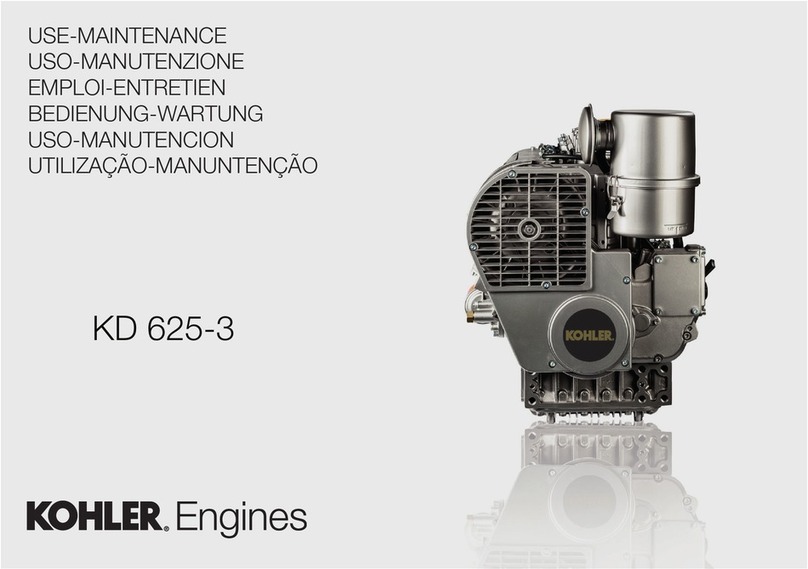

Preface

About this document

Kohler Co. will declare all possible undertakings carried out by Kohler Co. and/or their dealers,

such as guarantees, service orders, etc. null and void without advance notice, if fuel, lubricants

and coolants other than fuel, lubricants and coolants approved by Kohler Co. are used for main‐

tenance or repair.

Liability and warranty

Due to the wide variety of products offered by other manufacturers (e.g. service products, lubri‐

cants, tool attachments and spare parts), Kohler Co. cannot examine the general suitability and

absence of defects in third-party products which are used in or on KOHLER products. The same

applies to possible interactions between third-party products and products approved by Kohler

Co.

Third-party products are used in or on KOHLER engines at the user's own discretion. Kohler Co.

does not offer any warranty or accept any liability for losses of any kind caused by failures of or

damage to KOHLER engines attributable to the use of third-party products.

Furthermore, Kohler Co. will not recognize any warranty claims attributable to incorrect opera‐

tion, inadequate or insufficient maintenance or use of unapproved operating fluids or non-

compliance with safety regulations.

Kohler Co. will cancel any obligations entered into by Kohler Co. and/or its dealers, such as

guarantees, service contracts etc., without advance notice if any parts other than original

KOHLER parts or spare parts purchased from Kohler Co. are used for maintenance and repairs.

The aforementioned provisions do not extend the warranty and liability conditions in the

general terms and conditions of business of Kohler Co.

Modifications, conditions, copyright

Kohler Co. reserves the right to make modifications in the course of technical development,

without issuing prior notification.

The aforementioned provisions do not extend the warranty and liability conditions in the

general terms and conditions of business of Kohler Co..

Copyright - Proprietary notice ISO 16016

The reproduction, distribution, and utilization of this document as well as the communication of

its contents to others without express authorization is prohibited.

Offenders will be held liable for the payment of damage.

All rights reserved in the event of the grant of a patent, utility model, or design.

6

© 2022 by Kohler Co. All rights reserved. KD62V12 33525088601_8_1 EN_US

2022-09