BA-en-3041-2008_PC 3

Content

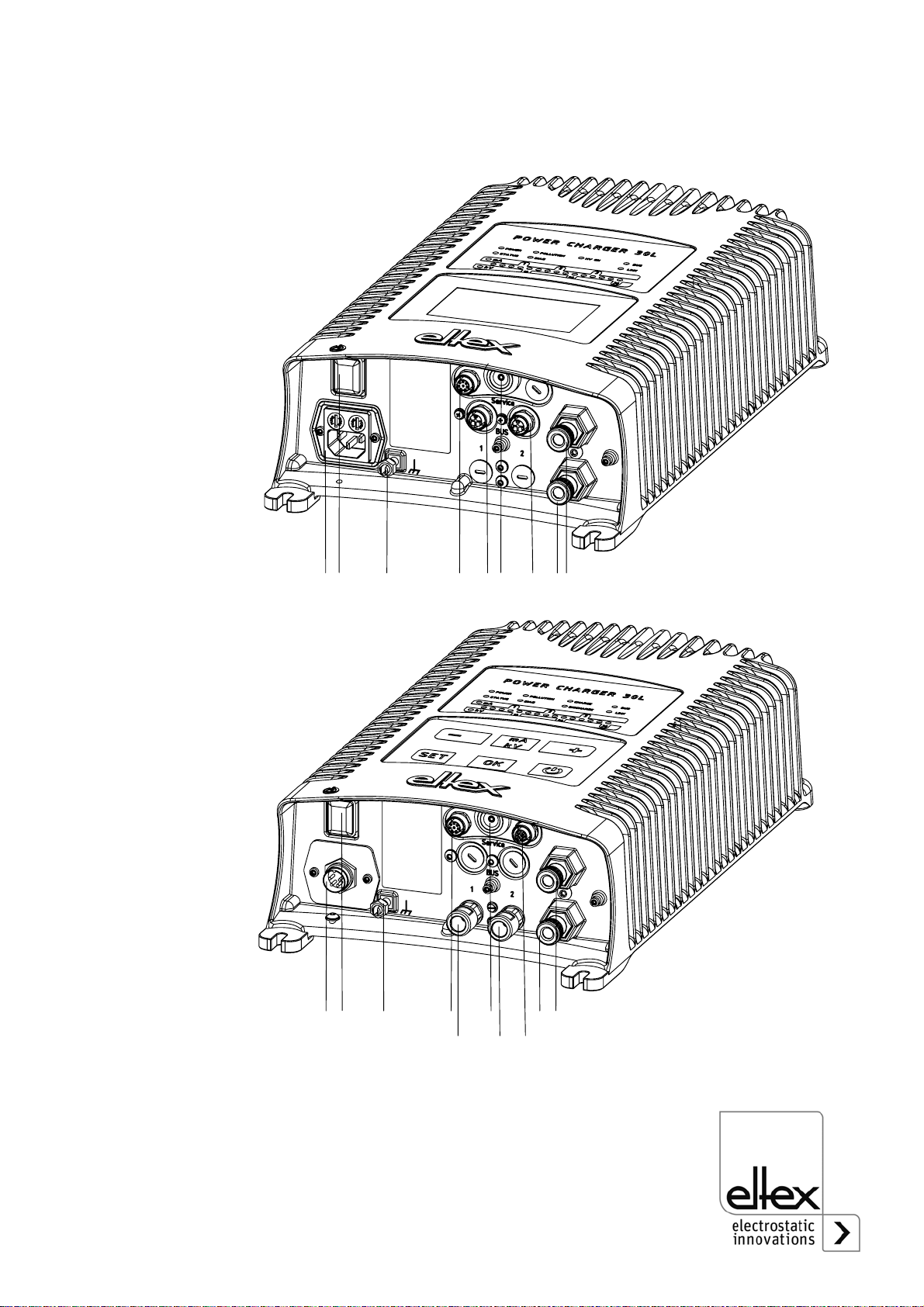

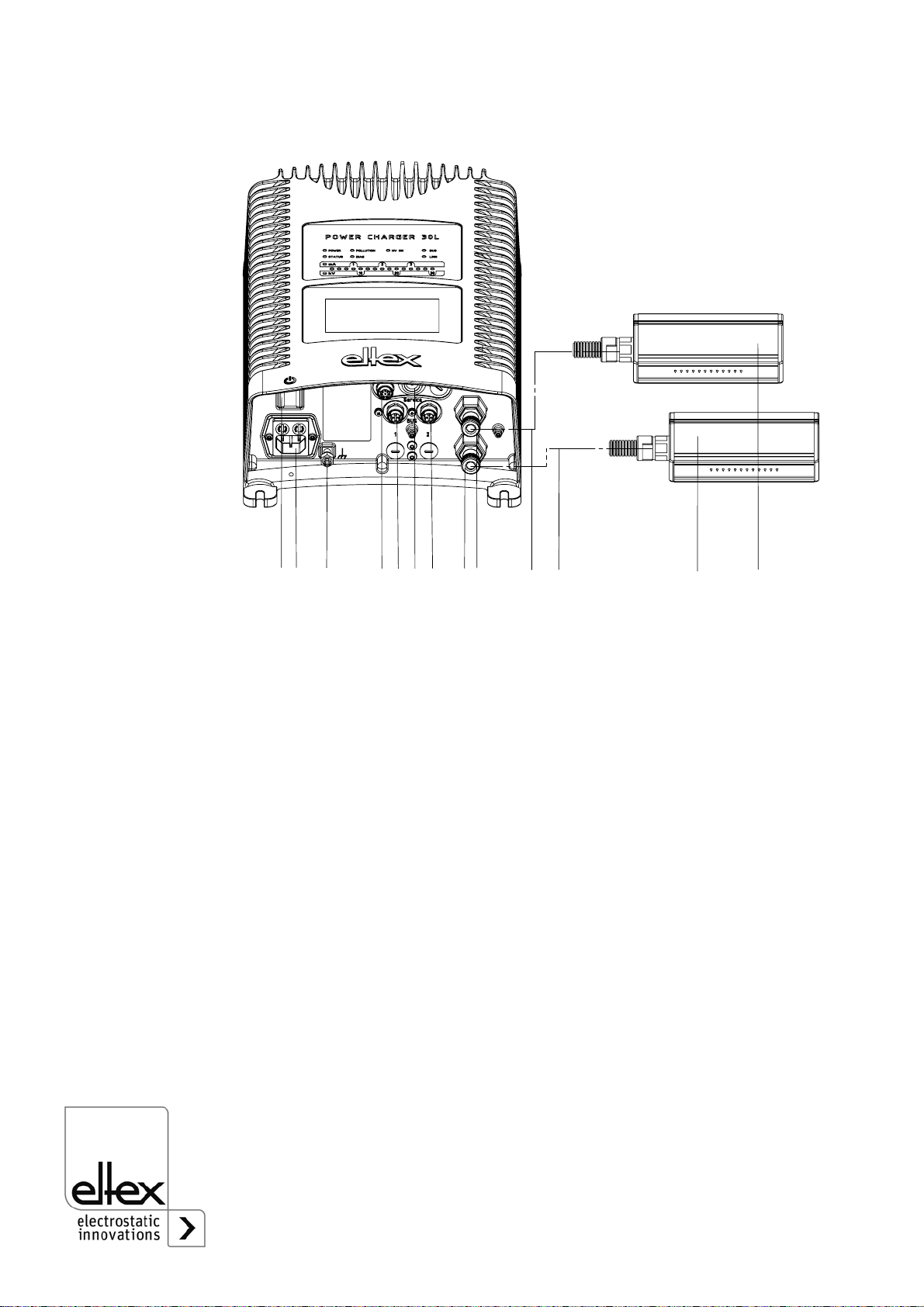

1 Outline of Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 High voltage setting range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 Identification of risks and hazards . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Contact protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Technical advance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.4 Proper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.5 Work and operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Assembly of the high voltage generator . . . . . . . . . . . . . . . . . . . . 17

3.2 Ground connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3 Installation of the high voltage cables . . . . . . . . . . . . . . . . . . . . . . 19

3.4 Bars suitable for connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4.1 Charging bars suitable for connection. . . . . . . . . . . . . . . . . . . . . 20

3.4.2 Discharging bars suitable for connection . . . . . . . . . . . . . . . . . . 22

3.5 Connecting the charging bar to the high voltage generator . . . . . . 22

3.6 Connecting the discharging bar to the high voltage generator . . . 23

3.7 Disconnecting the high voltage cable . . . . . . . . . . . . . . . . . . . . . . 24

3.8 Connecting the supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.8.1 Connecting the supply voltage 24 V DC . . . . . . . . . . . . . . . . . . 24

3.8.2 Connecting the supply voltage 90 - 264 V AC . . . . . . . . . . . . . . 25

3.9 Fieldbus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.9.1 CANopen® (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.9.2 ModbusTCP (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.10 Analog Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.10.1 Anlalog interface Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.10.2 Analog interface Discharging . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.11 Use of the Eltex signal cable CS and mains cable KN. . . . . . . . . . 31

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.1 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.2 Function monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

4.2.1 Variants with CANopen® (optional) . . . . . . . . . . . . . . . . . . . . . . 38

4.2.2 Variants with ModbusTCP (optional). . . . . . . . . . . . . . . . . . . . . . 39

4.3 Realising the high voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.4 Integrated control elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

4.4.1 Using he membrane keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . 42