EME 55II User manual

EME 55II Gasoline Engine

User Manual

Eagle Master Engine EME 55II User Manual ‐1‐

SAFETY INSTRUCTIONS

◎Thank you for purchasing EME 55II gasoline Engine. We at EME

always strive to product reliable engines that bring you pleasure of

flight. It is vitally important to read SAFETY INSTRUCTIONS very

carefully before operating EME 55II gasoline engine.

◎Gasoline is POISONOUS and HIGHLY FLAMMABLE. Do not

allow it contact with the eyes or mouth. Always store it in a cool and

dark place, out of the reach of children. It is possible that the fuel can

damage your health. Always store and transport it in an antistatic

container.

◎DO NOT start the engine in an area containing loose gravel or sand.

NEVER start the engine indoor.

◎For their safety, keep all onlookers (especially young children) well

back (at least 5 meters behind the engine). NEVER stand at the front

of, or to the side of the engine when it is running.

◎Check and tighten your propeller and spinner before one day’s flights.

DO NOT use a Nylon propeller. NEVER try to repair and use a

broken propeller.

Eagle Master Engine EME 55II User Manual ‐2‐

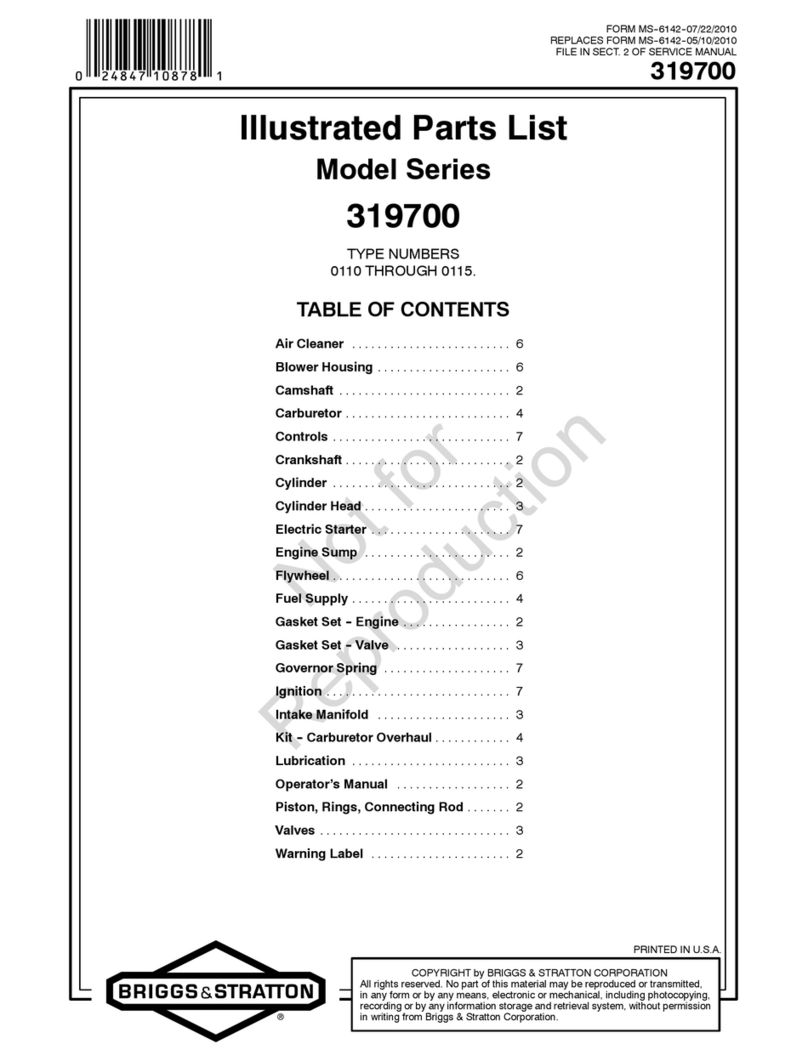

Specifications

Item

Technique Data

Displacement

55.6 cc

1380 g/Engine, 180 g/Muffler,

Weight

140 g/Ignition Module

Compression

7.6

Ratio

Power

5.7 HP @ 7500 RPM

Idle RPM

1350 RPM

Practical RPM

1350 ~ 7500 RPM

Thrust 1

14.2 kgf (50~200 m Altitude)

Thrust 2

12.5 kgf (1800~2000 m Altitude)

Spark Plug

EME / NGK CM6

Ignition Voltage

7.4V-8.4V

91~93 Octane,1:30~1:35 Mix

Fuel

Ratio

Package Contents

Item

Quantity

Engine

1 pcs

Muffler

1 pcs

Ignition Module

1 pcs

Spark Plug

1 pcs

Stand-off Spacer

4 pcs

M5*15 (front), 4 pcs

Spacer Screw

M5*22 (rear), 4 pcs

M5*4 for rear mounting

Spacer Washer

spacers

Muffler Screw

2 pcs

Muffler Gasket

1 pcs

Manual

1 pcs

Logo Tag

1 pcs

Eagle Master Engine EME 55II User Manual ‐3‐

Mounting the Engine

◎The engine should be mounted on a firewall that will in turn mount to

the fuselage. The firewall should have enough strength to prevent

engine vibration. The firewall should be made from at least 6 mm

aircraft plywood.

◎A tension free mounting is obligatory. The mounting surface should

be even. Mount the engine with high tensile bolts and stand-off

spacers, which are provided with the engine.

◎Proper cooling is vital for gasoline engines. Intake area should be

more than 60*80 mm. Outlet area should be at least as 3 times as the

intake area.

Ignition Information

◎Install the ignition module with sufficient anti-vibration, at

least 100 mm away from the engine and in the place where not

affected by engine exhaust heat and radiation heat.

◎Do not share the battery with receiver. Use separated battery for

ignition module. Equip an ON/OFF switch between the ignition

module and battery. Use a high quality switch such as Futaba HSW-J

or HSW-L heavy duty switch. Standard size receiver switches are not

recommended.

◎Install the ignition module and make its cable, switch and battery be as

far as possible away from the servos, the receiver battery and the

receiver.

◎Install the spark plug cap on the plug securely. Protect the signal wire

and high voltage spark plug cable from rubbing against fiberglass,

sharp edges of wood and metal of the fuselage.

Eagle Master Engine EME 55II User Manual ‐4‐

Propeller Option

◎A wooden propeller, as well as a carbon fiber propeller, is suggested.

Do not use a nylon propeller. XOAR,HAWK,VESS and MENZ

wooden propellers are suggested . XOAR,FALCON,RED

SWORD and MEJZLIK carbon propellers are also suggested. Since

there are so many good propellers on the market, your choice is not

limited to the brands mentioned above.

◎22*10, 23*8 and 23*10 two-blade propellers are suggested. With the

propellers mentioned above, the peak RPM range should be 6,300 to

7,100 RPM.

◎20*12, 21*10, 21*12 and 22*10 three-blade propellers are suggested

for scale purpose.

Starting Process

◎Close the choke and switch on the ignition switch. Advance the

throttle 1/8~1/4 from full closed.

◎Flip the propeller quickly until explosive sound can be heard.

◎After propeller stopping, open the choke and set the throttle to idle

position(or a little higher). Flip the propeller again until the engine

starts. BE CAREFUL!

◎Warm up the engine for about 30~45 seconds. Now the engine is

ready for flight.

Eagle Master Engine EME 55II User Manual ‐5‐

Fuel & Break-in

◎Use low to middle octane gas for break-in. Use the propeller same as

flight.

◎Use qualified 2-stroke petroleum based or synthetic oil with a mixture

of 25:1 to 30:1 in the break-in process。

◎With this fuel mixture ratio and regular needle setting, run the engine

for 1~2 hours. Too rich needle setting, which may cause misfiring or

erratic running, is not suggested.

◎After break-in, you can use a 2-stroke synthetic oil with a mixture of

30:1 to 35:1.

Needle Adjustments

◎A Walbro WT664A carburetor or equal carburetor is adopted. The

carburetor has two needles, which are low speed needle and high

speed needle. Low speed needle is effective through the high speed

range, while the high speed needle is not effective in the low throttle

status. Both needles are effective in the mid speed, but the low speed

needle is more effective. Default position of high speed needle is 1 ½

turns from full closed, as well as low speed needle is 1 ¼ turns.

◎For fine setting, please tune the engine for maximum RPM with the

high speed needle by using a tachometer. Then richen the high speed

needle until the motor runs 100~200 RPM less than the maximum

RPM. Now the engine is slightly rich on the high speed needle.

◎Furthermore, keep the engine at idle for 45~60 seconds. Check that

the idle RPM remains constant or not. If the RPM drops and the

engine stops finally, the speed needle should be too rich. Lean it until

stable idle status is achieved. Then check the transition with advancing

throttle quickly. The engine should make steady power immediately

without any hesitation. If the engine sounds hesitated to response,

please check the low speed needle again.

Eagle Master Engine EME 55II User Manual ‐6‐

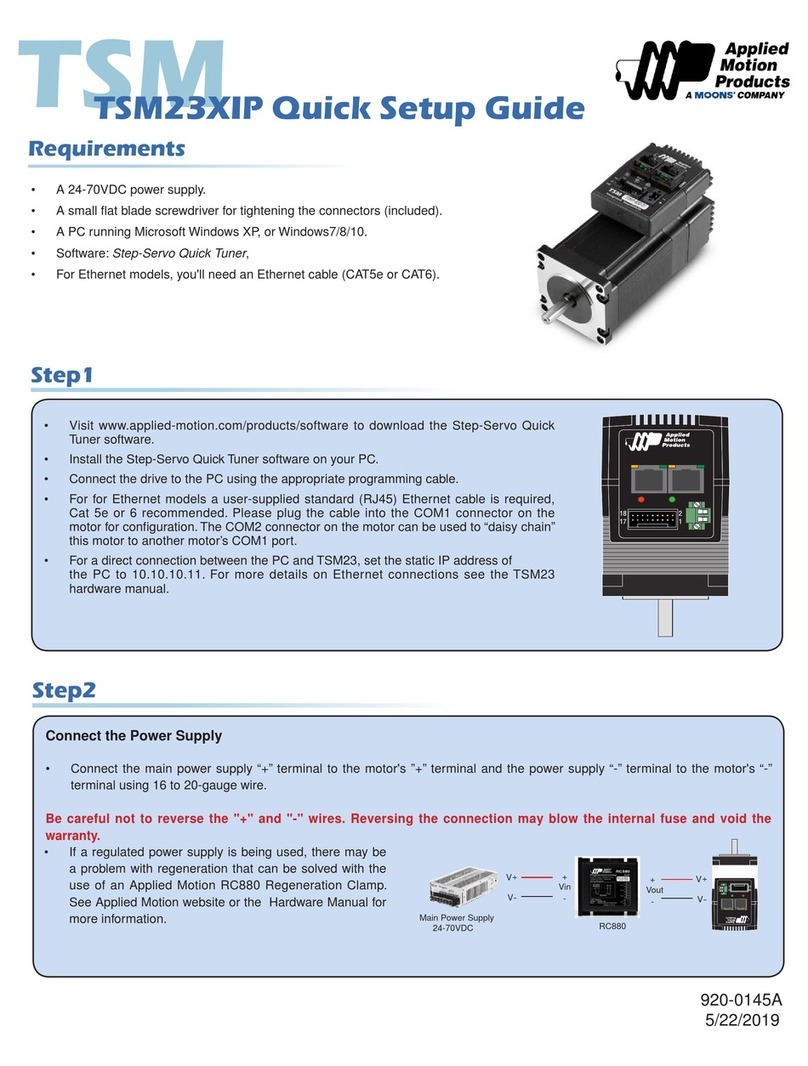

Mounting Pattern and Dimensions

Carburetor Introduction

Eagle Master Engine EME 55II User Manual ‐7‐

Engine Maintaince

◎NEVER mix different kinds of 2 stroke oils for flying. Before

changing oils, please clean the carburetor with pure gasoline.

◎To avoid incident carburetor failure, please remove carburetor pump

cover and clean the built-in fuel filter every 50~100 fights.

◎It is advisable to maintaince or replace piston, piston ring, crankshaft,

needle/ball bearing and spark plug every 300~500 flights, according to

engine status. Please consult your local dealer.

◎Please examine and clean your engine very carefully after a crash. If it

is damaged, please consult your local dealer to fix the engine. Repair

due to crash is NOT free.

WARRANTY

◎EME 55II engine and ignition module are covered with 18 months

warranty by Eagle Master Engine since purchasing date.

◎The warranty covers defects of materials and assemble issues.

◎Damage by improper installing, operation is not covered by warranty.

◎Damage by using improper fuel is not covered by warranty.

◎Damage by incident crash is not covered by warranty.

Eagle Master Engine,Yinghuang Technology Co., LTD

Chang Cheng Industry Park,Yongkang City, Zhejiang Province, China

Tel:86-135-88619003

;

Fax:86-579-87535076

Eagle Master Engine EME 55II User Manual ‐8‐

Table of contents

Other EME Engine manuals