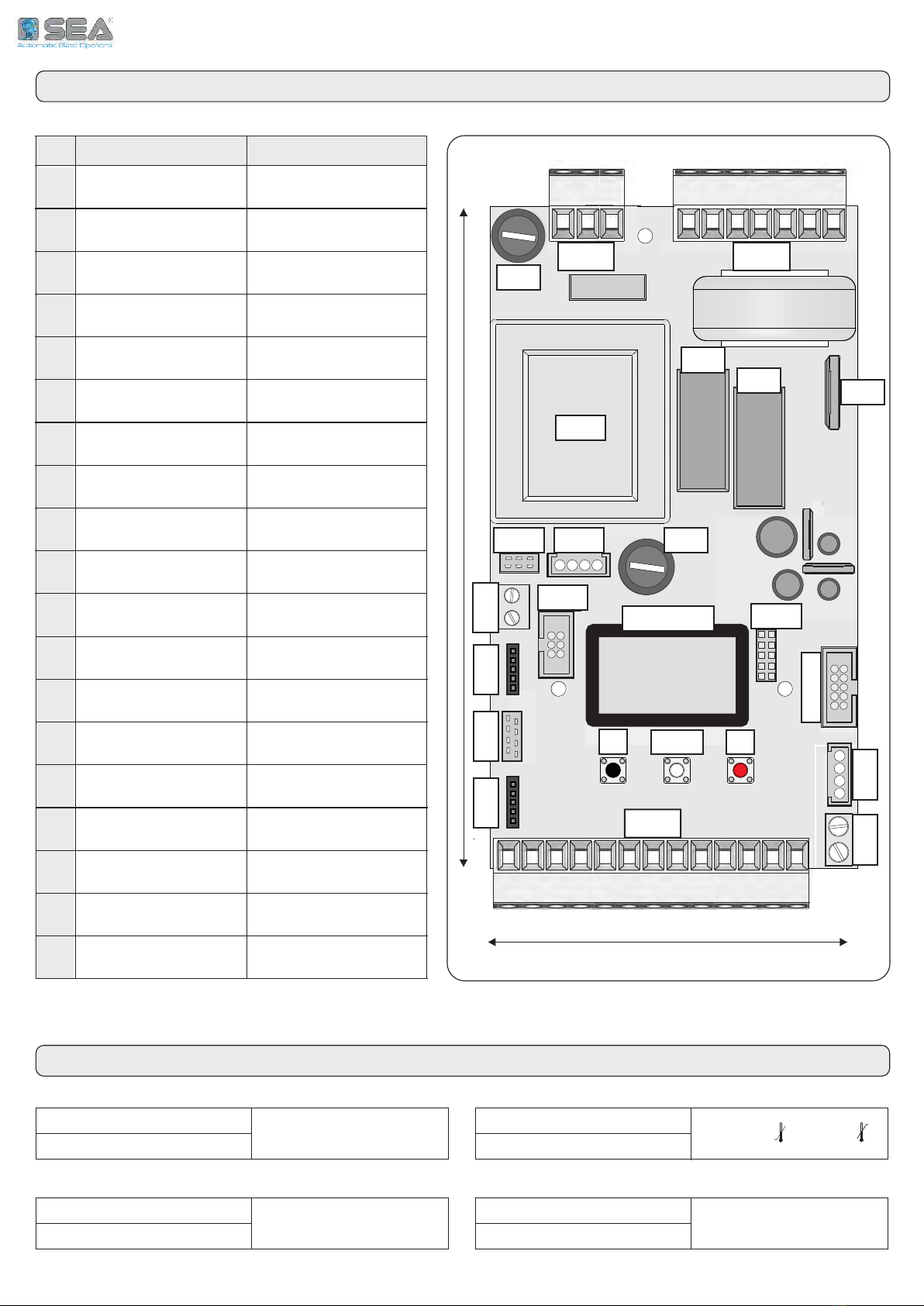

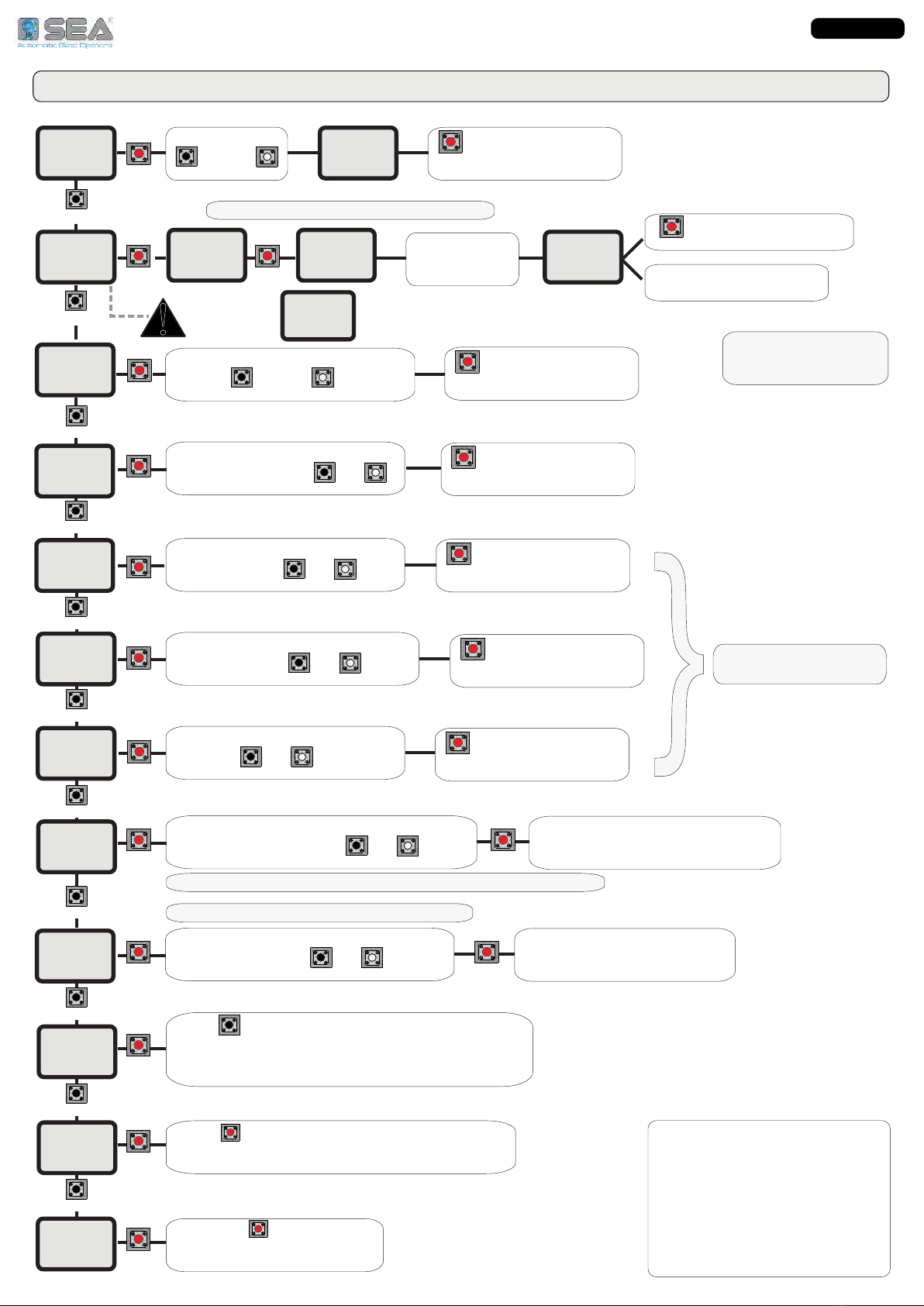

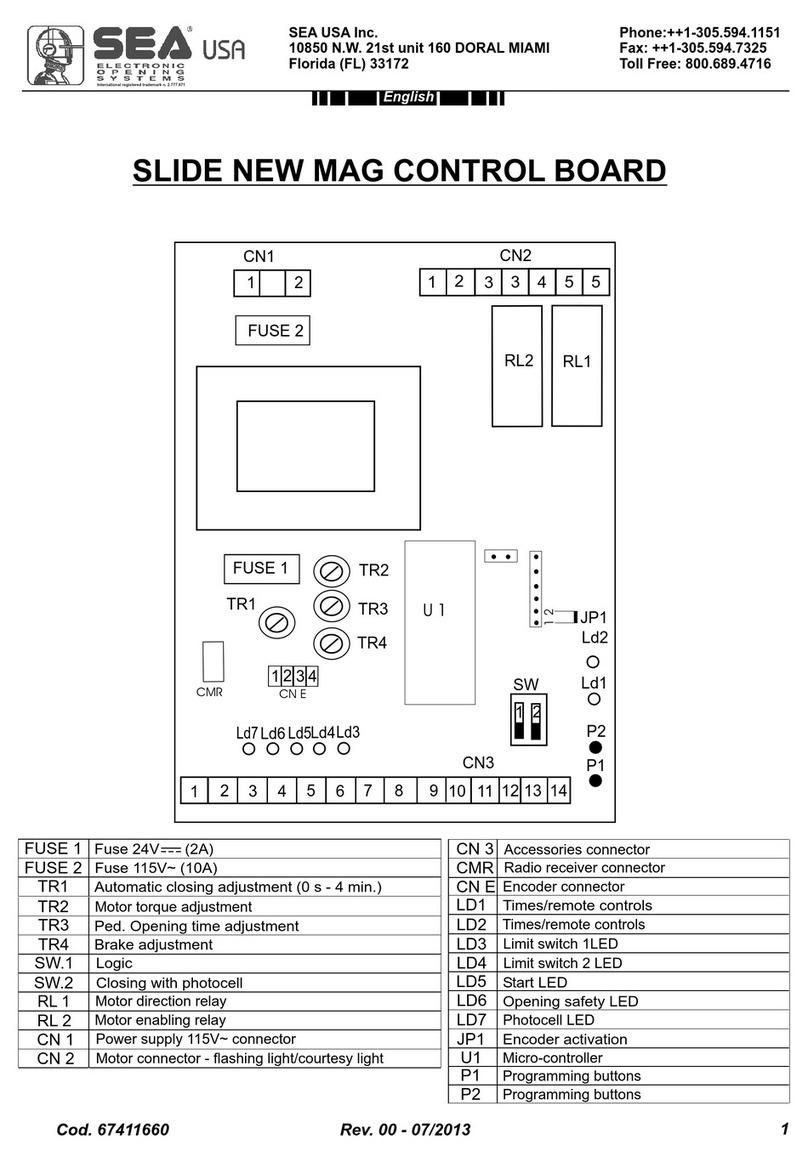

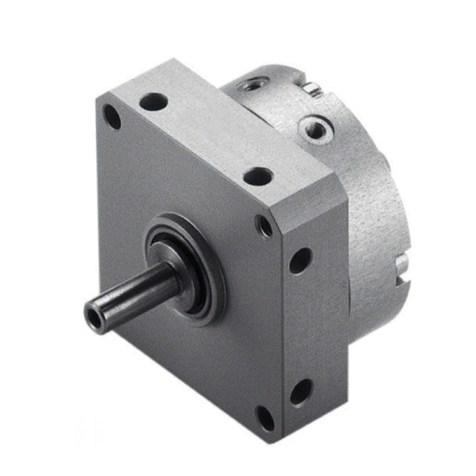

3 - CONNECTIONS ON CN1

Common

Common

Photocell 1

Common

Photocell 2

Partial Opening START

taliano

EGS

International registered trademark n. 804888

TX1

TX2

24V

1

1

12

11

1

1

2

1

Start

Stop

Antenna

RX1

RX2

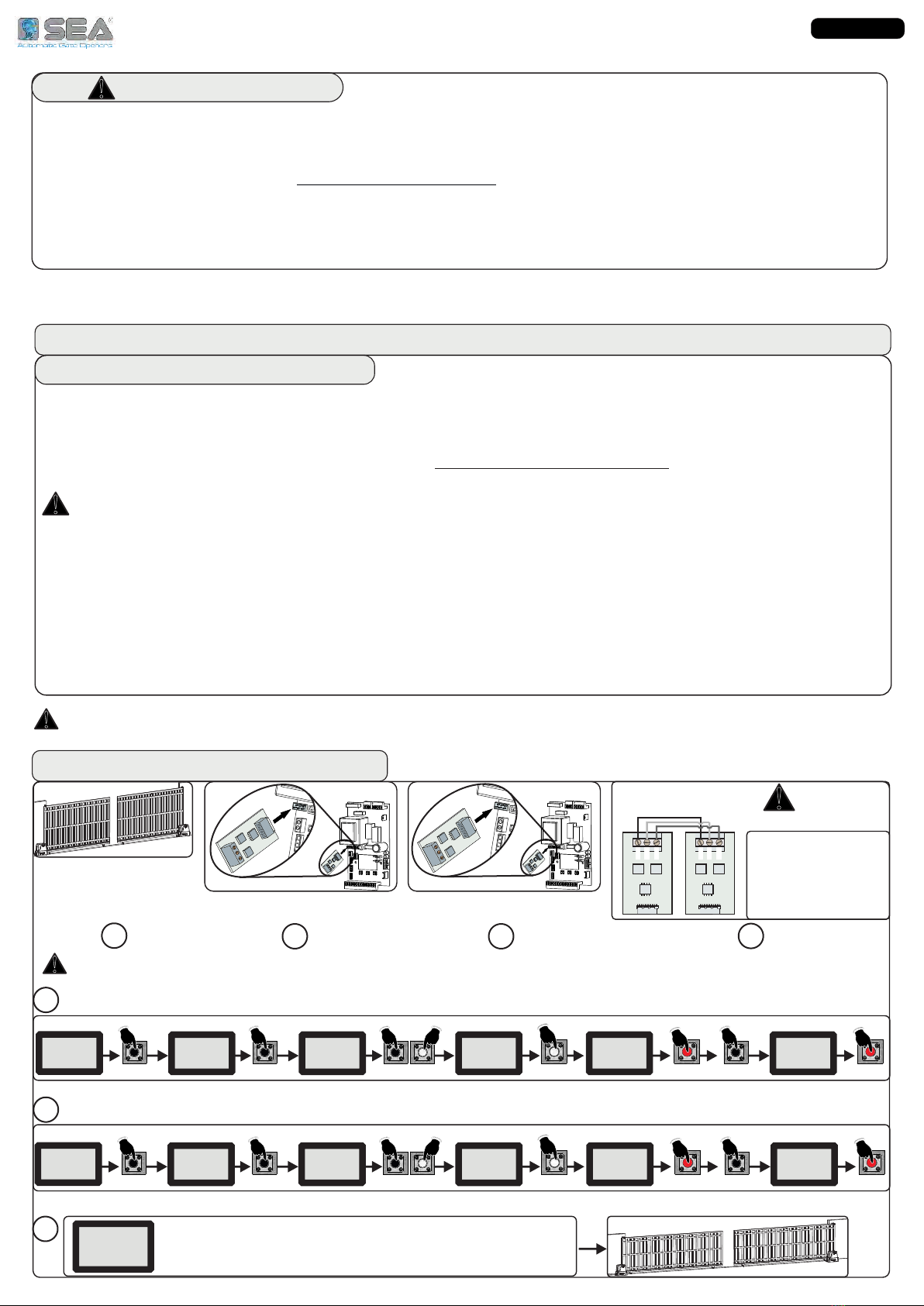

.1 START ..

n clamps 2 and

The automation can be opened or closed through an impulse

transmitted to this input (via e button, eboard, etc.). To

connect other Start devices (for ex. the magnetic loop) refer to

the respective instructions

ote 1 For details on the logics that can be associated to the

START button, see chapter 1 GS

ote 2 If this contact is engaged during the pause (eg. Timer),

the gate will not close until releasing

.2 ARTA EG START ..

n clamps 2 and

The input allows to obtain the partial opening. It is possible to

manage the opening space through the men or through

the OLLY 3. It is also possible to manage the partial opening

pause time through the men 1

ote 1 For details on the logics that can be associated to the

PARTIAL OPENIN START button, see chapter 1 GS

ote 2: If this contact is engaged during the pause (eg. Timer),

the gate will not close until releasing

. ST .. n clamps and

If this button is pressed the engine stops immediatel in whatever condition or position it is. A new Start

command will be required to restore the movement.

ote After the Stop command, the engine will always re-start in closing

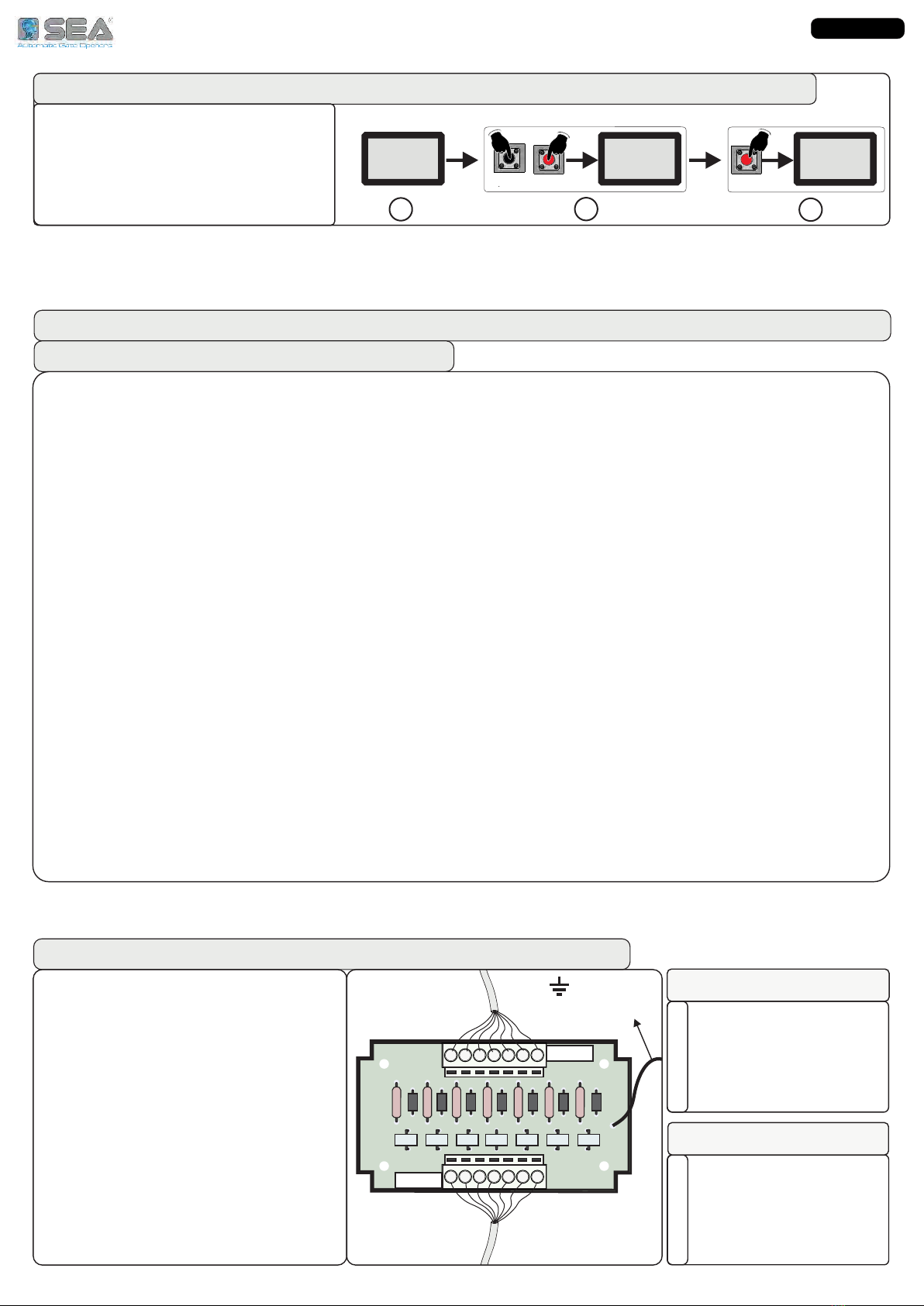

. TE 1 AD TE 2

ma m clamp CM clamps

otocell clamp otocell clamp

ote 1: To perform the self-test, connect the T positive to the clamp 10 (AU) and activate the Phototest

function on men From the TTEST menu it is possible to activate the self-test also on a

single photocell, choosing from the menu options.

ote 2: The default settings are: TE 1 closing TE 2 opening

for further functions and management, see menu-9 and menu-98

. A 2 TS ma mA

From men 2A or through the OLLY 3 it is possible to choose when to have voltage on the AU

output. It is advisable the use of an emerceng UPS. It is advisable to connect the unused accessories (eg.

Photocells) to the AU output and then configure the men 2A as CC D TTT so

it will be possible to save energ b lowering the power consumption in stand-b and increasing the sstem

autonom

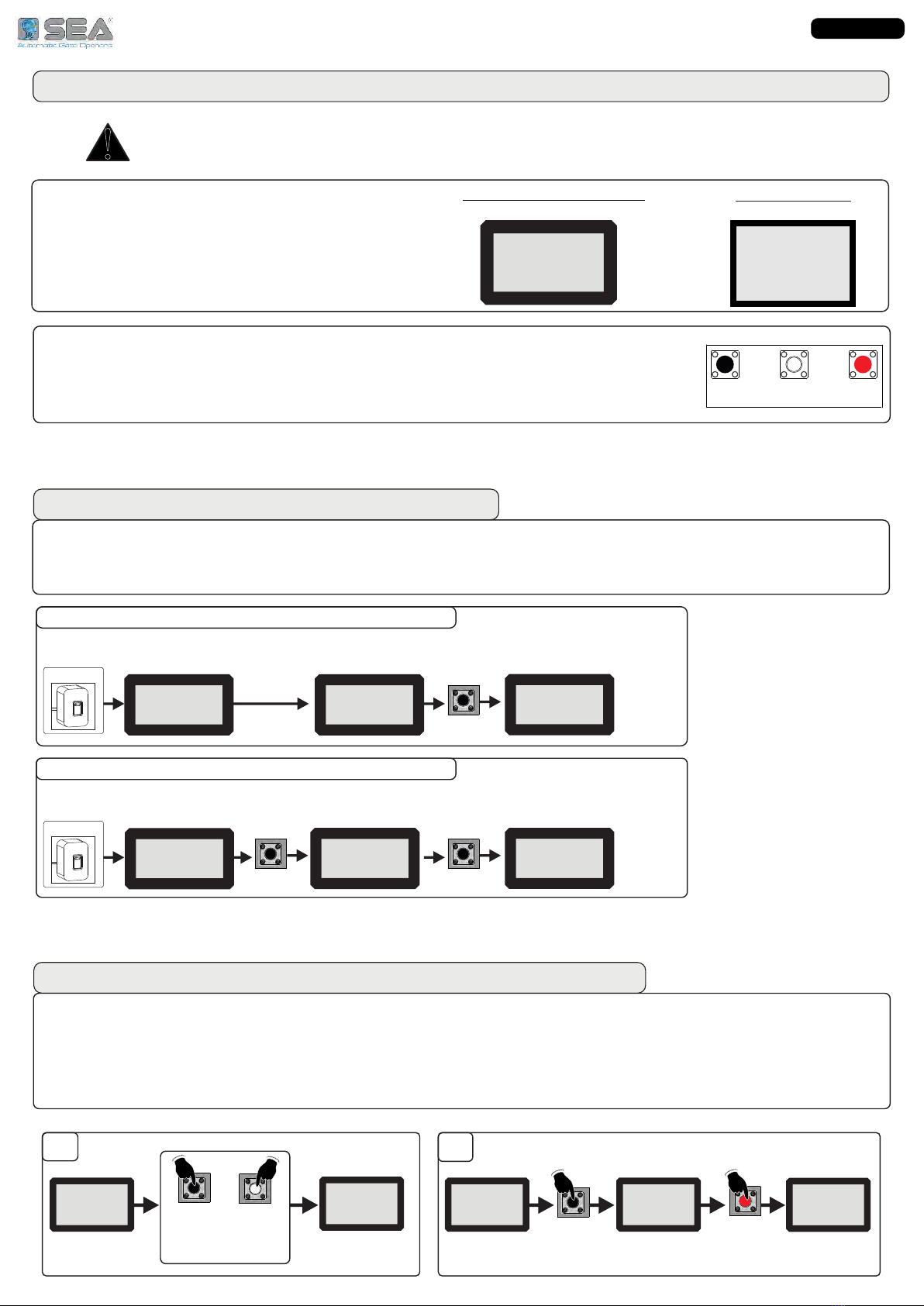

. TMER ..

n clamp artial penin Start or on clamp hotocell 2

It can be enabled through men2 or via OLLY 3. It opens and eeps the automation open until it

releases the contact. hen released, the operator will wait for the pause set then will close again

ote 1: If connected to the Partial Opening Start, this command will also be disabled on the remote control

ote 2: hen the timer is active, in the event of a safet intervention, a Start command will be required to

reset the movement

ote : In case of a power failure and with the gate open, if the TIMER is still active it will cause the gate

reclosing if no longer active, a new Start impulse will be required

MTT on menu TC T T it is

possible to activate the priority in opening or closing to be associated

to the START and the PARTIA OPENIN START buttons

only with SEM management unit)