M-Elec GDB-5K50 User manual

Table of contents

Other M-Elec DC Drive manuals

M-Elec

M-Elec RAPID User manual

M-Elec

M-Elec ADB-5K30 User manual

M-Elec

M-Elec ADB-2F45U User manual

M-Elec

M-Elec ADB-5F41EL User manual

M-Elec

M-Elec ADB-2F30BA User manual

M-Elec

M-Elec GDB-5K30 User manual

M-Elec

M-Elec ADB-2F50B User manual

M-Elec

M-Elec GD-5410 User manual

M-Elec

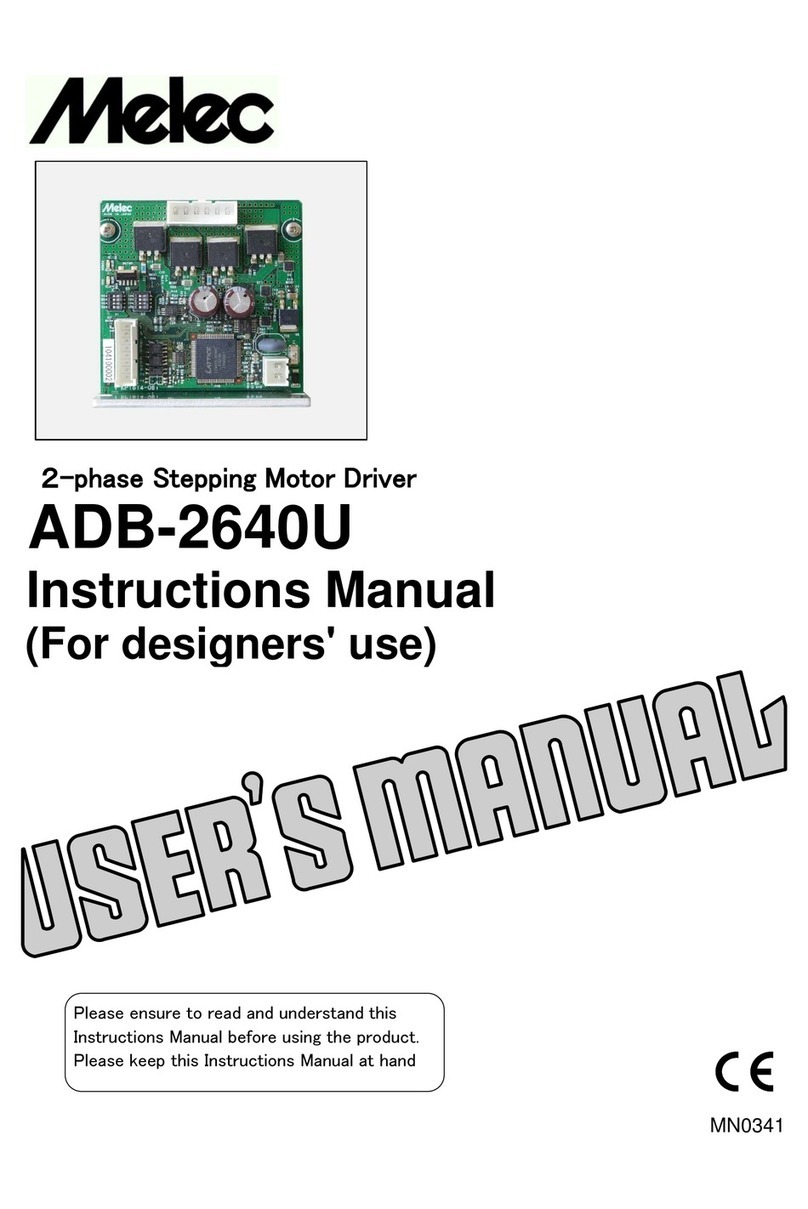

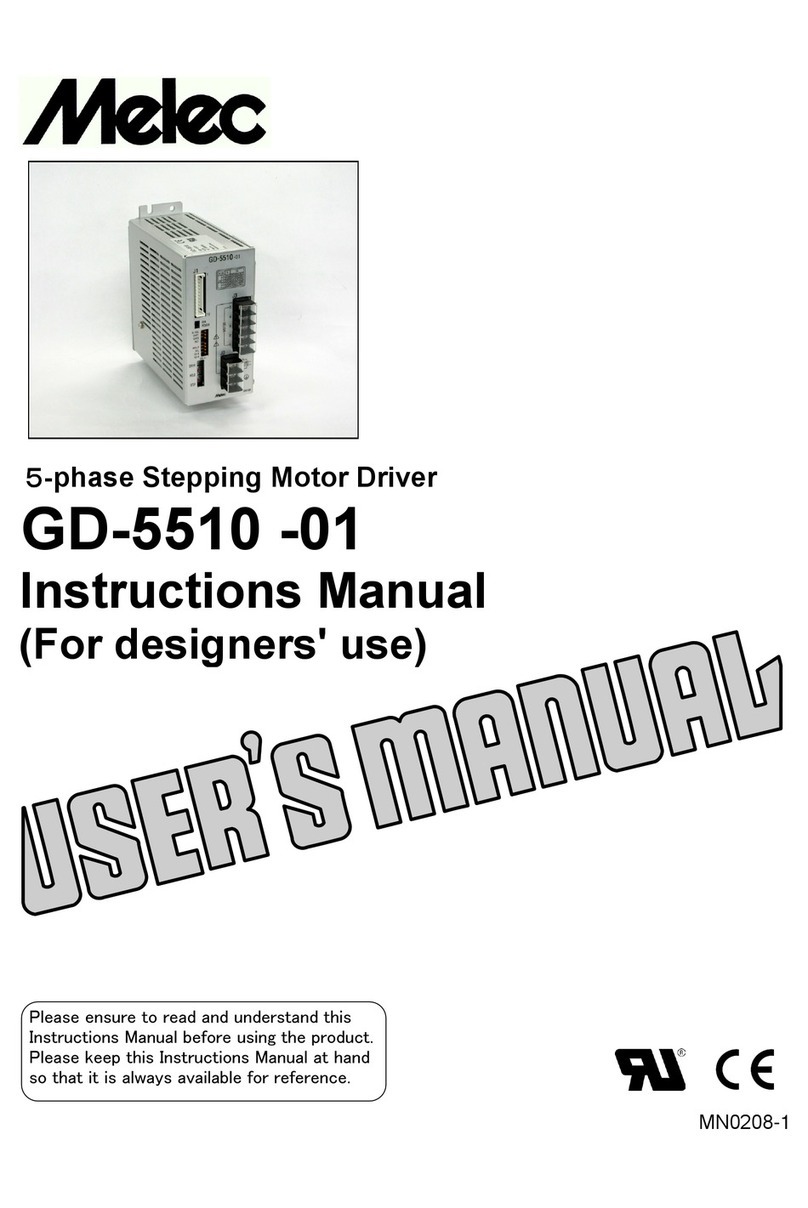

M-Elec GD-5510 -01 User manual

M-Elec

M-Elec GD-5610v1 User manual

Popular DC Drive manuals by other brands

HAUTAU

HAUTAU SKA 30 Mounting and operating instructions

Fujitsu

Fujitsu FP-1000 installation guide

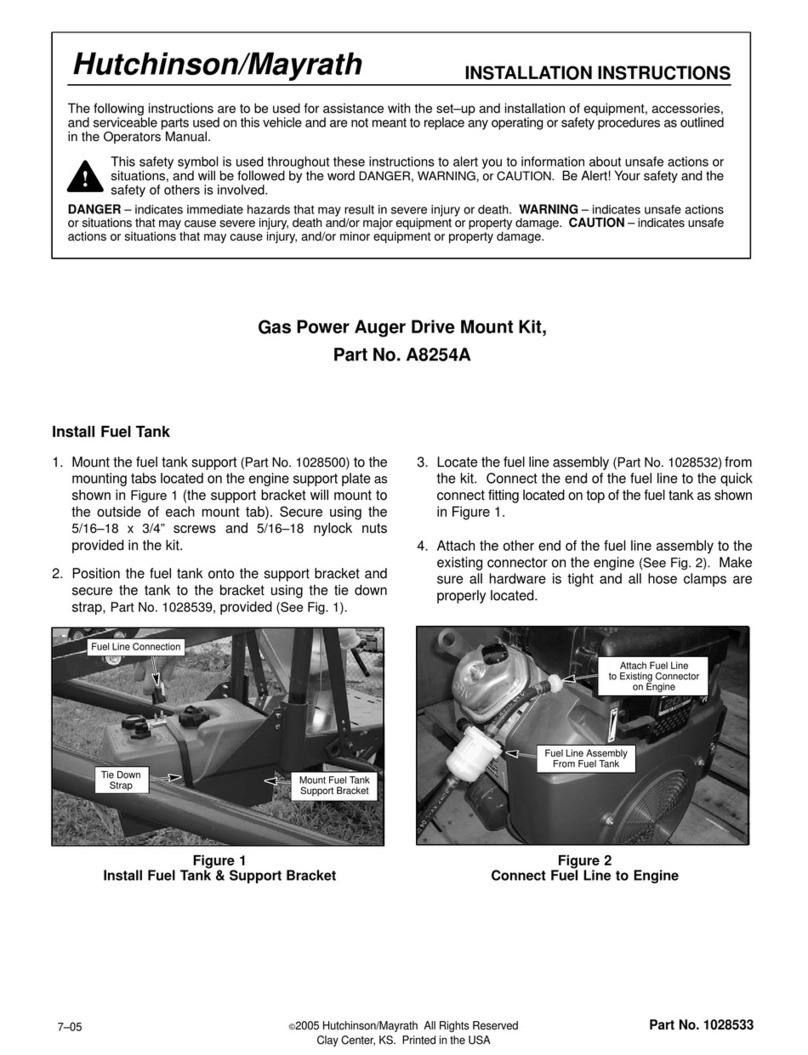

Hutchinson/Mayrath

Hutchinson/Mayrath A8254A installation instructions

ABB

ABB ACS580 Series Firmware manual

Carotron

Carotron Elite Pro Series instruction manual

Faulhaber

Faulhaber 3242 BX4 Series instruction manual

KB Electronic

KB Electronic KBVF Series Installation and Operation Manual Supplemental Information

Rhymebus

Rhymebus RM6F2 Series Operation manual

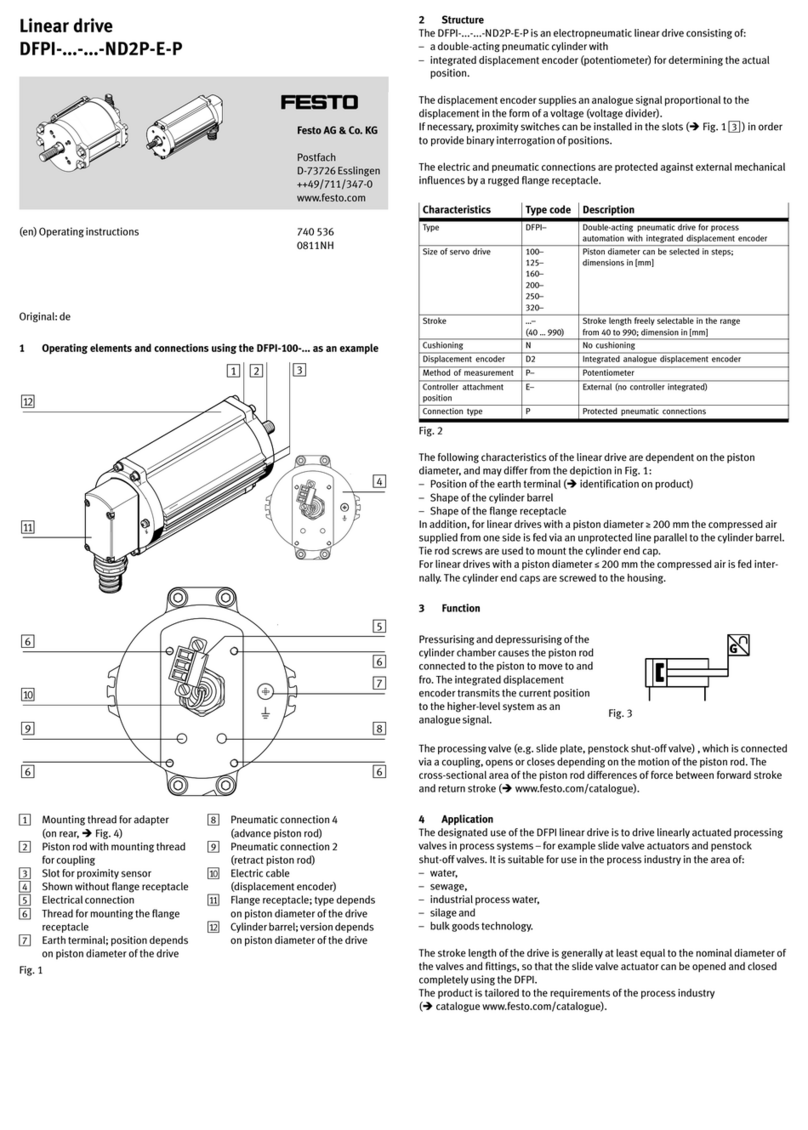

Festo

Festo DFPI-100-***-E-P operating instructions

ELMARK

ELMARK elmatic ED2000 manual

Siemens

Siemens SED2 Series Commissioning manual

Vicon

Vicon V3400APT-1 Additional Instructions for Installation and Operation