- 7 -

3-1 Operation

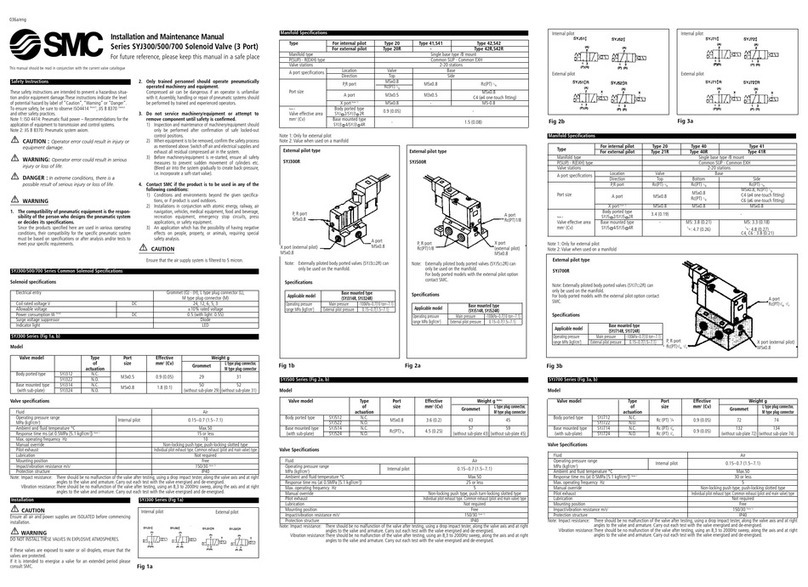

Figures 1 and 2B show the state in which Slit ①carrying the work piece is closed and Gate ③(Sealing

material ④) is not clamped (sealed) on Seal surface ②.

In Fig. 2A shows Slit valve opens and Slit ①of the body ⑤is released. So it is a state where the work

piece can be transported.

Figure 2C shows a state in which Gate ③is clamped and Seal surface ②is sealed by Sealing material

④of Gate ③.

3-2 Construction

In Figures 1 and 2, Piston rod ⑦integrated with Piston ⑥and Moving base ⑧are connected by a

displaceable mechanism. And Roller block ⑨is fixed to Moving base ⑧. In addition, Shaft ⑭fixed to

Lever ⑲is separated from each other by the force of Moving base ⑧and Spring ⑬. On the other hand,

since Lever ⑲is restricted by Roller block ⑨and Roller block ⑨that is guided by Cylinder tube ⑩and

Cam follower ⑪⑫ attached there. So Shaft ⑭and Roller block ⑨are mated by reacting force of Spring

⑬then it is possible to move up and down together. Also regarding the external seal, Shaft⑭moving

up and down is done with Bellows ASSY ⑰and O-ring ⑮⑯○

30 . And Static seal part of Bonnet ASSY

and Body ⑤is done with O-ring ⑱.

3-3 At the case Gate CLOSE (Fig2A⇒Fig2B)

By pressurizing to "CLOSE" side port (exhausting "OPEN" side), Moving base ⑧that is connected to

Piston rods ⑦are moving up. On the other hand, since Moving base ⑧pushes up Shaft ⑭integrated

with Lever ⑲by Spring ⑬, Lever ⑲, Shaft ⑭and Gate ③attached to it also go up at the same time,

then Cam follower C ○

21 comes into contact with Stopper ○

20 and stop the up motion and Slit ①of Body

⑤is closed.

In FIG. 2B, the left and right positions of Roller block ⑨and Lever ⑲are restricted by Cam grooves ○

24

○

26 of Roller block ⑨and Cam followers A ○

23 and B ○

25 . Furthermore, the position of Roller block ⑨of

the left-right direction is fixed by Guide groove ○

22 of Roller block ⑨and Cam follower ⑪⑫ fixed to the

cylinder tube ⑩. The distance for the vertical direction between Lever ⑲and Roller block ⑨is constant

because Cam groove ○

24 of Roller block ⑨and Cam follower ○

23 come in contact and are pressed by

Spring ⑬.Therefore, Shaft ⑭/Gate ③fixed by Lever ⑲move up stable when moving from Gate ③

OPEN position in Figure 2A to Gate ③CLOSE position in Figure 2B.

3-4 At the case Gate CLAMP (Seal) (Fig.2B⇒Fig.2C)

Cam follower C ○

21 comes into contact with Stopper ⑳then Lever ⑲/Shaft ⑭and ③stop. On the other

hand, Piston rod ⑦and Roller block ⑨are further going up with compressing Spring ⑬, so Cam

followers A ○

23 and B ○

25 move to the left side following the cam groove ○

24 ○

26 of Roller block ⑨.And

along with that, Lever ⑲/ Shaft ⑭and Gate ③also move to the left side, and O ring ④of the gate ③is

clamped (sealed) to the seal surface ②.

3-5 Unclamp(Fig.2C⇒Fig.2B)

By pressurizing to "OPEN" port side (exhausting "CLOSE" side), Moving base ⑧and Roller block ⑨that

is connected to Piston rods ⑦moves down, so by following Cam groove ○

24 ○

26 Cam follower ○

23 and

Cam follower B ○

25 move to the right, along with which Shaft ⑭and Gate ③also move to the right side

and make unclamp of Gate ③.At that time, Cam follower B ○

25 fixed to the lever ⑲and Cam groove ○

24

of Roller block ⑨come in contact with each other and are fixed vertically by the force of Spring ⑬.And

also Cam groove ○

26 of Roller block ⑨and Cam follower B ○

25 are fixed for the left and right direction so

the left, and right directions movement are fixed.

When Roller block ⑨moves down a slight downward force acts from Cam follower A and ○

23 Cam

follower ○

25 to Lever ⑲, but because pushing up force by Spring ⑬is greater than the downward force,

Gate ③leaves at a right angle.

3-6 At the case Gate OPEN(Fig.2B⇒Fig.2A)

After unclamp (unseal), Gate ③/ Shaft ⑭/ Lever ⑲and Roller block ⑨moves down together, then Gate

③opens and Slit ①of Body ⑤is released.