Emcore 5021D-IS User manual

System 5000

5021D-IS

Wideband Delay Line System

with Internal Spool

Installation Manual

Emcore Corporation

System 5000 series

Copyright © 2008 Emcore Corporation MAN-5021D-IS, Rev A

Page 2 of 11

Table of Contents

General................................................................................................................................................3

Interface....................................................................................................................................................4

Installation......................................................................................................................................5

Operation..........................................................................................................................................5

Delay System...................................................................................................................................5

LED Indicator Tables & Diagram.......................................................................................6

Remote Monitoring.............................................................................................................6

Discrete...............................................................................................................................................6

Specifications...............................................................................................................................7

Ordering Information.....................................................................................................8

Optics Handling & Safety.................................................................................9

Warranty.....................................................................................................................................10

EMCORECorporation offers a broad portfolio of compound semiconductor-based

components and systems for the broadband, fiber optic, satellite communication, defense and solar

power markets. EMCORE has two primary operating segments: Fiber Optics and Photovoltaics.

The company’s integrated solutions philosophy embodies state-of-the-art technology, material

science expertise, and a shared vision of our customer’s goals and objectives to be leaders in fiber

optics and photovoltaics.

EMCORE’s solutions include: optical components and subsystems for fiber-to-the-premise, cable

television, high speed data and telecommunication networks; defense photonics products for

commercial and military applications including lasers, modulators, spectrometers, sensors, fiber

gyro components and diagnostic instruments; solar cells, solar panels, and fiber optic ground station

links for global satellite communications.

2015 Chestnut Street Alhambra, California 91803, USA

(626) 293-3400 Fax: (626)293-3428 www.emcore.com

Deleted: 2

Deleted: 2

Deleted: 2

Deleted: 2

Deleted: 2

Deleted: 2

Deleted: 2

Deleted: 2

Deleted: 2

Deleted: 2

Deleted: 2

Deleted: 2

Deleted: 11

Deleted: 6

Emcore Corporation

System 5000 series

Copyright © 2008 Emcore Corporation MAN-5021D-IS, Rev A

Page 3 of 11

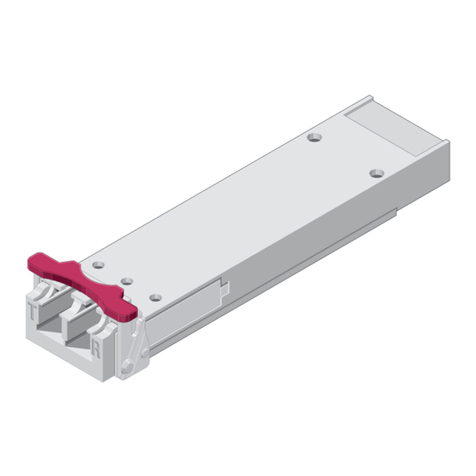

General

System 5000 Wideband Microwave Transceiver fiber optic intra-facility links are a high-

performance, cost-effective alternative to coaxial cable. They provide much longer transmission

distances than copper cables, which simplify network design, ease installation and even enhance

immunity from EMI, RFI and lightning. These transmitters and receivers take the best RF design

features of Emcore’s extensive families of products and combine them into a compact package

compatible with the 10901G Power Supply.

The System 5000 Wideband Microwave Transceiver family’s wide range of RF with a single

chassis. The final result is a system that can be factory or user custom configured to meet a wide

range of fiber transport applications.

• Stand alone system ideal for multi

platform enclosures.

• Fully integrated laser and photodiode

• Internal delay spool

(250 nanosecond

max)

• Bandwidth from 50 MHz to 18 GHz

• 50 Ohm

• Fixed RF gain

• Multiple monitoring options provide

for panel LED & discrete signal

ii

Deleted: 11

Deleted: 6

Emcore Corporation

System 5000 series

Copyright © 2008 Emcore Corporation MAN-5021D-IS, Rev A

Page 4 of 11

Interface

Figure 01

1. Power This LED illuminated indicates when DC power is present and off when there is no DC

power.

2. Laser Power The LED illuminated indicates the laser is operating 10% above its set-point.

3. Laser Temp This LED illuminated indicates the laser is operating within 2% of its set-point.

4. Photodiode Optical Power The LED illuminated indicates the photodiode is receiving optical

power greater the –12 dBm.

5. RF Input

6. RF output

7. DC Power

8. Mounting

1 2 3 4

6 8

7 5

Deleted: 11

Deleted: 6

Emcore Corporation

System 5000 series

Copyright © 2008 Emcore Corporation MAN-5021D-IS, Rev A

Page 5 of 11

Installation

Module Installation

Apply DC power

Verify that the Power On, Laser Power, Laser Temp and Optical Power LEDs are

illuminated.

Connect RF input and output signal cables.

DC Interface (Table 01)

Operation

Delay System

Every step has been taken to ensure simple hands free operation. This will provide the lowest

possible distortion.

After ensuring that the 5021 equipment is securely mounted, ensure that the LED’s listed below are

illuminated.

Power - Green: DC power is applied to the transmitter.

Laser Power - Green: Laser Power is operating 10% above set point.

Laser Temp - Green: Laser Temperature is operating 2% from set point.

Optical Power - Green: Optical power greater than –12 dBm is received.

Verify that the delay line has the specified delay and insertion loss, refer to the supplied test data

sheet.

J1 Pin Function

1 +15 VDC

2 +5 VDC

3 Future

4 Ground

5 Ground

6 Laser Current

7 Alarm Common

8 Photodiode Current

9 Alarm

Deleted: 11

Deleted: 6

Emcore Corporation

System 5000 series

Copyright © 2008 Emcore Corporation MAN-5021D-IS, Rev A

Page 6 of 11

LED Indicator Tables & Diagram

TX Status LED (Table 02)

LED,

Alarm LED,

Good

LED Notes,

Good State

Off Green Power DC Power, present

Off Green Laser Power Laser Power, 10%

above set point

Off Green Laser Temp

Laser Temp, 2%

above set point

Off Green Optical Power Optical power > -12

dBm

System 5000 Wideband Fiberoptic Delay Line

5021 Delay Line

Remote Monitoring

Discrete

The System 5000 System is designed to provide remote status. Use of this feature requires the use

of a network management system that can accept discrete inputs.

5021 – Delay Line

Monitored Values

Laser Current

Photodiode Current

Summary Alarm

1V/100mA

1V/1mA

Dry Contact – Sums the Laser Temp, Laser

Power and Photodiode Low Optical Power

alarms

Sout

Sp

Pr Photo

-diode

Lopt

Laser PL

Sin

Txcvr

SL

250 nano-Sec (51.12m)

Deleted: 11

Deleted: 6

Emcore Corporation

System 5000 series

Copyright © 2008 Emcore Corporation MAN-5021D-IS, Rev A

Page 7 of 11

Specifications

5021

RF Frequency 50 MHz – 18 GHz

RF Flatness 7 dB max (pp)

RF Return loss >-4 dB

Carrier/Noise ratio 115 dB/Hz(*)

Carrier/Intermod Ratio >55 dB(*)

Spur Free Dyn Range* 98 dBHz 2/3

* (Two tones peaked)

Photodiode Current 10 mA max

RF Flatness 5 dB max (pp)

RF Return loss >-4 dB

Fiber Delay 250 nano-sec max

Transmit Gain (TG) -24 dB

Receive Gain (RG) -11 dB

System Gain (SG) TG + RG +2*Optical Loss

3rd order intercept, >20 dBm

System 5000 General

Certifications CE,CSA,FCC,

Operating Temperature -40 to 60C

Storage Temperature -40 to 85C

Humidity, non-condensing 5 to 95%

Dimensions (HxWxD) 1.00” x 5.00” x 5.00”

Weight,Typical 1.5 lbs

Emcore Corporation

System 5000 series

Copyright © 2008 Emcore Corporation MAN-5021D-IS, Rev A

Page 8 of 11

Ordering Information

Model Number

Each Emcore product is assigned a unique model number and serial number, which

appears on the label of the unit. Model numbers for this series have the form 5021D-X11-

ZZZZZZ here; X’ is a one letter designation for the appropriate frequency of the unit, YY’ is a

two letter designation the unit overall height and max delay option 11 – 1 inch, 250

nanosecond max Delay Line and “ZZZZZZ” is a six letter designation specifying the Delay

time in microseconds, X (hundreds) X (tens) X (ones) X (tenths) X (hundredths) X

(thousandths). For the 5021D-(X)11 family only the X (tenths) X (hundredths) X

(thousandths) places are used the X (hundreds) X (tens) X (ones) are always zero .

Model Number Description

Delay Line System

5021D-A11-XXXXXX Delay, 3 GHz, 50 Ohm SMA, 1310nm, Delay Time to 250 nano-sec max

5021D-B11-XXXXXX Delay, 7 GHz, 50 Ohm SMA, 1310nm, Delay Time to 250 nano-sec max

5021D-C11-XXXXXX Delay, 12 GHz, 50 Ohm SMA, 1310nm, Delay Time to 250 nano-sec max

5021D-D11-XXXXXX Delay, 18 GHz, 50 Ohm SMA, 1310nm, Delay Time to 250 nano-sec max

Power Supplies

10901G-NA Power Supply for 10990A North America AC cord

10901G-UK Power Supply for 10990A United Kingdom AC cord

10901G-EU Power Supply for 10990A European AC cord

8218-003 DC power cable for use with the 10901G Power Supply

8218-002 DC power cable for use with the Laboratory Power Supply

Emcore Corporation

System 5000 series

Copyright © 2008 Emcore Corporation MAN-5021D-IS, Rev A

Page 9 of 11

Optics Handling & Safety

Working with fiber optic cables and interfaces require a clean dust free environment. The optical power is

confined in the optical core only a few microns in diameter. Small particles of dust can block the proper

transfer of light through the connectors. It is therefore important to keep connectors as clean as possible,

and when in doubt of the cleanliness of a connector, clean it prior to inserting into a transmitter or receiver

receptacle.

A number of events can damage fiber optic connectors. Unprotected connector ends can experience

damage by impact, airborne dust particles, or excess humidity or moisture. Never touch the fiber end face of

the connector.

When cleaning fiber optic connectors use only Industrial grade 99% pure isopropyl alcohol, lens-grade, lint-

free tissue, and optionally canned dry air. Alternatively, there are a number of simple, effective products that

are specifically designed for cleaning fiber optic connectors.

Never look onto an illuminated fiber end.

Disclaimer

Every attempt has been made to make this material complete, accurate and up-to-date. Users are cautioned

that EMCORE reserves the right to make changes without notice and shall not be held responsible for any

damages, including consequential, caused by reliance on the material presented, including, but not limited

to, typographical, arithmetical, or listing errors.

WARNINGS, CAUTIONS, LIABILITY, WARRANTY AND GENERAL NOTES

Safety Considerations

When installing or using this product, observe all safety precautions during handling and operation. Failure

to comply with the following general safety precautions and with specific precautions described elsewhere

in this manual violates the safety standards of the design, manufacture, and intended use of this product.

Emcore assumes no liability for the customer's failure to comply with these precautions.

The fiberoptic laser transmitter used in Emcore’s System 5000 link contains a class IIIb laser product as

defined by the U.S. Department of Health and Human Services, Public Health Service, Food and Drug

Administration. This laser product complies with 21 CFR, Chapter I, Subchapter J of the DHEW standards

under the Radiation Control for Health and Safety Act of 1968.

The laser operates at nominally 1310 nm with less than 30 mW optical output. The typical optical output for

this product is less than 10 mW. The protective laser plug-in module housing prevents a user from being

exposed to hazardous optical output levels. Since there is no human access to the laser output during

system operation, no special operator precautions are necessary when fiber is connected to the transmitter

and receiver. During installation, service, or maintenance, the service technician is warned to not look

directly into the end of the fiber connector or the fiber. The light emitted from the fiberoptic connector or any

fiber connected to the transmitter is invisible and may be harmful to the human eye. Use either an infared

fluorescent screen or an optical power meter for optical output verification. All handling precautions as

outlined by Federal agencies or other authorities of class IIIb lasers must be observed.

Do not attempt to modify or to service the laser diode module. Return it to Emcore for service and repair.

Contact the Emcore Customer Service Department for a return authorization and further instructions.

Emcore Corporation

System 5000 series

Copyright © 2008 Emcore Corporation MAN-5021D-IS, Rev A

Page 10 of 11

Electrostatic Sensitivity

Observe electrostatic precautionary procedures. Semiconductor laser transmitters and receivers provide

highly reliable performance when operated in conformity with their intended design. However, a

semiconductor laser may be damaged by an electrostatic charge inadvertently imposed by careless

handling.

Static electricity can be conducted to the laser chip from the center pin of the RF input connector, and

through the DC connector pins. When unpacking and otherwise handling the transmitter, follow ESD

precautionary procedures including use of grounded wrist straps, grounded workbench surfaces, and

grounded floor mats.

Exposure to electrostatic charge is greatly reduced after the transmitter or receiver has been installed in an

operational circuit.

Service

Do not attempt to modify or service any part of the system other than in accordance with procedures

outlined in this Operation Manual. If the system does not meet its warranted specifications, or if a problem

is encountered that requires service, return the apparently faulty plug-in or assembly to Emcore for

evaluation in accordance with Emcore's warranty policy.

When returning a plug-in or assembly for service, include the following information: Owner, Model Number,

Serial Number, Return Authorization Number (obtained in advance from Emcore's Customer Service

Dept.), service required and/or description of the problem encountered.

Warranty

Emcore warrants to the original purchaser all standard products sold by Emcore to be free of defects in

material and workmanship for one (1) year from date of shipment from Emcore. During the warranty

period, Emcore's obligation, at our option, is limited to repair or replacement of any product that Emcore

proves to be defective. This warranty does not apply to any product that has been subject to alteration,

abuse, improper installation or application, accident, electrical or environmental over-stress, negligence in

use, storage, transportation, or handling.

This warranty is the only warranty made by Emcore and is in lieu of all other warranties, expressed or

implied, except as to title, and can be amended only by a written instrument signed by an officer of Emcore.

Emcore sales agents or representatives are not authorized to make commitments on warranty returns.

Limitations of Liabilities

Emcore's liability on any claim of any kind, including negligence, for any loss or damage arising from,

connected with, or resulting from the purchase order, contract, or quotation, or from the performance or

breach thereof, or from the design, manufacture, sale, delivery, installation, inspection, operation or use of

any equipment covered by or furnished under this contract, shall in no case exceed the purchase price of

the device which gives rise to the claim.

EXCEPT AS EXPRESSLY PROVIDED HEREIN, EMCORE MAKES NO WARRANTY OF ANY KIND,

EXPRESSED OR IMPLIED, WITH RESPECT TO ANY GOODS, PARTS AND SERVICES PROVIDED IN

CONNECTION WITH THIS AGREEMENT INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. EMCORE

SHALL NOT BE LIABLE FOR ANY OTHER DAMAGE INCLUDING, BUT NOT LIMITED TO, INDIRECT,

SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH

Emcore Corporation

System 5000 series

Copyright © 2008 Emcore Corporation MAN-5021D-IS, Rev A

Page 11 of 11

FURNISHING OF GOODS, PARTS AND SERVICE HEREUNDER, OR THE PERFORMANCE, USE OF,

OR INABILITY TO USE THE GOODS, PARTS AND SERVICE.

Emcore will not be responsible for loss of output or reduced output of opto-electronic devices if the

customer performs chip mounting, ribbon bonding, wire bonding, fiber coupling, fiber connectorization, or

similar operations. These processes are critical and may damage the device or may affect the device's

output or the fiber output.

Emcore test reports or data indicating mean-time-to-failure, mean-time-between-failure, or other reliability

data are design guides and are not intended to imply that individual products or samples of products will

achieve the same results. These numbers are to be used as management and engineering tools, and are

not necessarily indicative of expected field operation. These numbers assume a mature design, good

parts, and no degradation of reliability due to manufacturing procedures and processes.

Emcore is not liable for normal laser output degradation or fiber coupling efficiency degradation over the life

of the device.

Every attempt has been made to make this material as complete and accurate and up to date. Users are

cautioned that Emcore reserves the right to make changes without notice and shall not be held

responsible for any damages, including consequential, caused by reliance on the material presented,

including, but not limited to, typographical, arithmetical, or listing errors.

Copyright 2009 EMCORE Corporation

Table of contents

Other Emcore Transceiver manuals