Emcotec RC Electronic DPSI LCD User manual

DPSI LCD Operating Instructions Version 1.0

Page 2 of 32

Contents

1. Preface .............................................................................................3

2. Characteristics ................................................................................ 4

3. Display- and Control-Elements......................................................6

4. Dimensions......................................................................................7

5. Assembly ......................................................................................... 8

6. Push-Buttons and LED-Indicators................................................. 9

6.1. Functions of Buttons................................................................9

6.2. Functions of LEDs .................................................................10

7. Readouts of the LC-Display ......................................................... 13

7.1. Readout after Power-On........................................................14

7.2. Readout of Receiver Information...........................................15

7.3. Readout of Receiver Errors ...................................................18

7.4. Readout of the Current Supply ..............................................19

7.5. Readout of Current Supply Errors .........................................21

8. Resetting Stored Values...............................................................22

9. Programming / Setup.................................................................... 23

9.1. Programming Options............................................................24

9.2. Operating Mode.....................................................................25

9.3. Switching Positions Failsafe..................................................26

9.4. Switching Positions Master/Slave..........................................27

9.5. Units.......................................................................................28

9.6. Battery Type ..........................................................................28

9.7. Buzzer On/Off........................................................................29

9.8. Language...............................................................................29

9.9. Factory Settings.....................................................................30

9.10. Exit / Return.........................................................................30

10. Technical Data of DPSI LCD.......................................................30

11. Warranty.......................................................................................31

DPSI LCD Operating Instructions Version 1.0

Page 3 of 32

1. Preface

With the DPSI LCD you purchased a high grade, modern and secure

product. We appreciate your trust!

Long lasting experience for years in development and manufacturing of

electronically systems as well as the knowledge of the world’s best

model airplane pilots has influenced the development. All products are

developed by experienced engineers and manufactured at EMCOTEC

GmbH in Germany on our own production line. Extensive optically and

electronically end tests for every system, which leaves our house,

assure that you, our customer acquire an absolute reliable product,

which considerably increases the reliability of your valuable RC-Model.

Of course, the DPSI LCD (just like all products from EMCOTEC) not

only has been tested extensively in the laboratory, but also went

through intensive flight-testing. Like done in the automobile industry an

FMEA (Failure Mode and Effect Analysis) reduces the possibility of

damage and malfunction on operating errors to a minimum.

Hint:

We kindly ask you to read these operating instructions carefully and observe the

installation hints. Thus, errors can be avoided in advance.

We are all ears for your wishes and questions. Challenge us!

Bobingen, January 2008

The Staff of EMCOTEC GmbH

DPSI LCD Operating Instructions Version 1.0

Page 4 of 32

2. Characteristics

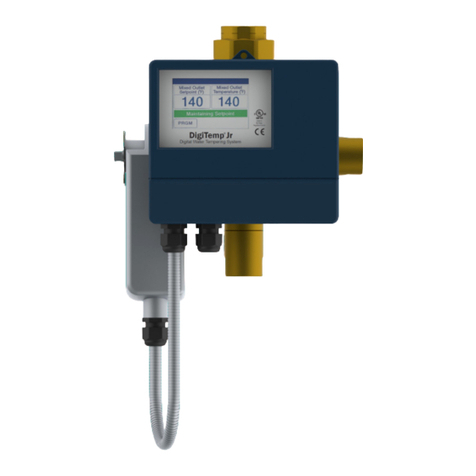

The DPSI LCD serves as an optional extension to DPSI products,

which can control a LC-Display:

•DPSI receiver switch (e.g. TWIN Mini stand alone)

•DPSI dual current supply (e.g. entire TWIN Mini)

•Additional future products

It displays (dependent on DPSI base system) important information in

plain text which is gathered during operation. These is information

about

•Signal quality of the receiver

•Supply voltage of receiver (batteries)

•Withdrawn capacities from batteries

•Current flow in receiver equipment

and much more.

Due to the integrated LEDs system states can be realized immediately

without first reading the text in the display. Critical situations are

indicated by quickly blinking LEDs. Root cause can than be read from

the display.

Three push buttons serve as display selectors or serve for setting up

options. It was never easier to display different data or set up diverse

options. The optimized handling concept was evaluated in practical

studies and is therefore nearly self explaining.

The DPSI LCD can also serve as On/Off switch for certain products of

the EMCOTEC DPSI program, thereby eliminating the need for the

regular switch actuator.

The DPSI LCD is mounted into the model just like a cockpit instrument.

In this way, a functional handling and display unit results, upgrading

the overall picture of the model by these small dimensions and a

shapely housing.

DPSI LCD Operating Instructions Version 1.0

Page 5 of 32

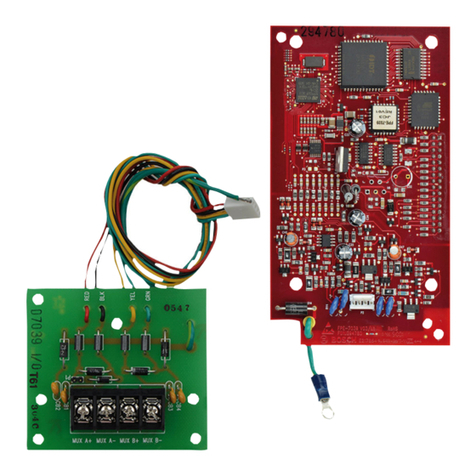

There is a 6-pin connector in the center of the back side of the DPSI

LCD for a connection cable. The connection cable (4-pin or 6-pin

depending on DPSI base system) is simply connected to the 6-pin

connector. Reverse polarity is impossible.

The other side of the cable is connected to the corresponding DPSI

system (e.g. DPSI TWIN Mini). Here, polarity must be observed. The

red wire is “positive” and must be “congruent” with the corresponding

markings (+) at the base system (see picture).

DPSI LCD Operating Instructions Version 1.0

Page 6 of 32

3. Display- and Control-Elements

DPSI LCD Operating Instructions Version 1.0

Page 7 of 32

4. Dimensions

DPSI LCD Operating Instructions Version 1.0

Page 8 of 32

5. Assembly

The DPSI LCD can be used as a cockpit instrument. Cut a squared

hole of 57mm edge length and 6mm inner radii into the cockpit (or

similar mounting plate). The DPSI LCD is then to be fed through the

hole from back to front (!) and secured using 4 regular M3 screws. The

screws are self cutting and find sufficient material in the plastic of the

mounting latches. Screw distance is 60mm.

Drilling template 1:1 scale:

DPSI LCD Operating Instructions Version 1.0

Page 9 of 32

6. Push-Buttons and LED-Indicators

6.1. Functions of Buttons

Depending on the used or connected DPSI system, the three push

buttons of the DPSI LCD can be used as On/Off switch (e.g. for the

DPSI TWIN Mini including adapted dual power supply).

Turning on is accomplished by pushing the “SET”-button. Turning off is

done by pushing the “DOWN” () and “UP” () buttons simultaneously

(!) for about 2 seconds.

When turned on, the buttons work for conforming entries (“SET”) or for

selections of information from the display “DOWN” () and “UP” ().

By pushing the “UP”- or “DOWN”-buttons multiple times, the menu

(one frame with text) advances.

There are some particular features in the layout of the buttons:

1.) If the “SET”-button is permanently pushed for about 5 seconds

during turning the power on, the system changes into programming

mode (setup). Here, several setups for the system can be

accomplished.

2.) If during operation first the “UP”-button () and additionally the

“SET”-button is pushed, memorized information can be deleted (reset

menu).

3.) If the “SET”-button is pushed during operation, all LEDs will be

turned off. After pushing this button again, the LEDs are turned back

on again. The ultra bright LEDs are very well recognizable even in

bright day light. If the ambient light is dim, the LEDs glare which cause

difficulties to read the display. Therefore, the LEDs can be turned off.

DPSI LCD Operating Instructions Version 1.0

Page 10 of 32

Function Buttons

Turning DPSI on * Push SET momentarily

Turning DPSI off * Push + for 2 seconds simultaneously

Turning LEDs off Push SET momentarily during operation

Turning LEDs on Push SET momentarily during operation

Start setup Push SET during power on for 5 sec.

Reset menu Push , then press SET simultaneously

* Not possible with all systems!

6.2. Functions of LEDs

After turning the DPSI LCD on, all eight LEDs are turned on

temporarily from left to right in order to test their functioning.

The LEDs have different meanings and therefore are assigned

distinctive groups. Depending on the connected system, the LEDs

have an assigned function or not. If e.g. there is no receiver switching

unit installed in the system, the corresponding LEDs (green and blue)

are not used. If no power supply is integrated into the system, the red

and yellow LEDs are not used.

Assignment of the LEDs (top view onto display)

Battery 1 Receiver 1 Battery 2 Receiver 2

Red Yellow Green Blue Red Yellow Green Blue

•The red and yellow LEDs are assigned to battery faults

•The green and blue LEDs are assigned to receiver (errors)

Red means: Error (Danger)

Yellow means: Warning

Green means: All ok

Blue means: Additional information (which receiver is active)

DPSI LCD Operating Instructions Version 1.0

Page 11 of 32

Indicating battery errors (DPSI battery switch)

Red LED

•Steadily lit if charging state of corresponding battery is low

for more than 10 minutes. There is low voltage (=>urgently

charge battery).

•Quick blinking, if the battery voltage drops below 5.0 volts.

Fast blinking therefore indicates e.g. loose contacts or a

totally emptied battery. The error indication is active until

power off.

Yellow LED

•Steadily lit if the battery is discharged down to about 60-70%

(no low voltage yet). The error indication is active until power

off.

Indicating receiver errors (DPSI receiver switch)

Green LED

•As long as the corresponding receiver provides a valid servo

signal to the failsafe input of the DPSI, the LED is steadily lit.

Green therefore stands for: receiver ok. If an erroneous or a

defined failsafe signal or no signal at all is recognized at the

failsafe input, the LED is turned off.

•If the receiving quality drops and the receiver shows several

malfunctions, the green LED flickers. The LED therefore is

an indicator for decreasing receiving quality (=> range test).

Blue LED

•The blue LED always indicates which receiver is active and

which receiver provides the connected servos connected to

the DPSI system control signals (left LED = RX1 active, right

LED = RX2 active).

DPSI LCD Operating Instructions Version 1.0

Page 12 of 32

•Quick blinking of both blue LEDs indicates failsafe issues of

both receivers simultaneously! This state is critical also,

because both receivers were malfunctioning during operation

at least for a short time!

Summary:

LED Status Indication

Red LED on Low voltage (battery almost discharged)

Red LED blinks Battery fault (malfunction) or voltage < 5.0 V

Yellow LED on Low battery capacity => charge battery

Yellow LED off Battery voltage ok

Green LED on Receiver signal ok

Green LED off No receiver signal, receiver defective or a

defined failsafe signal of the receiver

Blue LED on This receiver provides actually the signals for

servos connected to the DPSI

Blue LEDs blinks Both receivers malfunctioned during operation

simultaneously

Hint:

Fast blinking of a LED indicates a critical situation which can lead to a breakdown

of the total system!

Hint:

In order not to be dazzled by the LEDs when reading the LC-Display, the LEDs

can be turned off and back on by pushing the “SET“-button momentarily.

DPSI LCD Operating Instructions Version 1.0

Page 13 of 32

7. Readouts of the LC-Display

The LC-Display indicates all information in plain text using 3 lines, 12

characters each. The display varies, depending on which DPSI system

the DPSI LCD is connected to.

Display in respect to receivers (e.g. receiver switch):

- The currently active receiver

- How often the system switched receivers

- The receiving quality

- The servo position of the failsafe channel

- Indication of the operating mode (Failsafe or Master/Slave

=> Teacher/Student)

- Display of current receiver voltage

- Flight-time (operating time in minutes)

Display in respect to power supply (e.g. battery switch):

- Actual voltage battery 1 and battery 2

- Maximum voltage battery 1 and battery 2

- Minimum voltage battery 1 and battery 2

- Display of current receiver voltage

- Actual current battery 1 and battery 2

- Average current battery 1 and battery 2

- Maximum current battery 1 and battery 2

- Withdrawn capacity of battery 1 and battery 2

- Flight-time (operating time in minutes)

Withdrawn capacity (in milli-ampere-hours mAh) and operating time

can be reset on users demand (=> reset menu).

Hint:

The DPSI LCD displays two times: a total time (that is the time, the system stores

every 30 seconds and which can be reset by the user) and the time of the actual

turn on cycle (A) which is automatically set to zero at power off.

DPSI LCD Operating Instructions Version 1.0

Page 14 of 32

7.1. Readout after Power-On

When turning the DPSI LCD on (or

connecting it) the starting frame is displayed

for about 2 seconds. Here one can see

which DPSI system is supported (here:

DPSI TWIN Mini).

Now one can see how the system is

programmed (Failsafe or Master/Slave

mode). At the same time, the corresponding

switching values (= servo positions) are

displayed in ms or %.

For additional 4 seconds, the current servo

positions of both failsafe channels are

displayed (in ms or in %). This is for quick

control.

Optional Display:

In case the system is in Master/Slave mode

it will be optionally displayed. The numbers

indicate the threshold where switching

between Master (Teacher) and Slave

(Student) occurs.

Here too, the current servo positions of both

failsafe channels are displayed for

additional 4 seconds.

Hint:

Depending on the DPSI system the DPSI LCD is connected to, information

displayed varies after power on. Frames are only exemplarily described. Since

depicted information is self-explanatory, differences in other systems are not

further described.

DPSI LCD Operating Instructions Version 1.0

Page 15 of 32

7.2. Readout of Receiver Information

The system switches to regular display mode after displaying the start

information (first 3 frames). Different screen information can be

selected by the and buttons.

Receiver switch operating mode “Failsafe”

The main menu of the receiver switch shows information about the

connected receivers. The black arrow in the top most line indicates the

currently active receiver (here: “RX2”). The next lines means: “1x”

switched from receiver “1” to receiver “2”. Receiving quality of receiver

1 is “97%”.

DPSI LCD Operating Instructions Version 1.0

Page 16 of 32

The last line depicts information for receiver 2: “0x” switched from

receiver “2” to receiver “1”, its receiving quality is “100%”.

Hint:

The signal quality refers to the percental ratio of correctly evaluated servo pulses

to erroneous servo pulses at the failsafe input. This means, all “good” and all

“bad” (e.g. failsafe) servo pulses are recorded and the ratio is built.

As a matter of fact, a receiver’s receiving quality can be less than 100% but no

switching occurs. That’s due to the fact that only qualified errors can cause

switching and not just only a single (failsafe)-signal. This is not critical.

Even so, the quality can be 100%, but switching took place. Because time is

considered in the calculation, a single error does not count in long lasting

operation.

Hint:

If the receiving quality reaches less than 90%, this is considered critical and one

should take corrective actions like a different antenna layout or other counter

measures.

Here, receiver 1 is active. 12 transfers

occurred from RX1 to RX2 and 11 transfers

from RX2 to RX1. The quality of receiver 1

is 99%, receiver 2 has 89%.

Receiver switch in operating mode “Master/Slave” (=Teacher/Student)

While the system (DPSI TWIN Mini) is operated in Teacher/Student

mode, the display indicates who’s in control of the model and how long

the Teacher (Master) or Student (Slave) was in control during this

power on cycle.

DPSI LCD Operating Instructions Version 1.0

Page 17 of 32

Here, the Slave (=Student) is in control. The

servo position on failsafe input of the main

receiver (!) is -120%. The student is in

control since 00:01:12 h:m:s

Additional indications of the receiver switch:

By pushing the and buttons, other displays are possible. Thus,

one can change to a frame which shows the current servo positions at

the failsafe inputs of the receiver switch (DPSI TWIN Mini), displayed in

% or ms. Now, simple monitoring of the failsafe setup is possible.

Current servo position at both failsafe inputs

RX1 and RX2. Depiction in %-values (like in

transmitter) or in ms (units are

programmable.)

DPSI LCD Operating Instructions Version 1.0

Page 18 of 32

Output voltage / supply voltage of DPSI

TWIN Mini. At the same time, this is the

voltage, the receiver and eventually the

servos are supplied with. The actual and

minimum value (of this power on cycle) is

displayed.

Depiction of operating time. The line

“A”=Actual indicates the time since last

power on in the h:m:s format. The last line

indicates the operating time since last reset.

This time can be reset. Memorizing occurs

every 30 seconds, the maximum error can

therefore be 30 seconds

7.3. Readout of Receiver Errors

If a receiver totally malfunctions for at least 5 seconds or doesn’t

provide a reasonable servo signal, the regular frame alternates with a

corresponding error message frame every 2 seconds.

The error message display does not show up if the receiver outputs a

defined failsafe signal (e.g. PCM or FASST / IFS). A defined signal

does not point to a receiver malfunction, but rather to a bad radio

connection.

The error indication exists until power off and serves as control if a

receiver was totally malfunctioning during operation.

.

DPSI LCD Operating Instructions Version 1.0

Page 19 of 32

Hint:

If one of the or buttons is pushed during error display, output is inhibited

for 10 seconds and the regular display menu can be accessed.

7.4. Readout of the Current Supply

Depending on which “DPSI base system” the DPSI LCD is connected

to, additional frames are released. The DPSI TWIN Mini, configured as

plain receiver switch, only implements frames for receiver information.

The DPSI TWIN Mini with mounted dual power supply (battery switch)

owns additional displaying options, which refer to batteries and the

power consumption of the system.

This display shows the actual (“ACT”)

voltage of both connected batteries.

Here, the maximum voltage (“MAX”) of both

batteries is displayed for the current power

on cycle.

The minimum voltage (“MIN”) of both

batteries in current power on cycle is

displayed.

DPSI LCD Operating Instructions Version 1.0

Page 20 of 32

Supply voltage of the DPSI TWIN Mini and

therefore of the connected receiver and

servos. The actual value and the minimum

value during this power-on cycle are

displayed.

Display of actual (“ACT”) current flow from

battery 1 and / or battery 2. If the current is

less than 0.05A, <0.05A is displayed.

Display of maximum (“MAX”) current, which

is withdrawn from battery 1 and / or battery

2 in this power-on cycle. If the current is

higher than 19A, > 19.00A is displayed.

Display of average current flow, which was

withdrawn from battery 1 and / or battery 2

in this power on cycle.

Display of capacity withdrawn from battery 1

and / or battery 2 in milli-ampere-hours. The

value is being accumulated and only reset

to zero after deletion of the data. If

exceeding 9999mAh, the value “>9999mAh”

will be displayed.

Here, the sum of the values of both

batteries is displayed. First, actual total

current and secondly maximum current from

both batteries.

Here, the sum of capacity values of both

batteries is displayed. First, the withdrawn

capacity (since last reset) and second the

average current from both batteries. If

higher than 19.99Ah the value “>19.99Ah” is

displayed.

Table of contents

Popular Control Unit manuals by other brands

Broan

Broan PM390 SERIES instructions

DoorHan

DoorHan CV01 Installation and operation guide

Fike

Fike 55-043 installation instructions

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-R Series manual

Mitsubishi Electric

Mitsubishi Electric AJ65BT-68TD user manual

KLINGER

KLINGER KVN Series Mounting and operating instructions