Triamec TP150 User manual

TP150/TP350 Power Supplies

Hardware Manual

Document HWTP150-TP350_B_HardwareManual_EP

Version 017

Source :\doc\Hardware\HWTP\HWTP150-TP350_B_HardwareManual\

Destination T:\doc\Hardware\

Owner mvx

Copyright © 2014

Triamec Motion AG

All rights reserved.

Triamec Motion AG

Industriestrasse 49

6300 Zug / Switzerland

Phone +41 41 747 4040

Email inf[email protected]

Web www.triamec.com

Disclaimer

This document is delivered subject to the following conditions and restrictions:

This document contains proprietary information belonging to Triamec Motion AG. Such information

is supplied solely for the purpose of assisting users of Triamec products.

The text and graphics included in this manual are for the purpose of illustration and reference only.

The specifications on which they are based are subject to change without notice.

Information in this document is subject to change without notice.

2014-04-01

Table of Contents

1 Safety Information...................................................................................................................................3

2 Product Description.................................................................................................................................4

2.1 Block Diagram..................................................................................................................................5

3 Technical Specifications...........................................................................................................................6

3.1 Environmental conditions................................................................................................................6

3.2 Electrical Specifications....................................................................................................................7

3.3 AC-Line.............................................................................................................................................8

3.4 Discharge Currents...........................................................................................................................8

3.5 EN 61800-5-1...................................................................................................................................8

3.6 EN 61800-3.......................................................................................................................................8

3.7 Overvoltage......................................................................................................................................9

Internal brake capability 9

External brake resistor 9

Overvoltage protection 9

3.8 LED Diagnostics and Status............................................................................................................10

3.9 RS232 communication...................................................................................................................10

4 Mounting and Wiring............................................................................................................................11

4.1 Dimensions....................................................................................................................................11

4.2 Cooling...........................................................................................................................................11

4.3 Brake resistor.................................................................................................................................11

4.4 Capacitor reforming.......................................................................................................................11

4.5 Wiring and Connectors..................................................................................................................12

5 Warranty Information............................................................................................................................13

6 Revision History.....................................................................................................................................13

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 2/13

1 Safety Information

The user must have read and understood this documentation before carrying out any operation on Tria-

mec Motion AG hardware. Please contact Triamec Motion AG in case of missing information or doubt

regarding the installation procedures, safety or any other issue.

Caution

Caution Triamec Motion AG disclaims all responsibility to possible industrial accidents

and material damages if the procedures & safety instructions described in this

manual are not followed.

Never use the power supply for purposes other than those described in this manual.

A competent and trained technician must install and operate the power supply, in accordance with

all specific regulations of the respective country concerning both safety and EMC aspects.

Troubleshooting and servicing are permitted only by Triamec Motion AG technicians.

The safety symbols placed on the power supply or written in this manual must be respected.

If this power supply is integrated into a machine, the manufacturer of this machine must establish

that it fulfills the 2004/108EC directive on EMC before operating the system.

Danger

Danger To avoid electric arcing and hazards to personnel and electrical contacts, nev-

er connect/disconnect the power supply while the power source is on.

Danger

Danger Power cables can carry a high voltage, even when the motor is not in motion.

Disconnect the hardware from all voltage sources before it is disassembled

for servicing.

After shutting off the power and removing the power source from the equip-

ment, wait at least 5 minutes before touching or disconnecting parts of the

equipment that are normally loaded with electrical charges (such as capacit-

ors or contacts). Measuring the electrical contact points with a meter before

touching the equipment is recommended.

Caution

Caution The TP150/TP350 contains hot surfaces and electrically-charged components

during operation.

Caution

Caution The maximum AC power supply connected to this hardware must comply

with the parameters outlined in this guide.

Never connect directly to three phase European 400 VAC network. A 300VAC

to 230V transformer is required for three phase applications.

Never connect one European 230VAC Phase (single Phase configuration)

without the corresponding Neutral wire.

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 3/13

Caution

Caution Read the paragraph „Overvoltage“ on possible mechanical damage that may

occur if an external brake resistor is missing or improperly dimensioned.

2 Pro uct Description

The Triamec Motion AG TP150 and TP350 power supplies

complement the TS15x and TS35x series drives that do not

include an integral power supply. Their typical use is with

the TMPS2/4 mounting kits for up to 4 drives, a suitable ex-

ternal transformer and external means for optional safety

protection.

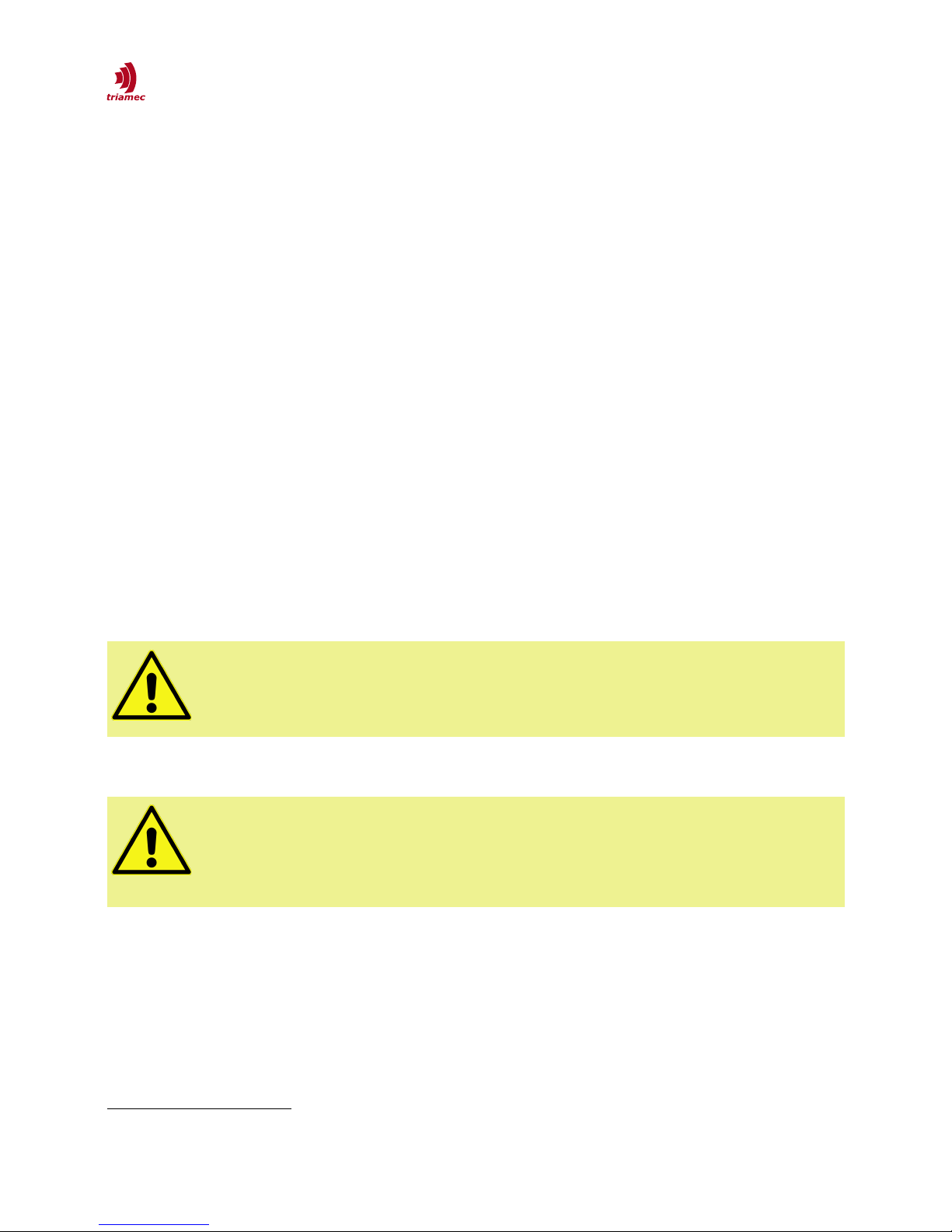

The TP150 and TP350 contain

a three phase rectifier, in-rush current limiter

a large capacitance to recuperate motion energy

an internal brake resistor and a connector for an extern-

al brake resistor to limit the DC-bus voltage

DC-Bus output connectors for up to four drives

Connectors for two cooling fans

Status output

The TP150 and TP350 include the following protective func-

tions:

Short term energy dissipation of the internal brake res-

istor

Over temperature of the device

Short circuit protection of the external resistor connect-

or

AC-Line input EMC protection and interference suppres-

sion

The TP350 is the power supply for up to four TS35x drives with one or three phase 230V AC line-input

or lower. It is therefore not intended for direct connection to European 3x400VAC power lines.

When using the TP150 for TS15x drives, the input must be limited to 1x or 3x110VAC. In a mixed config-

uration with TS15x and TS35x drives, the TP150 must be used to ensure correct brake action.

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 4/13

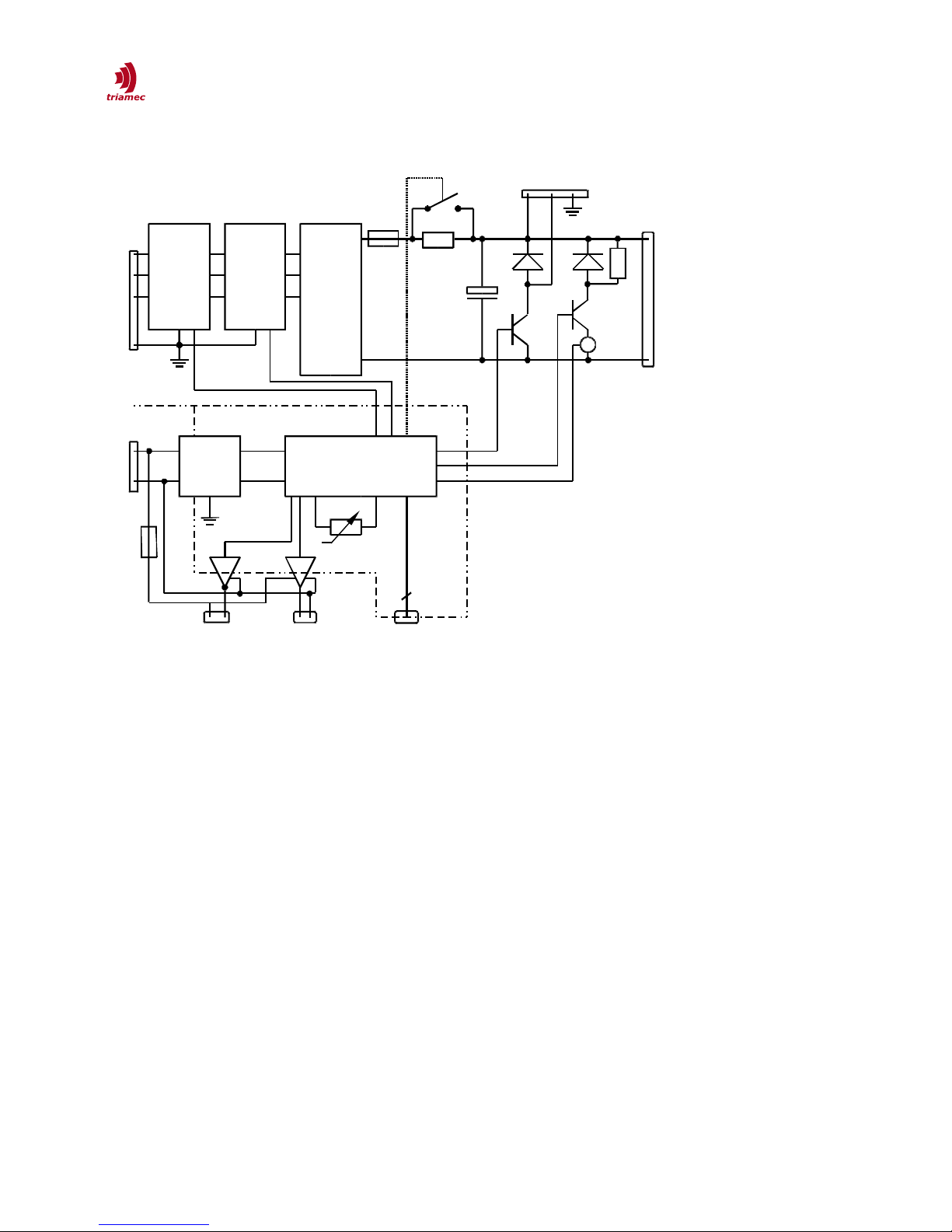

2.1 Block Diagram

Figure 1: lock Diagram

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 5/13

MOV

with

Monitoring

EMC

Filter

Rectifier

Fuse

Galvanic insulation

Controller

to four DC-Bus

Connectors

RS232

Config

DC Bus

Goo

Out

Ext. Brake

Resistor

AC-Line in

DC/DC

an

EMC

i

24V in

2 * Fan

Out

44

int. brake

+

-

Fuse

3 Technical Specifications

3.1 Environmental con itions

Transport and storage conditions

During the transport and the storage, the power supply must remain inside their original packaging

which complies with the ESD standard.

The transport conditions must respect the class 2K3 of the IEC 60721-3-2 standard (temperature

between -25°C (-13°F) and +70°C (+158+C), and humidity <95% without condensation) and

the storage conditions must respect the class 1K2 of the IEC 60721-3-1 standard (temperature

between +5°C (+41°F) and +45°C (+113°F), and humidity between 5 and 85% without

condensation). If either storing for more than two years or at temperatures higher than 35°C, ob-

serve the reforming procedure as shown under „Capacitor reforming“.

General Operating conditions

The power supply has the following electrical safety degree: IP 20 (according to EN 60529 standard).

The power supplies are designed to operate in a non-aggressive and clean environment, with a (non-

condensing) humidity ranging between 5% and 85%, an altitude < 2000m (6562 ft), and a temperature

ranging between +5°C (50°F) and +40°C (104°F).

The electronics must be in an enclosure respecting a pollution degree of 2 (refer to UL 508C and EN

61800-5-1 standards for more information). They are not designed or intended for use in the on-line

control of air traffic, aircraft navigation and communications, explosive atmosphere, as well as critical

components in life support systems or in the design, construction, operation and maintenance of any

nuclear facility.

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 6/13

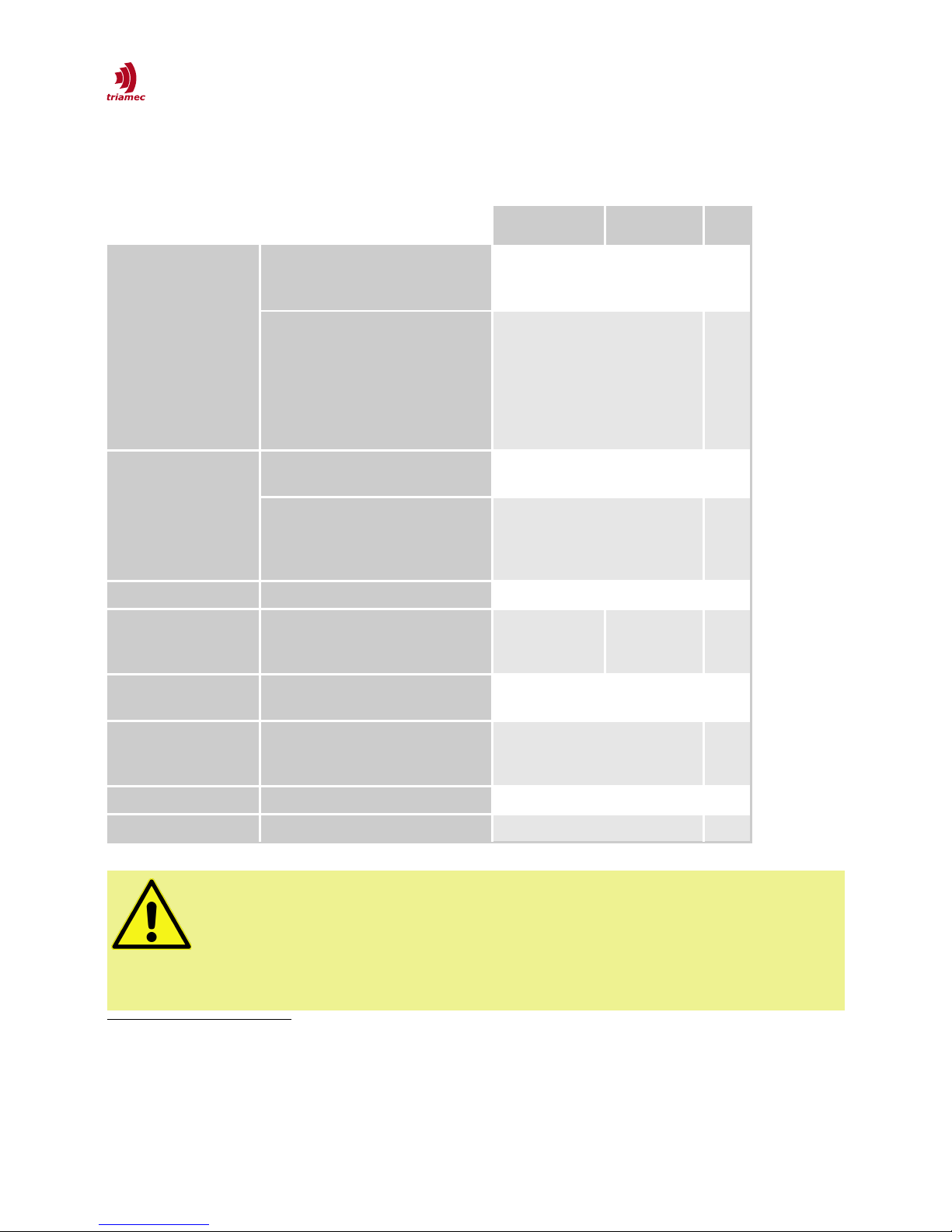

3.2 Electrical Specifications

All the specifications are given for an ambient temperature ranging from +10°C (50°F) to +40°C (104°F)

and with the air flow cooling system of the TMPS4 mounting kit.

TP150 TP350

3-phase AC-Line input Nominal voltage UVN

AC voltage (between the phases)

Primary ULN of autotransformer (1)

110

25 to 1.1UVN

400

230

25 to 1.1UVN

400

V AC

V AC

V AC

Nominal frequency

Nominal maximum AC current IVN

Require External fuse maximum

Internal Dc-Bus Fuse (Fast)

Power factor correction

In-rush limiter

Insulation test voltage (2)

50-60

22

20 , e.g., Hager NBN320

30

no

300

360

Hz

A rms

A rms

A rms

Ohm

VDC

DC-Bus output DC voltage nominal

DC voltage maximum

150

185 ± 2%

325

380 ± 2%

V

V

Max current (sum)

continuous

pulse 30s

pulse 2s

14

20

25

A

A

A

Capacitance C 3.4 ±20% mF

Internal brake res. Break - point U_break_I

A iabatic issipation energy

Continuous power

180 ± 2%

1000

120

375 ± 2%

1000

120

V

J

W

External brake res Min Resistance

Setpoint U_break_E

15,

180 ± 2%

15

375 ± 2%

Ohm

V

24V logic supply (3)

PELV

Voltage

max current

Output Fuse (4)

24 VDC ±20%

100 + Fan and status output

1.1

V

mA

A

Fan connectors (4) Low si e switch 24V on/off, 1A

Status out (4) High Si e switch 24V on/off, 0.8A

Caution

Caution Before running an Insulation test or voltage test on a machine, disconnect all

connectors from Triamec drives.

Caution

Caution Mains input voltage drops at maximum load on the Dc-Bus side may break

the internal fuse due to capacitor recharging. Consult Triamec on how to

avoid this problem.

1 See chapter 3.3

2 Limited by an internal arrestor circuit.

3 The logic supply is galvanically isolated from the internal logic power. It can be switched on and off independently of the

AC-Line. It is, however, recommended to turn on the logic before the AC-line and turn it off after the AC-Line. Hot-plug -

ging is not recommended. Drawing DC-Bus current without logic supply is prohibited.

4 The fan and status outputs are galvanically connected to the 24V logic supply (see Output-fuse).

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 7/13

3.3 AC-Line

The power supply must be connected to an electrical network

of overvoltage category 3 (refer to EN 61800-5-1 and UL 840 standards for more information)

capable of delivering not more than 40kArms, symmetrical amperes (prospective current according

to EN 60269-1).

The network must be a TN-C-S with center earth or similar. In these cases, a transformer with com-

mon center (not insulating) is sufficient. An IT-net with phase on earth requires an isolating trans-

former. The same applies, if the network supplies more than 400VAC+15%, due to arrestor limits if

only one of three lines is connected and due to double isolation requirements. In this case, a trans-

former with common center is not allowed.

3.4 Discharge Currents

Caution

Caution Discharge currents (EN 50178, IEC 60755). If the primary side of this power

supply contains a residual current device for the protection of personnel

against electric shock, this device must be of type B according to EN50178.

Otherwise, alternative protection must be enforced, such as: insulation from

the environment by double isolation or using an isolation transformer.

3.5 EN 61800-5-1

The power supply confirms to EN 61800-5-1 (2008). Monitored varistors at AC-Line input and gas dis-

charge tube allow internal reduction of the overvoltage category III to II in the basic isolation part. Safe

electrical separation according to EN 61800 between the power circuit and 24V / Earth.

3.6 EN 61800-3

The interference suppression filter in this power supply complies to EN 61800-3 C2 under certain condi-

tions as detailed in the following.

The hardware manuals of the drives contain

Guidelines for proper shielding.

Restrictions on the motor and motor cable properties depending on the PWM frequency.

In the following table, capacity refers to the sum of cable capacity and motor capacity with respect to

earth. The table shows the total permissible capacity of all motors and motor cables attached to the

same power supply and the expected EMC class according to the standard EN 61800-3.

100 kHz ECO (50 kHz)

Capacity per Power Supply 8-12 (EMC C3)

<8 (EMC C2)

16-24 (EMC C3)

<16 (EMC C2)

nF

nF

Table 1: Permissible total capacity and expected EMC class

The critical requirement is the conducted voltage limit in the frequency range between 2MHz and

4MHz. Lower frequencies are not expected to break the C2 limit. Therefore a Ferrite (5) is supplied with

5 TDK ZCAT3035-1330 or similar.

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 8/13

every power supply, which is to be introduced around the three phase wires of the AC-Line. In some

cases it might be beneficial to insert further blocking ferrites (6) into the DC-Bus pairs. If doing so, make

sure, every DC-Bus output of the power supply gets its own ferrite to prevent overheating of the ferrite.

Other combinations of motors and cable might require a single stage line EMC filter or an insulated

transformer between 3x400V line-in and TP350.

3.7 Overvoltage

A system of a motor coupled with a load has a certain amount of energy. This energy is mainly kinetic

when the load is moving or rotating. While stopping these loads, the energy must either be stored or

dissipated. The same applies during moves when gravitational energy or spring energy is involved.

The drives recuperate this energy back to the power supply and the bridge voltage rises.

Internal brake capability

The following measures are provided internally of the power supply to store and dissipate energy. The

internal capacitors can store a certain amount of energy

Ec = 0.5 * C * (U2 - UdcSupply2)

Since the maximum voltage is given, the energy stored is defined by the rectified supply voltage UdcSupply.

See technical specification sheet.

Above UBrake-I, the internal brake will be activated to dissipate energy. This resistor can dissipate a short

term energy Eb but only a small continuous power Pb. If an external brake is missing or not properly de-

signed and high mechanical energy is involved the internal brake resistor might reach its thermal limit.

It will turn off and the DC-bus voltage might increase further until the drives turn off. Then the axis does

not stop and might cause mechanical damage.

This failure is avoided by adding an external brake resistor or reducing the deceleration of the drives.

Slower stopping reduces the load on the brake resistor. See section RS232 communication on how to

measure the internal state of the brake resistor.

External brake resistor

The external brake resistor must be dimensioned properly to account for the amount of energy to be

dissipated in the axis system if the internal resistor is not sufficient.

It is recommended to use a resistor that is protected against overtemperature. Contact manufacturer

for dimensioning.

Overvoltage protection

If the external braking resistor is not dimensioned properly, the DC-bus voltage may exceed the limit U d-

cMax. The drives will not be damaged because they protect themselves by turning off their semiconduct-

or switches. The axis is not decelerated anymore and the voltage will not increase any further. However,

turning off the drives during fast motion leaves the axis at the original speed. The axis might crash into

its end-limits, which might cause significant mechanical damage to the mechanical system.

Therefore it is important to choose a well dimensioned braking resistor. Also, the overvoltage error

message of the drives may be used by the control system for further information.

6 Würth 742 7010 or similar.

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 9/13

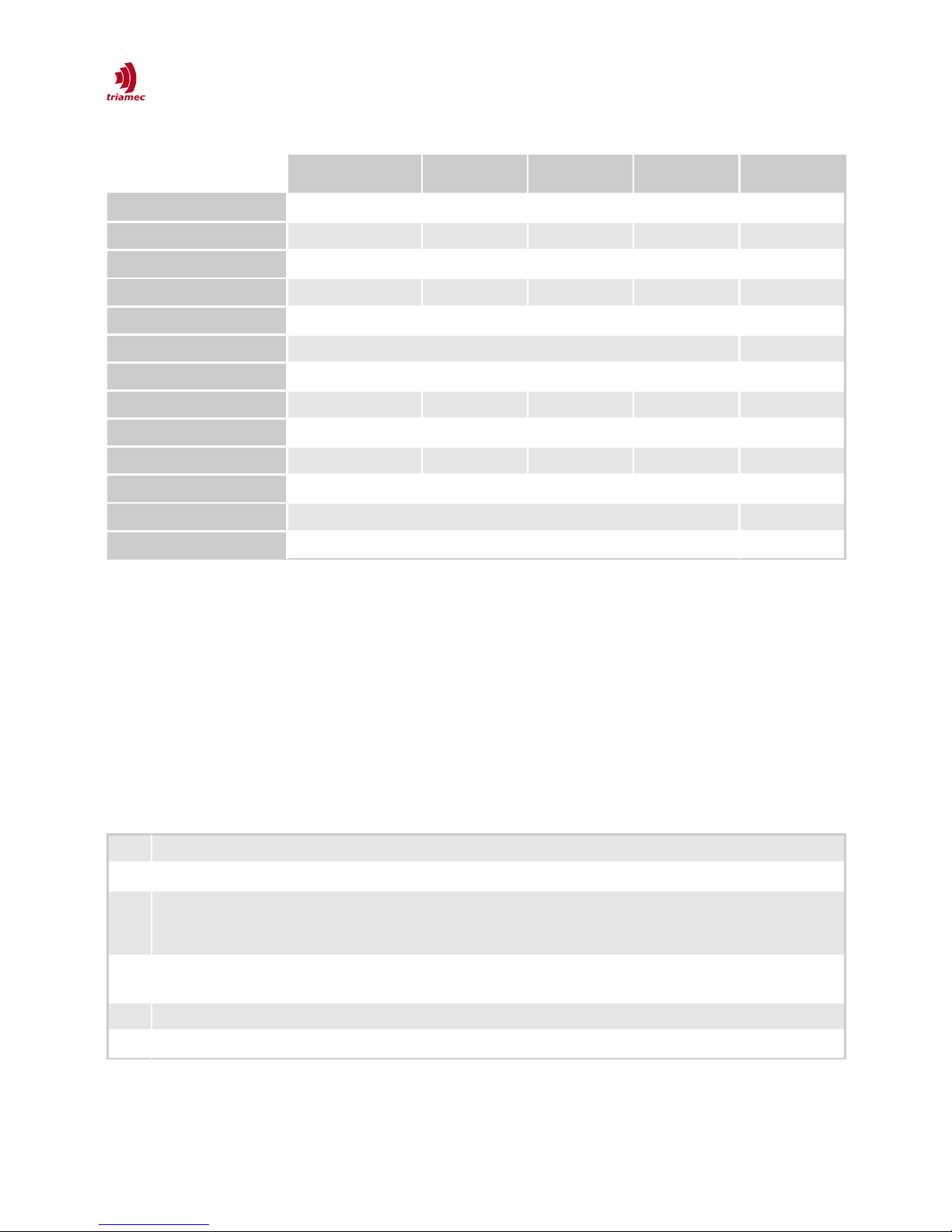

3.8 LED Diagnostics an Status

AC-Line DC-Bus Brake Int Brake Ext Status

No line power red flash off 0V

Inrush limiter green green flash 0V

Rea y green green 24V

AC-Line isturbance red flash green 24V

Discharging DC-Bus red flash green flash green flash 0V

Varistor broken all four LED moving red slow ( 1 per second) 0V

Internal brake active green

External brake active green

DC-Bus voltage excee e green alternate red flash green 0V

External brake short (*) red flash 0V

Over - temperature simultaneous blinking 4Hz 0V

Fuse Broken all four LED flashing 2 times then pause ones 0V

Internal error all four LED flashing 3 times then pause ones 0V

(*) cleared in state „no line power“

3.9 RS232 communication

Use the RS232 connection to check the internal state of the power supply, mainly the brakes.

Do not connect an active modem (Hyperterminal) during power-up or the power supply will enter

the firmware update state. If done unintentionally, power-off the power supply, disconnect RS232

and turn-on the hardware again.

Use a hyperterminal at 9600Baud (8data bits, no parity, one stop bit, no flow control).

Commands are one or two letters sent by the hyperterminal followed by „enter“. They are not case

sensitive.

? Show the list of the comman s

?i The SW version installed

LB Start the brake logger. The columns „D“ and „B“ show the DC-bus voltage in volt and the internal brake resistor

energy in Joule. If the adiabatic dissipation energy (see specifications) is reached, the internal brake resistor

will stop and only the external brake resistor continues running.

LV Start the Varistor logger showing voltages of Phases (R,S,T) against Earth and average voltage N and varistor

voltage V which should be the same as N.

LD Start the DcBus Logger showing voltages of DcBus N and P against Earth and their difference D.

L Stop logging

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 10/13

4 Mounting an Wiring

The power supply should be protected against any splashes of liquid and any contacts with smoke and

dust. It must be installed inside a closed cabinet and mounted as mentioned below.

4.1 Dimensions

Dimensions:

Width 91 mm

Height 205 mm

Depth 210 mm

The screw pattern is 100mm by 50mm.

4.2 Cooling

The maximum allowable ambient temperature is 40ºC. The TMPS4 mounting kit provides circulating air

to cool the power supply (and the drives). If this kit is not used, a minimum air speed of 3m/s is re -

quired at maximum current.

4.3 Brake resistor

Use only resistor with thermal shutdown protection. The use of an undersized power and energy with-

stand capability resistor might cause damage to the system. See section „Overvoltage“ for dimension-

ing.

Caution

Caution The cables connected to the external brake resistor must be shielded.

4.4 Capacitor reforming

Caution

Caution If the power supply has been stored without power for more than two years

after shipment or after last time use, the internal capacitors require reform-

ing. The same applies if storing above 35°C for more than one month without

power.

Solution: Add three series resistors 470Ohm/5W into the three phase power cable. Apply power for

half an hour without enabling the drives. Then shut down and disconnect for 4 hours, remove the

series resistors and the power supply is ready for use (7).

7 See the CECC 30302-809 detail specification and JIS C 5101-4 clause 4.1 for details.

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 11/13

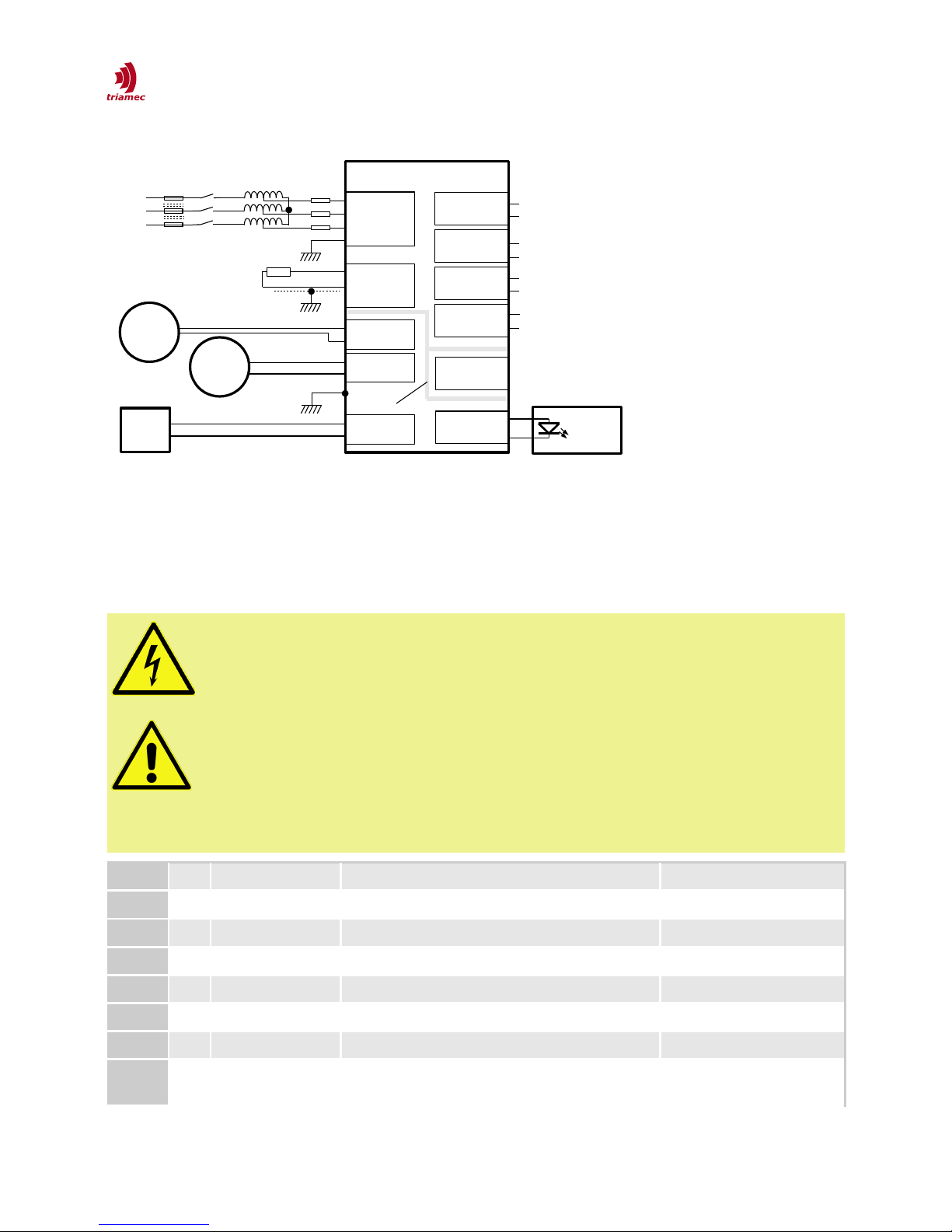

4.5 Wiring an Connectors

Supply TPx50

Fan 1

Fan 2

J1 DcBusP

DcBusN

J5

J6

U

V

W

PE

PE

Control

24VDC

Groun

Isolation

Mains

Switch Fuse

Mains Auto-

Transformer

L1

L2

L3

J2 DcBusP

DcBusN

J3 DcBusP

DcBusN

J4

UBreakN

UBreakP

J10

Fan

GND

J11

Fan

GND

J7

24V

GND

Ext.-Brake-Res

DcBusP

DcBusN

Drive 1

Drive 2

Drive 3

Drive 4

J8 RS232

J9 Status

GND

Ferrite

Figure 2: Power Supply Connections

The following measures must be taken to ensure personal safety and EMC requirements

There must be two earth connections. Each must have at least the same diameter as the AC-Line

wires.

The motor and encoder cable shield must be in firm contact with the earth at the drive and power

supply ground plate.

Danger

Danger

Must!

Must!

Always connect first the protective earth (PE) to the dedicated screws in the

top left corner of the housing!

Caution

Caution In a one phase configuration, never connect an European 230V phase L

without the corresponding neutral N. This might cause damage to the high

voltage protection circuit.

The TP350 is intended for 3x230VAC or lower. Never connect a European

3x400VAC power line.

Dir Name Connector Cross-section

J1-J4 out DC-Bus Sauro CGF029M7 1.5mm2 min, 2.5mm2 typ

J5 out External brake res. Sauro CGF039M7 1.5mm2 min, 2.5mm2 typ

J6 in AC-Line in Phoenix PC 5/4-G-7,62 (4 pins, Raster 7.62mm) 1.5mm2 min, 2.5mm2 typ

J7 in 24V logic supply Phoenix (or similar), 2 pins, 5mm pitch

J8 com Config RS232 9 pin sub-D female receptor, Pin3=RX

J9 out Status Out Phoenix (or similar), 2 pins, 3.5mm pitch

J10

J11

out Fan 1&2 Out Phoenix (or similar), 2 pins, 3.5mm pitch

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 12/13

PE Protective Earth M5 in the top left corner of the housing Same or larger than AC-Line

5 Warranty Information

The products covered in this manual are warranted to be free of defects in material and workmanship

and conform to the specifications stated either within this document or in the product catalog descrip-

tion. All Triamec Motion AG products are warranted for a period of 12 months from the time of installa-

tion, or 18 months from time of shipment, whichever comes first. No other warranties, expressed or

implied – and including a warranty of merchantability and fitness for a particular purpose – extend bey -

ond this warranty.

6 Revision History

Version Date E itor Comment

1.0 2010-08-18 mvx/up First edit

1.1 2010-10-06 mvx First delivery of Rev. B

1.2 2010-11-02 mvx Add RS232 communication

1.3 2010-11-18 mvx SW 1.1, Subversion 11102

1.4 2011-12-22 mvx Add warnings on single phase configuration

015 2012-11-30 mvx/chm Changed LED code for internal error, add logger Ld and Li. New document style

016 2014-03-22 mvx Extend chapter on EMC, discharge currents and earth and maximum current, add

requirement for external fuse.

017 2014-04-01 mvx Add wire cross-sections and PELV requirement for 24V, SW1.5

HWTP150-TP350_B_HardwareManual_EP017 2014-04-01 13/13

This manual suits for next models

1

Table of contents

Other Triamec Power Supply manuals