elysia Mpressor 500 User manual

mpressor 500

2

The compressor from the future

The mpressor 500 brings the heritage of our extremely pow-

erful rack mount mpressor into the 500 series format. Like its

bigger brother, the mpressor 500 combines serious punch

with a full and detailed class-A sound. Its great tone and ex-

ibility make it an excellent choice for recording and mixing,

while its remarkable special features take it far beyond the

borders of what normal compressors can do.

Extreme time constants, negative ratios, “antilog” release and

elysia’s innovative gain reduction limiter provide a whole

spectrum of unique dynamics shaping options. A new feature

of the 500 series module is its switchable THD boost allowing

on-the-y signal coloration and saturation eects capable of

delivering a grittier avor.

The elysia team wishes you great delight and compression de-

luxe with your new mpressor 500.

Compatibility ..............................................3

Installation ................................................3

Controls ...................................................4

Connectors ................................................6

Auto Fast ..................................................7

Anti Log ...................................................8

THD Boost .................................................9

Negative Ratios .......................................... 10

Gain Reduction Limiter................................... 11

Appendix................................................ 12

Deutsches Handbuch . . . 16 Manuel Français ... 30

3

Compatibility

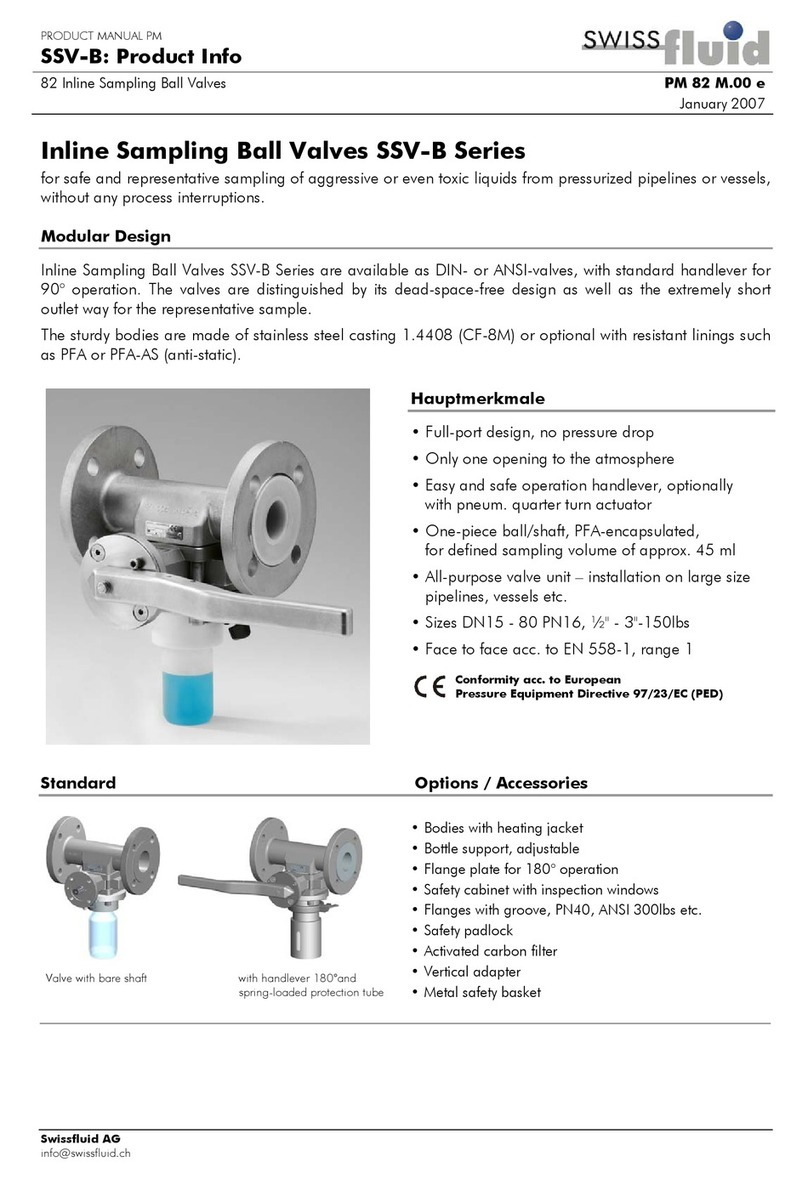

The mpressor 500 is a module to be installed into an API 500

series compatible rack frame (not included). It needs the pow-

er supply and the audio connectors provided by this frame

and does not function stand alone.

The current consumption is 75 milliamperes at +/- 16 volts DC.

The mpressor 500 meets all mechanical and electronic speci-

cations of the VPR Alliance, providing the highest level of com-

patibility with common 500 series rack frames.

Installation

Just follow these easy steps to install your mpressor 500:

1. Switch your API 500 series compatible rack o and discon-

nect the power cable from mains.

2. Insert the module into a free slot of your rack. Make sure the

PCB connector matches with the rack connector.

3. Gently push the module in place - do not use any extensive

force here!

4. Tighten the front panel with two screws provided by your

rack manufacturer.

5. Connect your audio cables (see page 6 for more info) and

apply power to your rack.

And this is already it. Have lots of fun with your mpressor 500!

Release

25

15

10

2k5

2k0

700

21095

5

1k3

420

Thresh

4

9

13

-25

-23

-18

-6

15

-21

-14

Attack

10

5.0

1.5

180

160

90

2520

0.01

140

45

Ratio

2.0

1.6

1.4

-1.3

-1.0

-0.5

5.03.0

1.2

-0.8

9.0

GRL

15

20

25

0

1

4

810

30

2

6

Gain

4.0

2.0

0.5 22

14

108.0

0

ms

dB

ms

1:X

dB

dB

18

12

MPRESSOR

500

DISCRETE

CLASS-A

COMPRESSOR

4

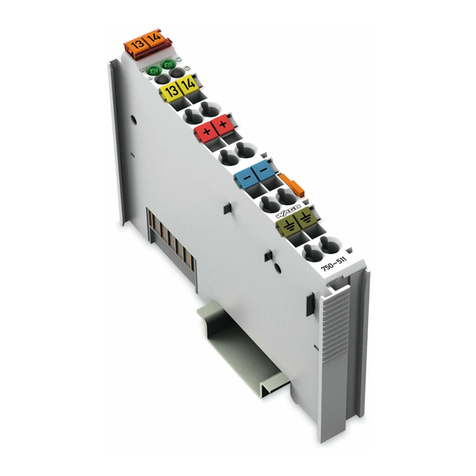

Controls

Threshold (Thresh): The operating point of the compres-

sor. If the input level exceeds the value set with this controller,

the compression process will start.

Attack: The transient response of the compressor. It deter-

mines the time the mpressor 500 needs to reach 10 dB of gain

reduction.

5

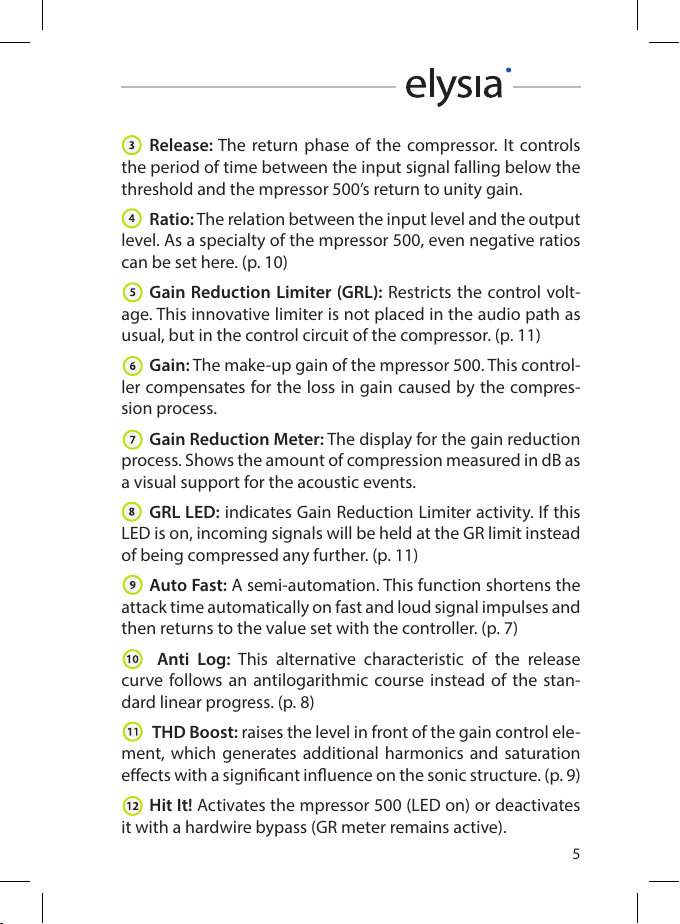

Release: The return phase of the compressor. It controls

the period of time between the input signal falling below the

threshold and the mpressor 500’s return to unity gain.

Ratio: The relation between the input level and the output

level. As a specialty of the mpressor 500, even negative ratios

can be set here. (p. 10)

Gain Reduction Limiter (GRL): Restricts the control volt-

age. This innovative limiter is not placed in the audio path as

usual, but in the control circuit of the compressor. (p. 11)

Gain: The make-up gain of the mpressor 500. This control-

ler compensates for the loss in gain caused by the compres-

sion process.

Gain Reduction Meter: The display for the gain reduction

process. Shows the amount of compression measured in dB as

a visual support for the acoustic events.

GRL LED: indicates Gain Reduction Limiter activity. If this

LED is on, incoming signals will be held at the GR limit instead

of being compressed any further. (p. 11)

Auto Fast: A semi-automation. This function shortens the

attack time automatically on fast and loud signal impulses and

then returns to the value set with the controller. (p. 7)

Anti Log: This alternative characteristic of the release

curve follows an antilogarithmic course instead of the stan-

dard linear progress. (p. 8)

THD Boost: raises the level in front of the gain control ele-

ment, which generates additional harmonics and saturation

eects with a signicant inuence on the sonic structure. (p. 9)

Hit It! Activates the mpressor 500 (LED on) or deactivates

it with a hardwire bypass (GR meter remains active).

6

Connectors

Audio outputs (+4 dBu)

Pin assignment balanced: 1ground 2hot (+) 3ground

Pin assignment unbalanced: 1ground 2hot (+) 3idle

Audio inputs (+4 dBu)

Pin assignment balanced: 1ground 2hot (+) 3cold (-)

Pin assignment unbalanced: 1ground 2hot (+) 3ground

7

Auto Fast

The attack parameter is a crucial factor for the op-

eration of a compressor. Choosing the right time

setting is very important, but depending on the dy-

namic progress of the source material this is a dicult task –

no matter if single tracks or complete mixes are processed.

If a very short attack time is chosen, the compressor is able

to catch the short peaks, but on the other hand the sustain-

ing signal will also be processed, which might result in audible

distortion. Longer settings reduce distortion signicantly, but

then the compressor is too slow for catching fast impulses.

This is where the Auto Fast function comes into play. If you set

a longer attack and engage the Auto Fast mode, the attack

time will be shortened automatically on fast and loud signal

impulses. The compressor reduces the signal quickly and pre-

vents it from slipping through.

Then the attack time directly and automatically returns to its

original setting. In Auto Fast mode the compressor can be

very fast, but only when it is really needed.

Attack phase without Auto Fast Attack phase with Auto Fast

Time (s) Time (s)

Output level (dB) Output level (dB)

8

Anti Log

It is characteristic of a logarithmic release that the

time constant shortens when the amount of gain

reduction increases. The advantage of this behavior

is that short and loud peaks (e.g. drums) have a fast release

time, while the remaining material is processed with a slower

release time.

But if intentionally striking and creative compression is the

goal, it makes sense to turn things upside down. In the Anti

Log mode of the mpressor, the curve behaves just the other

way round: If the threshold value is passed and compression

starts, the release time will be longer at the beginning. If the

input signal starts to decline, however, the release time will

become faster as a result.

A special circuitry makes this behavior independent from the

absolute amount of gain reduction. No matter if the compres-

sor reduces 10, 15 or 20 dB, the curve will always stay the same

at the beginning and it will only become faster at the end.

With this feature you can create many exceptional compres-

sion eects just by the push of a button!

Release phase without Anti Log Release phase with Anti Log

Time (s) Time (s)

Output level (dB) Output level (dB)

9

THD Boost

Activating the THD Boost function raises the level in

front of the gain control element. This generates ad-

ditional harmonics inside the input stage of this am-

plier, which has a signicant inuence on the sonic structure

of a signal.

The mpressor 500 is a pure feed forward compressor, and the

gain potentiometer is placed before the control element. This

means that the intensity of the saturation can be raised or

lowered by dierent settings of the gain controller.

What’s special: The detector in the sidechain of the compres-

sor runs in parallel and is therefore not inuenced by the THD

Boost at all. The actual compression does not change, it is only

the sound which is being inuenced.

You generate a saturated signal which as a result is also re-

duced in dynamics, but the actual control of the compressor

itself is always based on the original dynamics including all

transients, impulses and so on.

THD Normal THD Boost

Input level (dB) Input level (dB)

THD+N (%) THD+N (%)

10

Negative Ratios

Negative ratios – what exactly does this mean? To

get a better understanding of this function, it makes

sense to realize what the ratio control of a ‘normal’

compressor does:

• 1:1 The signal remains linear, there is no compression pro-

cess going on.

• 1:2 After crossing the threshold, an increase of 2 dB at the

input will be compressed to an increase of 1 dB at the

output.

• 1:∞ After crossing the threshold, the output signal is con-

stantly held at the threshold level without reacting to

further increases at the input (limiter).

At a negative ratio, the characteristic curve bends and returns

back down after crossing the threshold. The louder the input

signal, the lower the output signal – perfect for groovy com-

pression eects.

To get a grip on the extreme ‘destruction’ this can cause, en-

gaging the Gain Reduction Limiter is just the right idea.

Standard compression ratio Negative compression ratio

Input Level (dB) Input Level (dB)

Output Level (dB) Output Level (dB)

11

Gain Reduction Limiter

A specialty of the mpressor 500 is the Gain Reduction

Limiter. This limiter is not placed in the audio path

where you might expect it, but in the control path of

the compressor instead.

When activated, it limits the control voltage according to the

setting of the GRL controller. This means: No matter how high

the input level might become – the total amount of gain re-

duction will never exceed the value you have set.

Just think about the GRL as a second threshold controller:

While the ‘regular’ threshold controller tells the compressor

when to start working, the GRL controller tells it when to com-

press no further.

Loud parts in an arrangement can keep their dynamics, as

they will not be compressed beyond the limit of the Gain Re-

duction Limiter.

Note: In order to avoid GRL activity, just turn its controller fully

counter-clockwise.

GRL compression progress GRL input to output ratio

Time (s) Input Level (dB)

Output Level (dB) Output Level (dB)

Attack phase

Release phase

GRL phase

GRL phase

12

Technical Details

Frequency response: <10 Hz - 390 kHz (-3 dB)

THD+N @ 0 dBu, 20 Hz - 22 kHz: 0.04 %

THD+N @ 10 dBu, 20 Hz - 22 kHz: 0.19 %

THD+N @ 0 dBu, 20 Hz - 22 kHz, THD Boost: 0.24 %

THD+N @ 10 dBu, 20 Hz - 22 kHz, THD Boost: 2.20 %

Noise oor, 20 Hz - 20 kHz (A-weighted): -79 dBu

Noise oor, 20 Hz - 20 kHz (A-weighted), THD Boost: -87 dBu

Dynamic range, 20 Hz - 22 kHz: 99 dB

Maximum input level: 21 dBu

Maximum output level: 22 dBu

Input/output impedance: 10 kOhm/68 Ohm

CE Conformity

The conformity of this device to the EU directives is

conrmed by the CE mark on the device.

This declaration becomes invalid by any unapproved modi-

cation of the device.

Nettetal, 01.10.2016 - Ruben Tilgner

13

Precautions

CAUTION: Electricity

• Make sure to operate your API 500 series compatible rack at

the specic mains voltage of your country.

• Replace rack frame fuse with the same type and value only.

• Your rack frame must be connected to ground.

• Do not use a damaged power cord.

• Never place containers with liquid on the rack.

• Do not expose this device to rain or moisture.

• Do not use this device near water.

• Refer service to qualied service sta only.

CAUTION: Temperature

• Surfaces of the device may become hot during operation.

• Do not install this device near any heat source such as radia-

tors, stoves or other heat sources.

CAUTION: Connecting & Mounting

• Never connect to the output of a power amplier.

• Do not apply extensive force when installing this device.

• Use the device according to this manual only.

CAUTION: Humidity

• If this device is moved from a cold place to a warm room,

condensation can occur inside the device. To avoid damag-

ing the unit please allow it to reach room temperature be-

fore switching it on.

14

Warranty Info

The mpressor 500 is covered by a limited warranty for a period

of 2 years against defects in parts and labor from the date of

purchase. Natural wear is not covered by this warranty. Re-

pairs or replacements will not extend the warranty period.

The warranty is given to the original purchaser only and is not

transferable. elysia will only give warranty on products pur-

chased through authorized elysia dealers. The warranty will

only be valid in the country of the original purchase unless

otherwise pre-authorized by elysia.

All warranties become void when the product has been dam-

aged by misuse, accident, neglect, modication, tampering or

unauthorized alteration by anyone other than elysia autho-

rized service personnel.

The warrantor assumes no liability for property damage or any

other incidental or consequential damage whatsoever which

may result from failure of this product. Any and all warrantees

of merchantability and tness implied by law are limited to

the duration of the expressed warranty.

elysia will not pay for express or overnight freight service or

pay for shipments to locations outside Germany. All damages

caused by transport are not covered by this warranty.

This warranty gives you specic legal rights and you may also

have other rights which vary from state to state. Some of the

above limitations may not apply to you.

15

Legal Info

The information in this document is subject to change with-

out further notice and shall not be deemed as an obligation

or warranty of any kind by the manufacturer. No warranties,

express or implied, are made with regard to the quality, suit-

ability or accuracy of this document.

The manufacturer reserves the right to change the contents

of this document and/or the associated products at any time

without the provision of prior notice. The manufacturer shall

not be held liable for damages of any kind arising from the

use, or the inability to use this product or its documentation.

The information in this document is subject to copyright. All

rights, technical changes and errata are reserved. No part of

this manual may be reproduced or transmitted in any form or

for any purpose without the explicitly written permission of

the copyright holders.

elysia and mpressor are registered trademarks of elysia GmbH.

Other product and brand names contained in this document

are used for identication purposes only. All registered trade-

marks, product designations or brand names used in this doc-

ument are the property of their respective owners.

The product has been manufactured in com-

pliance with the RoHS directive. The purpose

of this directive of the European Union is

the Restriction of Hazardous Substances (RoHS) in electronic

equipment in order to protect health and nature. Dispose

separately!

Version 1.1 © 2019 elysia GmbH

16

Der Kompressor aus der Zukunft

Der mpressor 500 trägt das Erbgut des fantastischen mpressor

rack ins 500er Modulformat. Wie sein großer Bruder vereint

der mpressor 500 enormen Punch mit einem vollen und de-

taillierten Class-A Sound. Seine herausragende Klanggüte und

Flexibilität machen ihn zur exzellenten Wahl beim Aufneh-

men und Abmischen, während seine vielen Sonderfeatures

erstaunliche Dynamik-Eekte weit außerhalb der Reichweite

normaler Kompressoren erzeugen.

Extreme Zeitkonstanten, negative Ratios, Antilog Release und

elysias innovativer Gain Reduction Limiter erönen ein kom-

plettes Spektrum an einzigartigen Möglichkeiten. Eine neue

Funktion des 500er-Moduls ist der THD Boost für Klangfär-

bung per Knopfdruck und Sättigungseekte, die den Kom-

pressor deutlich kantiger in Szene setzen.

Das elysia Team wünscht viel Freude und Kompression Deluxe

mit deinem neuen mpressor 500.

Kompatibilität ........................................... 17

Installation .............................................. 17

Bedienelemente ......................................... 18

Anschlüsse .............................................. 20

Auto Fast ................................................ 21

Anti Log ................................................. 22

THD Boost ............................................... 23

Negative Ratios .......................................... 24

Gain Reduction Limiter................................... 25

Anhang.................................................. 26

English Manual . . . 2 Manuel Français... 30

17

Kompatibilität

Das mpressor 500 Modul ist zur Installation in ein API 500 Se-

ries kompatibles Rack (nicht im Lieferumfang enthalten) vor-

gesehen. Es ist auf dessen Netzteil und Audioanschlüsse ange-

wiesen und funktioniert nicht‚stand alone‘.

Der Strombedarf beträgt 75 Milliampere bei +/- 16 Volt DC.

Der mpressor 500 erfüllt sämtliche mechanischen und elektro-

nischen Anforderungen der VPR Alliance, was eine größtmög-

liche Kompatibilität mit handelsüblichen Racks garantiert.

Installation

Die Installation des Moduls verläuft denkbar einfach:

1. Schalte dein API 500 Series kompatibles Rack aus und ent-

ferne das Netzkabel.

2. Stecke das Modul in einen freien Slot und richte die Kontak-

te der Platine genau auf die Steckleiste im Rack aus.

3. Drücke das Modul nun vorsichtig in die Steckleiste – dabei

bitte keine Gewalt anwenden!

4. Befestige die Frontplatte mit zwei Schrauben aus dem

Rackzubehör.

5. Verbinde die Audiokabel (mehr dazu auf Seite 20) und

schließe das Rack wieder an das Stromnetz an.

Und das war es auch schon. Wir wünschen viel Spaß mit dei-

nem mpressor 500!

Release

25

15

10

2k5

2k0

700

21095

5

1k3

420

Thresh

4

9

13

-25

-23

-18

-6

15

-21

-14

Attack

10

5.0

1.5

180

160

90

2520

0.01

140

45

Ratio

2.0

1.6

1.4

-1.3

-1.0

-0.5

5.03.0

1.2

-0.8

9.0

GRL

15

20

25

0

1

4

810

30

2

6

Gain

4.0

2.0

0.5 22

14

108.0

0

ms

dB

ms

1:X

dB

dB

18

12

MPRESSOR

500

DISCRETE

CLASS-A

COMPRESSOR

18

Bedienelemente

Threshold (Thresh): der Arbeitspunkt des Kompressors.

Überschreitet der Eingangspegel den hier eingestellten Wert,

setzt die Kompression ein.

Attack: das Einschwingverhalten des Kompressors. Be-

stimmt die Zeit, die der mpressor 500 benötigt, um 10 dB Gain

Reduction zu erzeugen.

19

Release: die Rücklaufzeit des Kompressors. Regelt die

Zeitspanne zwischen der Unterschreitung des Thresholds und

der Rückkehr auf den Nominalpegel.

Ratio: das Verhältnis von Eingangs- zu Ausgangspegel. Als

besondere Spezialität des mpressor 500 können auch negati-

ve Ratios eingestellt werden. (S. 24)

Gain Reduction Limiter (GRL): begrenzt die Steuerspan-

nung. Dieser neuartige Limiter liegt nicht etwa wie üblich im

Audiopfad, sondern im Regelweg des Kompressors. (S. 25)

Gain: Die Aufholverstärkung des mpressor 500 kompen-

siert den Pegel, der zuvor durch den Kompressions-Prozess

reduziert worden ist.

Gain Reduction Meter: die Anzeige der Pegel-Reduktion.

Als optische Unterstützung der akustischen Ereignisse wird

hier der Kompressionsverlauf in dB angezeigt.

GRL LED: zeigt die Aktivität des Gain Reduction Limiters

an. Leuchtet die LED, werden die Signale auf dem GR Limit ge-

halten und nicht noch stärker komprimiert. (S. 25)

Auto Fast: eine Halb-Automation. Durch diese Funktion

wird die Attack-Zeit bei schnellen und lauten Signalimpulsen

automatisch verkürzt. (S. 21)

Anti Log: Diese alternative Charakteristik der Release-

Kurve nimmt anstelle des linearen einen antilogarithmischen

Verlauf und klingt damit deutlich auälliger. (S. 22)

THD Boost: erhöht den Pegel vor dem Regelverstärker

und erzeugt somit zusätzliche Obertöne und Sättigungs-

Eekte, welche die Klangstruktur deutlich verändern. (S. 23)

Hit It! Aktiviert den mpressor 500 (LED an) oder schaltet

einen Hardwire-Bypass via Relais.

20

Anschlüsse

Audio-Ausgänge (+4 dBu)

Pinbelegung symmetrisch: 1Masse 2heiß (+) 3Masse

Pinbelegung unsymmetrisch: 1Masse 2heiß (+) 3frei

Audio-Eingänge (+4 dBu)

Pinbelegung symmetrisch: 1Masse 2heiß (+) 3kalt (-)

Pinbelegung unsymmetrisch: 1Masse 2heiß (+) 3Masse

Table of contents

Languages:

Other elysia Control Unit manuals

Popular Control Unit manuals by other brands

Telit Wireless Solutions

Telit Wireless Solutions LE910C1-NS Hardware Design Guide

TELECO AUTOMATION

TELECO AUTOMATION TVPLD868C80TT3 manual

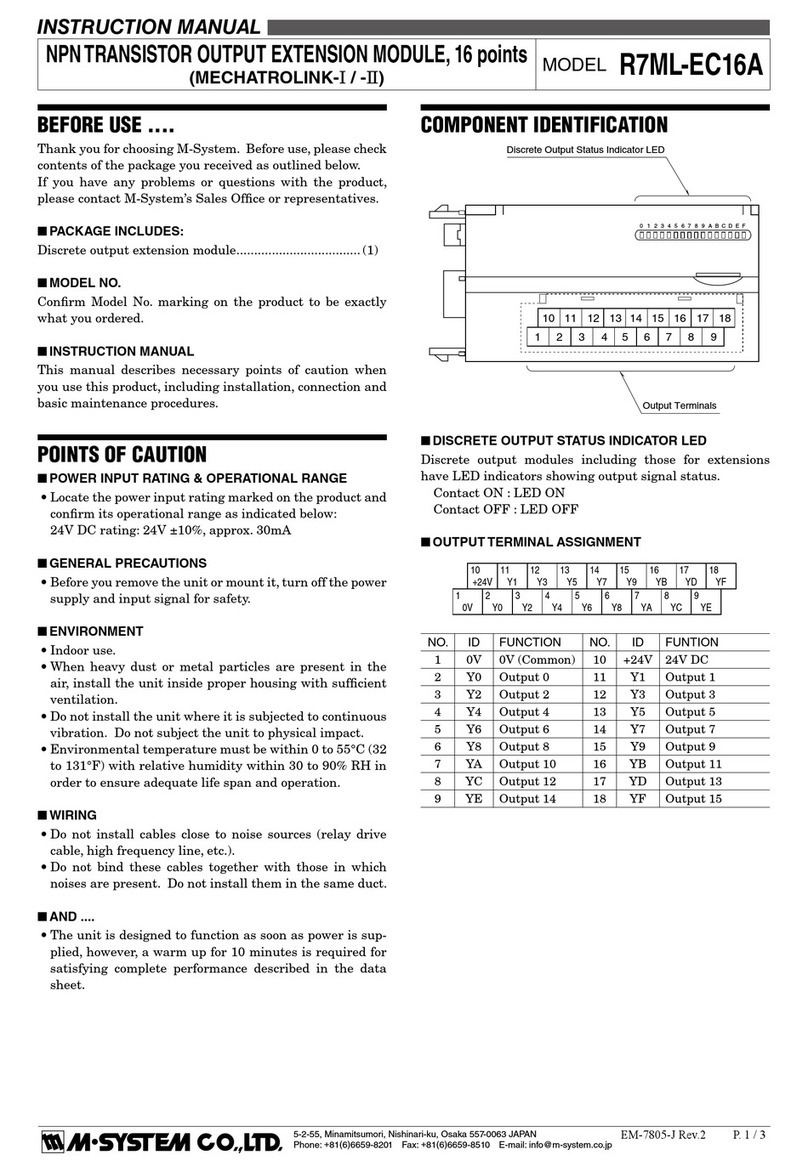

M-system

M-system R7ML-EC16A instruction manual

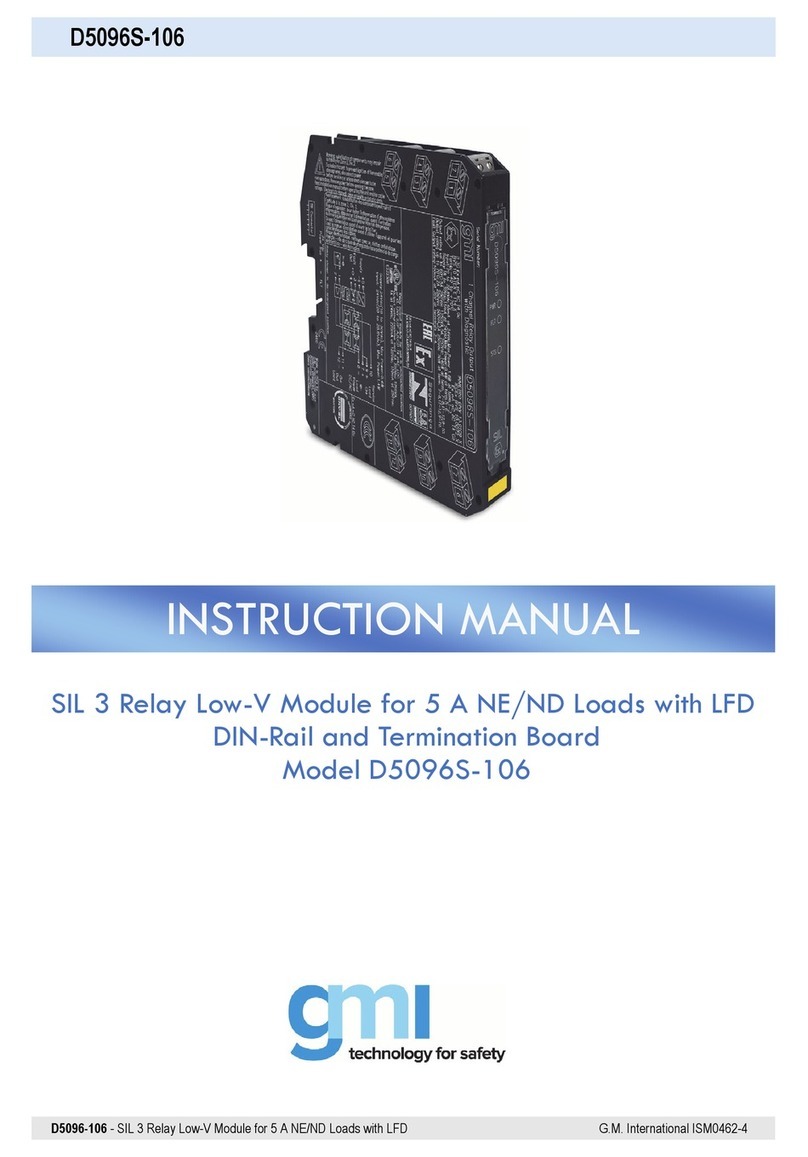

GMI

GMI D5096S-106 instruction manual

Tibbo

Tibbo EM1000 Programmable Hardware Manual

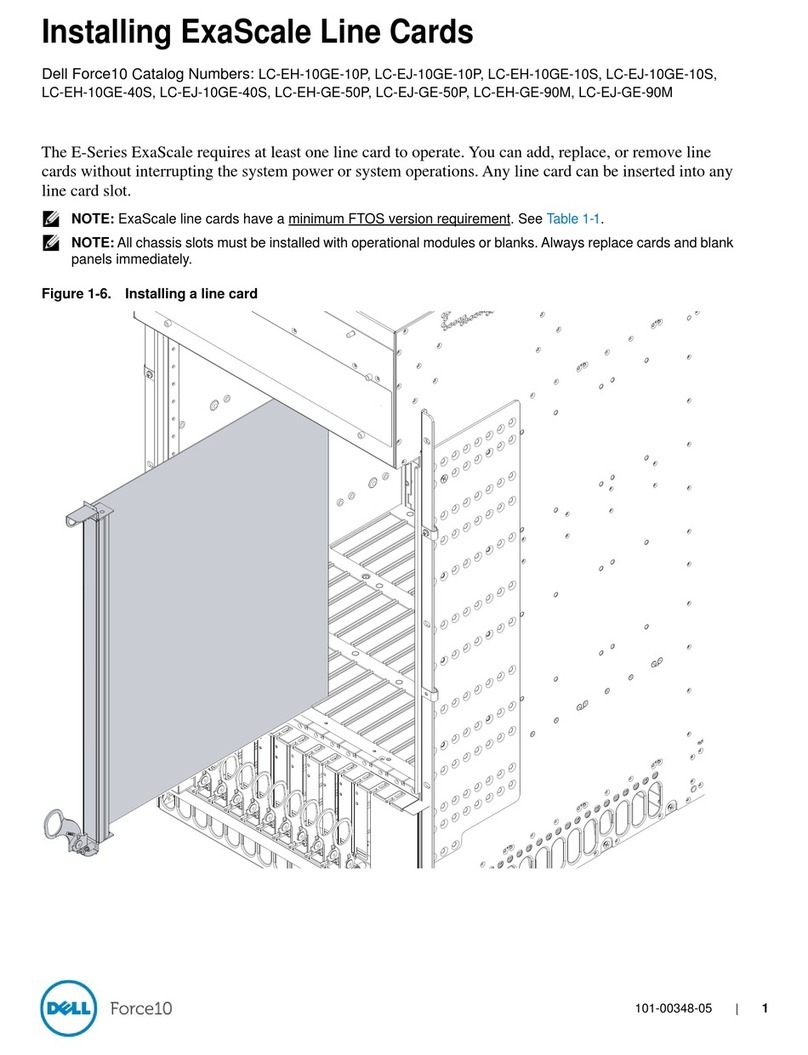

Dell

Dell LC-EJ-10GE-10P installation guide