Eltek Valere PSC18 User manual

DC/DC CONVERTER

PSC18

USER MANUAL

BHB.PSC-18.D30-1020.HB101

DC/DC Converter

PSC18

User Manual

Page 2 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

General information

IMPORTANT! Please read this operation and maintenance manual carefully before assembling and start up the unit!

The operation and maintenance manual is part of this unit, i.e. it should be made available to each and every person

concerned with the start up, maintenance or operation of the unit. The unit should be moved, mounted, started,

operated and maintained only by skilled personnel. The local specifications for the prevention of accidents as well

as the general guidelines according to IEC 364 should always be followed!

The functional description in the operation and maintenance manual correspond to those at the time of the publi-

cation. Technical design modifications or those of power ratings can be carried out by the supplier without an-

nouncing any revision or announcement. There is no responsibility for the constant revision of the operation and

maintenance manual

The module is manufactured in accordance with applicable DIN and VDE standards such as VDE 0106 (part 100) and

VDE 0100 (part 410). The CE marking on the module confirms compliance with EU standards 2006-95-EG (low volt-

age) and 2004-108-EG (electromagnetic compatibility) if the installation and operation instructions are followed.

The units are delivered according to our delivery conditions. Rights to alterations in the technical details in this

operation and maintenance manual as well as in the respective data sheets are reserved.

Claims about faulty goods have to be made as soon as possible after receipt of material. Packing note and invoice

as well as the information about the type, serial number and damage description have to be transmitted to the

supplier.

Warranty claims not be accepted in case of visible external influences (e.g. missing or loose screws, welding, loose

sheets, etc.), which could be attributed to an unauthorised opening of the unit. The supplier is not responsible for

applications of the unit, not intended by the manufacturer. The end user is responsible to take the necessary ac-

tion for the prevention of damage to personnel and material (see the upper text section).

Supplier

ELTEK VALERE INDUSTRIAL GmbH

Schillerstraße 16

D-32052 Herford

+ 49 (0) 5221 1708-210

FAX + 49 (0) 5221 1708-222

Internet http://www.eltekvalere-industrial.com

IMPORTANT!

Repetition, copying and /or taking possession of this operation and maintenance manual, even in ex-

tracts, with electronic or mechanical means, requires the written, prior permission of the SUPPLIER.

Copyright ELTEK VALERE INDUSTRIAL 2007. All rights reserved.

DC/DC Converter

PSC18

User Manual

Page 3 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

Table of Contents

1. GENERAL INFORMATION ...................................................................................................................................... 4

2. TYPE RANGE....................................................................................................................................................... 4

3. START UP PROCEDURE........................................................................................................................................ 4

4. OPERATION ........................................................................................................................................................ 5

5. FUNCTIONS......................................................................................................................................................... 6

5.1 Circuit diagram..................................................................................................................................... 6

5.2 Electrical function description......................................................................................................... 7

5.2.1 Electrical insulation....................................................................................................................................... 7

5.2.2 Input.................................................................................................................................................................. 8

5.2.3 Output .............................................................................................................................................................. 8

5.2.4 Output voltage dynamic behaviour........................................................................................................... 8

5.2.5 RFI suppression .............................................................................................................................................. 8

5.2.6 Parallel operation mode ............................................................................................................................... 8

5.3 Monitoring ............................................................................................................................................. 9

5.3.1 Mains Voltage Monitoring............................................................................................................................ 9

5.3.2 Operation Monitoring.................................................................................................................................... 9

5.3.3 Output Voltage Low...................................................................................................................................... 9

5.3.4 Output Voltage High...................................................................................................................................... 9

5.3.5 Protection Against Overheating ................................................................................................................ 9

5.3.6 Signals .............................................................................................................................................................. 9

5.4 Output and threshold adjustment................................................................................................10

6. EXTERNAL FUNCTIONS .....................................................................................................................................10

6.1 Output voltage sensor leads .........................................................................................................10

6.2 Temperature Compensation of Charging voltage....................................................................11

6.3 External Switch ON/OFF..................................................................................................................11

6.4 Discharge Test...................................................................................................................................11

6.5 Boost Charge Mode ..........................................................................................................................11

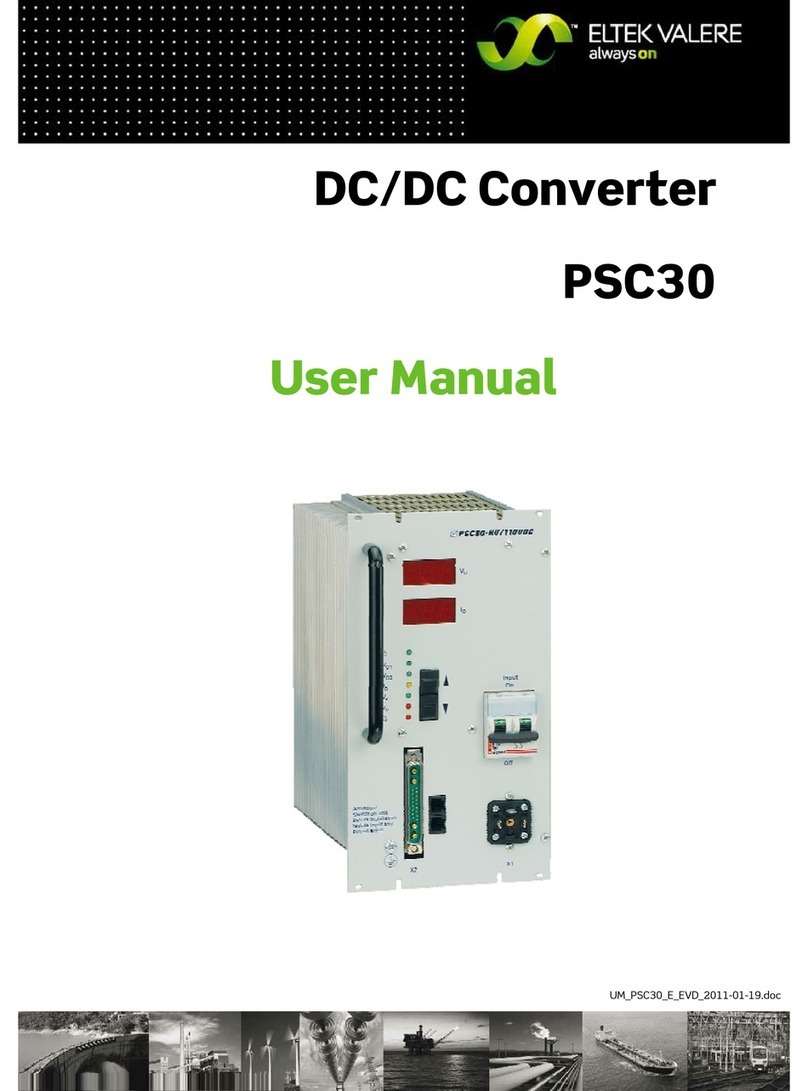

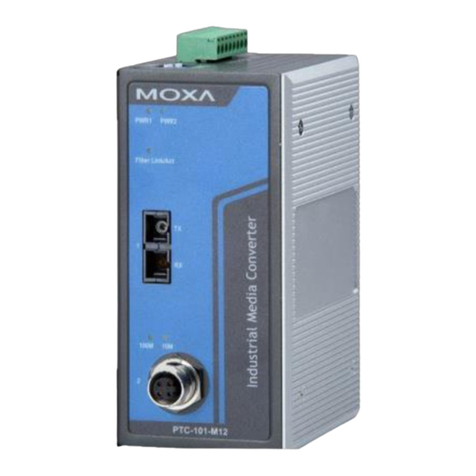

7. OPERATION ELEMENTS AND CONNECTORS ......................................................................................................12

7.1 Front View / Operation Elements .................................................................................................12

7.2 Front View / Operation Elements .................................................................................................12

7.3 Indication Instruments.....................................................................................................................13

7.4 Electrical Connectors of Input and Output.................................................................................13

8. MAINTENANCE .................................................................................................................................................15

9. FAULT FINDING INSTRUCTIONS...........................................................................................................................16

9.1 No Output Voltage............................................................................................................................16

9.2 Deviation of Output Voltage ..........................................................................................................16

10. TECHNICAL DATA.............................................................................................................................................17

10.1 General Technical Data ...................................................................................................................17

10.2 Type Specific Data............................................................................................................................20

11. DIMENSIONS /FRONT VIEW.............................................................................................................................21

11.1 Dimensions / Front View - PSC18 (24, 48, 60 and 110V Version) ........................................21

11.2 Dimensions / Front View - PSC18 (220V Version) ....................................................................22

DC/DC Converter

PSC18

User Manual

Page 4 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

1. General Information

The Switch Mode Power Supply units PSC18 (named SMPS in the following) supply an output power of 1500W (max.

1800W).

A typical application is a mains-connected secured DC-power supply source feeding the connected battery as well

as the consumer load. Hereby, the dynamic regulating performances are particularly advantageous during input

voltage and consumer load deviations.

The SMPS unit operates to an IV-characteristic according to DIN 41772/41773 and represents a complete unit for

implementation in a 19” assembly carrier according to DIN 41494. The operation and indication elements as well as

the plugs are located on the front plate of the unit.

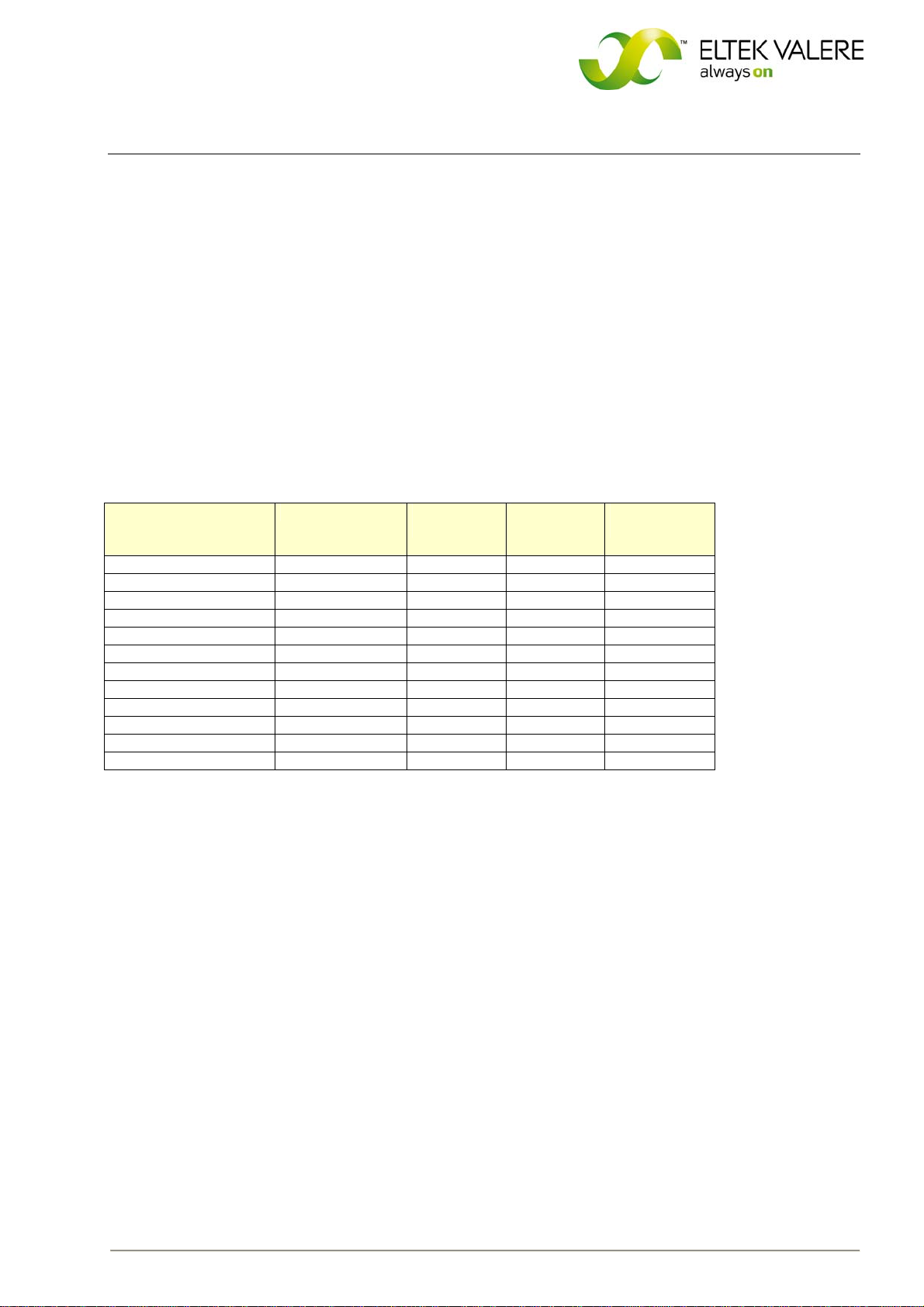

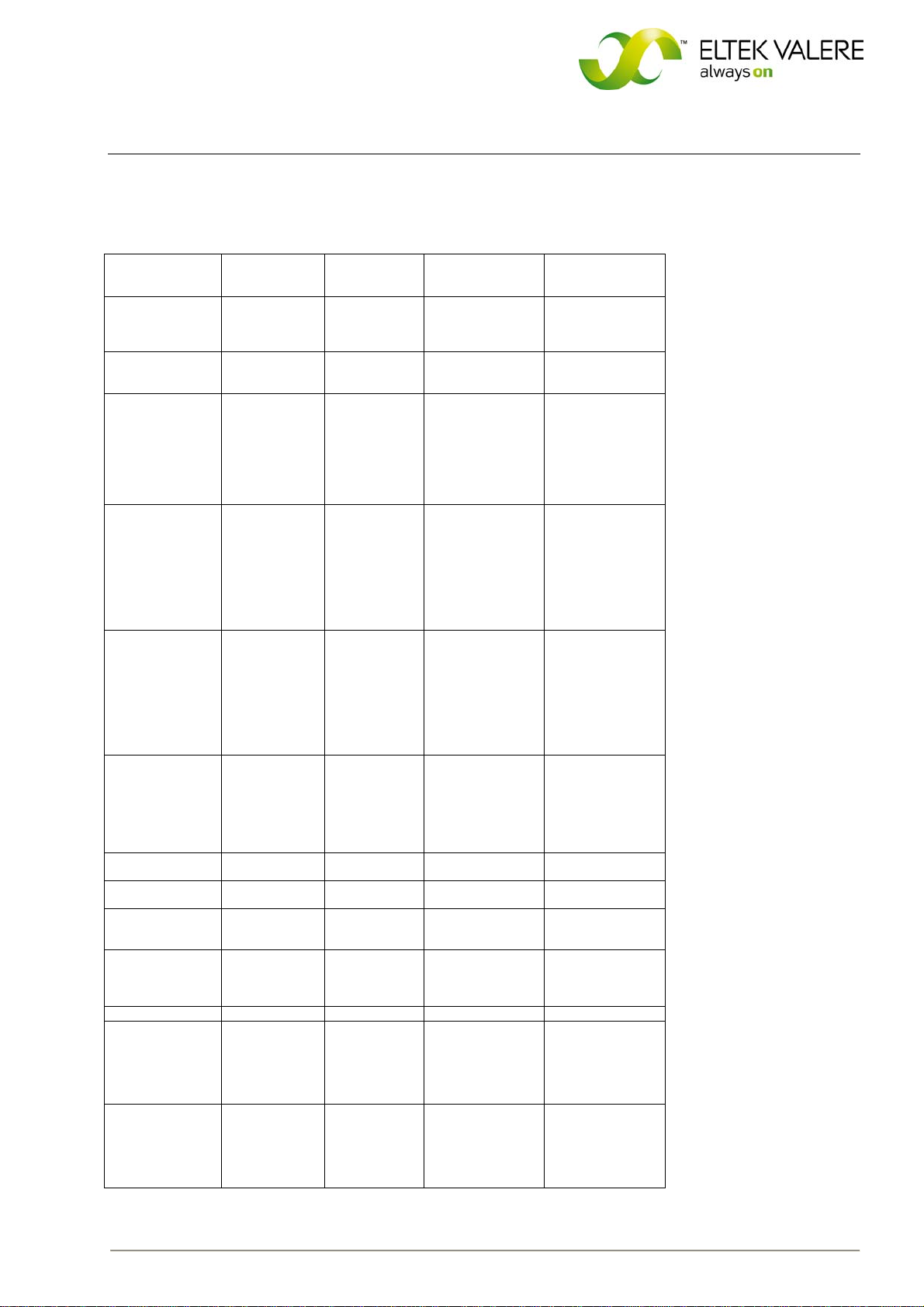

2. Type range

PSC18

Type designation

Article code Input-voltage

in V DC

Output-

voltage

in V DC

Output-current

in A DC

110/24-40 200-018-740.00 110 24 40

110/48-30 200-018-750.00 110 48 30

110/60-25 200-018-760.00 110 60 25

110/110-13.4 200-018-770.00 110 110 13.4

110/220-6.7 200-018-780.00 110 220 6.7

110/220-6.7 Relay 200-018-780.01 110 220 6.7

220/24-40 200-018-840.00 220 24 40

220/48-30 200-018-850.00 220 48 30

220/60-25 200-018-860.00 220 60 25

220/110-13.4 200-018-870.00 220 110 13.4

220/220-6.7 200-018-880.00 220 220 6.7

Available options and accessories:

Temperature sensor lead LM 335 (sensor lead in M5 cable shoes with 2m

wire)

CAN-Bus-interface

One set input and output plug:

24 – 110V DC

220V DC

3. Start up procedure

Before connecting to the input voltage, it should be checked whether the voltage information on the rating plate

corresponds to the available voltage and also that the polarity corresponds to the connection plan of the plug. The

mains connection is done via a unit plug at the front side. The protective conductor should be generally connected

(protection class 1, leakage current 3.5 mA).

DC/DC Converter

PSC18

User Manual

Page 5 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

Important:

If a pole of the output side has been earthed, then the SMPS unit should be grounded via the separate PE connec-

tion on the front plate at the left side near the DC- output connection.

In this case, the protective conductor at the input side should not be connected via the input plug (earth circuit).

This is particularly important for parallel connection without external decoupling diodes.

The DC-output connection is done via a SUB-MIN-D-plug of design 21 WA4 on the front side. The output plug also

contains the connections for the signals, sensor cable connections, symmetry regulation and temperature sensor

lead.

Note:

The SMPS is equipped with a high capacitive capacitor connected in the output. If the SMPS output in the dead

state is connected “hard” to a battery or other parallel operating SMPS, then it results in a considerable surge of

charging current, which could lead in welding the plug contacts when the plug is inserted.

This can be avoided by the following proceedings:

Switch on the SMPS before mounting without the output plug; insert the

connection plug only after the adjusted output voltage is attained.

Disconnecting the DC- circuit with a switch or a fuse

Charging with a protective resistance (approx. 1 Ohm/V)

Use of decoupling diodes

After switching off the unit, the capacitors in the input and output circuits can still conduct voltage; the discharge

time of the input circuit is approx. four seconds, that of the output circuit is approx. 15 seconds.

The SMPS unit operates with natural air cooling. The temperature of the inflow air should not exceed 45oC. If sev-

eral units are operated via one another in the cabinet, then either forced cooling should be provided or a vertical

distance of at least 134 mm = 3 HU should be maintained between the units. Air flaps should be mounted between

the mounting levels such that the temperature of the inflow air of the individual mounting levels does not exceed

the permissible operation temperature. Cabinet rooms should be designed for a max. ambient temperature of

40oC. Temperatures upto 60oC are permitted for a short time or in the case of forced cooling in the cabinet, but

should be avoided in the interest of the lifetime of the unit.

The power loss per unit is approx. 150 W to 170 W (depending on the type).

4. Operation

The unit is operated using the operating elements arranged on the front plate. The operating elements are de-

scribed in the respective sections and are assigned by the labels on the front plate of the unit (see Pt. 7.1/7.2).

DC/DC Converter

PSC18

User Manual

Page 6 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

5. Functions

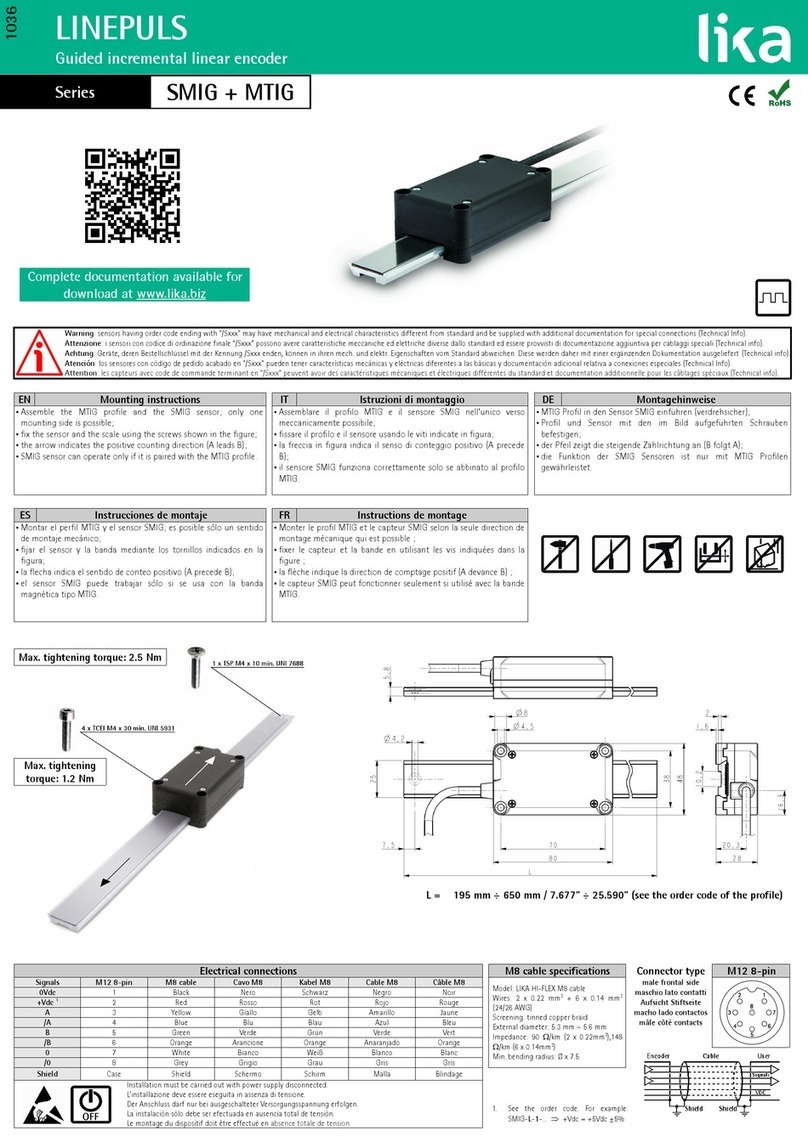

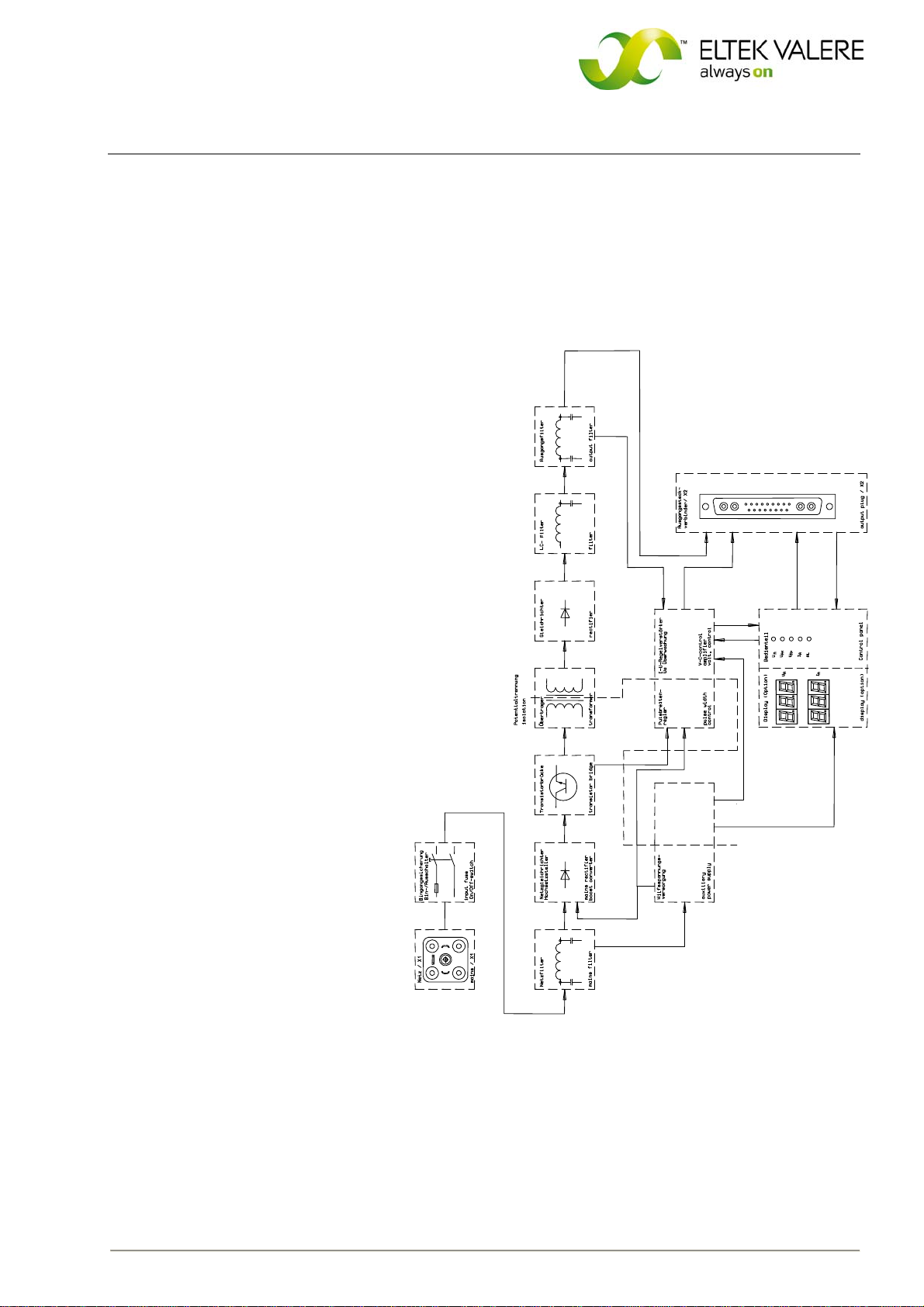

5.1 Circuit diagram

Fig. 1:

Circuit diagram

PSC18

DC/DC Converter

PSC18

User Manual

Page 7 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

5.2 Electrical function description

The SMPS unit consists of the following main functional components:

1. Input filter suppressing the feedback of high frequency interference pro-

duced by the unit into the mains as well as for the attenuation of the inter-

ference voltages and voltage transients superimposed on the mains.

2. Rectifier (polar protection) with synchronised power controller (operating

frequency 100 kHz) for converting the input voltage into a pre-regulated DC-

voltage of approx. 380V (DC – Input 110V DC: 170V ), regulating the input

voltage curve and restricting the inrush current.

3. Transistor bridge circuit for converting the 380 (170)V DC into a pulse-width

regulated stepped voltage with a frequency of 100 kHz.

4. Power transmitter to the potential separation and voltage adaptation at the

secondary side

5. Rectifier with fast switching diodes

6. LC filter for smoothing the DC- voltage ripple at the rectifier output

7. Output filter for smoothing the interfering voltages on the output voltage

8. Auxiliary current supply for the internal power supply to the control compo-

nents with potential separation at the primary and secondary side.

9. Regulating line with potential separation by optocoupler.

10. Operating component with parameter adjustments, signalling, monitoring

and indication elements

5.2.1 Electrical insulation

Due to the design of the unit and of the components as well as design of separated connections of the input and

output circuits

the SMPS series with UA60 V DC fulfil the EN 60950 and VDE 0100 Stan-

dard; i.e. protection against shock currents due to the functional extra low

voltage with a safe electrical insulation.

the SMPS series UA> 60 V DC satisfy the safe electrical insulation up to UA=

220 V DC according to EN 60950 and VDE 0160 Standard.

DC/DC Converter

PSC18

User Manual

Page 8 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

5.2.2 Input

The input is protected by a 2-pole circuit breaker. This circuit breaker is used also as on/off-switch.

The MCB is situated before the input filter. The SMPS has a current limitation which limits the inrush current to the

level of nominal input current.

5.2.3 Output

The output-characteristic is an IV-characteristic according to DIN 41772 or DIN 41773. An active current distribu-

tion or a characteristic curve (- 1% for 100 % Inom can be selected for parallel operation (factory adjustment: char-

acteristic curve)

The output is continuously short circuit proof due to a constant current regulation.

5.2.4 Output voltage dynamic behaviour

In case of load changes in the load between 10% and 90% Inom or 90% and 10% Inom the dynamic voltage deviation is

max. 3% and is compensated to the static limits within max. 1.5 ms.

5.2.5 RFI suppression

The SMPS unit fulfils the conditions of the RFI class “ B “ according to VDE 0878 T 1 or EN 5501 /55022. When

measured with a filter according to CCITT-recommendations, the output ripple is psophometric < 1 mV (24V), < 1.8

mV (48V) as well as < 2 mV (60V).

5.2.6 Parallel operation mode

Due to the parallel operation ability of the SMPS it is possible to design the redundant cabinets according to the

principle n+1.

Due to the 1% characteristic curve (factory adjustment) a load distribution of about 10% and due to the optional

active current distribution (see pt. 7.3, factory adjustment necessary), about 5% is attained.

During the adjustment of the characteristic curve, the load distribution can be optimised by increasing the output

voltage in the unit having the smallest load current and decreasing the output voltage in the unit having the larg-

est load current (see pt. 5.4).

The selective monitoring of the individual SMPS is possible only with internal or external decoupling diodes in the

output.

The delivery of units with an output voltage 60 V DC with already incorporated internal decoupling diodes is op-

tional. The units are labelled with p (internal decoupling diode in the plus branch) or m (internal decoupling diode in

the minus branch).

DC/DC Converter

PSC18

User Manual

Page 9 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

5.3 Monitoring

5.3.1 Mains Voltage Monitoring

Mains voltage monitoring; signaling with LED "Mains", criterion: output voltage of step-up-converter 370 V (165V),

at the same time operation monitoring of step-up-converter (equivalent to main voltage of appr. 195 (100)VAC;

depends on load).

The LED is dark if mains voltage low or the step-up-converter is out of order.

This signal is included in collective failure signal. Additional there is an optocouppler signal (mains O.K.)

5.3.2 Operation Monitoring

Functional monitoring; signaling with LED "UA1", criterion: output voltage 97 % of adjusted output voltage without

constant current regulation and 85 % of the adjusted output voltage with constant current regulation. The sig-

naling threshold of this monitoring follows the adjusted nominal output voltage automaticly.

This signal is included in collective failure signal of rectifier. Additional there is an optocouppler signal (UAO.K.)

At operation with internal decoupling diodes the voltage before diodes will be measured.

5.3.3 Output Voltage Low

Output voltage low monitoring; signaling with LED "U<", criterion: output voltage is higher than adjusted level U<;

This signal is included in collective failure signal. It has its own relay contact on signaling connector too. If the volt-

age value is O.K. Pin 13 and Pin 17 of X2 or Pin 11 and Pin 15 of X4 (220V – output voltage)are closed.

5.3.4 Output Voltage High

Output voltage high monitoring; signaling with red LED "U>", criterion: output voltage higher than adjusted level U>;

This signal is included in collective failure signal of SMPS. If there is an error the LED burnes and the SMPS switches

off internal. This protective unit has an automatic locking and should be set back with the mains switch or remote

ON/OFF.

5.3.5 Protection Against Overheating

Protection against overheating; signaling with red LED "Alarm", criterion: temperature of heat sink > 90°C.

The over-temperature protection switches OFF the SMPS when the limited temperature is attained.

This signal is included in collective failure signal. You have to reset the unit by ON/OFF switch.

5.3.6 Signals

The signals "UAO.K.", "Mains O.K." and "Constant Current Mode Iconst" are optocouppler signals with a loading of 30

V/5 mA. The optocoupplers switches off at error. The collective failure signal is delayed for appr. 10 sec. The relay

contacts between Pin 14 and Pin 15 of X2 and Pin 12 to Pin 14 of X4 (220V – Output voltage) are open and be-

tween Pin 15 and Pin 16 are closed at error.

DC/DC Converter

PSC18

User Manual

Page 10 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

5.4 Output and threshold adjustment

The adjustment of output values and monitoring thresholds are very easy. All values will be adjusted with front

keys by showing the actual value in the front side digital displays.

In normal operation the top display shows the output voltage (UA1/UA2/UA3) and the bottom display shows the out-

put current (IA).

For any adjustment please follow these instructions:

press both keys UP/DOWN() together for a short time; the SMPS

changes to adjustment mode

press the key UP() or DOWN() to change the adjustment parameter

(see also table on bottom)

press both keys UP/DOWN() together for a short time; the SMPS

changes to value change mode

press the key UP() or DOWN() to change the adjustment value (if you

hold the key the value changes quicker)

press both keys UP/DOWN() together for a short time; the SMPS

changes back to adjustment mode (at this moment the changed value

will be storaged)

press both keys UP/DOWN() for appr. 3 sec. to change back in opera-

tion mode

Adjustable parameters in adjustment mode:

Display Parameter

Uo1 (=UA1) tripple charge voltage

Uo2 (=UA2) boost charge voltage (look also cap. 6.5)

Uo3 (=UA3) voltage at discharge test (look also cap. 6.4)

Io (=IA) output current

U< output voltage low threshold (look also cap. 5.3.3)

U> output voltage high threshold (look also cap.

5.3.4)

t coefficient of temperature for temperature

compensation of charge voltage (look also cap.

6.2)

The monitoring thresholds follow automaticly the adjusted nominal values of output voltage. The monitoring

thresholds for mains/step-up-converter and over heating are not changeable.

The adjustment ranges for several thresholds you can find in technical specifications.

6. External Functions

6.1 Output voltage sensor leads

With sense links for output voltage you can compensate voltage losses over wires or diodes.

The max. regulation difference is approx. 4 % of the nominal voltage.

Interruption on sense links, confusing of poles or short circuit can`t damage the rectifier. At interrupt it can be a

voltage increase of max. 4%.

DC/DC Converter

PSC18

User Manual

Page 11 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

6.2 Temperature Compensation of Charging voltage

At using of closed batteries we recommend the temperature controlled compensation of charge voltage. You has

to connect a external active temperature sensor (option) on signaling connector. The coefficient of temperature

normally is -4 mV/K per cell (in temperature range of 0-50 °C). The basic temperature is 20°C. The coefficient can

be adjusted between -1 to -6mV/K per cell (look cap. 5.4).

The sensor will be connected with a 2pole wire (0.25 mm2). It can be mounted directly on top of battery or on bat-

tery poles. At big distances (from 2m) we recommend a shielded wire with connection of the shield on SMPS

ground.

6.3 External Switch ON/OFF

The SMPS can be switched on/off with an external signal. The input is free of potential by an optocouppler and

fulfills the suppostion for safe electrical decoupling to mains and output side. The signaling voltage is 10-24 V, the

internal resistance 2.7 kOhm. The input is protected against confusing the poles. At higher supply voltages the

current in the control circuit has to be limited to 5-7mA with a resistor (for instance 6.8 kOhm at 48/60V DC).

6.4 Discharge Test

The discharge test voltage can be adjusted by the user

(parameter UA3; see cap. 5.4). If the discharge test mode active the LED UA1 is on.

6.5 Boost Charge Mode

The SMPS module has a second charge line (boost charge line). To select this mode, a voltage is to be to connected

to pin 2 of the output connector X2 (look cap. 7.3). The boost charge mode will be signalized with LED UA2. The

user is able to adjust the voltage value (see cap. 5.4).

DC/DC Converter

PSC18

User Manual

Page 12 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

7. Operation Elements and Connectors

7.1 Front View / Operation Elements

24/48/60/110 V-Version

X2

X1

Netz

Mains

U

A1

U

A2

I

A

U<

U>

Alarm

U

A

I

A

A1

A2

A3

A4

1

9

10

17

Digital displays

LED signals

Up / Down

Input fuse - ON / OFF switch

DC - Input con. X1

Ground

DC - Output con. X2 / signals

7.2 Front View / Operation Elements

220 V-Version

X2

X1

Netz

Mains

U

A1

U

A2

I

A

U<

U>

Alarm

U

A

I

A

X4

11

815

Digital displays

LED signals

Input fuse - ON / OFF switch

DC - Input con. X1

Ground

DC - Output con. X2

Signals X4

Up / Down

DC/DC Converter

PSC18

User Manual

Page 13 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

1

PE

2

17

A4

A3

9

10

A2

A1

1

7.3 Indication Instruments

The PSC has digital instruments from 0-999 for current and voltage. The accuracy is equivalent to class1 in rela-

tion to nominal output voltage. The displays can be switched over to showing the adjustment values of monitoring

thresholds. In this mode the parameter short name is shown in the top display and its value (UA1, UA2, UA3, IA, U<,

U>) in the bottom display.

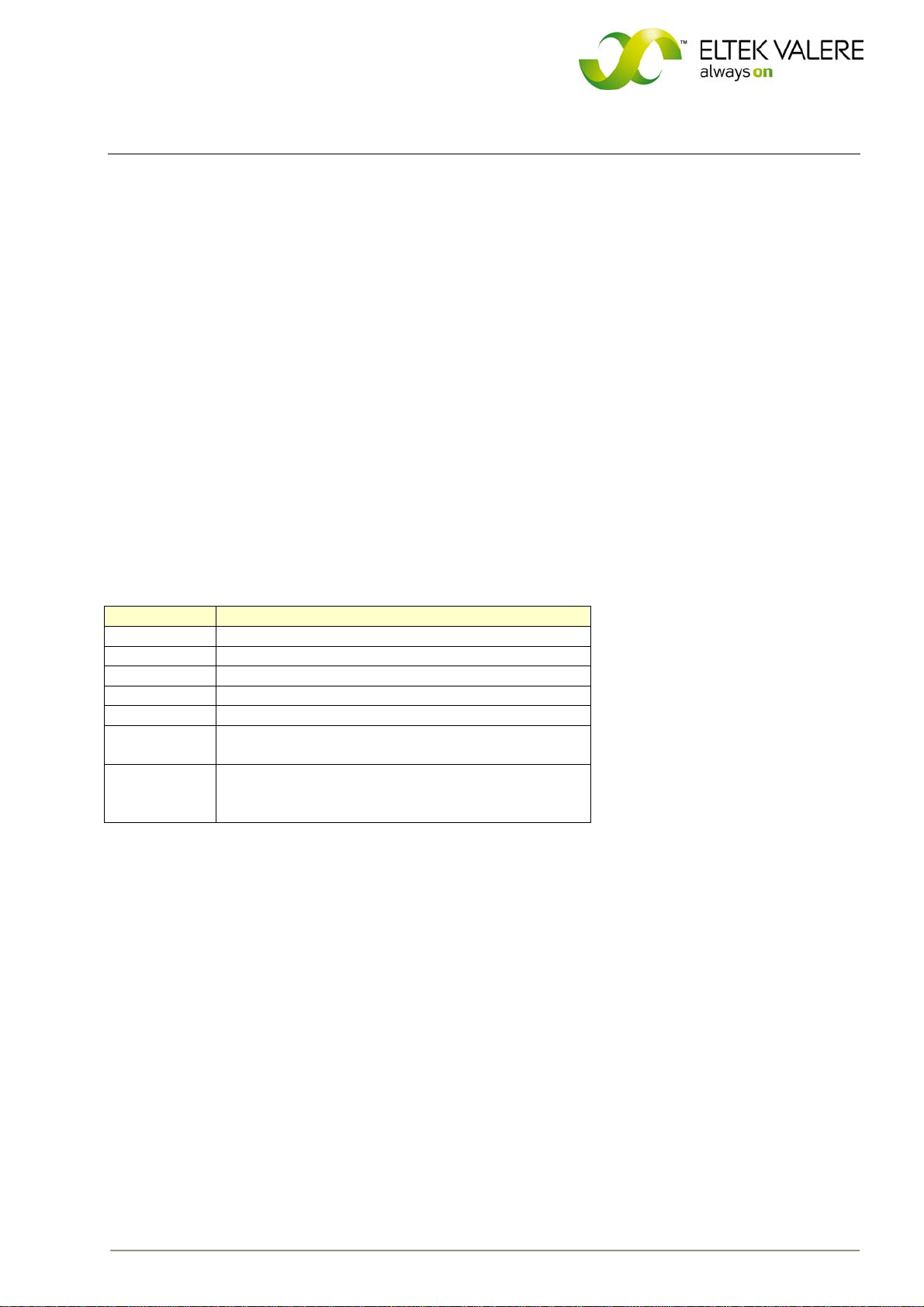

7.4 Electrical Connectors of Input and Output

X1: DC-mains input / GDM-connector

X1, Pin Function

1 + DC - Input

2 - DC - Input

PE PE

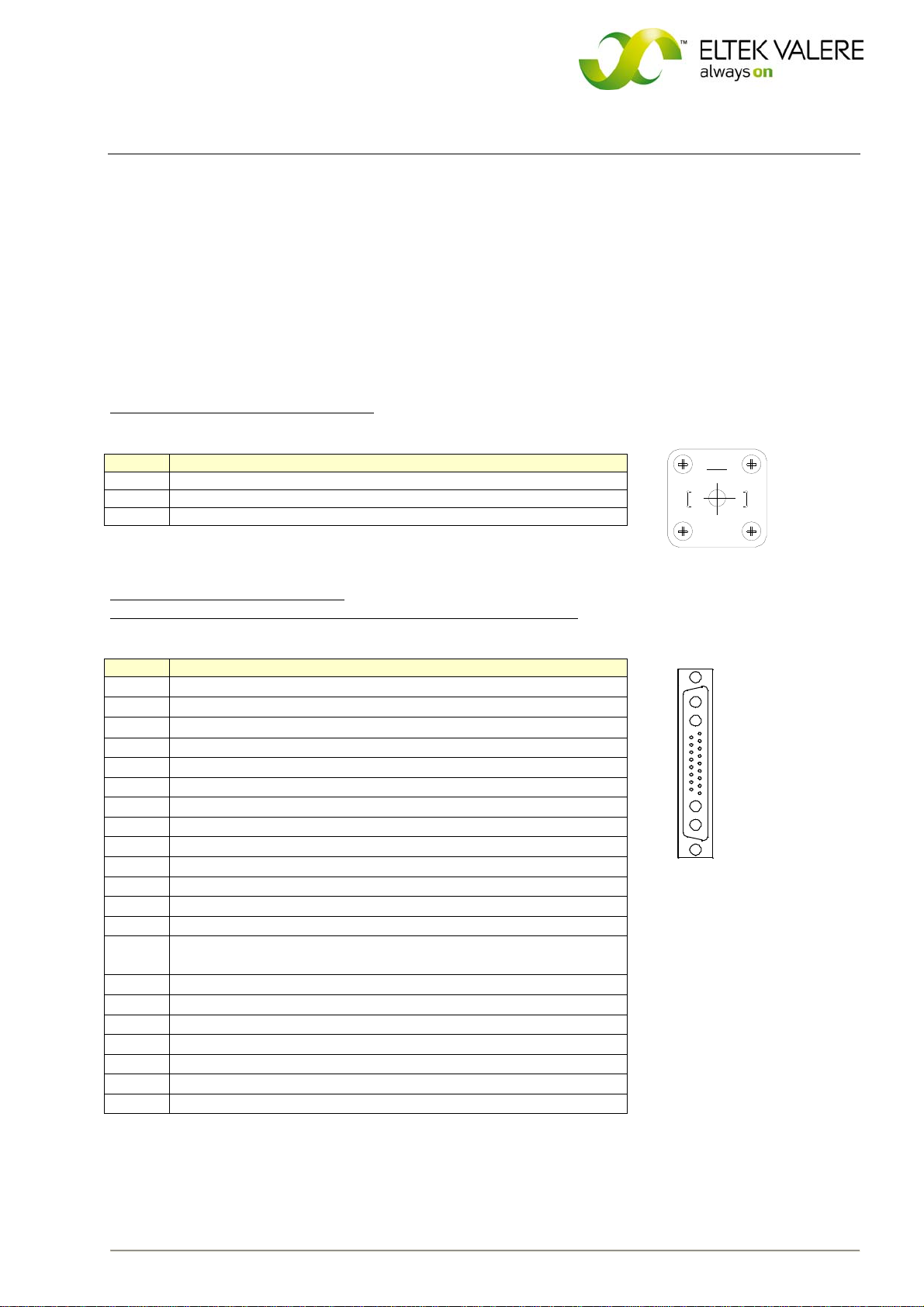

X2: 24, 48, 60 and 110V- version

DC output and signaling contacts / SUB-MIN-D-connector 21WA4

X2, Pin Function

A1 (+) - output

A2 (+) - output (additional for IA40 A)

A3 (-) - output (additional for IA40 A)

A4 (-) - output

1 (+) - output voltage sense link

2 signal input discharge test mode / boost charge mode 1)

3 optocouppler emitter

4 optocouppler collector "Mains O.K."

5 optocouppler collector "UAO.K."

6 optocouppler collector "IA"

7 temperatur sensor (+) 2)

8 control wire for active current sharing 3)

9 (-) - output voltage sense link

10 analog ground (for temperature sensor (-), active current

sharing)

11 (+) external switch ON/OFF 4)

12 (-) external switch ON/OFF

13 relay contact U< , N/O 5)

14 relay contact collective failure , N/O

15 relay contact collective failure , COM

16 relay contact collective failure , N/C

17 relay contact U< , COM

1)

tri-state-input, pin 2 on -UA= discharge test mode,

pin 2 on +UA= boost charge mode

Note:

At 60/110V units there has to connect an additional resistor

DC/DC Converter

PSC18

User Manual

Page 14 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

1

8

1

15

in the control wire to +UA(60V:18 kOhm; 110V:56 kOhm.

2)

connection of temperature sensor with 2pole wire to pin 7(+) and pin 10 (-)

Note:

If several modules are in paralleling then the pin 7 and pin 10 from every unit has to closed.

3)

At active current sharing mode of paralleling units the pin 8 of every module has to connect together.The Analog –

GND (pin 10) has to connect too.

ATTENTION: If you have decoupling diodes in minus at output side the using of sense links are not allowed

4)

external switch ON/OFF with optocouppler: internal resistor 2,7kOhm, Imin 5 mA, Imax = 10 mA

Note:

The input is free of potential with safe electrical decoupling to primary side and with 500V DC to secondary side.

5)

The relay outputs are free of potential with safe electrical

decoupling to primary side and with 500V DC to secondary side.

X2: 220V version (DC output - 8xCOMBICON 4mm2)

X4: (Signals - 15xCOMBICON 1,5mm2)

X4, Pin Function

1 (+) external switch ON/OFF 4)

2 (-) external switch ON/OFF

3 optocouppler emitter

4 optocouppler collector "Mains O.K."

5 optocouppler collector "UAO.K."

6 optocouppler collector "IA"

7 BUS ground

8 signal input discharge test mode / boost charge mode 1)

9 temperature sensor (+) 2)

10 control wire for current sharing mode 3)

11 relay contact U< , NO 5)

12 relay contact collective failure , NO 5)

13 relay contact collective failure , COM

14 relay contact collective failure , NC 5)

X2, Pin Function

1 (+) – Output

2 (+) - output (additional for IA40 A)

3 (+) - voltage sense link

4 control wire for active current sharing 6)

5 BUS ground

6 (-) - voltage sense link

7 (-) - output (additional for IA40 A)

8 (-) - output

DC/DC Converter

PSC18

User Manual

Page 15 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

15 relay contact U< , COM

1)

tri-state-input, pin 8 on -UA= discharge test mode, pin 8 on +UA= boost charge mode

Note:

There has to connect an additional resistor in the control wire to +UAof 150 kOhm.

2)

connection of temperature sensor with 2pole wire to pin 9(+) and pin 7 (-)

Note:

If several modules are in paralleling then the pin 7 from every unit has to closed.

3)

At active current sharing mode of paralleling units the pin 10 of every module has to connect together. The Analog

– GND (pin 7) has to connect too.

ATTENTION!!! If you have decoupling diodes in minus at output side the using of sense links are not allowed.

4)

External switch ON/Off with optocouppler: internal resistor 2,7kOhm, Imin 5 mA, Imax = 10 mA

Note:

The input is free of potential with saved electrical decoupling to primary side and with 500V DC to secondary side.

5)

The relay outputs are free of potential with saved electrical

decoupling to primary side and with 500V DC to secondary side.

6)

At active current sharing mode of paralleling units the pin 4 ( DC – Output) of every module has to connect to-

gether. The BUS – GND (pin 5) has to connect too.

ATTENTION!

You can use version 6) or 3) of wiring for active current sharing mode, not both together!

8. Maintenance

In general, the module is maintenance-free.

A yearly inspection with following checks is recommended:

Mechanical inspection

Removal of dust and dirt, especially on radiator surfaces

Check for internal dust or humidity

Attention! Dust combined with moisture or water may influence or destroy the internal electronic circuits.

Dust inside the unit can be blown out with dry compressed air.

The interval between the checks depends on ambient conditions of the installed module.

DC/DC Converter

PSC18

User Manual

Page 16 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

9. Fault finding instructions

Only skilled and trained technical personnel should carry out all necessary operations at the unit.

9.1 No Output Voltage

- DC - mains voltage is present?

- mains switch is on?

- input plug is connect strong and correctly?

- confusing the poles or short circuit on output?

- at paralleling: confusing the poles at external decoupling diodes?

- monitoring of output voltage high U> signalize an error (light on LED U>)?; switch the unit off and on again

and check the adjusted value of U> (see cap. 5.4)!

If the module still does not work even though all checks have been done, contact your sales agent or the ELTEK

VALERE INDUSTRIAL service department.

9.2 Deviation of Output Voltage

- operates the module in constant current mode (overload)?;

reduce the load!

- adjustment of voltage value UAwrong?

adjust output voltage to nominal values (look cap. 5.4)!

- interruption in external sense links?

- voltage losses over decoupling diodes on output side? ;

adjust the output voltage to higher level or use sense links!

If the module still does not work even though all checks have been done, contact your sales agent or the ELTEK

VALERE INDUSTRIAL service department.

DC/DC Converter

PSC18

User Manual

Page 17 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

10. Technical Data

10.1 General Technical Data

Nominal input voltage 220V DC (110V DC) +20/ -15%

Monitoring input voltage LED - signals UE <195V DC (100V DC)

Varistor protection UE > 270V DC (150V DC)

Inrush current 16A at 10ms

Recommended mains fuse gL 16A

Output characteristic IV line acc. to DIN 41772/ DIN 41773

Emission acc. to EN50081-1

conducted interference voltage acc. to EN 55011/EN55022 class "B"

radiated electromagnetic

fieldstrength acc. to EN 55011/EN55022 class "B"

Immunity acc. to EN50082-2

cabinet ESD-test acc. EN61000-4 part 2; 6kV contact;

8kV air discharge

HF-field acc. to EN61000-4 part 3; 10V/m

(30MHz- 1GHz)

power wires Burst-test acc. to EN61000-4 part 4; 2kV

Surge-test acc. to EN61000-4 part 5; 4kV

unsymmetric; 2kV symmetric

signal wires Burst-Test acc. to EN61000-4 part 4; 2kV

Surge-Test acc. to EN61000-4 part 5; 2kV

unsymmetric

Protection (electr.) with safed decoupling at UA60V DC acc.

to VDE0100 part 41011.83 cap. 4.3.2;

at 110 V DC UA220V DC acc. VDE 0160

5.88 cap. 5.6

Dynamic voltage difference 3 % at load changes between 10 % - 90 % -

10 % of nominal output current (regulation

time1 ms)

Short circuit capability continuously short circuit proof

(constant current controlling)

DC/DC Converter

PSC18

User Manual

Page 18 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

Protection / monitoring /

signaling 2pol. MCB (220V DC:10A; 110V DC:20

A) at front;

mains monitoring „Mains“ green LED

operation monitoring „UA1“ greenLED

output voltage low „U<„ green LED with relay contact

output voltage high „U>„ red LED

constant current mode „IA“ yellow LED

over temperature blinking red LED

digital instruments

for current: displays values from 00,1 to 99,9 A DC

for voltage: displays values from 00,1 to 999 V DC

External functions

signal U< with relay contact

(contact loading:

60V DC/1A, 125V DC/1A)

collective failure with relay contact

(approx. 10sec. delayed)

(contact loading:

60VDC/1A, 125VDC/1A)

control wire for active current sharing

discharge test mode /

boost charge mode (voltage values adjustable)

temperature controlled

compensation of charge voltage

coefficient of temperature -4mV/K per cell (adjustable)

with external sensor (optional)

external sense links

for output voltage signaling with optocouppler „UAO.K.“ ,

„Mains O.K.“ and „Iconst“

external switch ON/OFF function

Operation in paralleling up to 20 modules possible, load shar-

ing appr.10%

Construction 19"-cassette to mount in 19“ subracks

acc. to DIN 41 494

Protection (mech.) IP 20

Cooling temperature controlled fan cooling

Ambient temperature 0°C to 45°C,

0°C to 40°C at mounting in cabinet

DC/DC Converter

PSC18

User Manual

Page 19 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

Storage temperature -30°C to + 70°C

Ambient conditions IEC 721 part 3-3 class 3K3 / 3Z1 / 3B1

/ 3C2 / 3S2 / 3M2

Max. operation altitude 1000 m

Mechanical construction acc. to VDE 0160 rev. 5.88 cap. 7.2.2

Painting color RAL 7035 (front panel only)

Dimensions 262 x 142 x 285 mm H x W x D (1/3-

19“ x 6U)

Connectors

Mains connector X1 3-pole, type GDM 2011

DC connector X2 24-110V DC: SUB-Min-D-connector

21WA4

220V DC: front terminals 8x4mm2,

COMBICON (DC-output);

front terminals 15x1,5mm2(signal

contacts)

None-fused earthed conductor screw M4

DC/DC Converter

PSC18

User Manual

Page 20 ( 22 )

Eltek Valere Industrial GmbH 2007 BHB.PSC-18.D30-1020.DB101

10.2 Type Specific Data

Typ

G110 G24/40

G220 G24/40

G110 G48/30

G220 G48/30

G110 G60/25

G220 G60/25

G110 G110/13,3

G220 G110/13,3

G110 G220/6,7

G220 G220/6,7

Name in brief

PSC18

/110/24-40

/220/24-40

PSC18

/110/48-30

/220/48-30

PSC18

/110/60-25

/220/60-25

PSC18

/110/110-13,3

/220/110-13,3

PSC18

/110/220-6,7

/220/220-6,7

Input current

9,8 A DC

4,9 A DC

14,5 A DC

7,3 A DC

15,2 A DC

7,6 A DC

14,9 A DC

7,4 A DC

14,9 A DC

7,4 A DC

Output voltage

UA1 in V DC

Adjusted

value

24,0 ± 1 %

Adjusting

range

23,4 to 28,8

48,0 ± 1%

46,6 to 57,6

60,0 ± 1 %

58,5 to 72,0

110,0 ± 1 %

105 to 130

220,0 ± 1 %

211 to 260

Output voltage

UA2 in V DC

(Boost charge)

Adjusted

value

28,8 ± 1 %

Adjusting

range

24 bis 30

57,6 ± 1 %

48 to 60

72,0 ± 1 %

60 to 73

129,6 ± 1 %

108 to 135

259,2 ± 1 %

216 to 270

Output voltage

UA3 in V DC

(discharge test)

Adjusted

value

22,2 ± 1 %

Adjusting

range

20,4 bis 24

44,4 ± 1 %

40,8 to 48

55,5 ± 1 %

51 to 60

99,9 ± 1 %

91,8 to 108

200 ± 1 %

184 to 216

Output current IA in

A DC

Adjusted value

40 ± 2 %

Adjusting

range

20 bis 40

30 ± 2 %

15 to 30

25 ± 2 %

12,5 to 25

13,3 ± 2 %

6,7 to 13,4

6,7 ± 2 %

3,4 to 6,7

Type of battery

12 Pb - cells

24 Pb - cells

30 Pb – cells

54 Pb - cells

108 Pb - cells

Efficiency

90 %

91 %

91 %

91 %

91 %

Voltage wave

20 mV ss

20 mV ss

20 mV ss

20 mV ss

20 mV ss

Error volt. according

to CCITT

1,0 mV

1,8 mV

2,0 mV

Monitoring

DC-Undervoltage

U< in V DC

Threshold value

20,4

Adjusting range

19,2 to 24

40,8

38,4 to 48

51,0

48 to 60

91,8

86,4 to 108

184

173 to 216

DC-Overvoltage U>

in V DC

Threshold value

30

Adjusting range

26 to 30

60

52 to 60

75

66 to 75

135

119 to 135

270

238 to 270

Table of contents

Other Eltek Valere Media Converter manuals