Do not remove, cover, or obscure any permanent instructions, labels,

or data labels located on the exterior or interior of the unit.

Only a qualified person should perform relocation, repair, and

maintenance tasks on the unit and not attempt to do so yourself.

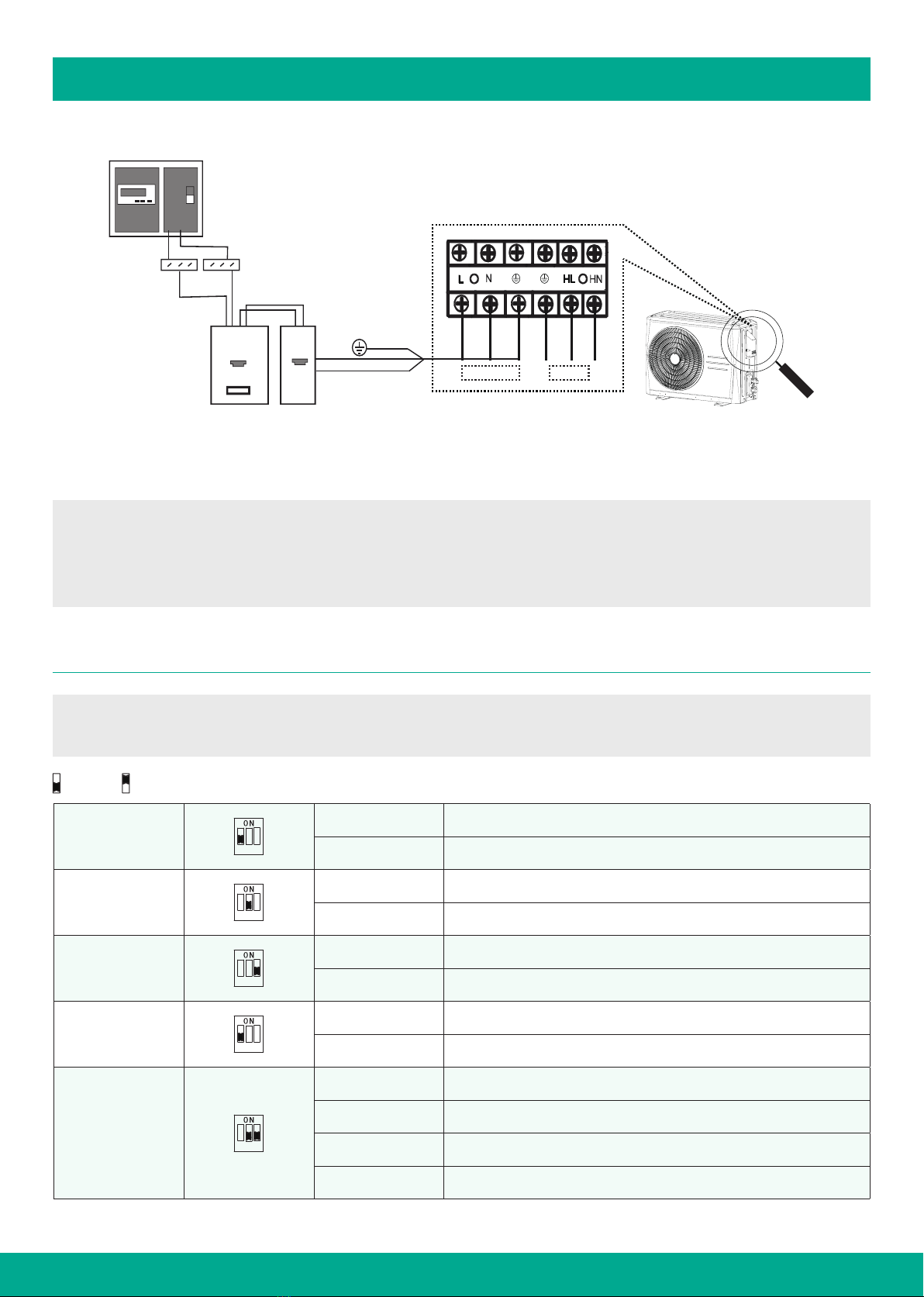

Electric connection work must comply with the instructions of the

local power company and electric utility, as well as the manual.

Never use wiring and fuses with incorrect rated current as it can

result in equipment failure and pose a fire hazard.

Do not insert fingers, rods or other objects into the air inlet or outlet.

When the fan is rotating at high speed, it will cause injury.

Never use a flammable spray such as hair spray, lacquer paint near

the unit. It may cause a fire.

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities or lack of expe-

rience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible

for their safety. Children should be supervised to ensure that they do

not play with the appliance.

Tear apart and throw away plastic packaging bags so that children

will not play with them. Children playing with plastic bags face

danger of death by suocation.

Safely dispose of packing materials such as nails and other metal or

wood parts that could cause injuries.

Ask your dealer or qualified personnel to perform installation work in

accordance with this manual. Do not install the unit yourself. Improper

installation could result in water leakage, electric shocks or fire.

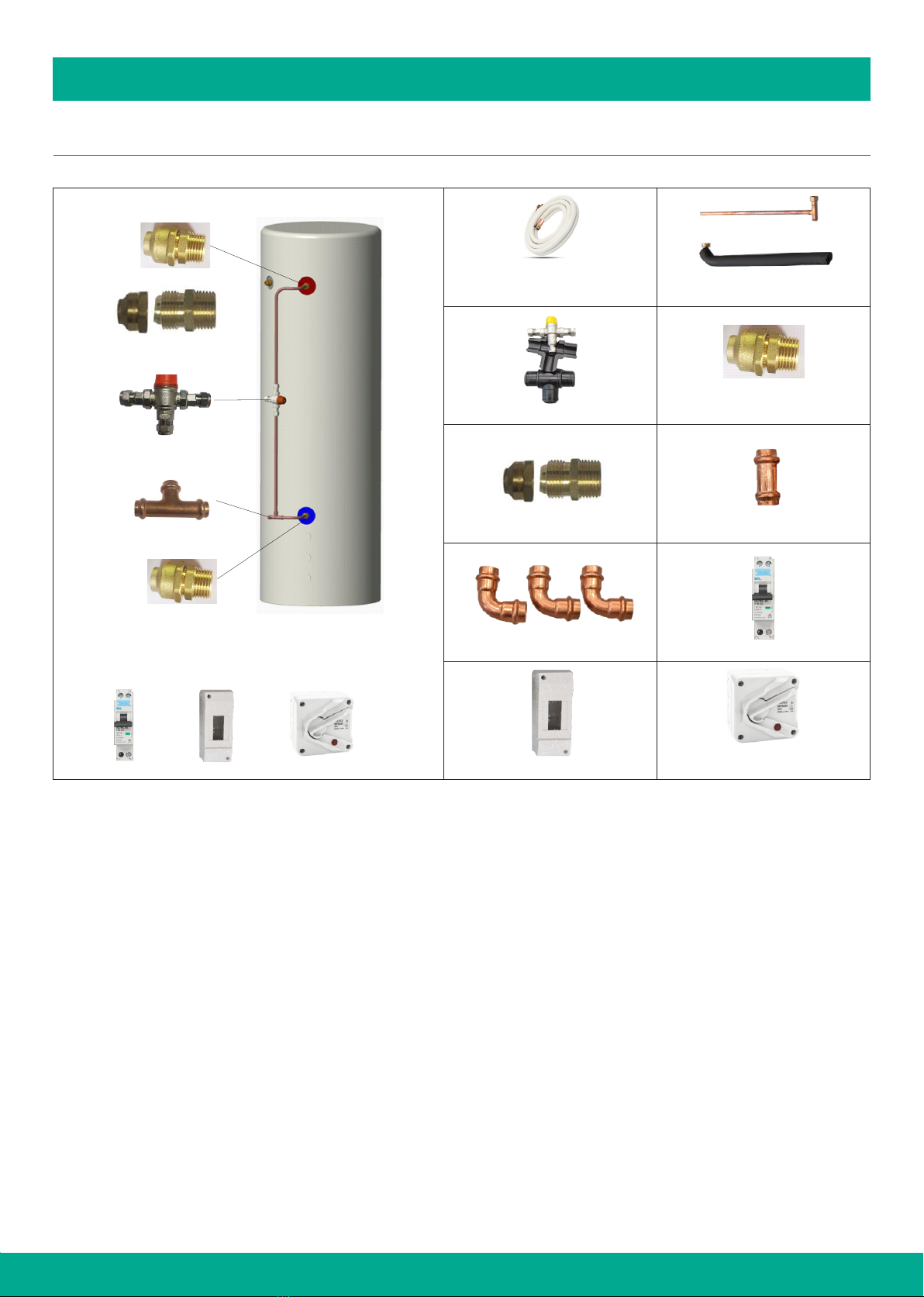

Be sure to use only specified accessories and parts for installation

work. Failure to use specified parts may result in water leakage,

electric shocks, fire, or the unit falling from its mount.

Install the unit on a foundation that can withstand its weight.

Insucient physical strength may cause the equipment to fall and

possible injury.

Perform specified installation work with full consideration of strong

wind, hurricanes, or earthquakes. Improper installation work may

result in accidents due to equipment falling.

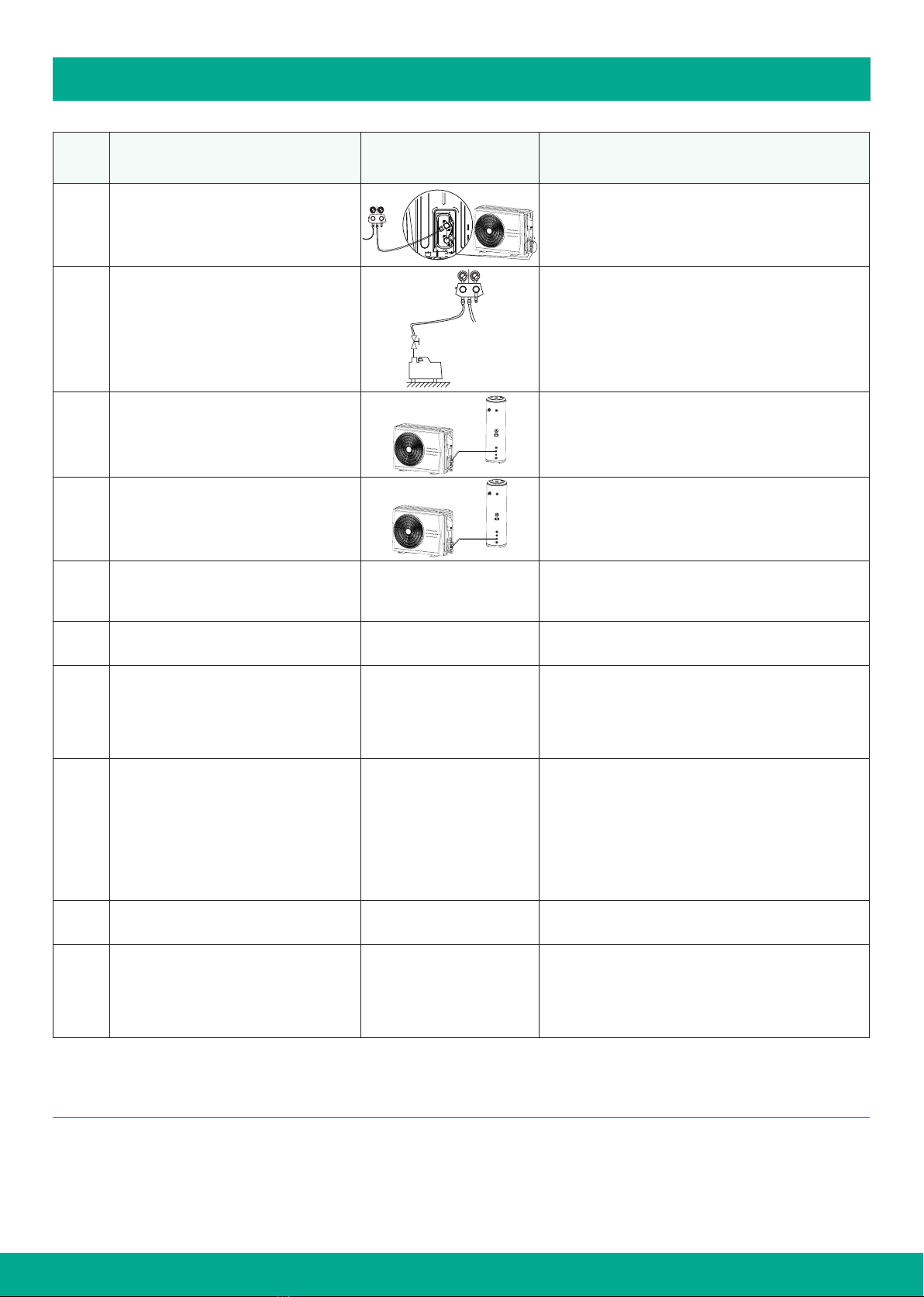

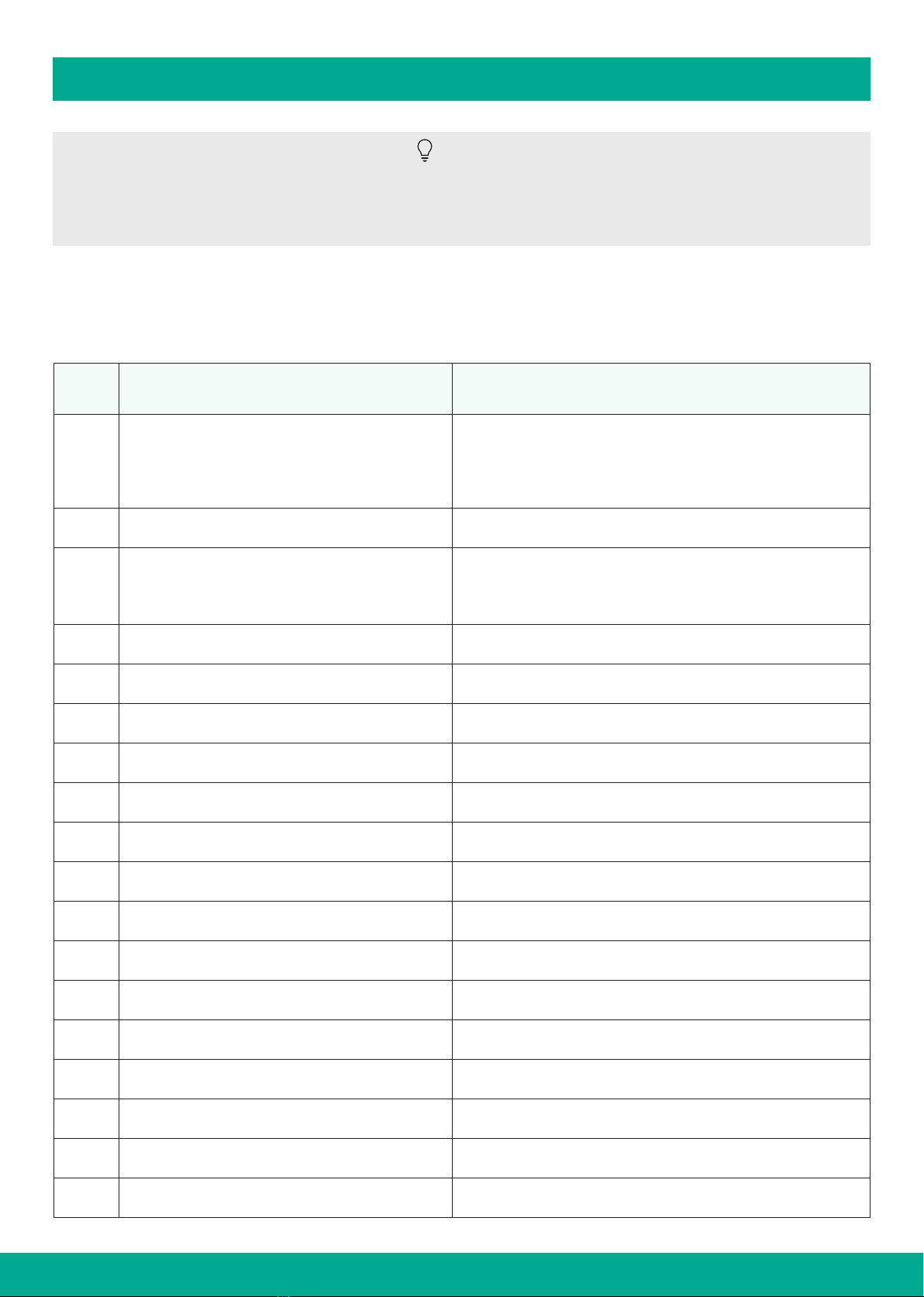

Ensure that all electrical work is performed by qualified personnel in

accordance with local laws and regulations and this manual, using a

dedicated circuit. An inadequate capacity of the power supply circuit

or improper electrical work could result in electrical shock or fire.

Be sure to install a ground fault circuit interrupter according to local

laws and regulations. Failure to install a ground fault circuit interrupter

may cause electric shocks and fire.

Make sure all wiring is secure. Use the specified wires and ensure

that terminal connections or wires are protected from water and

other adverse external forces. Incomplete connection or axing may

cause a fire.

When making the power supply connections, arrange the wires in

such a way that the front panel can be securely fastened. If the front

panel is not securely in place, the terminals may overheat, causing

electrical shocks or fire.

After completing the installation work, check to make sure that there

is no refrigerant leakage.

Avoid direct contact with any leaked refrigerant as it may cause

severe frostbite. Do not handle the refrigerant pipes during or

immediately after operation as they can be hot or cold, depending

on the refrigerant flowing through them, the compressor, and other

refrigerant cycle components. Touching the refrigerant pipes can

cause burns or frostbite, so be sure to wait until they return to normal

temperature or wear protective gloves if necessary.

Do not touch the internal parts (pump, backup heater, etc.) during

and immediately after operation. Touching the internal parts can

cause burns. To avoid injury, give the internal parts time to return

to normal temperature or, if you must touch them, be sure to wear

protective gloves.

1. SAFETY PRECAUTIONS

33

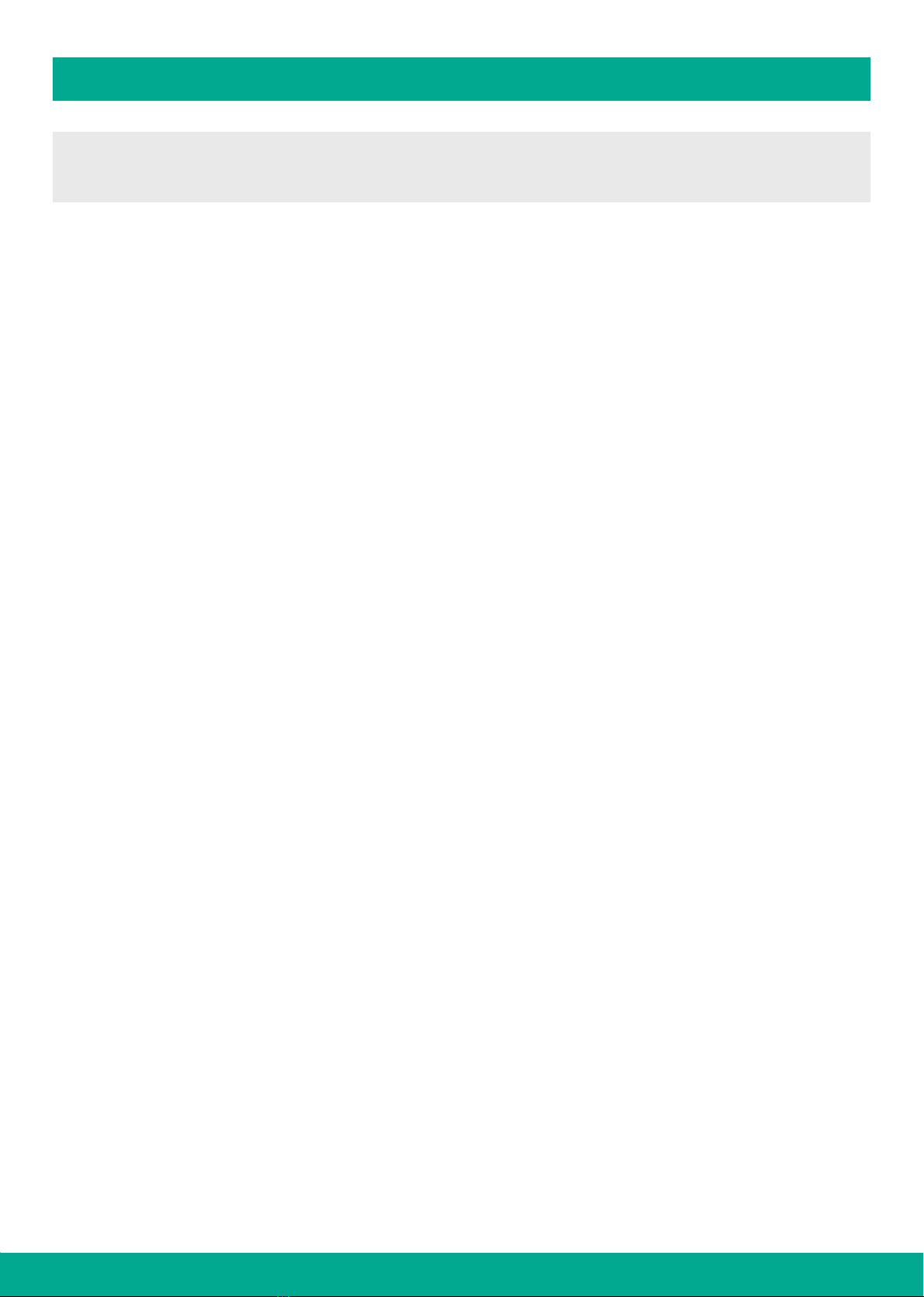

Servicing shall only be performed as recommended by the

equipment manufacturer. Maintenance and repair requiring the

assistance of other skilled personnel shall be carried out under

the supervision of the person competent in the use of flammable

refrigerants.

⚠ CAUTION

Make sure the earthing pole of the socket is well grounded and the

power supply socket and plug are dry and connected securely.

Before cleaning, turn o the breaker or unplug the unit.

After prolonged use, inspect the unit's base and fittings for damage,

as it may sink and cause injury if damaged.

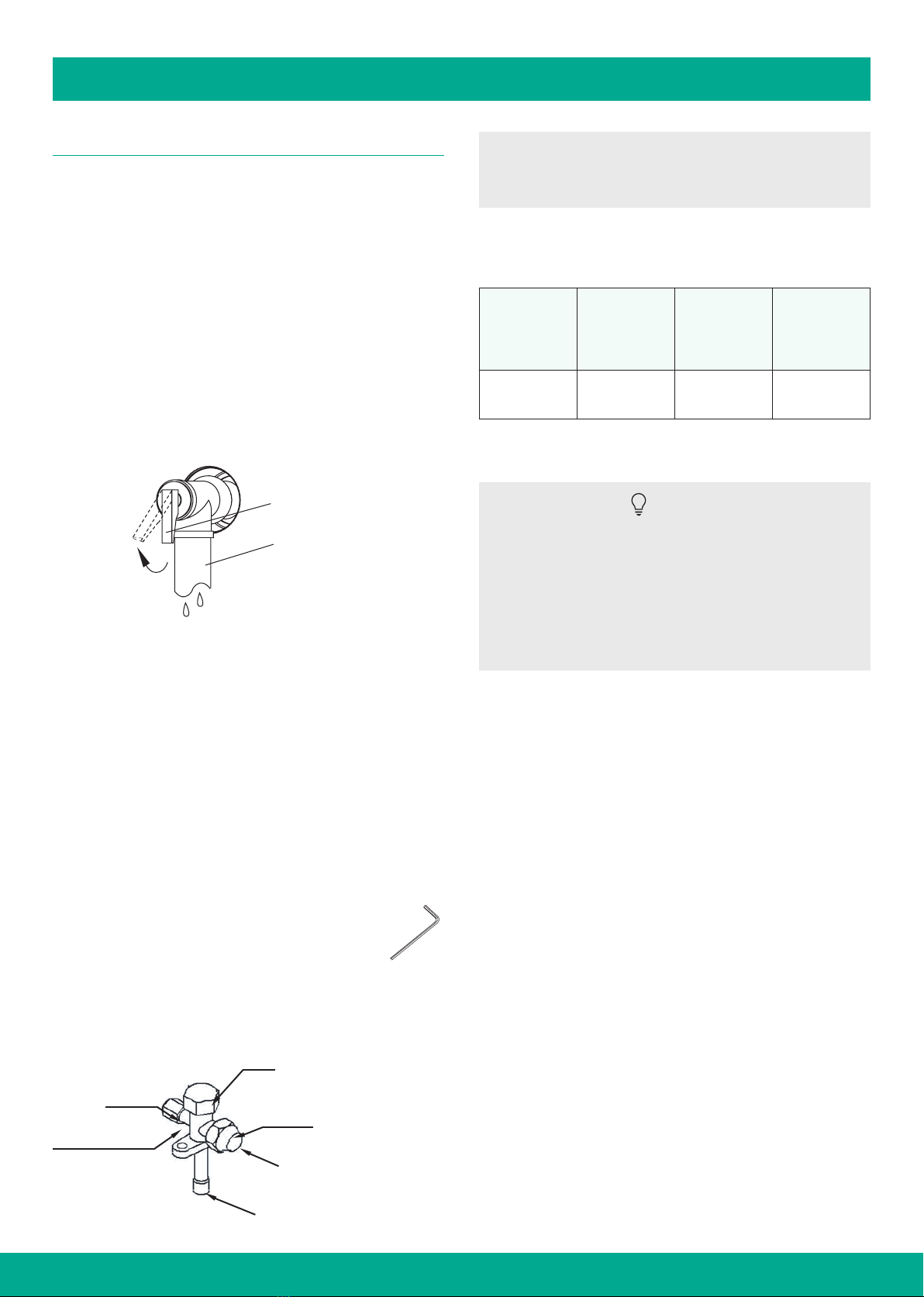

Ensure the drain pipe is properly arranged for smooth draining, as

improper drainage may result in building, furniture, and other items

getting wet.

The unit must be grounded with a resistance that complies with local

laws and regulations.

Do not connect the ground wire to gas or water pipes, lightning

conductors or telephone ground wires.

Incomplete grounding may cause electric shocks.

- Gas pipes: Fire or an explosion might occur if the gas leaks.

- Water pipes: Hard vinyl tubes are not eective grounds.

- Lightning conductors or telephone ground wires: Electrical

threshold may rise abnormally if struck by a lightning bolt.

The installation height of power supply should be over 1.8m, if there

is any water spattered, separate the power supply from water.

Do not wash the unit. This may cause electric shocks or fire.

The appliance must be installed in accordance with national wiring

regulations. If the supply cord is damaged, it must be replaced by a

qualified electrician.

Do not install the unit in the following places:

- Where there is mineral oil, oil spray (eg: kitchen) or vapors.

Plastic parts may deteriorate, and cause them to come loose

or water to leak.

- Where corrosive gases (such as sulfurous acid gas) are

produced. Where corrosion of copper pipes or soldered parts

may cause refrigerant to leak.

- Where there is machinery which emits electromagnetic waves.

Electromagnetic waves can disturb the control system and cause

equipment malfunction.

- Where flammable gases may leak, where carbon fiber or

ignitable dust is suspended in the air or where volatile flammables

such as paint thinner or gasoline are handled. These types of

gases might cause a fire.

- Where the air contains high levels of salt such as near the

ocean.

- Where voltage fluctuates a lot, such as in factories.

- In vehicles or vessels.

- Where acidic or alkaline vapors are present.

- Other special environments.