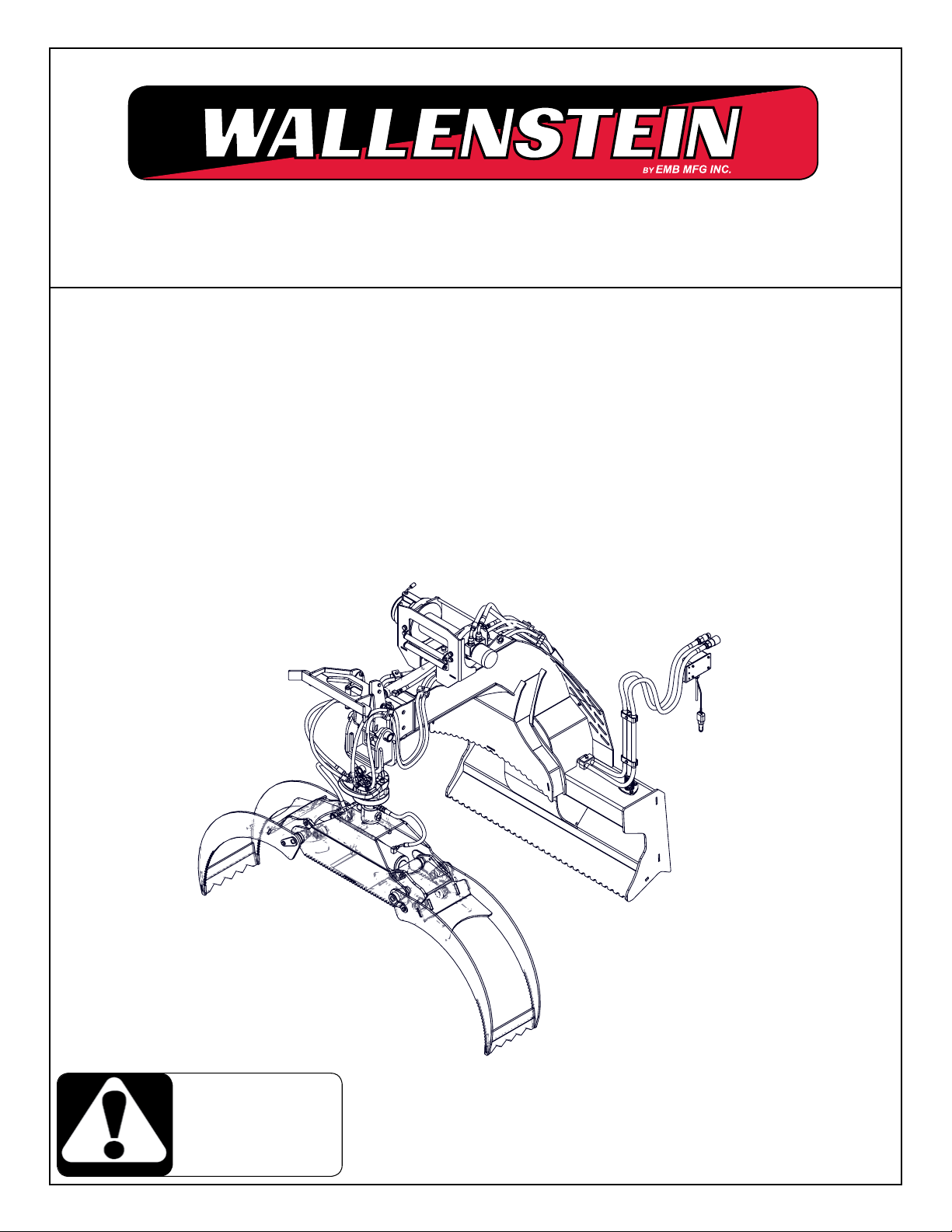

EMB WALLENSTEIN LXG430RP User manual

Table of contents

Other EMB Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Schulze

Schulze PRETREATMaker III instruction manual

Endress+Hauser

Endress+Hauser Flexdip CYH112 operating instructions

Festo

Festo ELGA-TB Instructions & Operating

Weidmüller

Weidmüller IE-TO-RJ45-FJ-A 8946930000 Mounting informations

MR

MR VACUTAP VV III 250 Y/D operating instructions

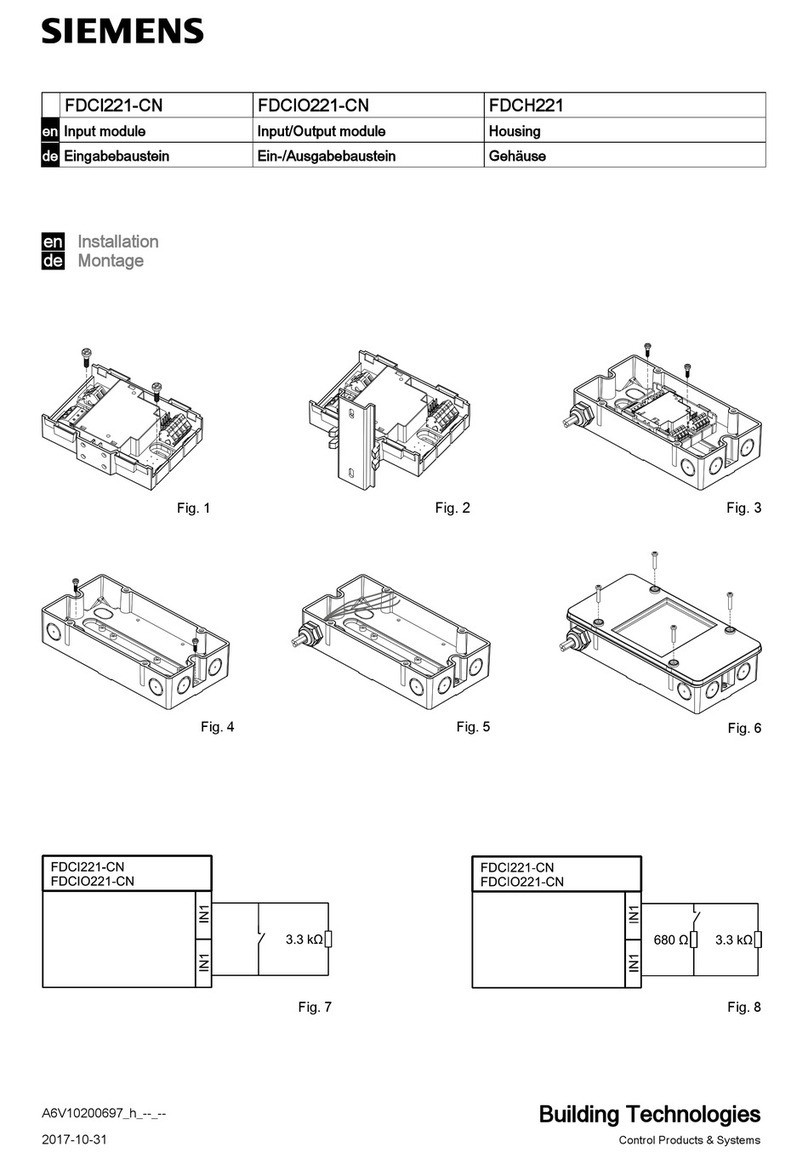

Siemens

Siemens FDCI221-CN Installation

TRAK

TRAK VMC7 Site preparation guide

CAT Pumps

CAT Pumps 7590 datasheet

Powermatic

Powermatic PF Series Operating instructions and parts manual

EDER Maschinenbau

EDER Maschinenbau Powerwinch 500 operating manual

Eastern Roadside Creations

Eastern Roadside Creations Phoenix Forge owner's manual

ABB

ABB HT566961 Operation manual

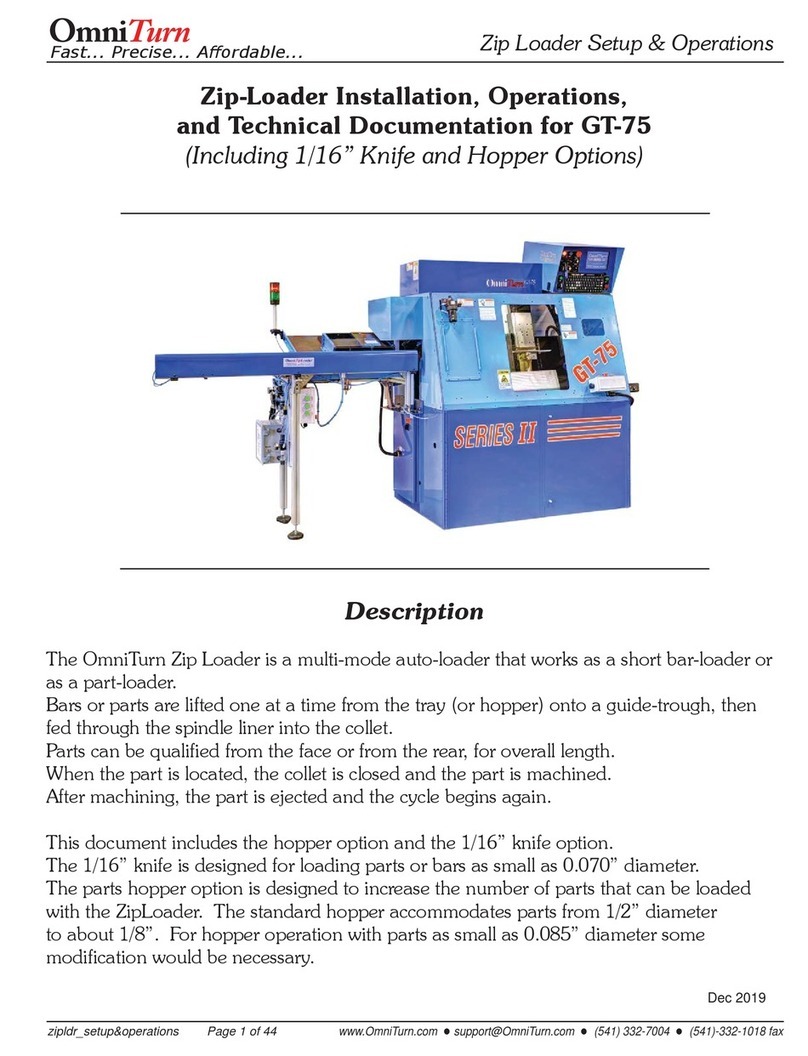

OmniTurn

OmniTurn GT-75 Installation, Operations, and Technical Documentation

Henkel

Henkel Loctite EQ CL36 LED Cure Chamber operating manual

Pulsar

Pulsar AWZ 710 quick start guide

Honeywell

Honeywell VR9105V installation instructions

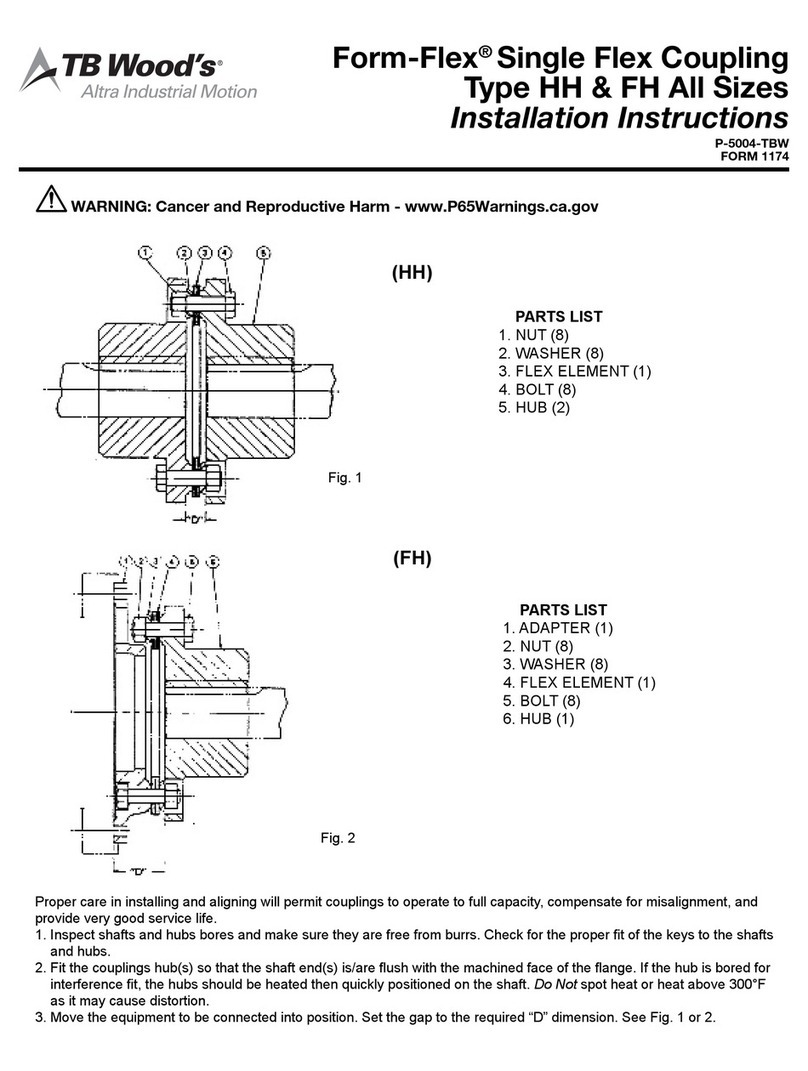

TB Wood's

TB Wood's Form-Flex HH Series installation instructions

ABB

ABB HT610868 Operation manual