Eltroplan REVCON DC Series User manual

ELTROPLAN-REVCON

Elektrotechnische Anlagen GmbH

Operating instructions

Power feed- and feedback unit REVCON

DC(S)

Power range 13 ... 135kW

Voltage range 400V and 460V

V 3.2 Issue 14/02

Contents

Operating instructions DC(S) 1

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

1 Preface and general information ......................................................................................... 3

1.1 About these Operating Instructions ..................................................................................... 3

1.1.1 Terminology used ............................................................................................................... 3

1.1.2 Ordering code ..................................................................................................................... 4

1.2 cope of delivery ................................................................................................................. 4

1.3 Legal regulations ................................................................................................................. 5

1.4 EC-Directives / Declaration of conformity ............................................................................ 6

1.4.1 What is the purpose of EC-Directives? ................................................................................. 6

1.4.2 What is the meaning of the CE-mark? .................................................................................. 6

1.4.3 EC-Low-Voltage Directive .................................................................................................... 6

1.4.4 Directive Machinery ............................................................................................................ 8

1.4.5 EC-directive Electromagnetic compatibility .......................................................................... 9

2 afety information ............................................................................................................ 10

2.1 General safety information................................................................................................ 11

2.2 afety-responsible persons ................................................................................................ 15

2.3 Layout of the safety information ....................................................................................... 16

2.4 Residual hazards ............................................................................................................... 16

2.5 General instructions .......................................................................................................... 17

2.6 UL- permission .................................................................................................................. 27

3 Technical data ................................................................................................................... 28

3.1 General data / application conditions ................................................................................ 29

3.2 Rated data ........................................................................................................................ 30

3.3.1 Power feed/feedback unit ................................................................................................. 30

3.3.2 Current load ...................................................................................................................... 31

3.3.3 Hints for proportion .......................................................................................................... 32

3.3.4 Thermal limited load graphs .............................................................................................. 34

3.3.5 Fuses and wire cross sections ............................................................................................ 37

3.3.5.1 eries fuses ....................................................................................................................... 37

3.3.5.2 Internal fuses .................................................................................................................... 38

3.4 witch on current limiter ................................................................................................... 39

3.5 RFI-filter ........................................................................................................................... 39

4 Installation ....................................................................................................................... 40

4.1 Mechanical installation ..................................................................................................... 40

4.1.1 Important hints ................................................................................................................. 40

Contents

2 Operating instructions DC(S)

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

4.2 Dimensions ....................................................................................................................... 41

4.2.1 Power feed/feedback unit ................................................................................................. 41

4.3 Electrical installation ......................................................................................................... 44

4.3.1 Operator’s safety .............................................................................................................. 44

4.3.2 Protection of the power feed/feedback unit ...................................................................... 44

4.3.3 Mains types / Mains characteristics ................................................................................... 45

4.3.4 pecifications of the used wires ......................................................................................... 45

4.3.5 Mains resp. Commutation chokes (Option) ........................................................................ 46

4.4 Connection ....................................................................................................................... 48

4.4.1 Power connection ............................................................................................................. 48

4.4.1.1 Wiring schematic .............................................................................................................. 50

4.4.2 Control wires .................................................................................................................... 52

4.4.3 Control functions .............................................................................................................. 52

4.5 Application example ......................................................................................................... 56

4.6 Installation of a power feed/feedback unit in a CE-typical drive system .............................. 57

4.6.1 Installation ....................................................................................................................... 58

4.6.2 Connection of a RFI-filter ................................................................................................... 59

4.8.3 Design of an EMC-conformal enclosure .............................................................................. 60

4.6.4 Remarks ........................................................................................................................... 61

4.6.5 Installation of control wires ............................................................................................... 62

5 Commissioning.................................................................................................................. 63

5.1 First powering up .............................................................................................................. 64

6 Configuration .................................................................................................................... 65

7 Troubleshooting and fault elimination ............................................................................... 68

7.1 LED-messages ................................................................................................................... 69

8 ervice .............................................................................................................................. 71

9 Appendix .......................................................................................................................... 72

9.1 Options ............................................................................................................................. 72

9.2 REVCON Product overview ................................................................................................ 74

9.3 Contact ............................................................................................................................. 75

Preface and general information

Operating instructions DC(S) 3

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

1Preface and general information

1.1 About these Operating Instructions

•These Operating Instructions help you to work properly on and with the power

feed/feedback units REVCON

DC(S). They contain safety information which

must be observed and information which are necessary for an undisturbed opera-

tion of the units together with the exploitation of all the advantages of the sys-

tem.

•All persons who work on and with the power feed/feedback units REVCON

DC(S), must have the Operation instructions available and observe all relevant

notes and instruction.

•The Operating Instructions must always be in a complete and perfectly readable

state.

1.1.1 Terminology used

Power feed/feedback unit

For „Power feed/feedback unit REVCON

DC(S)“ in the following the term

„Power feed/feedback unit“ is used.

Controller

For the frequency inverter which is used together with the power feed/feedback unit in

the following the term „Controller“ is used.

Drive system

For a drive system with power feed/feedback units, controller and other components of

the drive system in the following the term „Drive system“ is used.

Preface and general information

4 Operating instructions DC(S)

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

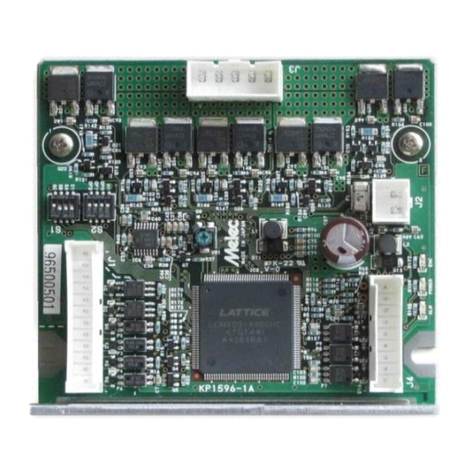

1.1.2 Ordering code

DC (S) 45 - 400 - 1 - 0

Auxilary voltage ≙

≙≙

≙not required

Number of fans

Mains voltage e. g. 400 (3 x 400V AC)

Max. feedback power e. g. 45 (45 kW)

Prepared for the connection of an

harmonic filter (SKS)

Power feed/feedback unit

with controller DC-bus supply

1.2 Scope of delivery

•1 Power feed/feedback unit REVCON

DC(S)

•1 Operating Instructions

After receipt of delivery, check immediately whether the scope of supply matches with

the accompanying papers. We do not accept any liability for deficiencies claimed subse-

quently.

Claim

•Visible transport damage immediately to the forwarder.

•Visible deficiencies/incompleteness immediately to ELTROPLAN REVCON.

Preface and general information

Operating instructions DC(S) 5

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

1.3 Legal regulations

Labelling Nameplate CE-mark Manufacturer

Power feed/feedback units REVCON

DC(S) are unequivocally marked by the

contents of the nameplate.

Conforms the EC Low

Voltage Directive

ELTROPLAN-

REVCON

Edisonstraße 3

D-59199 Bönen

Patent rights The power feed/feedback unit REVCON

DC(S) is protected in Germany and Europe by patents:

Patent-No.: DE 3938654C1 and Patent-Nr.: 90123584.6-2207.

Patent infringements become prosecute.

Application

as directed

Power feed/feedback unit REVCON

DC(S)

•Must only be operated under the conditions prescribed in these instructions.

•Are components

– to feed/feedback electrical energy

– used for installation into a machine

– used for assembly together with other components to from a machine

•Are electric units for the installation into control cabinets or similar enclosed operating enclo-

sure.

•Comply with the requirements of he Low-Voltage Directive

•Are not machines for the purpose of the Machinery Directive

•Are not to be used as domestic appliances, but only for industrial purpose.

Drive systems with power feed/feedback unit REVCON

DC(S)

•Comply with the EMC-Directive if they are installed according to the guidelines of CE-typical

drive systems.

•Can be used

– on public and non-public mains

– in industrial as well as residential and commercial premises

•The user is responsible for the compliance of this application with the EC directives.

Liability

•

The information, data and notes in these Operating Instructions met the state of the art at the

time of printing. Claims referring to power feed/feedback units which have already been sup-

plied cannot be derived from information, illustrations and descriptions given in these Opera-

tion Instructions.

•The specifications, processes and circuitry described in these Operating Instructions are for

guidance only and must be adapted to your own specific application. ELTROPLAN-REVCON

does not take responsibility for the suitability of the process and circuit proposals.

•The indications given in these Operating Instructions describe the features of the product with-

out warranting them.

•ELTROPLAN-REVCON does not accept any liability for damage and operating interference

caused by:

– disregarding these instructions

– unauthorized modifications to the power feed/feedback unit

– operating errors

– improper working on and with the power feed/feedback unit

Warranty

•

Warranty conditions: see sales and delivery conditions of ELTROPLAN-REVCON GmbH.

•Warranty claims must be made immediately after detecting defects or faults.

•The warranty is void in all cases where liability claims cannot be made.

Disposal Material recycle disposal

Metal -

Plastic -

Printed-board assemblies -

Preface and general information

6 Operating instructions DC(S)

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

1.4 EC-Directives / Declaration of conformity

1.4.1 What is the purpose of EC-Directives?

The EC-Directives have been drawn up by the European council to define common tech-

nical standards and certification procedures within the European Community. At the

moment there are 21 EC-Directives for product sectors. The directives are or will be con-

verted in national laws by the member states. If a certificate is conferred in one member

state, it is valid in all other member states automatically.

The directives only describe the basic standards. The technical details are or will be de-

scribed in harmonized European standards.

1.4.2 What is the meaning of the CE-mark?

After a conformity-assessment-procedure the conformity with the standards of the EC-

Directives is certified by fixing the CE-marking. Within the EC there are no trading ob-

stacles for a CE-marked product.

Power feed/feedback units with CE-mark themselves are compliant with the Low-

Voltage Directive only. For observing the EMC Directive recommendations are made.

1.4.3 EC-Low-Voltage Directive

Modified by: CE – Marking Directive (93/68/EEC)

CE – Marking Directive (2006/95/EC)

General:

•The Low-Voltage Directive is valid for all electrical equipment which is used at a

nominal voltage between 50V and 1000V AC and between 75V and 1500V DC to-

gether with customary environment conditions. Excluded is e.g. the use of electrical

equipment in explosive areas and electrical components of lifts for persons or mate-

rial.

•Aim of the Low-Voltage Directive is to put only those products into commerce

which don’t endanger the safety of persons and animals as well as the preservation of

material assets.

Preface and general information

Operating instructions DC(S) 7

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

EC-declaration of conformity

According to the EC-Low Voltage Directive (2006/95/EC)

The power feed/feedback units REVCON

DC(S) have been developed, designed and

manufactured in accordance with the above mentioned EC-Directive and in sole respon-

sibility of

ELTROPLAN-REVCON

Elektrotechnische Anlagen GmbH,

Edisonstraße 3, D-59199 Bönen

Considered standards:

Standard

DIN VDE 0160 5.88 +A1 / 4.89 +A2 / 10.88

PRDIN EN 50178

Class VDE 0160 / 11.94

Equipment of power installations with

electronic components

EN 61558-1/A1 Safety of power transformers, power supplies,

reactors and similar products

EN 60529 International protection rating

DIN EN 61000-6-3:2007 part 6.3 /

IEC 61000-6-3:2006

Generic standards – Emission standard for

residential, commercial, and light- industrial

environments

DIN EN 61000-6-4:2007 part 6.4 /

IEC 61000-6-4:2006

Generic standard for industrial environments

DIN VDE 0100 Guidelines for the design of

power installations

Preface and general information

8 Operating instructions DC(S)

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

1.4.4 Directive Machinery

EMC directive (89/336/EC)

Replaced by: EMC-directive (2006/42/EC)

The objective target describes article 4 (2004/108/EG), as follows:

Machinery means an assembly, fitted with or intended to be fitted with a drive system

other than directly applied human or animal effort, consisting of linked parts or compo-

nents, at least one of which moves, and which are joined together for a specific applica-

tion.

EG-declaration by the manufacturer

in terms of the EG-directive machines (2006/42/EG)

When installing the machines, commissioning (i.e. the staring of operation as directed)

the power feed/feedback unit is prohibited until it is proven that the machine corresponds

to the regulations of the EC Directive 2006/42/EG (Machinery Directive).

ELTROPLAN-REVCON Elektrotechnische Anlagen GmbH,

Edisonstraße 3, D-59199 Bönen

Preface and general information

Operating instructions DC(S) 9

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

1.4.5 EC-directive Electromagnetic compatibility

EMC directive (89/336/EC)

Replaced by: EMC-directive (2004/108/EC)

General:

The objective target describes article 4 (2004/108/EG), as follows:

The... designated devices must be so manufactured, that

(a) an intended operation of radio- and telecommunication devices and other devices is

possible and

(b) the devices have an adequate stability against electromagnetically disturbances, so

that an intended operation is possible.

EG-declaration by the manufacturer

in terms of the EG-standard EMC (2004/108/EG)

The listed REVCON

products are in terms of the EMC no independently recoverable

products, this means only after integration in the overall system would they be rateable

regarding to EMC. The rating became detected for typical plant constructions, but not for

the several products.

ELTROPLAN-REVCON Elektrotechnische Anlagen GmbH,

Edisonstraße 3, D-59199 Bönen

afety information

10 Operating instructions DC(S)

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

2Safety information

Safety and application notes

for controller

(according to: Low voltage directive 2006/95/EG)

1. General

During operation, power feed/feedback unit may have, according

to their type of protection, live, bare, in some cases also movable

or rotating parts as well as hot surfaces.

Non –authorized removal of required cover, inappropriate use, in-

correct installation or operation, creates the risk of severe injury to

persons or damage to material assets.

Further information can be obtained from the documentation.

All operations concerning transport, installation and commission-

ing as well as maintenance must be carried out by qualified,

skilled personnel (IEC 364 and CENELEC HD 384 or DIN VDE

0100 and IEC-Report 664 or DIN VDE 0110 and national regula-

tions for the preventions of accidents must be observed).

According to this basic safety information qualified skilled per-

sonnel are persons who are familiar with the erection, assembly,

commissioning and operation of the product and who have the

qualifications necessary for their occupation

.

2. Application as directed

Power feed/feedback units are components which are designed for

installation in electrical systems or machinery.

When installing in machines, commissioning of the power

feed/feedback unit (i.e. the starting of operation as directed) is

prohibited until it is proven, that the machine corresponds to the

regulations of the EC Directive 2006/42/EG (Machinery Direc-

tive); EN 60204 must be observed.

Commissioning (i.e. starting operation as directed) is only allowed

when there is compliance with the EMC-Directive 2004/108/EG).

The power feed/feedback units meet the requirements of the Low-

Voltage Directive (2006/95/EEC). The harmonized standards of

the prEN 50178/DIN VDE 0160 series together with EN 60439-

1/DIN VDE 0660 part 500 and EN 60146/DIN VDE 0558 are ap-

plicable for the power feed/feedback unit. The technical data and

information on the connection conditions must be obtained from

the nameplate and the documentation and must be observed in all

cases.

3. Transport, Storage

Notes on transport, storage and appropriate handling must be ob-

served.

At non-observance any warranty expires.

The power feed/feedback unit has to be protected from inadmissi-

ble stress.

The transport is only valid in original packaging and in the thereon by

pictograms marked transport position.

In particular during transport and handling no components are al-

lowed to be bent and / or isolating distances may not be altered.

The units are equipped with electrostatic sensitive devices, which

may be damaged by improper handling. Therefore it has to be

avoided to get in contact with electronic components. If electronic

components are damaged mechanically the unit must not be put

into operation, as it cannot be ensured, that all relevant standards

are observed. Climatic conditions must be observed according to

prEN 50178

4. Erection

The devices must be erected and cooled according to the regula-

tions of the corresponding documentation.

The power feed/feedback units must be protected from inappro-

priate loads. Particularly during transport and handling, compo-

nents must not be bent and / or isolating distances must not be

changed. Touching of electronic components and contacts must be

avoided.

Power feed/feedback units contain electro-statically sensitive

components which can easily be damaged by inappropriate han-

dling. Electrical components must not be damaged or destroyed

mechanically (health risk are possible!).

5. Electrical Connection

When working on live power feed/feedback units, the valid na-

tional regulations for the prevention of accidents (e.g. VBG 4)

must be observed. Before any installation or connection works,

the pant has to be switched off and to be secured properly.

The electrical installation must be carried out according to the ap-

propriate regulations (e.g. cable cross-sections, fuses, PE-

connection). More detailed information is included in the docu-

mentation. When using the power feed/feedback unit with control-

lers without safe separation from the supply line (to VDE 0100)

all control wiring has to be include in further protective measures

(e.g. double insulated or shielded, grounded and insulated).

Notes concerning the installation in compliance with EMC – such

as screening, grounding, arrangement of filters and laying of ca-

bles – are included in the chapter installation of this documenta-

tion. These notes must be also observed in all cases for power

feed/feedback units with the CE-mark. The compliance with the

required limit values demanded by the EMC legislation is the re-

sponsibility of the manufacturer of the system or machine.

6. Operation

Systems where power feed/feedback units are installed, if appli-

cable, have to be equipped with additional monitoring and protec-

tive devices according to the valid safety regulations e.g. law on

technical tools, regulations for the prevention of accidents, etc. .

After disconnecting the power feed/feedback unit from the supply

voltage, live parts of the power feed/feedback unit and power

connections must not be touched immediately, because of possi-

bly charged capacitors. For this, observe the corresponding labels

on the drive controllers.

During operation, all covers and doors must be closed.

7. Maintenance and service

The manufacturer’s documentation must be observed.

This safety information must be kept!

The product-specific safety and application notes in

these Operating Instructions must also be observed!

afety information

Operating instructions DC(S) 11

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

2.1 General safety information

•These safety regulations are not entitled to completeness. In case of questions

please contact our technicians.

•When commissioning the power feed/feedback unit it is compliant with the state

of the art. The power feed/feedback unit generally allows safe operation.

•The statements of this manual describe the attributes of the products without guar-

anteeing them.

•The power feed/feedback unit may expose persons, the power feed/feedback units

itself and other material to danger, if

– Non-qualified personal works at and with the power feed/feedback unit.

– The power feed/feedback unit is used in opposite to its purpose.

•Power feed/feedback units have to be projected in a way, that they fulfil their

function and don’t expose persons to danger, if they are mounted correctly and are

used in accordance with their purpose. This applies also for the interplay with the

whole plant.

•The units, operational data and circuit details described in this manual have to be

understood analogously and have to be checked for transferability to each applica-

tion.

•For the reasons of personal safety, the observance of the EMC-regulations and for

the regular cooling the operation of the device is only allowed with a closed cover

of the housing and with mounted flanges!

•

•Use the drive system only in flawless condition.

afety information

12 Operating instructions DC(S)

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

•Modifications of the power feed/feedback units without consultation of a

REVCON

-technician are not allowed generally.

•The warranty given by us expires, if the unit is modified or (even partially) dis-

mantled or if it is used in contradiction to our instructions.

•The constructor of the plant, who has to know the technical guidelines, bears the

responsibility for the correct selection and arrangement of the electrical compo-

nents.

•Putting into operation of the power feed/feedback unit is only admissible at VDE-

conform nets of electrical power supply. Non-observance may damage the device!

•In accordance with the corresponding standards and guidelines the operation on

even for a short time over-compensated networks (cosϕ≤1) respectively on un-

choked compensation-units is not admissible. If this is done nevertheless, over-

voltage will occur (caused by oscillating currents), which may damage all con-

nected components, especially electronic units like controllers and power

feed/feedback units.

•To low powered or unloaded generators and to regulating transformers it is never

allowed to feed back power without a previous consultation of our application de-

partment. Otherwise unintended voltage rises / excess voltages are generated,

which may damage or destroy REVCON

and combined units!

•Before operating at nets without reference to neutral ground additional safety

measures (e.g. installation of over voltage suppressors like MOV’s) have to be

done. If necessary, please ask for technical support by our technicians.

afety information

Operating instructions DC(S) 13

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

•An undisturbed operation of the power feed/feedback unit is only probable, if the

following instructions are observed. If these instructions are not observed, tripping

of the unit and damages may occur.

–Pay attention to the correct values of mains and DC-bus voltage.

–Separate power and control wires (> 15cm)

–Use shielded or twisted control wires. Connect both ends of the shield to

ground!

–When using the digital input devices, only use suitable switching devices,

whose contacts are able to switch the connected voltages.

–Connect the housings of drive, controller and power feed/feedback unit to

ground carefully. Connect shields of power cables to ground at both ends

with as big surface as possible (remove lacquer)!

–Connect the cabinet or the plant by a star-shaped network to ground

(ground loops have to be avoided!)

•The power feed/feedback unit has been designed for a fixed connection to mains

only. Especially when using RFI-filter leakage current values> 3,5mA may occur.

The cross section of the earthing conductor must be al least 10mm² copper, or a

second conductor has to be connected in parallel (star shaped grounding network).

•If components are used, which have no electrical separated inputs / outputs it is

necessary to equalize the potentials (e.g. by a equalizing wire). If this is not ob-

served these components may be damaged by equalizing currents.

•When carrying out an insulations test in accordance with VDE0100/part 620 the

device has to be disconnected to avoid damage to the power semiconductors. This

procedure corresponds with the standard, as each device performs a high voltage

test in accordance with VDE 0160 (EN 50178) in the course of final testing after

manufacturing.

afety information

14 Operating instructions DC(S)

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

•A standard fault-current circuit breaker (sensitive on peak currents) is not al-

lowed to be used as the only protective measure when using controller and

power feed/feedback unit Caused by a DC-component in the mains current a

controller with 3-phase input voltage may prevent a fault-current circuit breaker

from tripping in case of an earth fault. In accordance with VDE 0160 a fault-

current circuit breaker is not allowed to be used as the only protective measure.

In dependence on the kind of network (TN, IT, TT) further protective measures

in accordance with VDE 0100 part 410 are necessary. For a TN-network this

may be an over current protection, for a IT-network a insulation supervision with

pulscode-measurment. For all kind of networks protective insulation (-

transformer) may be used, if required power and length of wires allow that.

When selecting a fault current circuit breaker the following measures have to be

considered:

–The fault current circuit breaker has to be compliant with the VDE 0664

standard.

–The tripping current should be 300mA or more, to prevent a premature

tripping caused by the leakage current of the controller. In dependence on

the load, the length of the motor cables and the usage of a RFI-filter the

leakage current may even be much higher.

Faults current circuit breakers, which are sensitive to all kinds of leakage currents grant

a good protection and are suitable as the only protection measurement for one ore three

phase controllers. The connection instructions of the manufacturer have to be observed.

afety information

Operating instructions DC(S) 15

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

2.2 Safety-responsible persons

User

•User is any natural or legal entity, who uses the drive system or by whom order

the drive system is used.

•The user respectively his security officer have to grant

– that all relevant regulations, instructions and laws have to be observed

– that only qualified personnel works with or at he drive system

– that the relevant manual is available for the personnel during any works.

– that non-qualified personnel is prohibited to work on the drive system.

Qualified personnel

Stop!

Qualified personnel are persons who are, based on their education, experience, instruction and

knowledge about standards and guidelines, regulations for the prevention of accidents and the

situation in the plant, authorized by the safety officer of the plant to execute the necessary

works and are able to recognize possible dangers and to avoid them.

(Definition of qualified personnel in accordance with IEC 364)

Usage as directed

Stop!

Power feed/feedback units are electrical drive components, which are directed to be installed in

electrical plants or machines. They have to be used only for drive systems with infinity variable

speed controls of 3-phase asynchronous or permanent magnet motors. The usage with other

electrical loads is not permitted and may damage the devices. The power feed/feedback unit

may only be connected to symmetrical networks. Non-observance may damage the devices.

STOP

STOP

afety information

16

2.3

Layout of the s

•

All safety notes have

-The icon

character

-

The signal word ch

-

The note describes

Signal word

Legend

Used pictogram

Warning of

injury to

persons

Imm

by c

War

mine

Dan

situa

War

surfa

Warning of

property dam-

ages

Harm

situa

Useful informa-

tion and appli-

cation notes

Info

2.4

Residual hazar

Operator’s safety

After mains disconnections, th

Protection of the device

Cyclic connection and disconn

overload the internal input cur

Allow at least 1 minute betwee

STOP

STOP

Operating

ins

ELTROPLAN -

REVCO

Elektrotechnische

e safety information

e a uniform layout:

terizes the type of danger.

characterizes the severity of danger.

es the danger and suggests how to avoid the da

ms

Signal words

minent danger

current

Danger!

Warns of an immediate

Consequences by disre

Death or severe injurie

arning

of a im-

inent danger

Warning!

Warns of a possible, ve

situation. Possible

con

Death or severe injurie

angerous

tuation

Caution!

Warns of a possible, da

Possible consequences

Minor or small injuries

arning of hot

rface

Warning!

Warns of touching a ho

Possible consequences

Burnings

armful

tuation

Stop!

Warns of possible prop

Possible consequences

Damage of the drive sy

ings

formation

Note!

Marks a generally, use

If you follow it, you m

handling of the system

ards

the power

terminals + and –

remain live for sev

nnection of the supply voltage at terminals L1,

urrent

limitation:

een disconnection and reconnection.

instructions

DC(S)

ON

e Anlagen GmbH

danger.

iately imminent Danger.

sregard:

ries

, very danger

onsequences by disregard:

ries

, dangerous situation.

es by disregard:

ies

hot

surface.

es by disregard:

roperty damages.

es by disregard:

system or its surroun

d-

seful note, tip.

make the

m easier

several minutes.

1, L2 und L3, may

afety information

Operating instructions DC(S) 17

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

2.5 General instructions

By this information to erectors and users of a plant hints on properties and directions con-

cerning the power feed/feedback unit are given. These hints are not entitled to complete-

ness.

Special features in comparison towards a chopper

Unlike a braking resistor a power feed/feedback device isn't a constant sink, but it's de-

pendent on the momentary characteristics of the supplying net. Commutation brake downs

and voltage-flicker in the net have a considerable effect to the backward current of the de-

vice. In case of a short time voltage brake down the backward current has to raise corre-

spondingly to feed/feedback the demanded power-amount. Does the level of the supply

voltage sink for a longer time, the maximum feed/feedback power is reduced.

If only one phase fails, the device is able to work on, but the current in the two remaining

conductors will rise up to 150% of the normal level.

afety information

18 Operating instructions DC(S)

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Length of the DC-connection

The maximum inductivity of the DC-connection between output B6 bridge of the inverter

and the power feed/feedback device mustn't exceed a certain level, as this inductivity in-

ducts an additional voltage to the DC-bus, when the IGBT’s are switched off. To avoid an

overload to the components of the power feed/feedback unit, this additional voltage must

not exceed 100V. Resulting from this and other relevant characteristics of the power

feed/feedback unit (DC-capacity and absolute maximum value of the grid current) the

maximum inductivity

(

)

2

2

max

ˆ

i

UC

L

GL

∆⋅

=

can be calculated. This inductivity always has to

be higher or equal than the sum of the DC-bus inductivity of the frequency inverter and the

conductor inductivity of the DC connection. The DC-bus inductivity of the frequency in-

verter has only to be considered, if it is placed between the inverter B6 bridge and the

power feed-back unit. The cables, which are normally used for power applications, have an

inductance per unit length of about 0,6µH/m. If the values of the input capacitance C, the

during power feed back maximum allowed rise of the DC-voltage ∆U

GL

=100V, the top

level of the AC-current of the device (=2xI

eff

), the inductance per unit length L´ and the in-

ductance of the DC-bus ´choke L

ZKD

are known the maximum longitude of the conductors

can be calculated with the following equation:

L

L

Li

UC

l

ZKD

GL

′

−

′

⋅

∆⋅

=

2

2

max

ˆ

afety information

Operating instructions DC(S) 19

ELTROPLAN - REVCON

Elektrotechnische Anlagen GmbH

Operation on a generator

The usage of a power feed/feedback unit within an island network (e.g. with an

diesel generator) is possible, but there are restrictive regulations concerning the power lim-

its.

M

M

REVCON

R

0,4kV

100kVA

20kW

20kW

G

FC

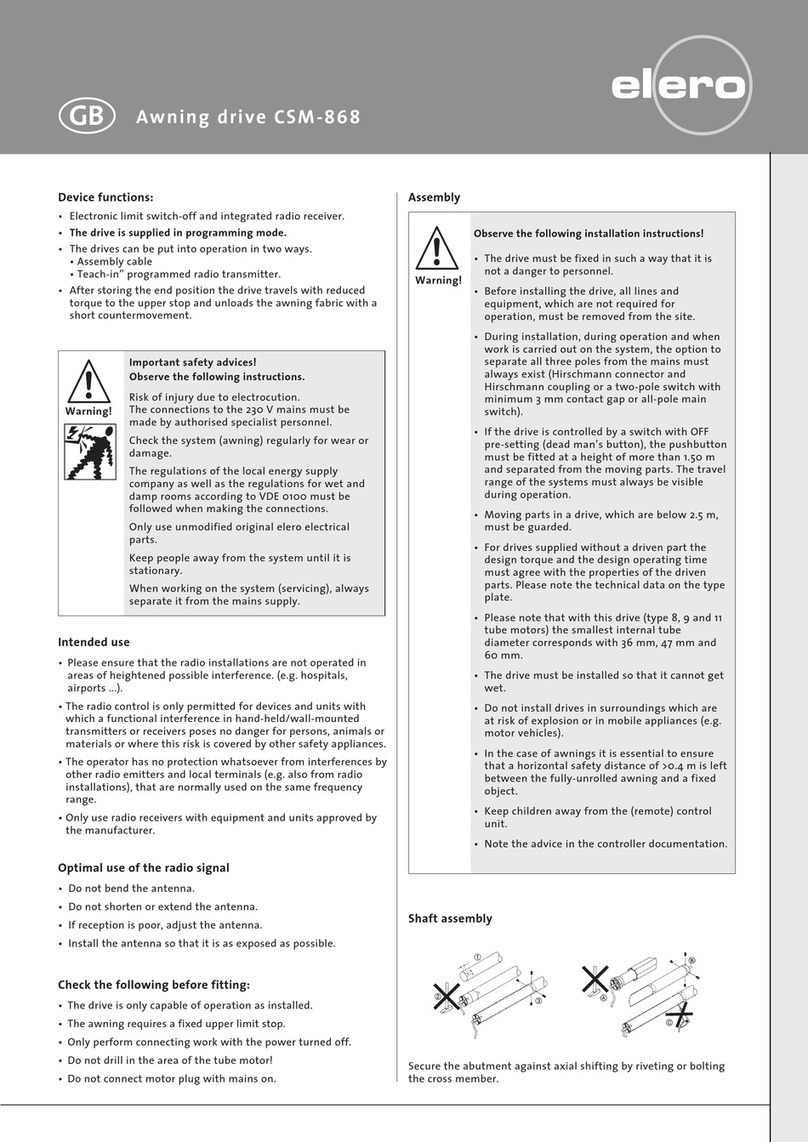

Figure 2.6.1

Within a network that is assembled like in figure 2.6.1, there are two additional restric-

tions: First the power of the motor connected to the inverter must be lower than half of the

nominal power of the generator. Second the total amount of the power of the two other

loads must be more than double of the feed back power.

If these conditions aren't checked up a change from motor to generator operation may re-

sult in load shocks. These shocks are too dynamic for the voltage regulator of the genera-

tor. The regulator reacts with an overshoot and as a result of this with an over voltage

within the island network.

Danger!

Over voltages may cause serious damages to the connected frequency inverter and /or to the

power feed/feedback unit and to the other loads.

This manual suits for next models

27

Table of contents