Emerson Network Power RDU-S User manual

RDU-S Rack Data Unit

User Manual

Version

V1.4

Revision date

December 13, 2011

BOM

31012350

Emerson Network Power provides customers with technical support. Users may contact

the nearest Emerson local sales office or service center.

Copyright © 2010 by Emerson Network Power Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Emerson Network Power Co., Ltd.

Address: No.1 Kefa Rd., Science & Industry Park, Nanshan District 518057, Shenzhen

China

Homepage: www.emersonnetworkpower.com.cn

E-mail: support@emersonnetwork.com.cn

Contents

Chapter 1 Overview ............................................................................................................................................................1

1.1 Product Introduction..............................................................................................................................................1

1.1.1 Appearance...............................................................................................................................................1

1.1.2 Indicators...................................................................................................................................................1

1.1.3 Ports..........................................................................................................................................................2

1.2 Technical Specifications .......................................................................................................................................3

1.2.1 Input Specifications ...................................................................................................................................3

1.2.2 Output Specifications.................................................................................................................................3

1.2.3 Ambient Specifications ..............................................................................................................................4

1.2.4 Mechanical Specifications .........................................................................................................................4

1.3 Options .................................................................................................................................................................4

Chapter 2 Installation ..........................................................................................................................................................5

2.1 Installation Preparation.........................................................................................................................................5

2.2 Installation Tool.....................................................................................................................................................5

2.3 Installing Data Unit................................................................................................................................................6

2.3.1 Installation Hole Position...........................................................................................................................6

2.3.2 Installing The Data Unit In A Standard 19” Rack .......................................................................................6

2.3.3 Installing The Data Unit On The Wall ........................................................................................................7

Chapter 3 Connection .........................................................................................................................................................8

3.1 Connection Notes .................................................................................................................................................8

3.2 Connecting Sensor Ports......................................................................................................................................8

3.2.1 Connecting 1-Wire Sensor Port.................................................................................................................8

3.2.2 Connecting DI1, DI2 And DI3 Ports...........................................................................................................9

3.2.3 Connecting IRM Sensor Port...................................................................................................................10

3.3 Connecting Serial Ports......................................................................................................................................11

3.4 Connecting Relay Ports......................................................................................................................................12

Chapter 4 Parameter Setting.............................................................................................................................................13

4.1 Connecting Data Unit With Computer.................................................................................................................13

4.2 Setting HyperTerminal........................................................................................................................................13

4.3 Powering On.......................................................................................................................................................14

4.3.1 Checking Before Powering On ................................................................................................................14

4.3.2 Checking After Powering On ...................................................................................................................14

4.4 Logging Onto Data Unit ......................................................................................................................................15

4.5 Setting IP Address..............................................................................................................................................15

4.6 Restarting Data Unit............................................................................................................................................16

Chapter 5 Software Operation...........................................................................................................................................17

5.1 Login...................................................................................................................................................................17

5.2 Monitor Interface Operation Description .............................................................................................................18

5.2.1 Environmental..........................................................................................................................................18

5.2.2 PDU.........................................................................................................................................................20

5.2.3 Camera....................................................................................................................................................25

5.3 Control Interface Operation Description..............................................................................................................27

5.4 Configure Interface Operation Description..........................................................................................................29

5.5 Events Interface Operation Description ..............................................................................................................39

5.6 History Interface Operation Description..............................................................................................................41

5.7 System Information Interface Operation Description...........................................................................................43

5.8 Logout.................................................................................................................................................................43

Chapter 6 Troubleshooting................................................................................................................................................44

Appendix 1 Command Lines.............................................................................................................................................45

1. Overview...............................................................................................................................................................45

2. Main Command Lines...........................................................................................................................................45

Chapter 1 Overview 1

RDU-S Rack Data Unit User Manual

Chapter 1 Overview

This chapter gives a brief introduction to the appearance, indicators, ports, technical specifications and options of

RDU-S rack data unit (data unit for short).

1.1 Product Introduction

The data unit is an intelligent acquisition system developed by Emerson to monitor the environment in rack and IDC

machine room. It is also suitable for other applications, such as small base station environment monitoring, power

equipment & environment monitoring in telecom machine room, power grid monitoring and bank ATM machine

monitoring. When configured with a proper sensor or proper sensors, it can detect corresponding electric signals and

non-electric signals in real time. The small profile design makes it suitable for installation in small space in the rack.

1.1.1 Appearance

The appearance of the data unit is shown in Figure 1-1.

100-a

InputDO212VGND

DO112VGND

USBUSB

MicroSD

USBCONFIG

ETH

DI1

DI2

DI3

COM1

DO1

DO2

ALARM

POWER

RUN

240V

TH_BUS

COM2

COM1

12

TH_BUS

COM2

Figure 1-1 Appearance

1.1.2 Indicators

The indicators are located on the front panel, as shown in Figure 1-2. Their descriptions are listed in Table 1-1.

100-a

InputDO212VGND

DO112VGND

USBUSB

MicroSD

USBCONFIG

ETH

DI1

DI2

DI3

COM1

DO1

DO2

ALARM

POWER

RUN

240V

TH_BUS

COM2

COM1

12

TH_BUS

COM2

ALARM

POWER

DO1

DO2RUN

Indicators

Power indicator Alarm indicator

Relay output indicators

Running indicator

Amplified figure of indicators

COM1

COM2

TH_BUS

TH_BUS communication indicator

Serial port indicators

Figure 1-2 Indicator position

2 Chapter 1 Overview

RDU-S Rack Data Unit User Manual

Table 1-1 Indicator descriptions

Silkscreen

Definition

Color

Status

Descriptions

DO1, DO2

Relay output indicators

Yellow

On

The relay is closed

Off

The relay is open

POWER

Power indicator

Green

On

The data unit is powered on normally

Off

The data unit is not powered on

ALARM

Alarm indicator

Red

On

The data unit has an critical alarm

Blinking

The data unit has an warning alarm

Off

The data unit is starting up or normal

RUN

Running indicator

Green

Blinking

The data unit is operating normally

Off

The data unit is starting up

TH_BUS

TH_BUS communication

indicator

Green

Blinking

The data unit is receiving or sending data

Off

The data unit is not receiving or sending data

COM1, COM2

S

erial port indicators

Green

Blinking

The serial port is receiving or transmitting data

Off

The serial port is not receiving or transmitting data

1.1.3 Ports

The ports of the data unit are located on the front panel, as shown in Figure 1-3.

100-a

InputDO212VGND

DO112VGND

USBUSB

MicroSD

USBCONFIG

ETH

DI1

DI2

DI3

COM1

DO1

DO2

ALARM

POWER

RUN

240V

TH_BUS

COM2

COM1

12

TH_BUS

COM2

DI1 port

Amplified figure of RJ45 ports

DI1DI3

COM1

DI2TH_BUS

COM2

RJ45 ports

Power input port 12Vdc power

ground port

Relay ports USB ports USB CONFIG port

Ethernet port

Micro SD

card slot

12Vdc power

output port

DI2 port

DI3 port 1-wire sensor port

1-wire sensor port

Serial ports

IRM sensor port

Figure 1-3 Port position

The definitions, functions and features of the ports are listed in Table 1-2.

Table 1-2 Port descriptions

Silkscreen

Port

Functions and features

100

-240V ~

Input

Power input port

Adopt power socket to feed power to the data unit. The power input

range is 100Vac ~ 240Vac

DO1, DO2

Relay ports

Output relay status

12V

12Vdc power output port

Feed power to external sensor (12Vdc power)

GND

12Vdc power ground port

12Vdc power ground

Micro SD

Micro SD card slot*

Support 2G, 4G or 8G Micro SD card to store video information and

configuration file

USB1, USB2

USB ports

Provide two A type ports of 2.0 standard; capable of recognizing

standard U disk, getting USB camera image and connecting GPRS

Modem

USB CONFIG

USB CONFIG port

Display the current IP and restore the default password

Chapter 1 Overview 3

RDU-S Rack Data Unit User Manual

Silkscreen

Port

Functions and features

ETH

Ethernet port (RJ45 port)

10M/100M, half/full-duplex self-adaptive; cable auto-crossing function;

supportive of IEEE802.3 protocol

DI1, DI2, DI3

DI1, DI2, DI3 ports (RJ45 ports)

Connect to digital sensors. Each port can connect up to four digital

sensors

TH_BUS

IRM sensor port (RJ45 port)

Connect to IRM series temperature sensor, temperature & humidity

sensor

COM1, COM2

Serial ports (RJ45 ports)

COM1 serial port is compatible with RS485, RS422 and RS232

communication modes; COM2 serial port is compatible with RS485 and

RS232 communication modes

1-wire sensor port (RJ45 port)

Connect to 1-wire sensor

Note*: After unplugging and plugging the Micro SD card, the data unit must be restarted to read the data

Except for the Ethernet port, the pin definitions of the RJ45 ports are listed in Table 1-3.

Table 1-3 Pin definitions of RJ45 ports

Pin No.

RJ45 ports

(1-wire)

DI1, DI2, DI3

TH_BUS

COM1

COM2

1

VCC (5Vdc)

12Vdc

12Vdc

R+

NC

2

1-wire signal

NC

NC

R-

NC

3

NC

D1

NC

TXD

TXD

4

NC

GND

GND

GND

GND

5

NC

GND

NC

GND

GND

6

NC

D2

NC

RXD

RXD

7

NC

D3

D+

T+/D+

D+

8

GND

D4

D-

T-/D-

D-

1.2 Technical Specifications

1.2.1 Input Specifications

The input specifications of the data unit are listed in Table 1-4.

Table 1-4 Input specifications

Input parameters

Corresponding port

Measurement accuracy

Descriptions

1

-wire

sensor

input

1

-wire

signal

1

-wire

sensor port

The

final accuracy is

determined by the used

sensor

Capable of measuring temperature and

humidity.

The 1-wire sensor can also be

connected with the digital signal from water

sensor, door magnet sensor, and so on

D

igital signal input

DI1, DI2, DI3 ports

-

Capable of measuring the digital signal

from door magnet sensor, smoke sensor

and infrared sensor

PDU input

Serial ports

-

Capable of connecting Switched PDU,

Metered PDU and Mps PDU

IRM sensor input

IRM sensor port

The final accuracy is

determined by the used

sensor

C

apable of measuring temperature and

humidity

1.2.2 Output Specifications

The output specifications of the data unit are listed in Table 1-5.

Table 1-5 Output specifications

Output parameters

Specification

Descriptions

Relay output

Route number

Two routes

S

upportive of two triggering m

odes: level mode

and pulse mode

Output contact

Relay normally open contact output

Contact capacity

5A/24Vdc; 5A/220Vac

4 Chapter 1 Overview

RDU-S Rack Data Unit User Manual

Output parameters

Specification

Descriptions

Sensor power

output

12Vdc output

11.5Vdc ~ 12.5Vdc, maximum output

current: 0.8A

The output current is the total current which the

sensor power can provide.

The total power

consumption of 12Vdc power

does not exceed

10W

USB port output

Maximum output current: 500mA

-

1.2.3 Ambient Specifications

The ambient specifications of the data unit are listed in Table 1-6.

Table 1-6 Ambient specifications

Item

Requirement

Application location

Indoor

Working temperature*

0ºC ~ 45ºC

Relative humidity

5%RH ~ 95%RH (non-condensing)

Working environment

Dust: compliant with GR-63 indoor standard. No corrosive gas, flammable gas, oily mist, steam,

water drops or salt

Air pressure

70kPa ~ 106kPa

Storage temperature

-40ºC ~ +70ºC

Cooling

Natural cooling

Note*: It is the working temperature of the data unit, not including the sensors connected with it. Make sure that the used sensors

will not be damaged within the temperature range

1.2.4 Mechanical Specifications

The mechanical specifications of the data unit are listed in Table 1-7.

Table 1-7 Mechanical specifications

Dimensions (L × W × H)

Weight

440mm × 44.2mm × 55mm

≤1.5kg

1.3 Options

The options of the data unit are listed in Table 1-8.

Table 1-8 Options

Classification

Optional model

D

igital sensors

1. ER-ST01P infrared sensor (RJ45 port)

2. EE

-SD01S smoke sensor (RJ45 port)

3. ER

-DR02J door magnet sensor (RJ45 port)

4. EW

-WT01B water sensor (RJ45 port)

5.

IRM-S01W (5m, 10m) water sensor(RJ45 port)

6

. SN-TH temperature & humidity sensor (RJ45 port)

7

. SN-2D door dry contact sensor (RJ45 port)

8

. SN-3C dry contact sensor (RJ45 port)

9

. IRM-S01T intelligent temperature sensor (RJ45 port)

10

. IRM-S02TH intelligent temperature/humidity sensor (RJ45 port)

11. SN-L leak detection sensor (RJ45 port)

Relay connectors

1. SL79LED stroboscopic alarm (two cables, non-RJ45 port)

2. HX-F8502 acousto-optic alarm (two cables, non-RJ45 port)

C

ameras

1. KS-188 USB camera

2. ICAM-01 camera (with PTZ control)

Installation options of sensors

1. IDS-08 5cm simple installation support

2. Mushroom head magic paste

3. 16mm gummed magic paste

4. CT3Y 3cm

round magnet

5. RJ45 three-way connector

Chapter 2 Installation 5

RDU-S Rack Data Unit User Manual

Chapter 2 Installation

This chapter expounds the installation preparation, installation tools and installation method of the data unit.

2.1 Installation Preparation

Notes

To avoid personnel injury and damage to the device in installation and use of the data unit, take the following

precautions:

zNever put the data unit in watery places and always prevent liquid from entering the data unit.

zIn installation and connection, wear anti-static clothing and an anti-static wrist strap; if anti-static clothing and

anti-static wrist strap are not available, wash your hands instead and dry them before installation and

connection.

zArrange the wires properly. Do not put any heavy objects on the wires or stamp the wires.

zGround the data unit properly.

zAlways cut off the power before performing any hardware operation.

Operating environment

The data unit must be installed indoors. The temperature and humidity should meet the product specifications (see

Table 1-6).

EMI

For EMI purpose, take the following measures:

zDo not connect the working ground of the data unit to ground of electrical power equipment or lightning ground.

Instead, place them away from each other as far as possible.

zKeep the data unit away from large-power radio transmitters, radar transmitters and high-frequency large current

electrical equipment.

zTake electromagnetic shielding measures if necessary.

Heat dissipation

The heat dissipation requirements of the data unit are given as follows:

zKeep the data unit as far as possible from heat sources.

zKeep at least 10mm clearances around the data unit for adequate heat dissipation.

2.2 Installation Tool

The installation tools of the data unit are listed in Table 2-1.

Table 2-1 Installation tools

Tool

Specification

Tool

Specification

Crimping pliers for network cable

Standard

Slotted screwdriver

100mm, 200mm

Electrician diagonal cutting pliers

150mm

Wire cutter

Maximum 300mm2

Electrician long nose pliers

150mm

Digital multimeter

Three and a half digit

Crossed screwdriver

100mm, 200mm

Drill

With a Φ6aiguille

6 Chapter 2 Installation

RDU-S Rack Data Unit User Manual

2.3 Installing Data Unit

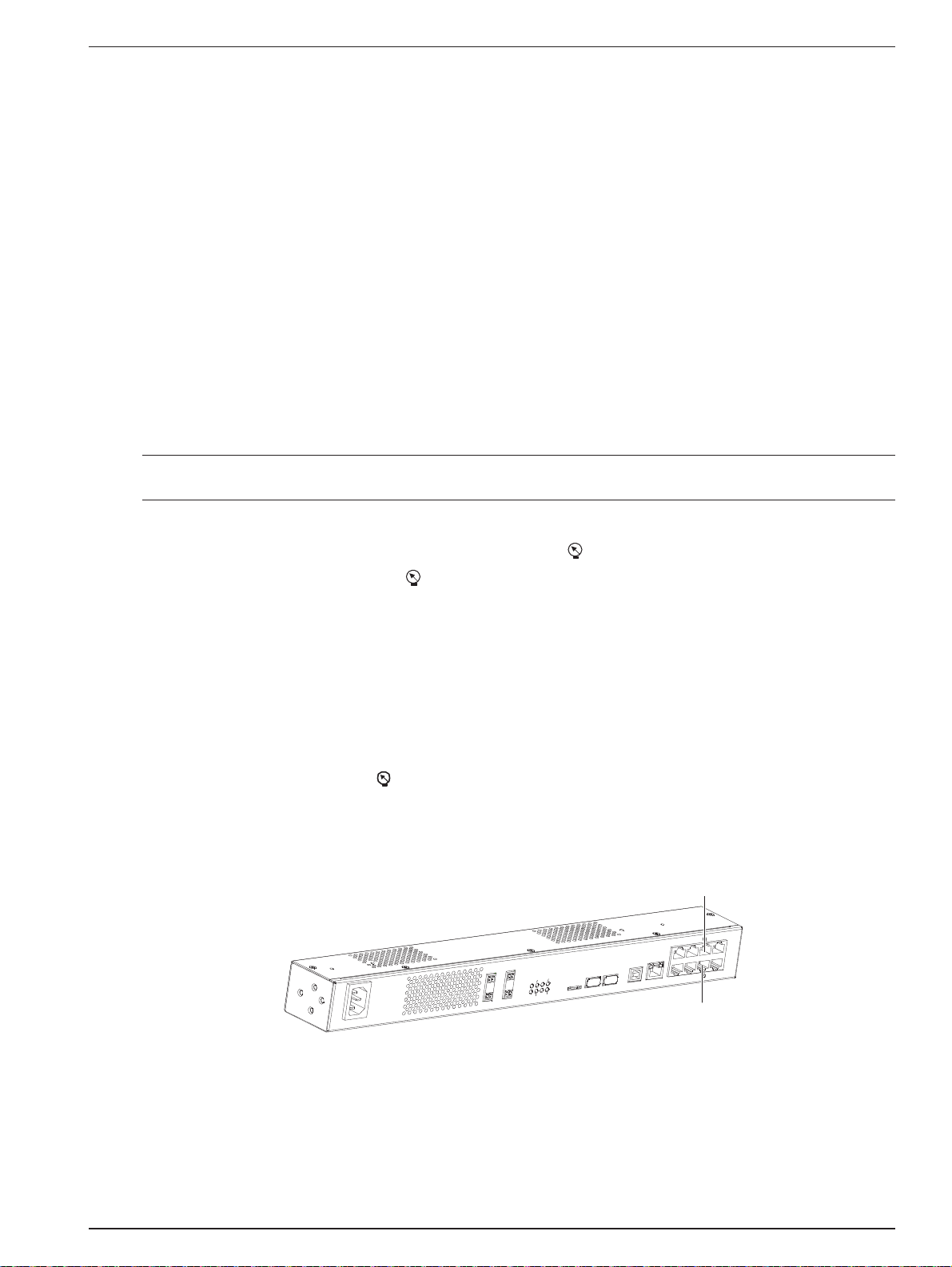

The data unit can be installed in a standard 19”rack through hangers (accessories) or a round hanger (accessory). It

can also be mounted on the wall through hangers.

2.3.1 Installation Hole Position

The hangers are installed on the side panels and the round hanger is installed on the back panel or top panel. The

installation holes on the panels are shown in Figure 2-1.

1

2

356

4

7

89

10

Top panel

Back panel

Left panel

Figure 2-1 Positions of installation holes

The installation holes ķand ĸ(also two installation holes on the right panel) are used for installing the hangers

and the installation holes Ĺ~ ŀare used for installing the round hanger.

2.3.2 Installing The Data Unit In A Standard 19”Rack

Installing the data unit through hangers

1. Fasten two hangers respectively to both sides of the data unit with M3 screws, as shown in Figure 2-2.

ᆹ㻵ᆄ

ᤲ㙣

Installation hole

Hanger

Figure 2-2 Installing hangers (rack mounting)

The completed status is shown in Figure 2-3.

Hanger Hanger

Processing unit

Fixing hole

(4 pcs)

Figure 2-3 Completed status figure

2. Put the data unit onto the guide rails in the rack and push it into the rack completely.

3. Wrench M6 screws into the fixing holes (see Figure 2-3) of the hangers to fasten the data unit onto the rack.

Chapter 2 Installation 7

RDU-S Rack Data Unit User Manual

Installing the data unit through a round hanger

1. Fasten the round hanger onto the top panel or back panel of the data unit with an M3 screw, as shown in

Figure 2-4.

ᆹ㻵ᆄ

ശᤲ㙣

ᮠᦞঅݳ

Installation hole

Round hanger

Processing unit

Figure 2-4 Installing round hanger

2. Hang the data unit onto the vertical pole in the rack through the round hanger.

2.3.3 Installing The Data Unit On The Wall

1. Fasten two hangers respectively to both sides of the data unit with M3 screws, as shown in Figure 2-5.

Note

The installation direction of the hangers in wall mounting mode is opposite to that in rack mounting mode.

ᤲ㙣

ᆹ㻵ᆄ

Hanger

Installation hole

Figure 2-5 Installing hanger (wall mounting)

2. Use a drill (aiguille: Φ6) to drill four holes (depth: 70mm) on the wall according to the dimensions in Figure 2-6 and

knock four plastic expansion pipes into the holes.

45.8

31.3

Figure 2-6 Hole dimensions (unit: mm)

3. Put the data unit in the position, and wrench self-tapping screws into the plastic expansion pipes through the fixing

holes of the hangers to fix the data unit on the wall.

8 Chapter 3 Connection

RDU-S Rack Data Unit User Manual

Chapter 3 Connection

This chapter expounds the connection of the data unit, including connection notes, and connecting the sensor ports,

serial ports, relay port and multiple signals of RJ45 ports.

3.1 Connection Notes

The connection notes are given as follows:

1. The power and external signals that are connected to the data unit must be SELV circuits. The isolation and

insulation must be enhanced between them and the power grid.

2. When making RJ45 port cables, pay attention to the pin definitions to avoid wrong connection. For the pin

definitions, refer to Table 1-3 and the pin definition figures of the RJ45 ports in this chapter.

3.2 Connecting Sensor Ports

Note

Refer to the corresponding sensor instructions to carry out the installation and wiring operation.

Before sent to the data unit, the site signals should be transformed into electrical signals by sensors. The data unit

provides six sensor ports (silkscreen: DI1, DI2, DI3, TH_BUS and ) to connect the sensors.

zThe 1-wire sensor port (silkscreen: ) is supportive of 1-wire sensor.

zThe DI1, DI2 and DI3 ports are supportive of digital sensors, including infrared sensor, water sensor, door

magnet sensor, smoke sensor, and so on.

zThe IRM sensor port (silkscreen: TH_BUS) is supportive of IRM series sensor, including temperature sensor and

temperature & humidity sensor.

If the used sensor needs 12Vdc power, the 12Vdc power output port (see Figure 1-3) of the data unit can be used.

3.2.1 Connecting 1-Wire Sensor Port

The 1-wire sensor port (silkscreen: ) is used to connect the SN-TH temperature & humidity sensor, SN-2D door

dry contact sensor, SN-3C dry contact sensor or SN-L leak detection sensor.

Port position

The positions of the 1-wire sensor ports are shown in Figure 3-1.

DO212VGND

DO112VGND

USBUSB

MicroSD

USBCONFIG

ETH

DI1

DI2

DI3

COM1

DO1

DO2

ALARM

POWER

RUNTH_BUS

COM2

COM1

12

TH_BUS

COM2

1-wire sensor port

1-wire sensor port

100-240V~

Input

Figure 3-1 Positions of 1-wire sensor ports

Pin definition

The pin definition of the 1-wire sensor port is described in Figure 3-2.

Chapter 3 Connection 9

RDU-S Rack Data Unit User Manual

12345678

2: 1-wire signal

3: NC

4: NC

Pin definition

1: VCC (5Vdc) 5: NC

6: NC

7: NC

8: GND

Figure 3-2 Pin definition of 1-wire sensor port

Connection method

Use a standard network cable with RJ45 connectors on both ends, insert one end into the 1-wire sensor port, and

insert the other end into the RJ45 port of SN-TH temperature & humidity sensor, SN-2D door dry contact sensor,

SN-3C dry contact sensor or SN-L leak detection sensor.

3.2.2 Connecting DI1, DI2 And DI3 Ports

The DI1, DI2 and DI3 ports are used to connect the digital sensors.

Port position

The positions of the DI1, DI2 and DI3 ports are shown in Figure 3-3.

DO212VGND

DO112VGND

USBUSB

MicroSD

USBCONFIG

ETH

DI1

DI2

DI3

COM1

DO1

DO2

ALARM

POWER

RUNTH_BUS

COM2

COM1

12

TH_BUS

COM2

DI1 port

DI2 port

DI3 port

100-240V~

Input

Figure 3-3 Positions of DI1, DI2 and DI3 ports

Pin definition

The pin definition of the DI1, DI2 and DI3 ports is shown in Figure 3-4.

12345678

2: NC

3: D1 (smoke sensor)

4: GND

Pin definition

1: 12Vdc 5: GND

6: D2 (door magnet sensor)

7: D3 (water sensor)

8: D4 (infrared sensor)

Figure 3-4 Pin definition of DI1, DI2 and DI3 ports

Connection method

Note

1. It is recommended to use the auxiliary sensors shown in Figure 3-5. If you want to connect other types of sensors, make the

connection cables according to the port pin definition in Figure 3-4 and then connect them.

2. Both vibration sensor and water sensor use D3 channel. If the vibration sensor is selected, it cannot share the same digital

sensor port with the water sensor.

3. The line sequence (see Figure 3-4 for detailed definition) of the DI1, DI2 and DI3 ports is fixed. The types of the sensors

connected to a port cannot be the same.

If the digital sensor (with a connection cable in factory) recommended by Emerson is connected, insert the RJ45

connector of the connection cable into the DI1, DI2 or DI3 port.

The recommended sensors are shown in Figure 3-5.

10 Chapter 3 Connection

RDU-S Rack Data Unit User Manual

EE-SD01S smoke sensor

ER-DR02J door magnet sensor

IRM-S01W water sensor

ER-ST01P infrared sensor

Figure 3-5 Recommended sensors

Connecting multiple signals of RJ45 ports

DI1, DI2 and DI3 ports can be connected with multiple signals simultaneously.

When a port is connected to multiple signals, RJ45 three-way connectors (optional) are required for transferring

according to the signal amount. Use standard straight network cables to cascade-connect the signals in daisy chain

mode and then connect them with the corresponding port. Figure 3-6 indicates the connection method that DI1 port is

connected with infrared sensor, door magnet sensor and smoke sensor.

ᮠᆇՐᝏಘ᧕

㖁㓯

䘎᧕㓒ཆՐᝏಘ

㖁㓯

й䙊 й䙊

䘎᧕䰘⻱Րᝏಘ

䘎᧕✏ᝏՐᝏಘ

DI1 port RJ45 three-way connector RJ45 three-way connector

Network

cable Network

cable Connecting smoke sensor

Connecting door magnet sensor

Connecting infrared sensor

Figure 3-6 Connecting multiple sensors

When a port is connected with multiple signals simultaneously, you must note that the line sequence conflict of the

signals cannot occur. For example, the DI1 port can be connected with four sensors simultaneously. The

recommended sensors include smoke sensor, door magnet sensor, water sensor and infrared sensor. If the DI1 port

is connected with vibration sensor and water sensor simultaneously, signal conflict will occur, resulting in signal

acquisition failure, because both sensors use the DI3 channel.

3.2.3 Connecting IRM Sensor Port

The IRM sensor port (silkscreen: TH_BUS) is used to connect the IRM series temperature sensor and temperature &

humidity sensor.

Note

The address range of the IRM series temperature sensor and temperature & humidity sensor is 10, 11, 12, 13, 20, 21, 22 and 23;

besides the above addresses, the address range of the IRM series temperature sensor also includes 30, 31, 32, 33, 40, 41, 42 and

43.

Port position

The position of the IRM sensor port is shown in Figure 3-7.

Chapter 3 Connection 11

RDU-S Rack Data Unit User Manual

DO212VGND

DO112VGND

USBUSB

MicroSD

USBCONFIG

ETH

DI1

DI2

DI3

COM1

DO1

DO2

ALARM

POWER

RUNTH_BUS

COM2

COM1

12

TH_BUS

COM2

IRM sensor port

100-240V~

Input

Figure 3-7 Position of IRM sensor port

Pin definition

The pin definition of the IRM sensor port is shown in Figure 3-8.

12345678

1: 12Vdc

2: NC 5: NC

Pin dfinition

3: NC

4: GND

6: NC

7: D+

8: D-

Figure 3-8 Pin definition of IRM sensor port

Connection method

Use a standard network cable with RJ45 connectors on both ends, insert one end into the IRM sensor port, and insert

the other end into the RJ45 port of IRM series temperature sensor or temperature & humidity sensor.

3.3 Connecting Serial Ports

The serial ports (silkscreen: COM1, COM2) are used to connect Emerson serial PDU.

Port position

The positions of the serial ports are shown in Figure 3-9.

DO212VGND

DO112VGND

USBUSB

MicroSD

USBCONFIG

ETH

DI1

DI2

DI3

COM1

DO1

DO2

ALARM

POWER

RUNTH_BUS

COM2

COM1

12

TH_BUS

COM2

Serial ports

100-240V~

Input

Figure 3-9 Positions of serial ports

Pin definition

The pin definitions of the serial ports are shown in Figure 3-10.

12345678

1: R+

2: R- 5: GND

Pin dfinition

3: TXD

4: GND

6: RXD

7: T+/D+

8: T-/D-

12345678

1: NC

2: NC 5: GND

Pin dfinition

3: TXD

4: GND

6: RXD

7: D+

8: D-

COM1 COM2

Figure 3-10 Pin definitions of serial ports

Connection method

When Emerson serial PDU is required to be monitored by the data unit, use standard Cat5 cable to connect the

RS485 port of PDU with the serial port of the data unit. If multiple PDUs need to be monitored, use standard Cat5

cable to connect the Link port of the upper PDU with the RS485 port of the lower PDU in daisy chain mode, as shown

in Figure 3-11.

12 Chapter 3 Connection

RDU-S Rack Data Unit User Manual

100-240V~

Input

DO1

DO2 12V GND

12V GND

DO1

DO2

ALARM

TH_BUS

POWER

RUN COM2

COM1

Micro SD USB1 USB2 USB CONFIG ETH D12

D11 D13

TH_BUS

COM1

COM2

ĂĂ

Connecting to the RS485 port of lower PDU

Connecting to the Link port of upper PDU

At most eight PDUs can be connected.

PDU1

PDU2

PDU8

Data unit

RS485 port

Link port

Figure 3-11 Connecting the data unit and the PDUs

Note

At most eight Emerson serial PDUs can be monitored by the data unit through the serial ports (COM1 and/or COM2).

3.4 Connecting Relay Ports

Port position

The positions of the relay ports are shown in Figure 3-12.

DO212VGND

DO112VGND

USBUSB

MicroSD

USBCONFIG

ETH

DI1

DI2

DI3

COM1

DO1

DO2

ALARM

POWER

RUNTH_BUS

COM2

COM1

12

TH_BUS

COM2

Relay ports

100-240V~

Input

Figure 3-12 Positions of relay ports

Connection method

When the relay output specification reaches 5A/24Vdc, connect the required cables with the relay ports (silkscreen:

DO1, DO2). The relay of the data unit is normally open passive dry contact. Properly arrange the wiring according to

the site conditions.

Note

Pay attention to the port silkscreen before connection to avoid the wrong connection. Otherwise, the device may be damaged.

Chapter 4 Parameter Setting 13

RDU-S Rack Data Unit User Manual

Chapter 4 Parameter Setting

This chapter introduces the parameter setting, including connecting data unit with computer, setting HyperTerminal,

powering on, logging onto data unit, setting IP address and restarting data unit.

4.1 Connecting Data Unit With Computer

A computer is a must for commissioning the data unit. Therefore, before commissioning the data unit, connect the

data unit with the computer using a standard network cable and set the communication parameters through the

computer.

4.2 Setting HyperTerminal

This section takes Windows XP as an example to illustrate how to set HyperTerminal.

After the network cable is connected, set the HyperTerminal according to the following procedures:

1. Click Start -> Programs -> Accessories -> Communications -> HyperTerminal, and the HyperTerminal

interface pops up, as shown in Figure 4-1.

Figure 4-1 Connection description interface

2. Type the name ‘RDU-S’in the Name field and click OK, as shown in Figure 4-2.

-s

Figure 4-2 Connect to interface 1

14 Chapter 4 Parameter Setting

RDU-S Rack Data Unit User Manual

3. Select ‘TCP/IP (Winsock)’ in the Connect using field, as shown in Figure 4-3.

Figure 4-3 Connect to interface 2

4. As shown in Figure 4-3, type the host address (factory default IP: 192.168.0.10) and port number, and click OK to

complete the HyperTerminal setting.

4.3 Powering On

After the communication cable connection between the data unit and the computer, and the HyperTerminal setting are

completed, you can power on the data unit.

4.3.1 Checking Before Powering On

Ensure the following items before powering on the data unit:

1. The power cable and communication cable are connected properly.

2. The power supply voltage meets the device requirement.

3. The HyperTerminal setting is completed.

Note

Before powering on the device, confirm the location of the power input port (see Figure 1-3) to make sure that the power can be

cut off in time in case of an accident.

4.3.2 Checking After Powering On

Insert the power cable to power on the data unit and check that:

1. The indicators (see Figure 1-2) of the data unit are working normally.

See Table 1-1 for the descriptions of the indicators during normal operation. If the indicators work abnormally, check

the cable connection and the working status of the base site to which the data unit is connected.

2. The information displayed on the HyperTerminal is normal.

If no information is displayed, check that the connection between the data unit and the computer, and HyperTerminal

settings are correct.

You can log onto the data unit through the HyperTerminal after the above checks.

Chapter 4 Parameter Setting 15

RDU-S Rack Data Unit User Manual

4.4 Logging Onto Data Unit

The logging procedure is shown in the following figure.

The detailed procedures are given as follows:

1. Power on the data unit.After it starts up normally, the HyperTerminal will display RDU-S login:.

2. Type the user name ‘rduadmin’and press the Enter key, and the HyperTerminal will prompt Password:.

3. Type the password ‘rduadmin’following Password:, and the HyperTerminal will display the command prompt

RDU_admin#.

Note

Both the user name and the password are case-sensitive.

4.5 Setting IP Address

After logging onto the command line, use the command ‘setip’first to set the IP address of the data unit. The detailed

setting procedures are given as follows:

1. Type ‘setip’following the command prompt RDU_admin# and press the Enter key, as shown in the following

figure.

2. Respectively type the new IP address, sub_net mask and default gateway in Please input IP_address, Please

input Subnet_mask and Please input Default_gateway.

3. Type ‘Y’or ‘N’under Y/N [N] according to the system prompt.

Typing ‘N’will cancel the settings. Typing ‘Y’will confirm that the network parameters are set successfully, then the

system will prompt whether to save these network parameters.

16 Chapter 4 Parameter Setting

RDU-S Rack Data Unit User Manual

Note

After the network parameters are set, the system will prompt whether to save them. If ‘Y’is typed, the system will maintain the

network parameters and reboot automatically; otherwise, the system will retrieve the factory default IP address after 5 minutes.

4.6 Restarting Data Unit

Use the command ‘reboot’to restart the data unit after all parameters are set. The detailed procedures are given as

follows:

1. Type ‘reboot’following the command prompt RDU_admin# and press the Enter key, as shown in the following

figure.

2. Type 'Y’or ’N’according to the system prompt.

Typing ‘Y’will restart the data unit; typing ‘N’will cancel the restarting operation.

Table of contents

Popular Network Hardware manuals by other brands

NCR

NCR Invenco 6009-0008-8801 installation guide

Idis

Idis DR-6308P-S installation manual

Cisco

Cisco Remote PHY Shelf 7200 Software configuration guide and command reference

StorageTek

StorageTek FLEXLINE 96126 installation instructions

Idis

Idis DR-8432 installation manual

TCL

TCL LIFE CONNECT quick start guide

F5

F5 i15000 Series Setting up

EnvirPro

EnvirPro NSH-4242 Operation manual

Cabletron Systems

Cabletron Systems BRIM-A6DP user guide

Keysight

Keysight ixia BreakingPoint Storm installation guide

Draytek

Draytek Vigor2866ac quick start guide

Lucent Technologies

Lucent Technologies Stinger Installation and configuration guide