zipldr_setup&operations

www.OmniTurn.com support@OmniTurn.com (541) 332-7004 (541)-332-1018 fax

Fast... Precise... Affordable...

Zip Loader Setup & Operations

OmniTurn

Page 2 of 44

Table of Contents

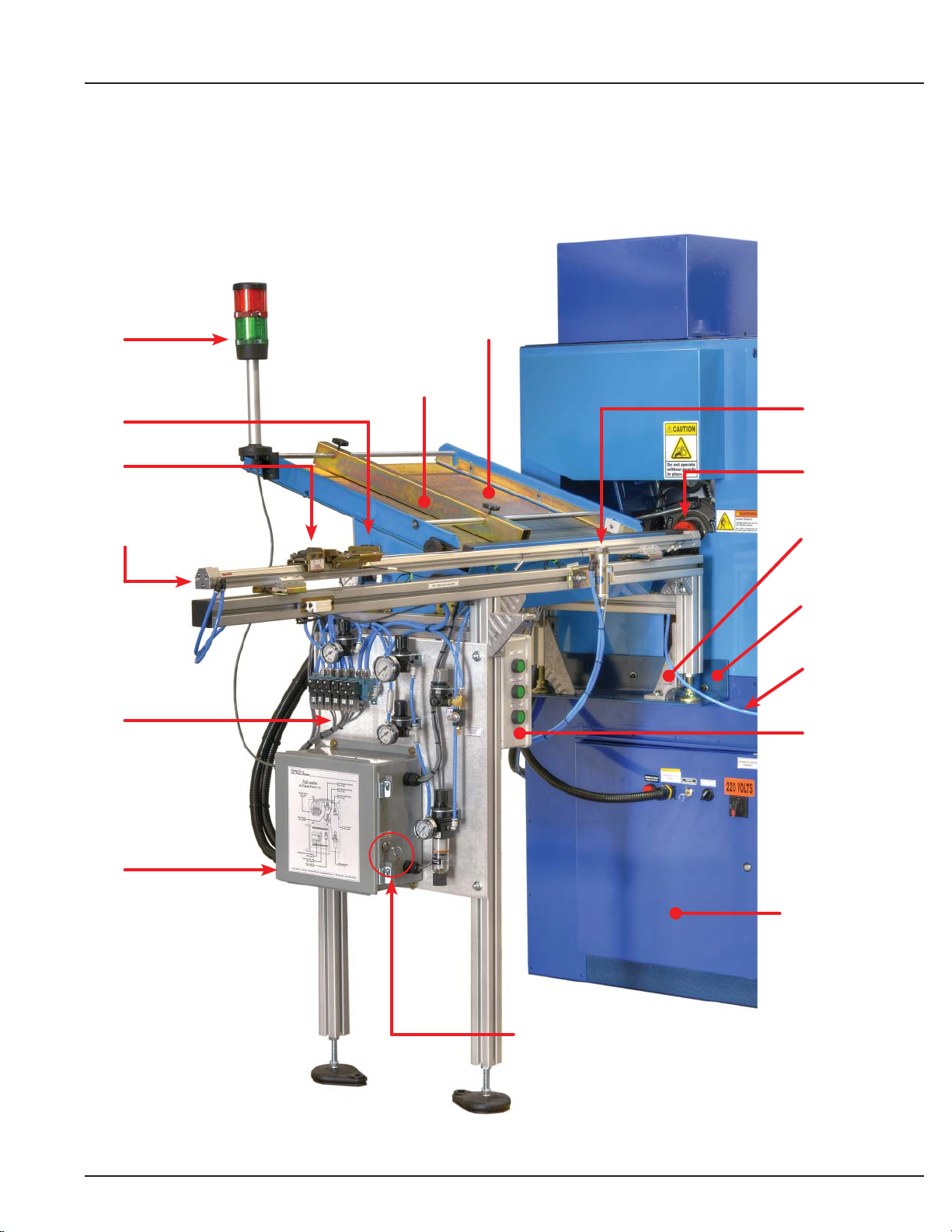

Section 1: Component Descriptions

Zip Loader w/Hopper: Major Components. . . . . . . . . . 3

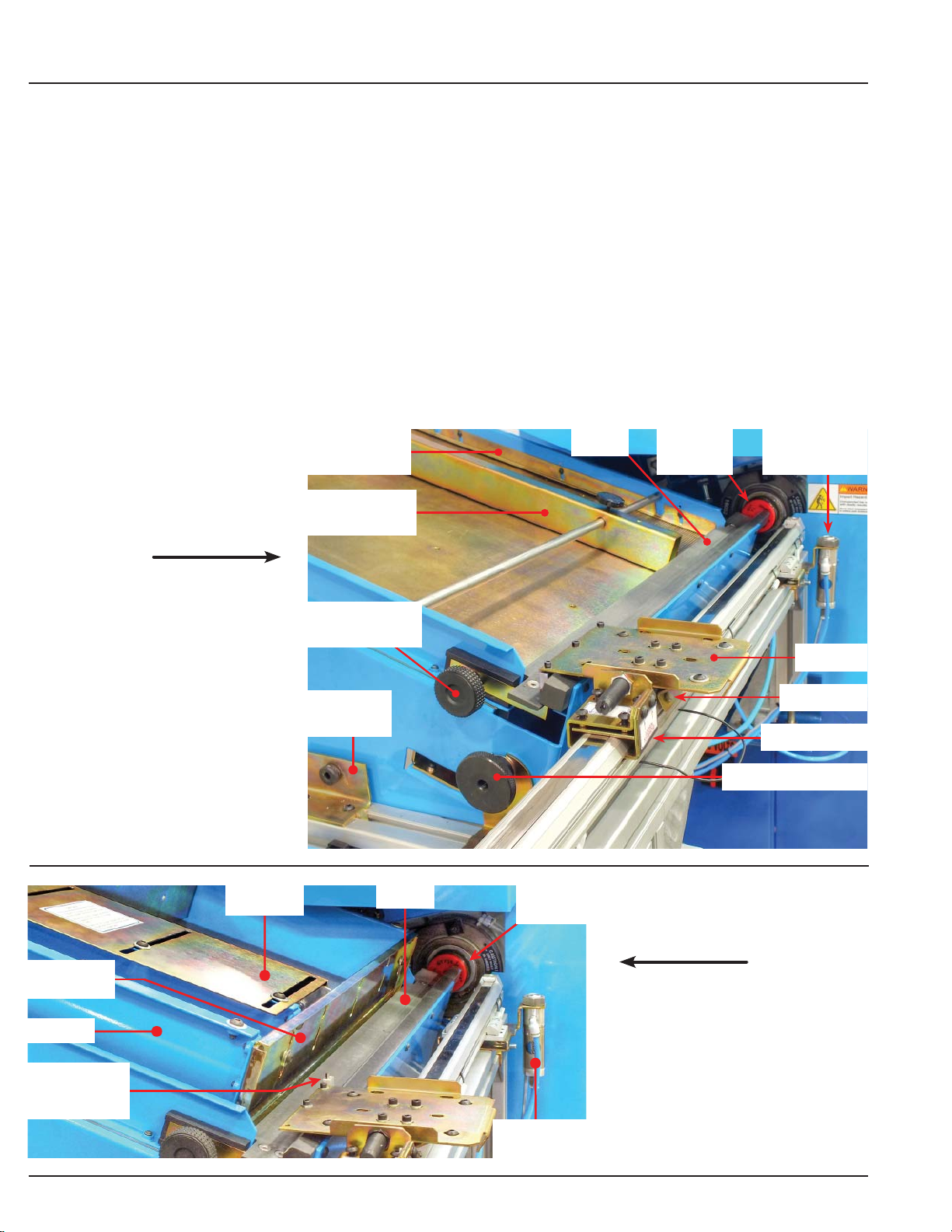

Component Parts, Overview . . . . . . . . . . . . . . . . . . . . 4

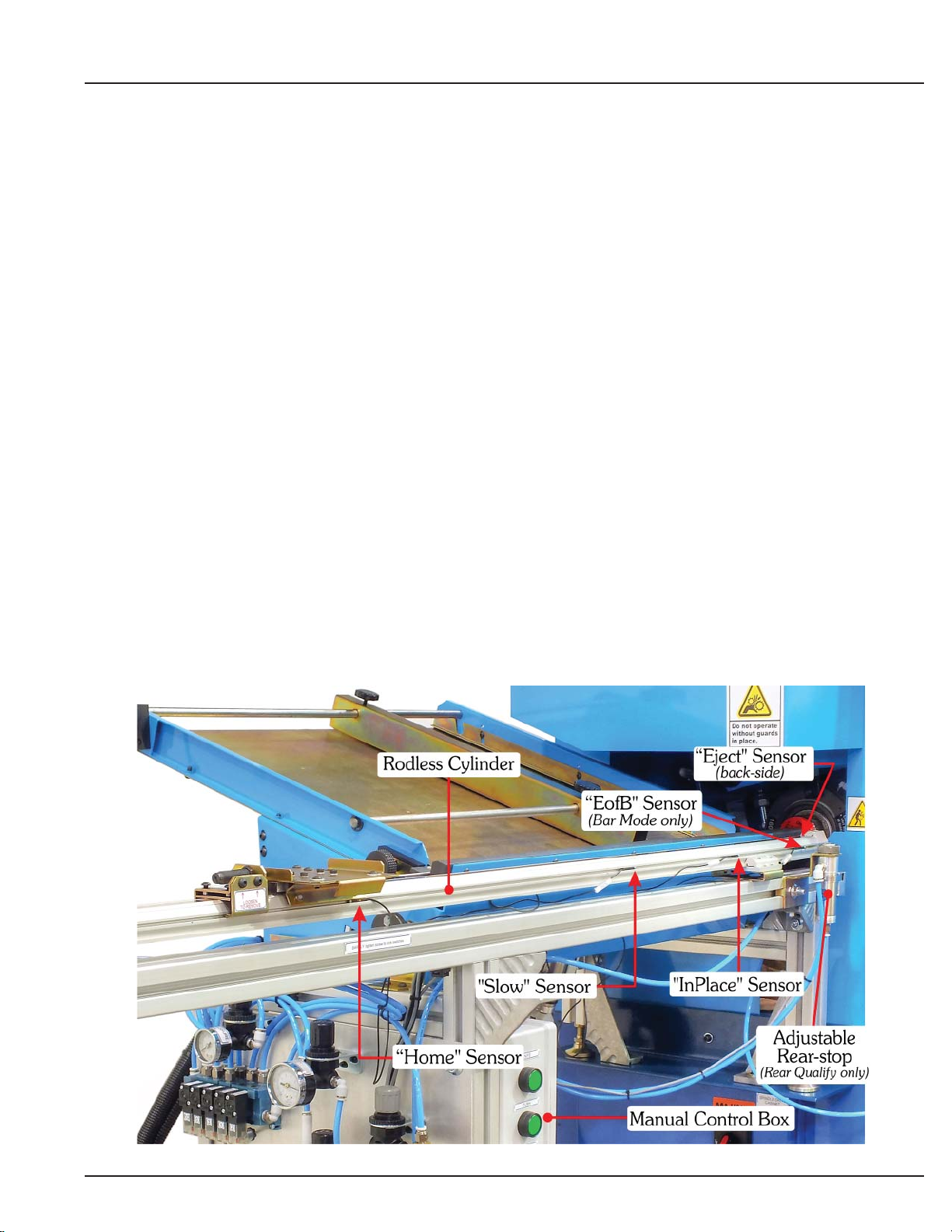

Component Parts, Sensors . . . . . . . . . . . . . . . . . . . . . 5

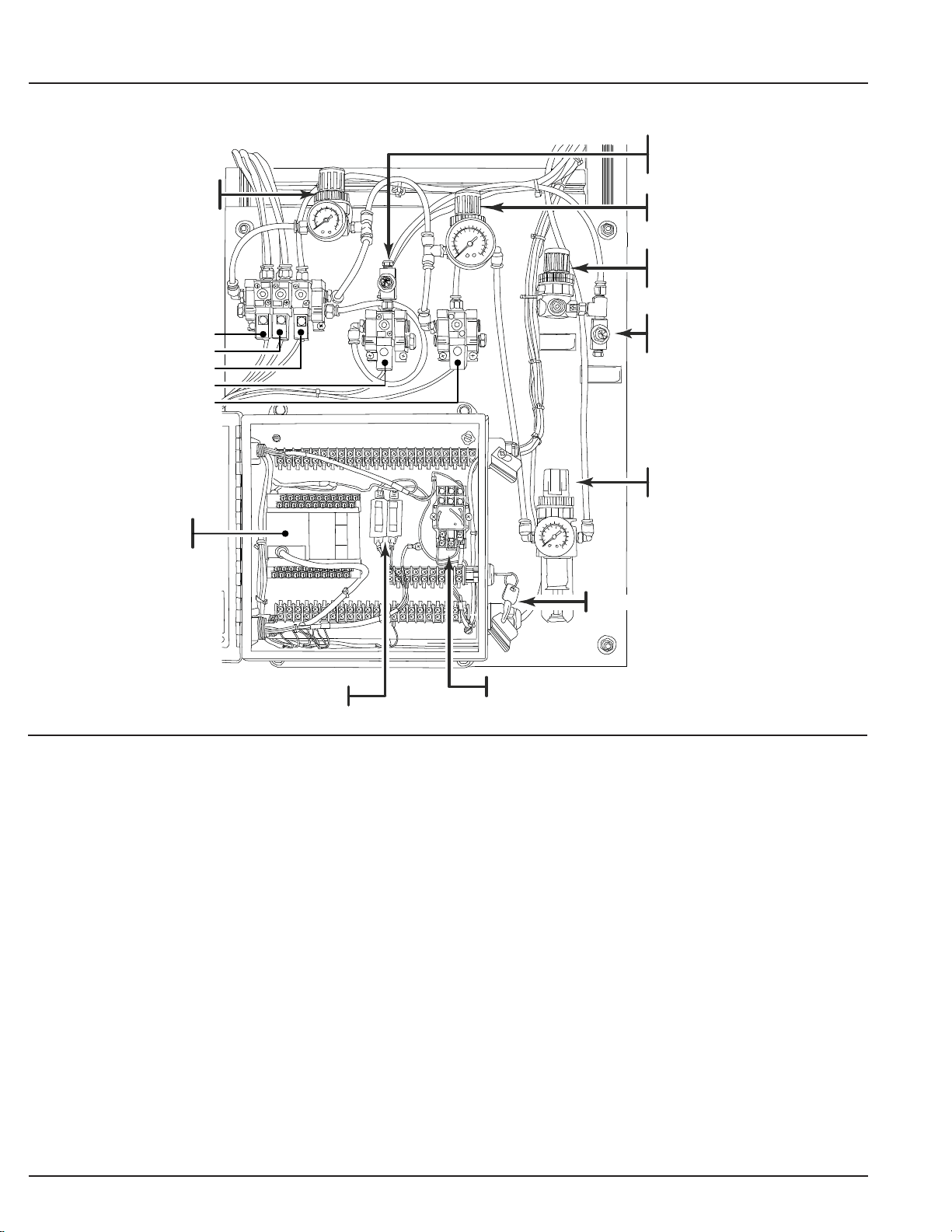

Component Parts, Air Panel . . . . . . . . . . . . . . . . . . . . 6

About Pressure & Speed. . . . . . . . . . . . . . . . . . . . . . . 6

Component Parts, Tray-guide Shoulders . . . . . . . . . . 7

Component Parts, Knife-down Jack-screws . . . . . . . . 7

Component Parts, Manual Control Box. . . . . . . . . . . . 7

Component Parts, Tray Pivot. . . . . . . . . . . . . . . . . . . . 8

Component Parts, Micrometer Adjustment . . . . . . . . . 8

Component Parts, Vee & Pushrod. . . . . . . . . . . . . . . . 9

Component Parts, Optional Hopper . . . . . . . . . . . . . . 9

Pusher and Push-rods. . . . . . . . . . . . . . . . . . . . . . . . . 10

Push-rods for small diameter parts . . . . . . . . . . . . . . . 10

Vee & 1/8” pushrod adjustment. . . . . . . . . . . . . . . . . . 11

1/8” Push-rod and Pushrod Adapter . . . . . . . . . . . . . . 11

Section 2: Setup and Alignment

Loader Setup and Alignment, Mechanical. . . . . . . . . . 12

Loader Setup and Alignment, Electrical. . . . . . . . . . . . 13

Loader Setup and Alignment, Air. . . . . . . . . . . . . . . . . 14

System Test, Manual. . . . . . . . . . . . . . . . . . . . . . . . . . 14

Loader Alignment and Changing Diameters . . . . . . . . 15

Aligning the Shuttle Plate Assembly . . . . . . . . . . . . . . 16

Aligning the loader for Small Diameter Parts. . . . . . . . 17

Section 3: Hopper

Hopper Operational Description . . . . . . . . . . . . . . . . . 18

Adjusting the Hopper. . . . . . . . . . . . . . . . . . . . . . . . . . 18

Hopper Adjustments, 1/8” and 1/16” in Knife. . . . . . . . 19

Section 4: Operation

Using the Loader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

All Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Bar Mode (M50). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Part Mode (M51) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Stop Mode (M52). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2Part Mode (M53) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

PLC Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

M-Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

M97 - Jump to Sub-routine, Conditional . . . . . . . . . . . 36

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Air Panel Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Shuttle Components Parts List . . . . . . . . . . . . . . . . . . 38

Section 5: Technical Documents . . . . . . . . . . . . . . . 39

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44