Contents

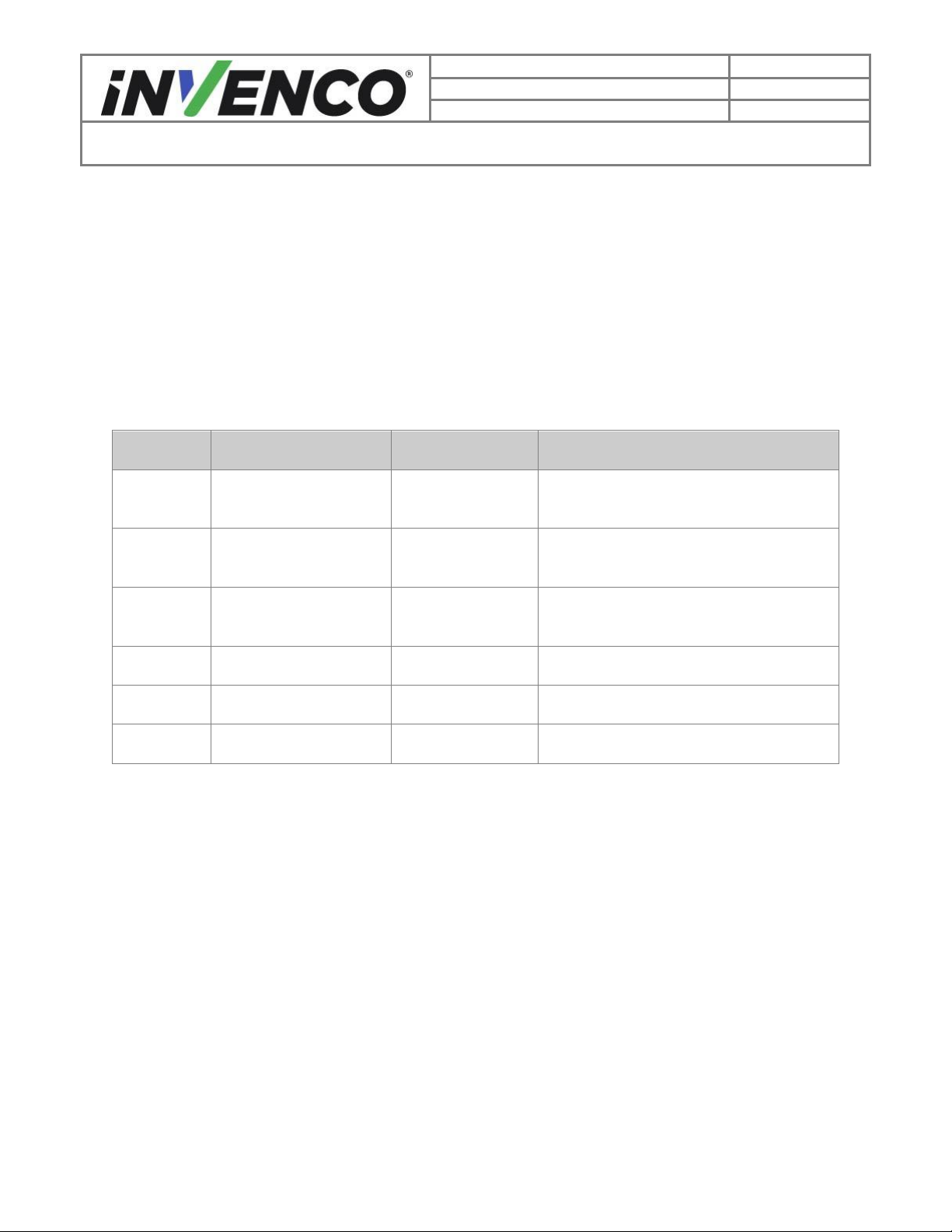

Release History.....................................................................................................................2

1 Introduction....................................................................................................................4

1.1 Tools Required .......................................................................................................4

1.2 Installation Kit Contents ..........................................................................................5

2 Safety & Compliance Information...................................................................................6

2.1 Preliminary Precautions..........................................................................................6

2.2 Emergency Total Electrical Shut-Off .......................................................................6

2.3 Total Electrical Shut-Off Before Access ..................................................................6

2.4 Evacuation, Barricading and Shut-Off.....................................................................6

2.5 Read the Manual ....................................................................................................6

2.6 Follow the Regulations............................................................................................7

2.7 Replacement Parts .................................................................................................7

3 Safety Symbols and Terminology...................................................................................7

3.1 Prevent Explosions and Fires .................................................................................7

3.1.1 No Open Flames..............................................................................................8

3.1.2 No Sparks - No Smoking .................................................................................8

3.1.3 Working Alone .................................................................................................8

3.1.4 Working with Electricity Safety.........................................................................8

3.1.5 Hazardous Materials........................................................................................8

3.1.6 In an Emergency..............................................................................................8

3.1.7 Approvals.........................................................................................................9

3.1.8 Laser Warning .................................................................................................9

3.2 Computer Programs and Documentation................................................................9

4 Disassembly Procedure...............................................................................................10

5 Pre-Installation Procedure............................................................................................40

6 Installation Procedure..................................................................................................41

6.1 Wiring Completion.................................................................................................58

7 First Power-Up.............................................................................................................59