Do not heat unopened food containers in the oven. Pressure

could build up and the container could burst, causing

injury or damage to the range.

Keep oven vent ducts unobstructed.

Keep oven free from grease build up.

Place oven rack in desired position while oven is cool.

If rack must be handled when hot, do not let pot holder

touch heating elements in the oven.

Pull out oven rack to the rack stop to reduce chance of

burns from touching hot surfaces of the door and oven.

When using cooking or roasting bags in oven, follow the

manufacturer’s directions.

Do not use your oven to dry newspapers.

Aluminum Foil

Do not use aluminum foil to cover oven racks. This will

restrict heat circulation. Do not place aluminum foil in

bottom of oven as a spill protector. Permanent damage to

oven will result.

Plastics

All plastics are vulnerable to heat, although some will

withstand higher temperatures than others. Keep all

plastics away from parts of the range which may become

slightly more than warm when the range is in operation.

Self-Cleaning Oven

The door gasket is essential for a good seal. Care should

be taken not to rub, damage or move the gasket.

Do not use oven cleaners on self-cleaning ovens prior

to cleaning. Damage may occur to oven finish at high

temperatures. Remove aluminum or plastic utensils, food

or combustible materials from oven and cooktop before

self-cleaning. (See Self-Cleaning – Page 15)

NOTE: Oven cleaner will not harm porcelain oven but

should not be used in conjuction with selfcleaning.

Surface Cooking

Use proper pan size. Select pans large enough to cover the

element. The use of undersized pans will expose a portion

of the element which may result in burns, ignition of

clothing or spillovers directly on element.

Never leave surface units unattended at high heat setting.

Boil over or boil dry conditions could result in a fire.

Do not use glass or glazed ceramic cookware on the surface

burners, as sudden change in temperature may break them.

Always turn off surface unit, before removing pots or pans.

Turn handle of the pan toward the center of the cooktop,

without extending over nearby elements. This will reduce

the possibility of accidentally overturning the pan.

Let hot pans cool in a safe place, out of the reach of young

children. Never set hot pots on a combustible surface.

Do not use decorative metal covers on electric surface

elements. A covered element, when turned on, could

result in a burn or damage to the element.

Frying

Use as little oil as possible. Filling the pan too full of oil

can cause spillovers when food is added.

Foods for frying should be as dry as possible. Frost on frozen

foods or moisture on fresh foods can cause hot oil to bubble

up. Spillovers, fire and burns from splatters could occur.

Use a deep fat thermometer whenever possible to prevent

overheating oil beyond smoking point.

Deep Fryer

Use extreme caution when moving a hot grease kettle or

disposing of hot grease.

Ventilating Hoods

Clean ventilation hood frequently — grease should not be

allowed to accumulate on hood or filter. When flaming

foods under the hood, turn the fan off. The fan, when

operating, may spread flame.

Service

Do not repair or service any part of the range unless

specifically recommended in this manual. All other

servicing should be referred to a qualified technician.

Disconnect the range from wall receptacle, fuse, or breaker

before performing service.

Safety

Your range, like many other household items, is heavy and

can settle into soft floor coverings such as cushion vinyl or

carpeting. When moving the range on this type of flooring

use care.

If your range must stand beside a refrigerator, allow at

least 2” between the two appliances for air circulation. The

heat from the range may affect refrigerator performance.

Make sure that all the packing materials have been removed

and that all controls are in the off position before plugging

in the power cord.

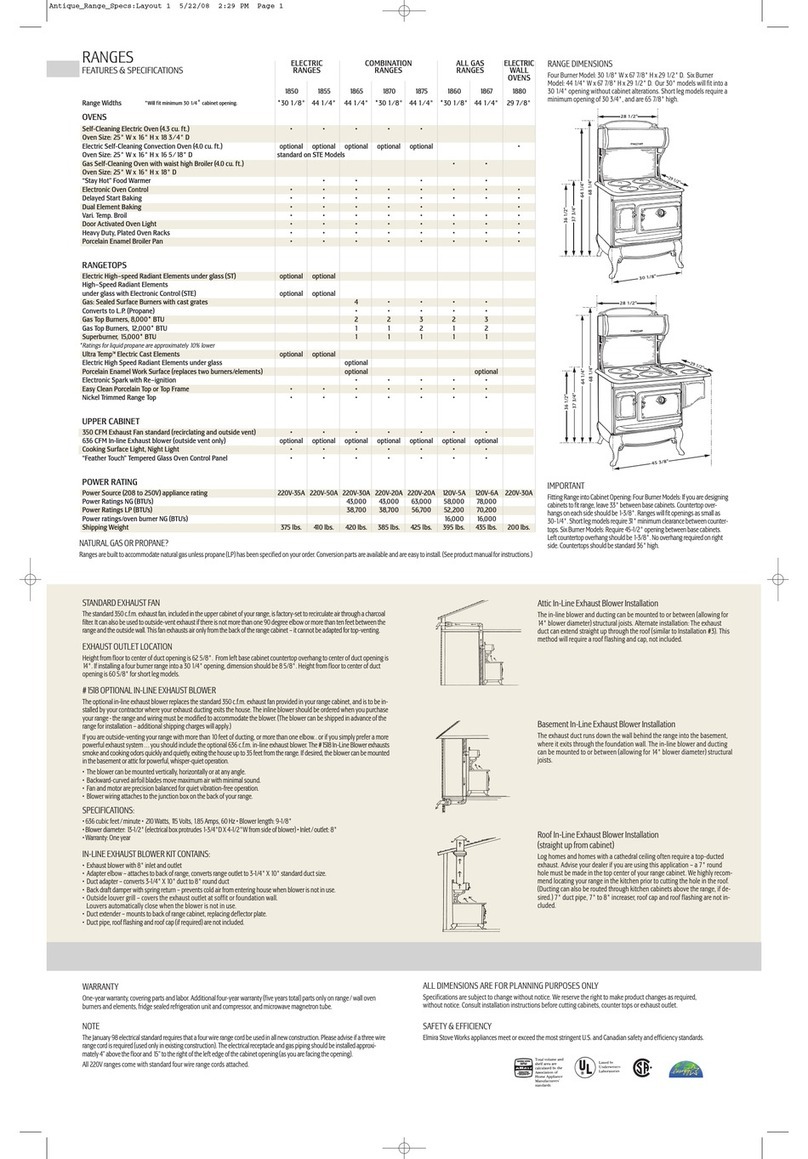

Electrical Connection

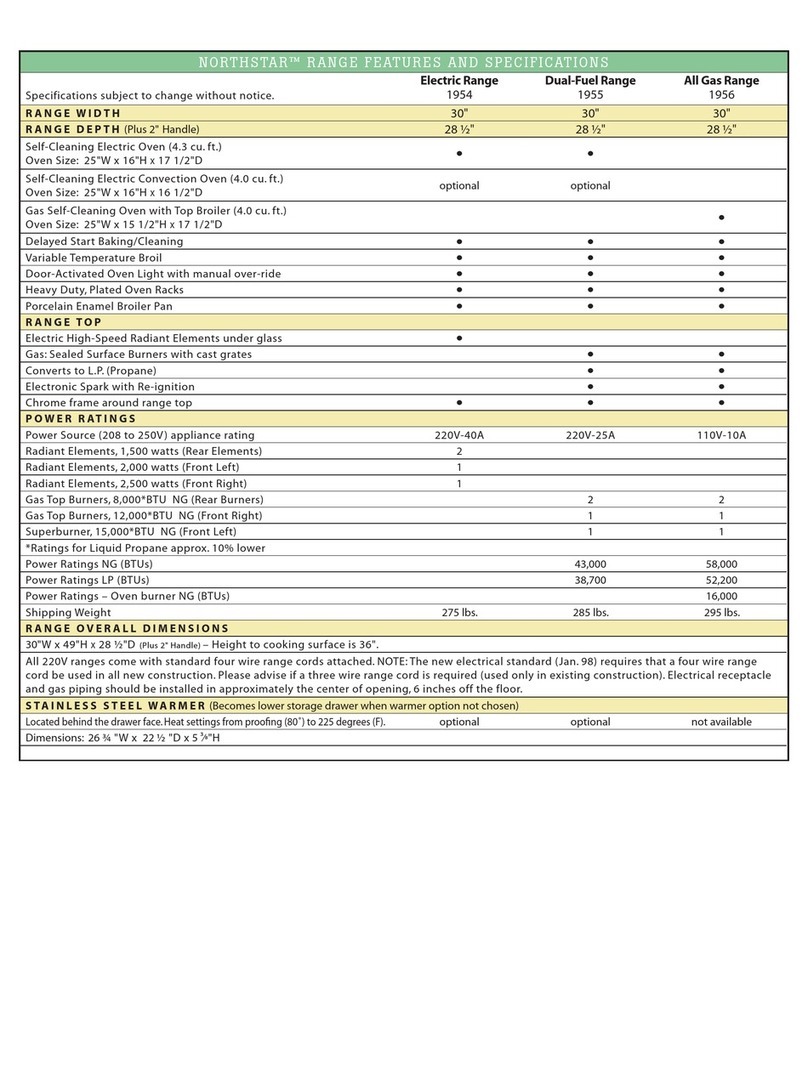

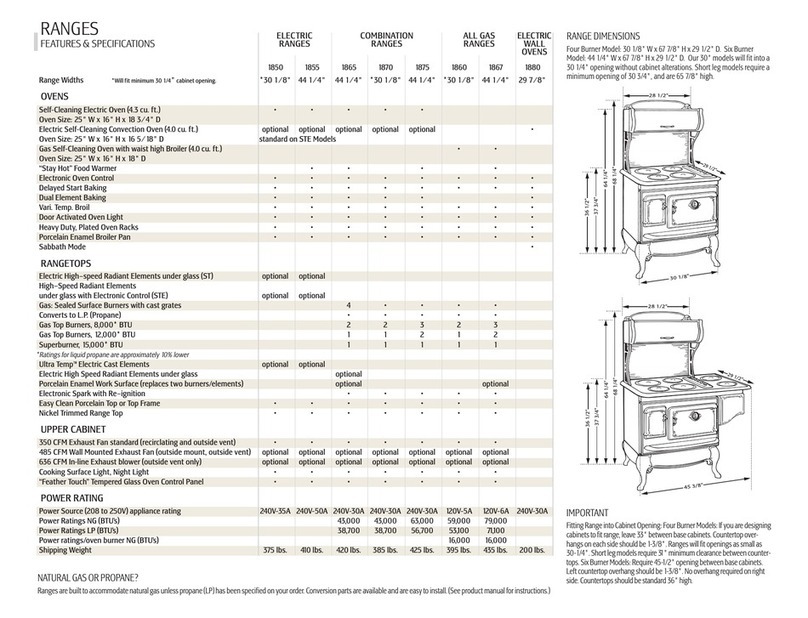

Amperage requirements BTU’s NAT BTU’s LP

Model 1947- 40 Amps, 240 Volts 66,000 59,400

1954- 40 Amps,240 Volts — —

1955- 25 Amps, 240 Volts 43,000 38,700

1956- 10 Amps,110 Volts 59,000 53,100

All ranges come with standard 4 wire range cord

attached. This cord must be plugged into a standard

range receptacle provided by your electrician.

Power Cord Installation on Electric Oven

Models

Be sure your appliance is properly installed and grounded

by a qualified electrician in accordance with installation

instructions and local building codes.

5