field

Tanks and containers

Coating material, e.g.:

Polyethylene (PE)

Bitumen

Butyl rubber bands

Petroleum jelly

Gummings

Rilsan

Halar

Ceramic

Enamel

Epoxy resin

Powder coatings

Carrier material, e.g.:

Fe-based metals

Ne-based metals

Electrically conductive fillers

Electrically conductive fleece

Concrete with sufficient residual

moisture

Before testing, the test object as well as the ISOTEST®test equipment

must be grounded.

Subsequently, a suitable testing electrode is moved in close distance to

the test object across the latter's entire surface. The test voltage applied

to the testing electrode should be chosen according to the coating

thickness as well as the relevant standards and manufacturer

specifications.

Operation manual ISOTEST 4S / 4Splus Page 7

A void is detected by sparking between the testing electrodes and the

electrically conductive carrier material as well as an acoustic and visual

alarm.

Voids and porosity with or without inclusions can be detected in

non-conducting material such as welded or glued seams.

Material types, e.g. All types of plastic

Ceramic

Manufacturing types, e.g. Foils

Plates

Enclosures

Pipelines

Hoses

The test object and the ISOTEST®test equipment are grounded by

applying the suitable coating of electrically conductive material.

Subsequently, a suitable testing electrode is moved in close distance to

the test object across the latter's entire surface. The test voltage applied

to the testing electrode is to be chosen according to the coating thickness

as well as the relevant standards and manufacturer specifications. A void

can be detected by sparking between the testing electrode and the

electrically conductive ground electrode, and is indicated by an acoustic

signal and a red LED on the membrane-switch front panel.

Among others, the following grounding methods can be applied:

Applying electrically conductive foils and fleeces

Applying electrically conductive rubber mats

Filling with electrically conductive liquids or solid matters

Insertion of a metal wire

Missing or marginal grounding of the ISOTEST®test equipment

and/or test object may result in accidents and injury to persons.

Chapter "Grounding" contains a detailed description of all

possible grounding methods.

Page 8 Operation manual ISOTEST 4S / 4Splus

4. Technical data

Power Supply

Supply Voltage Lead-acid accumulator, 6 V/4.5 Ah,

with integrated fuse, connecting

cable and two-prong safety plug *

Lithium battery

Current consumption (load-

dependent) Approx. 0.8 A (2.0 A maximum)

Test duration (cycle operation) Approx. 9 h

Test duration (continuous

operation) 2.5 to 5.5 h

Test voltage

Magnitude of test

voltage ISOTEST

ISOTEST

4S : adjustable in 4 steps from

10 to 25 kV in steps of 5 kV

4Splus: adjustable in 7 steps in the

range of 5 to 35 kV

Signal shape Unipolar high-voltage pulses

Cycle duration Approx. 10 µs

Pulse repetition frequency 25 Hz

Current (rms) Approx. 40 mA

Dimensions and weights

(complete unit, including carrying

case)

Length 280 mm

Height 230 mm

Width 120 mm

Length of high-voltage cable 1500 mm

Weight, including handle 4.5 kg

Weight of rechargeable battery 0.9 kg

Type of protection IP 42

Ambient temperature limit: -10oC to +50oC

(Heat timing constant: > 10 K/h)

* To avoid fire hazards and damage to the rechargeable battery, the

pins of the safety plug must not be shorted under all circumstances.

Even shorting these pins over a short period of time may cause the

fuse to blow and prevent from testing the charge state.

To ensure proper safety and functionality of the rechargeable battery,

defective fuses may only be replaced with original fuses.

Operation manual ISOTEST 4S / 4Splus Page 9

5. Performance characteristics

ISOTEST®test equipment excel with the following features:

Maximum safety of personnel by fiber optic controlled safety button

and ground connection monitoring

Significantly reduced hazards for personnel by pulse-shaped test

voltage and processor-controlled, load-dependent supply voltage

regulation

The processor-controlled, load-dependent supply voltage regulation

guarantees a constant test voltage even under worst-case load

conditions

The test voltage is adjusted using a self-calibrating spherical spark

gap according to VDE 0433 or an electronic spark gap

The high pulse repetition frequency allows testing speeds of up to

300 mm/s

By making use of extremely short, unipolar high-voltage pulses and a

specially designed evaluation circuitry, even the smallest pinholes

(channels) and voids can be detected and indicated with only a

minimum of material stress

Residual electrostatic charge on the test object is negligible if the

tests are performed correctly

Pinhole and leakage tests of non-conducting or semiconducting

materials

Testing of completely coated test objects by making use of capacitive

grounding

All ISOTEST®test equipment carries the CE label and meets the

requirements of all relevant standards and specifications

(DIN EN/ISO, DVGW, etc.)

Page 10 Operation manual ISOTEST 4S / 4Splus

EC Conformity Declaration

It is herewith confirmed that the products listed below

ISOTEST 4S

ISOTEST 4S plus

meet the safety requirements within the scope of the conformity evaluation procedure of the

related competent authority, which are defined in the regulation 2004/108/EG of the European

Council for the approximation of laws of the member states with respect to electromagnetic

compatibility. The same applies to the provisions of the law on electromagnetic compatibility of

electrical equipment (EMVG) as of 9 November 1992.

This declaration applies to all units that are manufactured in accordance with the appropriate

manufacturing documentation which is part of this declaration.

For the evaluation of products regarding the electromagnetic compatibility, relevant

harmonized standards have been used.

Immunity: EN 61000-6-2:2005 including:

EN 61000-4-2:2009; EN61000-4-3:2006 + A1:2008

IEC 61000-4-2:2008

IEC 61000-4-3:2006 + A1:2007

Emission: EN 55011:2009 (IEC/CISPR 11:2009 modified)

The devices meet the requirements of class A in the standby mode and are designed for

operation in industrial environments. In occurrence of radio interference while using the

devices in residential or commercial areas, the use must be kept as short as possible or the

device must be switched off.

Design-engineering modifications that have such significant effects on both the

technical specifications and the proper use defined in this operation manual so as to

change the instrument significantly shall nullify this declaration of conformity.

This declaration has been signed for manufacturer

ELMED Dr. Ing. Mense GmbH, Heiligenhaus

by

Claudia Mense

Managing director

Heiligenhaus, 14th February 2012

Operation manual ISOTEST 4S / 4Splus Page 11

General safety information

1. User's Responsibility

All ISOTEST®test equipment has been designed and manufactured,

considering hazard analyses and compliance with the relevant

harmonized standards as well as additional technical specifications.

Therefore, ISOTEST®test equipment is state-of-the-art equipment and

offers a maximum of safety.

However, this safety level can only be achieved if all required measures

have been taken. The user of the test equipment is responsible for

planning and performing these measures and for verifying their proper

execution.

The user is especially responsible for ensuring that

-ISOTEST®test equipment is only used as intended by the

manufacturer (please refer to Chapter "Product Description"),

-the test equipment is only operated if in perfect condition,

-required personal protective equipment is available and being used,

-the operating instructions are always legible and available at the

workplaces where the test equipment is used,

-the test equipment is only operated by qualified and authorized

personnel,

-this personnel is trained in all aspects of industrial safety and

environmental protection, and knows the contents of the operating

instructions and the relevant safety regulations,

-no safety labels are removed from the equipment and that all safety

labels are clearly legible.

Page 12 Operation manual ISOTEST 4S / 4Splus

2. Explanation of safety symbols being used in this manual

The following symbols are used in these operating instructions:

Safety symbols indicate the presence of adjacent safety notes.

Special symbols indicate important information that should strictly be

observed.

This symbol indicates that the relevant action imposes a hazard for life

and limb.

Danger

The symbol indicates information provided for improving the

understanding of processes.

NOTE

Operation manual ISOTEST 4S / 4Splus Page 13

3. Basic safety measures

The basic safety guidelines and regulations of the relevant professional

associations apply.

Before turning on the ISOTEST®test equipment, the workplace should be

checked for potential obstacles and safety hazards, e.g., tripping hazards.

Intentional or inadvertent touching of a metal part possibly carrying high

voltage and an uncontrolled action resulting from this electric shock must

not lead to hazard for personnel. This also applies to working on ladders

and scaffolds.

Before insertion or removal of testing electrodes, the ISOTEST®test

equipment must be turned off using the main switch.

After turning on the unit with the main switch, the area behind the red

insulator (electrode clamping device) as well as the testing electrode in

the handle must not be touched.

During the tests, suitable work clothes and shoes meeting the

requirements of industrial safety regulations should be worn.

If tests are performed in small rooms or containers, the relevant safety

regulations and guidelines must be observed

(e.g., safety guards).

High-voltage sparks lead to the formation of ozone. To avoid excessive

ozone concentrations in rooms or containers, sufficient ventilation must

be provided.

Special care should be taken when using high-voltage extension cords or

extension bars as this will tamper safety shielding against accidental

contact with hazardous live adjacent to the electrode clamping device.

When using circular electrodes for testing the inner side of cylindrical

parts, the ISOTEST®test equipment must be turned off during insertion or

removal of the electrode.

Page 14 Operation manual ISOTEST 4S / 4Splus

By using suitable testing electrodes, a test method should be available

that avoids touching of the testing electrodes during the tests.

To maintain the high safety standards, only original ELMED accessories

such as testing electrodes may be used.

4. Operator requirements

ISOTEST®test equipment must not be used by unqualified or

unauthorized personnel. Persons who intend to operate the test

equipment must have read the operating instructions, especially Chapter

"Safety Information", and observe these instructions.

These persons must have been trained in the basic regulations on

industrial safety and accident prevention.

Operating personal still being in the training phase must not operate the

ISOTEST®test equipment unless supervised by a sufficiently trained

person.

A certificate of a successfully completed training course is required.

Operation manual ISOTEST 4S / 4Splus Page 15

5. Special hazards

Important notice for wearers of a

Heart pacemaker

During operation of the ISOTEST®unit it is necessary to take into

consideration a fault in the form of switching over of the heart

pacemaker into error mode. It is possible to avoid this effect on heart

pacemakers by ensuring that patients with implanted pacemakers do

not get closer than 3 m to

the test unit and the spark gap

the test electrodes

the test object being tested and all parts connected to it electrically

and the earthing cable.

Patients with pacemakers must not use this insulation testing

equipment!!

Excerpt from the expert opinion of 20.02.1997

Important advice for epileptics

Contact with high voltage or parts which conduct high voltage could lead

to epileptic attacks if you are accordingly susceptible to them.

Page 16 Operation manual ISOTEST 4S / 4Splus

Grounding

To enable safe porosity tests with high voltage, both the ISOTEST®test

equipment and the test object shall be grounded.

Independently of the grounding method, all electrical

connections should exhibit the lowest resistance possible.

The contact surfaces for attaching the clamping tongs should

be free from contamination and stain.

To prevent inadvertent pulling of the grounding plug from the

ISOTEST®test equipment, the stress relief attached to all

grounding cables should be hooked to the snap link at the bag.

When describing the grounding methods, basically both the

grounding of the ISOTEST®test equipment and the test object

described.

Depending on the test assignment, the following grounding methods can

be employed.

1. Direct grounding

Direct grounding is used when the grounding conductor can be

connected to a contact surface free from contamination and stain.

Required accessories:

Standard grounding cable with plug and clamping tongsPart number:

0174320000 (supplied)

Grounding cable, length of 15 m, with plug and clamping tongs Part

number: 0174200100

Application:

1. Connect the plug of the standard grounding cable to the grounding

receptacle of the ISOTEST®test equipment.

Connect the clamping tongs at the other end of the grounding cable

to the test object.

2. Connect a pair of clamping tongs of the second grounding cable (part

number 0174200100) to the test object.

Connect the second pair of clamping tongs to a ground terminal.

3. Turn the ISOTEST®test equipment on and perform the high-voltage

test.

Operation manual ISOTEST 4S / 4Splus Page 17

alternatively

Required accessories:

Grounding cable Y - type (clamping tongs - clamping tongs/plug)

Part number 0174250010

Application:

1. Connect the plug of the Y grounding cable to the grounding

receptacle of the ISOTEST®test equipment.

2. Connect the clamping tongs at the other end of the grounding cable

to the test object.

Connect the second pair of clamping tongs to a ground terminal.

3. Turn the ISOTEST®test equipment on and perform the high-voltage

test.

alternatively

Required accessories:

Standard grounding cable with plug and clamping tongs

Part number: 0174320000

(supplied)

Grounding stick with cable, 2 m Part number 0174200000

Application:

1. Connect the plug of the standard grounding cable to the grounding

receptacle of the ISOTEST®test equipment.

Connect the clamping tongs at the other end of the grounding cable

to the test object.

2. Connect the clamping tongs at the cable from the grounding stick to

an accessible area of the test object.

3. Deeply bury the grounding stick in the soil. If the soil is dry,

thoroughly water the respective area to obtain a low-resistance

connection.

4. Turn the ISOTEST®test equipment on and perform the high-voltage

test.

Page 18 Operation manual ISOTEST 4S / 4Splus

2. Special grounding methods

Testing plastic material

In most cases, welding seams will be tested when testing plastic material.

To allow using the high-voltage test method, coat the welding seam

and/or area with a electrically conductive material (grounding electrode).

Attach a grounding electrode to the entire rear of the area to be tested.

Pinholes and voids will safely be detected by sparking between the

testing electrode and the grounding electrode.

Required accessories:

Grounding foil

Part number 0174500100

Grounding cable Y - type (clamping tongs - clamping tongs/plug)

Part number 0174250010

Application:

1. Cut the grounding foil to the required size.

Tear off the protective foil by holding at the edges, and fold one

corner. Glue the remainder of the grounding foil to the entire rear of

the welding seam or area to be tested, press against the test object,

and remove all air bubbles by wiping. Remove the protective foil step

by step.

2. Connect the plug of the Y grounding cable to the grounding

receptacle of the ISOTEST®test equipment.

3. Attach a pair of clamping tongs at the grounding cable to the folded

corner of the grounding foil, and attach the second pair of clamping

tongs to ground, ensuring a low-resistance path.

To obtain safe stress relief for the clamping tongs at the folded corner

of the grounding foil, secure the grounding foil with adhesive tape,

e.g., friction tape.

4. Turn the ISOTEST®test equipment on and perform the high-voltage

test. Remove the grounding foil after the test.

As an alternative to the grounding foil described above, you can also use

electrically conductive fleeces, grounding mats or grounding collars made

of electrically conductive rubber for testing of plastic parts.

The leakage test of containers can be performed using electrically

conductive liquids, e.g., saltwater, acids, etc.

Welding seams can also be tested by inserting a wire.

Grounding brushes are available for cylindrical test objects.

Operation manual ISOTEST 4S / 4Splus Page 19

3. Indirect grounding through the soil

Indirect grounding is used where the distance between the test object and

a suitable grounding terminal is greater than 15 m. Typical examples are

completely muffled pipelines.

Required accessories:

Trailing ground wire Part number 0174120000

Grounding stick with cable, 2 m Part number 0174200000

Application:

1. Connect the plug of the trailing ground wire to the grounding jack of

the ISOTEST®test equipment.

Spread the bronze spiral of the trailing ground wire (6.5 m) on the soil

in full length.

2. Connect the clamping tongs at the cable from the grounding stick to a

non-insulated area of the test object.

3. Deeply bury the grounding stick in the soil. If the soil is dry,

thoroughly water the respective area to obtain a low-resistance

connection.

4. Turn the ISOTEST®test equipment on and perform the high-voltage

test.

Indirect grounding can only be used if the following conditions are met:

the test object is grounded

because of its characteristics, the soil exhibits the required

conductivity

-all types of moist soil are suitable

-unsuitable are, e.g., dry sand, asphalt, and flags.

4. Capacitive grounding

Capacitive grounding is used where direct or indirect grounding is not

possible.

This is the case when the test object has metal carrier material that is

inaccessible or consists of completely coated material.

Page 20 Operation manual ISOTEST 4S / 4Splus

a) Grounding of coated test objects, using grounding collars

Commonly used test objects are pipelines that have been coated in the

field after repair and are subject to high-voltage testing.

As there is normally no possibility of direct or indirect grounding,

grounding collars offer the only possibility of proper and safe grounding.

Required accessories:

Grounding collar, type 1, for DN 100 - 200

Part number 0174401020

Grounding collar, type 2, for DN 200 - 400 (alternative)

Part number 0174402040

Grounding collar, type 3, for DN 300 - 600 (alternative)

Part number 0174403060

Grounding collar, type 4, for DN 500 - 1000 (alternative)

Part number 0174450100

Grounding stick with cable, 2 m

Part number 0174200000

Application:

1. Wrap the grounding collar tightly (without any air gaps) around the

pipe and fix it with the lashing strap. The grounding collar must be

aligned such that the two connecting bolts can be used for the

connection of the grounding cables.

2. Bury the grounding stick deeply in the soil. If the soil is dry, water the

respective area thoroughly to obtain a low-resistance connection.

3. Connect the clamping jaw on the cable of the grounding stick to one

of the connecting bolts on the grounding collar.

4. Connect the plug of the standard grounding cable to the ground jack

of the ISOTEST®test device. The clamping jaw on the other end of

the ground cable must be connected to the remaining connection bolt

of the grounding collar. The bolts must be metallic bright.

The bolts should be free from contamination and stain.

5. Switch the ISOTEST®holiday detector on and perform the high-

voltage test.

This manual suits for next models

5

Table of contents

Other ELMED Test Equipment manuals

Popular Test Equipment manuals by other brands

Metrohm

Metrohm E1612 instruction manual

Wiltron

Wiltron 560-9 Series Operation and maintenance manual

Alcohol Countermeasure Systems

Alcohol Countermeasure Systems Alcolock V3 B-2 Series instruction manual

Huazheng

Huazheng HZJY-10K-IA user manual

Intellinet

Intellinet 515566 user manual

Tietzsch

Tietzsch ZAP 1050L User instructions