GB-5

GB

▷

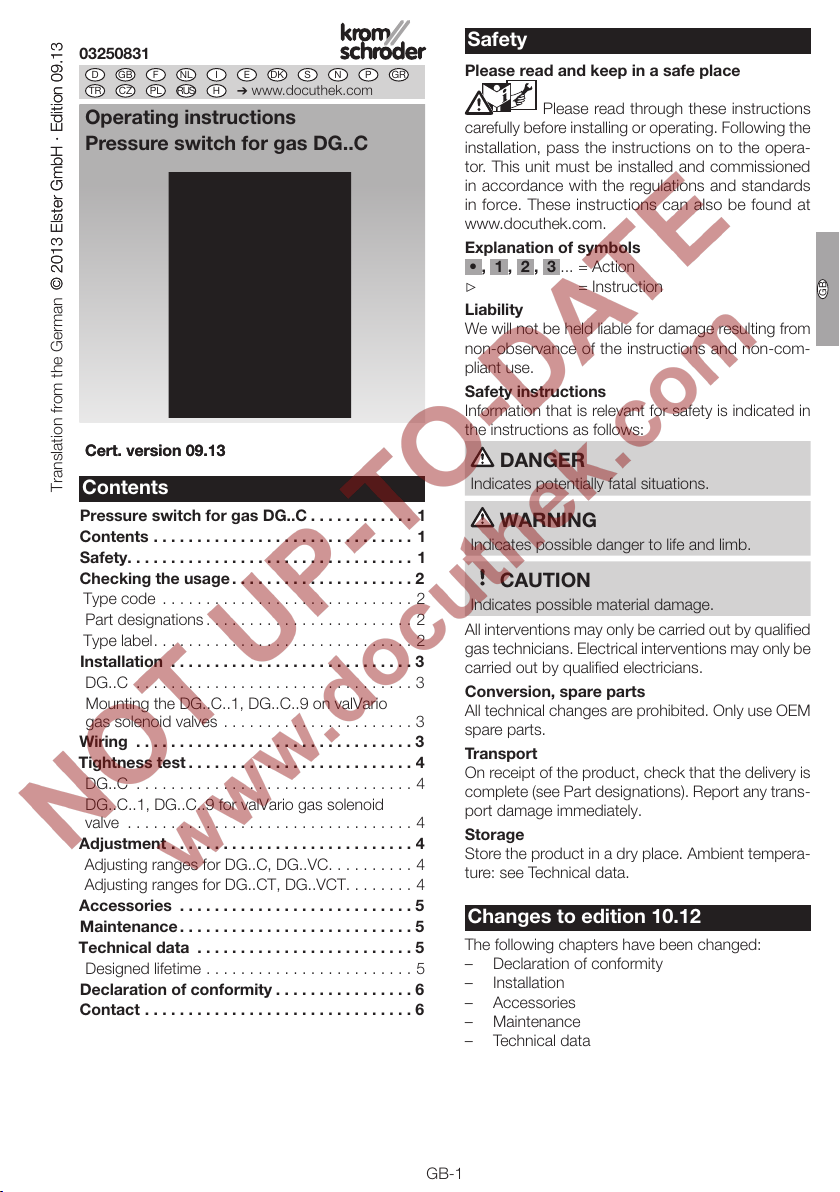

For the DG..VC, the switching point is adjustable

via hand wheel.

2 31

4 5

Accessories

See Technical Information DG (D, GB, F) –

www.docuthek.com

Maintenance

We recommend a function check once a year, or

every six months if operated with biologically pro-

duced methane.

Technical data

Gas type: natural gas, town gas, LPG (gaseous), flue

gas, biologically produced methane (max. 0.1%-by-

vol. H2S) and air.

Max. inlet pressure pu max.600mbar (8.5psig).

Max. test pressure for testing the entire system:

temporarily <15min. 2bar (29psig).

Switching capacity:

DG..C, 24 – 250 V AC:

I = 0.05 – 5 A at cosϕ=1,

I = 0.05 – 1A at cosϕ= 0.6.

DG..C..G, 5 – 250VAC:

I = 0.01 – 5A at cosϕ=1,

I = 0.01 – 1A at cosϕ= 0.6.

DG..C..G, 5 – 48 VDC: I = 0.01– 1 A.

DG..VCT, 30 – 240 VAC:

I = 5A at cosϕ= 1,

I = 0.5A at cosϕ= 0.6.

DG..VCT..G, <30VAC:

I = 0.1A at cosϕ= 1,

I = 0.05A at cosϕ= 0.6.

RoHS compliant pursuant to 2002/95/EC.

Ambient temperature:

DG..C: -10 to +70°C (14 to 158°F),

DG..CT: -15 to +60°C (5 to 140°F).

Diaphragm pressure switch, silicone-free.

Diaphragm: NBR.

Housing: glass fibre reinforced PBT plastic with

low gas release.

Lower housing section: AlSi12.

Enclosure:

IP54 pursuant to DIN EN 60529 with standard

socket pursuant to DINEN175301-803,

IP00 with AMP plug.

Safety class: 1.

Weight: 60g (2.12 oz).

Designed lifetime

The Pressure Equipment Directive (PED) and the

Energy Performance of Buildings Directive (EPBD)

demand regular checks on and maintenance of heat-

ing systems in order to ensure a high level of use

in the long term, a clean method of operation and

safe function.

The service life on which the construction is based,

hereinafter referred to simply as the “designed

lifetime”, is compiled from the relevant standards.

You can find further explanations in the applicable

rules and regulations and on the afecor website

(www.afecor.org).

This information on the designed lifetime is based on

using the product in accordance with these operat-

ing instructions.

The product must be serviced at regular intervals.

Once the specified designed lifetime has been

reached, the safety-related functions must be

checked in accordance with the section entitled

“Maintenance”.

If the product passes the aforementioned function

tests, you can continue to use it until the next sched-

uled maintenance operation. At this point, these tests

must be repeated.

If the product fails one of the aforementioned tests,

it must be replaced immediately.

This procedure applies to heating systems. For ther-

moprocessing equipment, observe national regula-

tions.

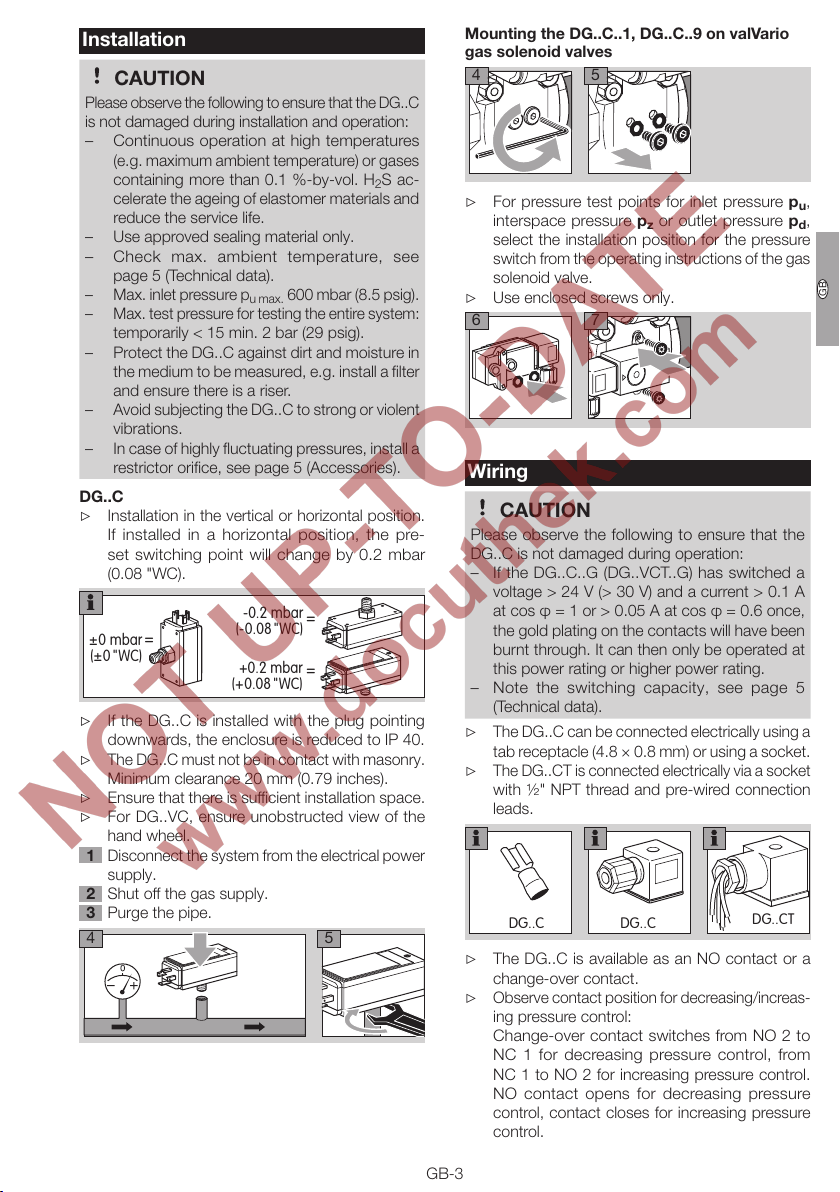

Designed lifetime (based on date of manufacture)

in accordance with EN 1854 for pressure switches:

Medium Designed lifetime

Switching cycles Time [years]

Gas 50,000 10

Air 250,000 10

Long-term use in the upper ambient temperature

range accelerates the ageing of the elastomer ma-

terials and reduces the service life (please contact

manufacturer).