4

Disclaimer

Thank you for purchasing the ZXV condensing unit from

Emerson. ZX platform CDUs are the best in class within the

capacity and operating range available in the market. ZX CDU

is designed to operate reliably and to deliver high operating

efficiencies in medium and low temperature refrigeration

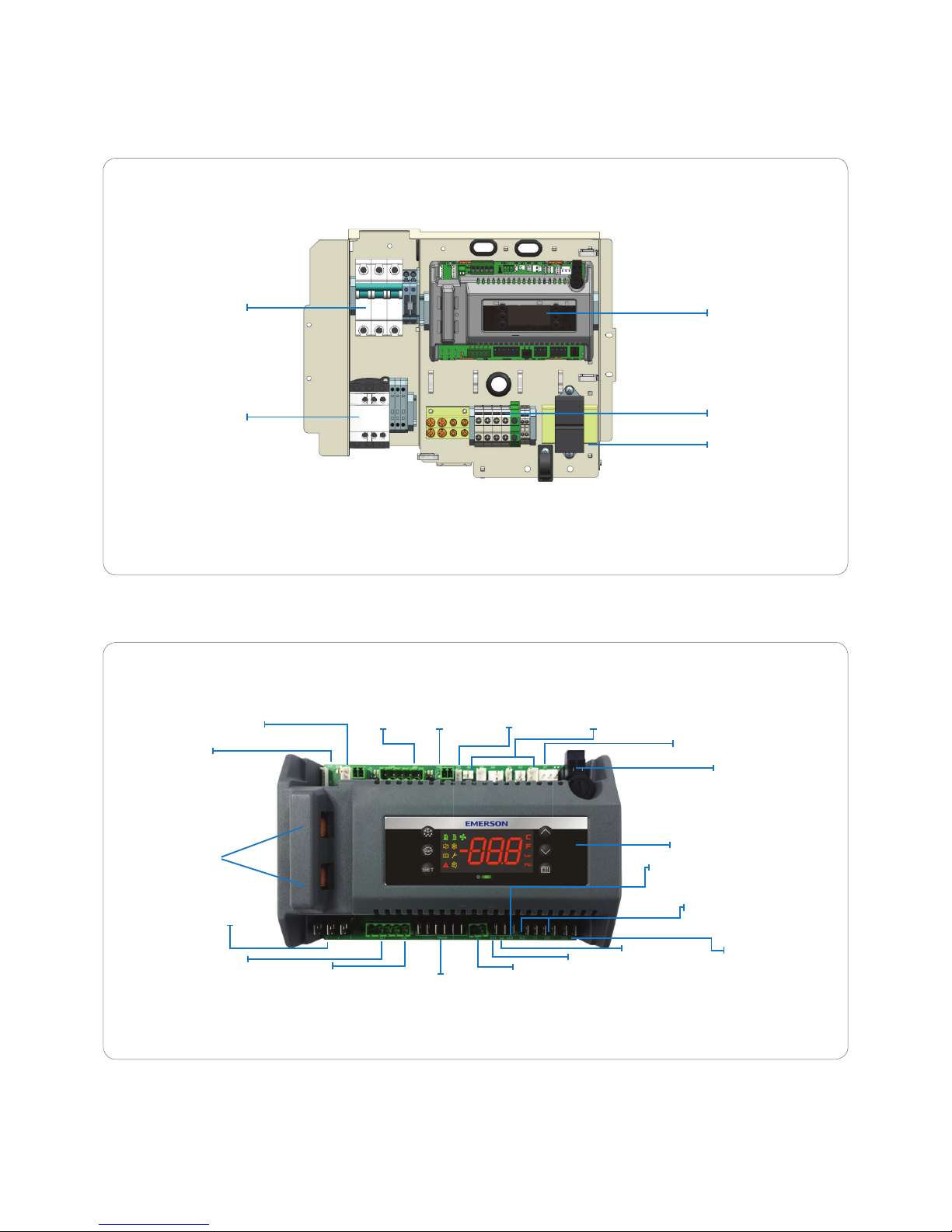

applications. It also provides constant monitoring of the

compressor operating conditions and displays the running

or fault conditions of the CDU. ZX platform CDUs have to be

installed by following the industry trade practices for its safe

and reliable operation. It is assumed that the CDU is selected,

installed and serviced only by professionals. The user manual

does not cover good industry practices which are essential on

a refrigeration equipment installation. No responsibility can be

accepted for damage caused by inexperienced or inadequately

trained site technicians or improper installation design.

If in doubt, please consult your local sales office, quoting unit

model and serial number as shown on each unit nameplate. In

case of any ambiguity, the wiring diagram supplied with each

unit takes precedence over the diagram in this manual.

Introduction to ZX platform CDU

ZX and ZXB medium temperature, ZXL low temperature, ZXD/

ZXLD digital modulated capacity medium temperature and low

temperature, ZXV/ZXLV variable speed medium temperature

and low temperature series have been highly successful in the

Asian market and enjoys proven success with its energy savings

and customer-friendly electronic features. ZX platform CDUs

have been applied by several well-known end-users and chain

retailers throughout Asia. The ZX platform is also gaining wider

acceptance in the global market and specific variants have been

developed and exported to the US, European and Middle East

markets.

Receiving your unit

All units are shipped with a holding charge of dry nitrogen

inside at a low but positive pressure. Suitable labeling is

prominently displayed on both the unit and the packaging.

Service connectors are provided on the CDU service valve for

the convenient checking of the integrity of the holding charge.

Caution! It is very important to check that this holding

pressure exists at the time you receive each unit from us or our

authorized representatives. Please inform us or our authorized

representative if the holding charge is non-existent. Failure to do

so could void the claim for other related system faults at a later

period.

Transit damage is essentially an insurance claim and is not covered

under manufacturing defect. It is also advisable to inspect the

rest of the unit for obvious physical damage and inform us or our

authorized representative in case any is discovered.

ZX platform condensing unit was designed based

on three factors demanded by industry users

Intelligent Store™solution - A most innovative approach

to enterprise facility management, Intelligent Store by Emerson

architecture integrates hardware and services, to provide

retailers a single view into their entire network of facilities

and understanding what facilities actually cost to operate and

maintain.

The Intelligent Store architecture transforms data from store

equipment and controls into actionable insights. Designed to

deliver value in both new and existing stores, Emerson aims to

help the retailers:

• Make better decisions on recourse investment for

greatest impact

• Gain accurate feedback and customized service for your

specific needs

• Reduce operational costs and boosting profitability

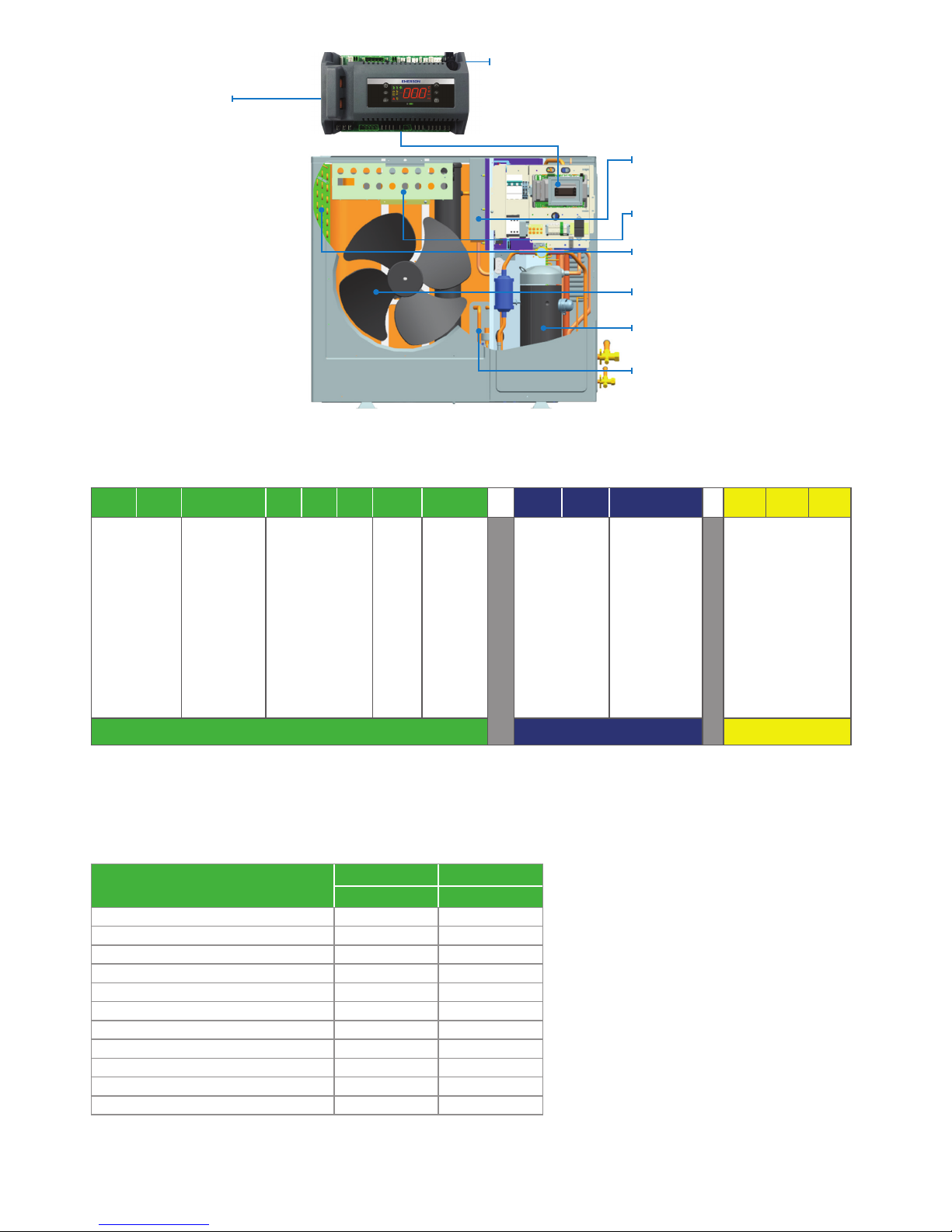

Energy efficiency -Utilizing Copeland Scroll™ compressor

technology, variable speed fan motor, large capacity condenser

coil and advanced control algorithms, energy consumption

is significantly reduced. End-users can save more than 20%

on annual energy costs compared to than using hermetic

reciprocating units.

Reliability - Combining the proven reliability of Copeland

Scroll compressors with advanced electronic controllers and

diagnostics, equipment reliability is greatly enhanced. Fault code

alerts and fault code retrieval capabilities provide information

to help improve speed and accuracy of system diagnostics.

Integrated electronics provide protection against over-current,

over-heating, incorrect phase rotation, compressor cycling, high

pressure resets, low pressure cut-outs. It can also send out a

warning message to an operator when there is a liquid floodback,

which can prevent critical damage on the unit.

Intelligent store

Highest efficiency

Reliability

Better decision making

Lower energy bills

Lower maintenance cost

ZXV condensing unit

for refrigeration applications