b. Avoid Over Torquing Connectors. Over tor-

quing connectors is destructive; it may damage

the connector center pin. Finger-tight is usually

sufficient for Type N connectors. Always use a

connector torque wrench (8 inch-pounds) when

tightening GPC-7, WSMA, or K type connectors.

Never use pliers to tighten connectors.

c. Avoid Mechanical Shock. SWR Autotesters

are designed to withstand years of normal bench

handling. However, do not drop or otherwise

treat them roughly. Mechanical shock will sig-

nificantly reduce their service life.

d. Avoid Applying Excessive Power. Series

560-9XXXX and Series 5400-6XXXX SWR

Autotesters are rated at +27 dBm (0.5W) maxi-

mum input power. Exceeding this input power

level, even for short durations, can permanently

damage their internal components.

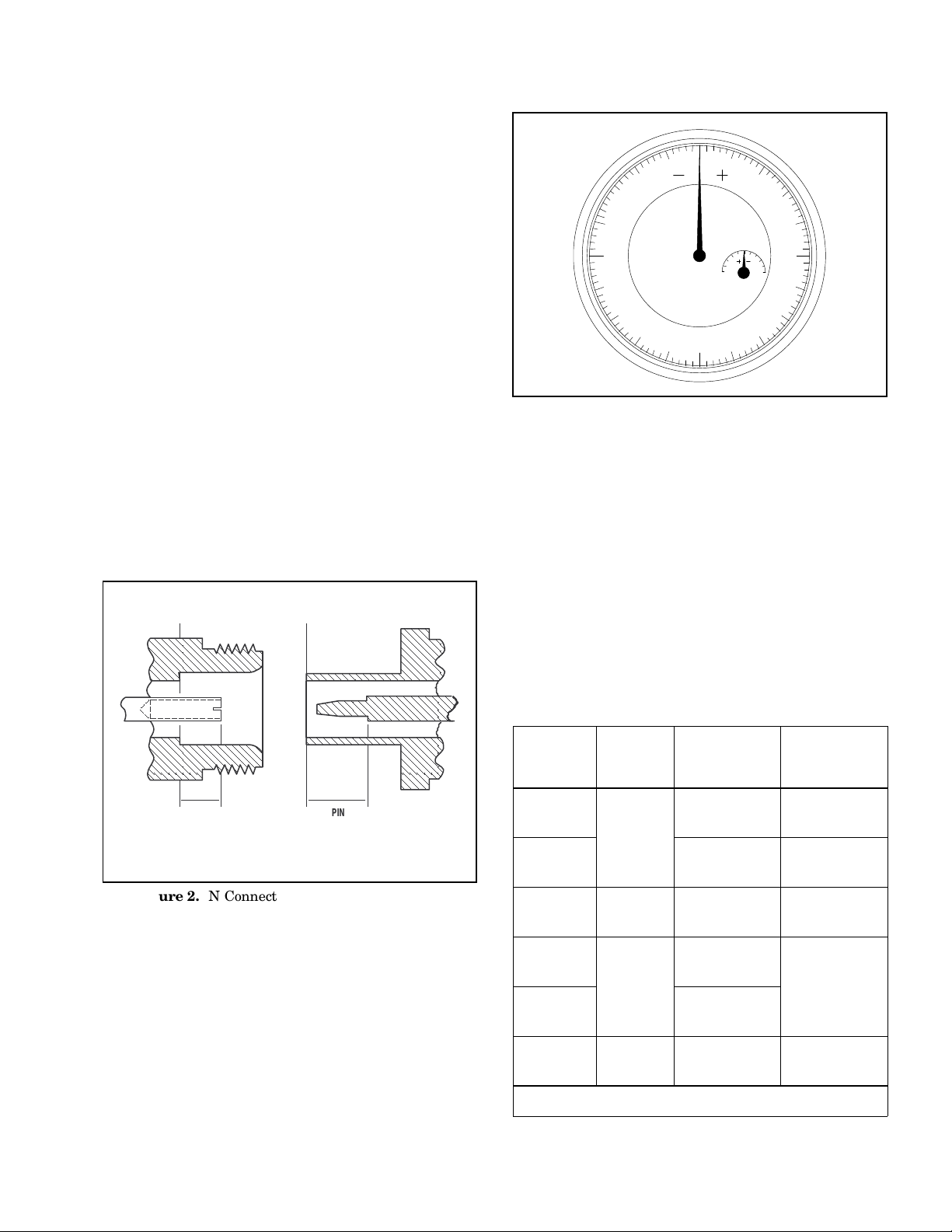

e. Do Not Disturb Teflon Tuning Washers On

Connector Center Pins. The center conduc-

tor of many RF component connectors contains

a small teflon tuning washer that is located near

the point of mating (Figure 4). This washer com-

pensates for minor impedance discontinuities at

the interface. Do not disturb this washer. The

location of this washer is critical to the perform-

ance of the RF component.

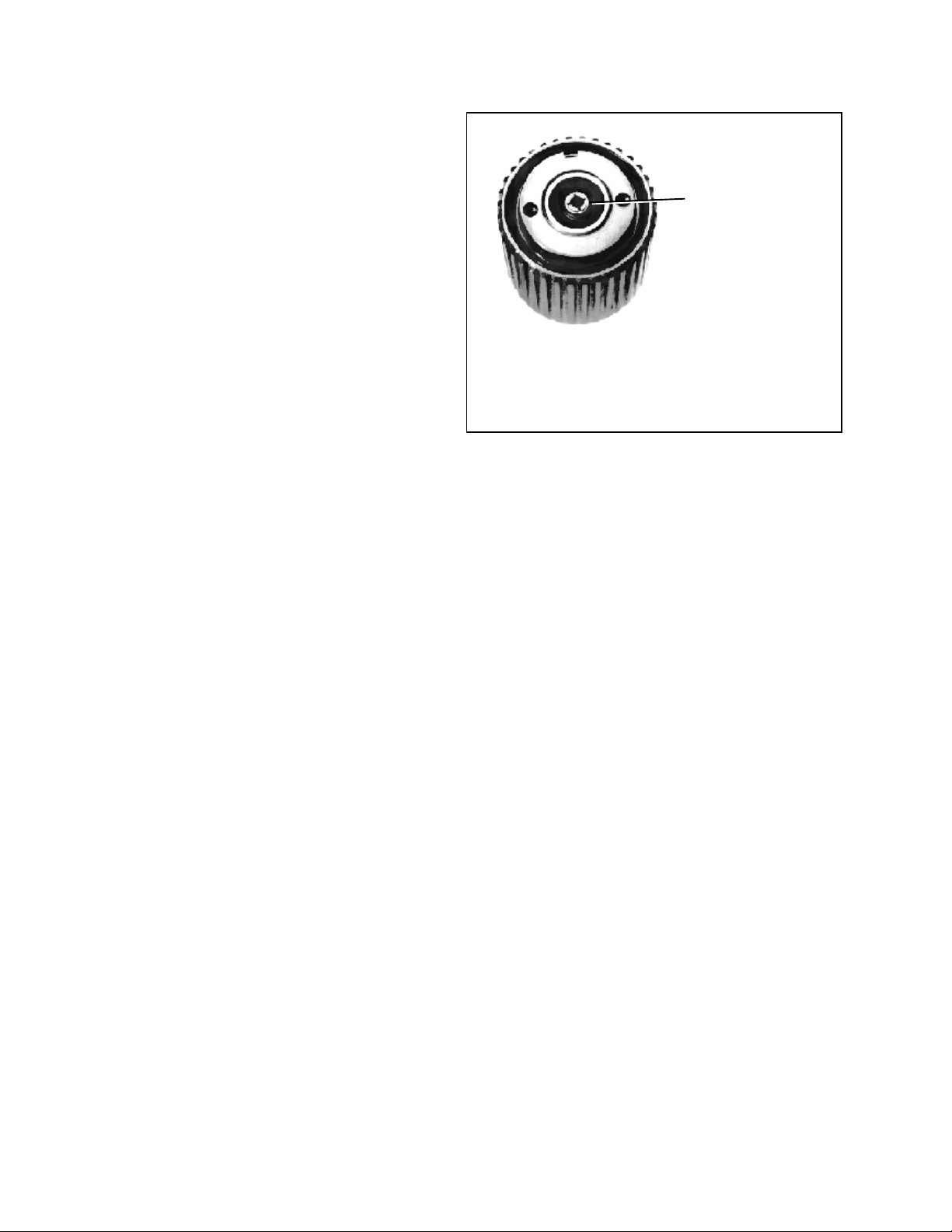

f. Compensation Washers (WSMA Connec-

tors). WSMA connectors are optimized for con-

nection to standard SMA connectors. Whenever

two WSMA connectors are mated, a metallic

compensation washer should be inserted

between the two connectors at the point of mat-

ing (to provide electrical compensation for this

connector combination). The only exceptions are

the WSMA Open/Short and the RF Output con-

nectors of the 54XXX and other WILTRON RF

signal sources. A vial containing five of these

washers (P/N ND38252) is packaged with each

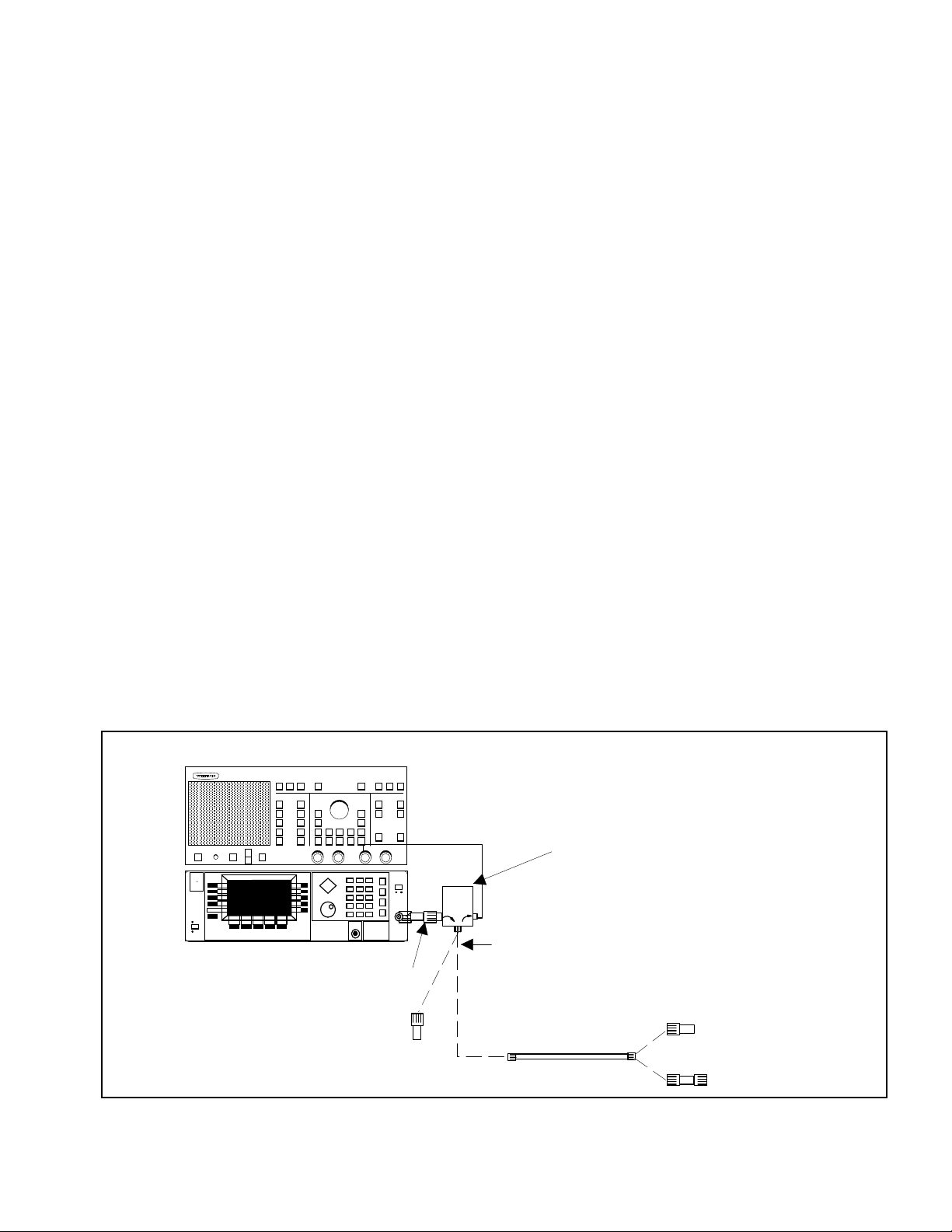

Series 19SX50 Air Line. Figure 10, beginning on

page 11, describes the procedure for installing

these washers.

g. Keep Connectors Clean. The precise geom-

etry that makes possible the RF component’s

high performance can be easily disturbed by dirt

and other contamination adhering to connector

interfaces. When not in use, keep the connectors

covered. Refer to paragraph 7 for cleaning in-

structions.

6. PERFORMANCE VERIFICATION

Performance verification consists of measuring the

directivity of the SWR Autotester and measuring

connector pin depth.

6.1. Pin Depth Measurement

Gauging sets for measuring the pin depth of the test

port connectors of SWR Autotesters and other preci-

sion RF components are available from WILTRON.

Table 2 lists the appropriate gauging set for each

connector type used on Series 560 and 5400 SWR

Autotesters. Refer to the instructions for gauging

connectors that are provided with each gauging set.

Refer also to the pin-depth specifications in Table 2

for each connector type.

6.2. Directivity Measurements

Directivity measurements are frequency limited. For

frequencies above 2 GHz, a magnified reflection tech-

nique (air line) measurement is used. Below 2 GHz,

where an air line is not effective, an error averaging

measurement method is used.

Table 3 (page 6) lists recommended test equipment

for performing these measurements. Measurement

procedures are given below.

Measuring the directivity of Series 560-9XXXX SWR

Autotesters above 2 GHz requires the use of a Series

18XX540 or 19XX50 Air Line that matches the test

port connector of the SWR Autotester being tested

(see Table 3). If a series 19SX50 air line is used

(WSMA connectors), compensation washers are re-

TEFLON WASHER

NOTE

The teflon washer is shown on a GPC-7

connector. A similar washer may be installed

on any WILTRON precision connector.

Figure 4. Tuning Washer on GPC-7 Connector

4SWR OMM