7

© 2016 Emerson Climate Technologies, Inc.

AE8-1384 R5

3. CoreSense History Status Messages

4. CongurationMessages

5. Command Messages

6. Firmware Update Messages

CoreSense status, conguration, history, and device

information messages available to the master include

those listed in Table 4.

The history status messages give the order in which the

Warning/Alert has happened, with the total compressor

run time. Information about the Warning/Alert

occurrence during the last 7 days and the cumulative

Warning/Alert counter are also available.

For more information on CoreSense™Communications

features and to request Modbus maps please contact

your Application Engineer.

DIP Switch Conguration

DIP switch selection for the Modbus address, baud rate,

parity, and other operating conditions simplify service

and start-up procedures. Table 5 lists the purpose of

each switch.

NOTICE

The module must be reset after changing any of

the DIP switch settings for changes to take effect.

CoreSense Communications modules are shipped from

the factory with the DIP switches set to default settings

for standalone operation. Default settings are shown

in Table 5. Switch 1 is turned “on” as part of a quality

control check to verify communications capability of the

module before it leaves the compressor manufacturing

plant. Switch 9 is also turned “on” for TE* motor code. All

other DIP switch default settings are in the “off” position.

NOTICE

If DIP switch settings are inadvertently changed,

the compressor will operate, but could have some

loss of protection. Scroll temperature protection

and short cycle protection could be disabled.

The following steps cover the DIP switch settings

throughout the commissioning process for a multiple

compressor system with communications.

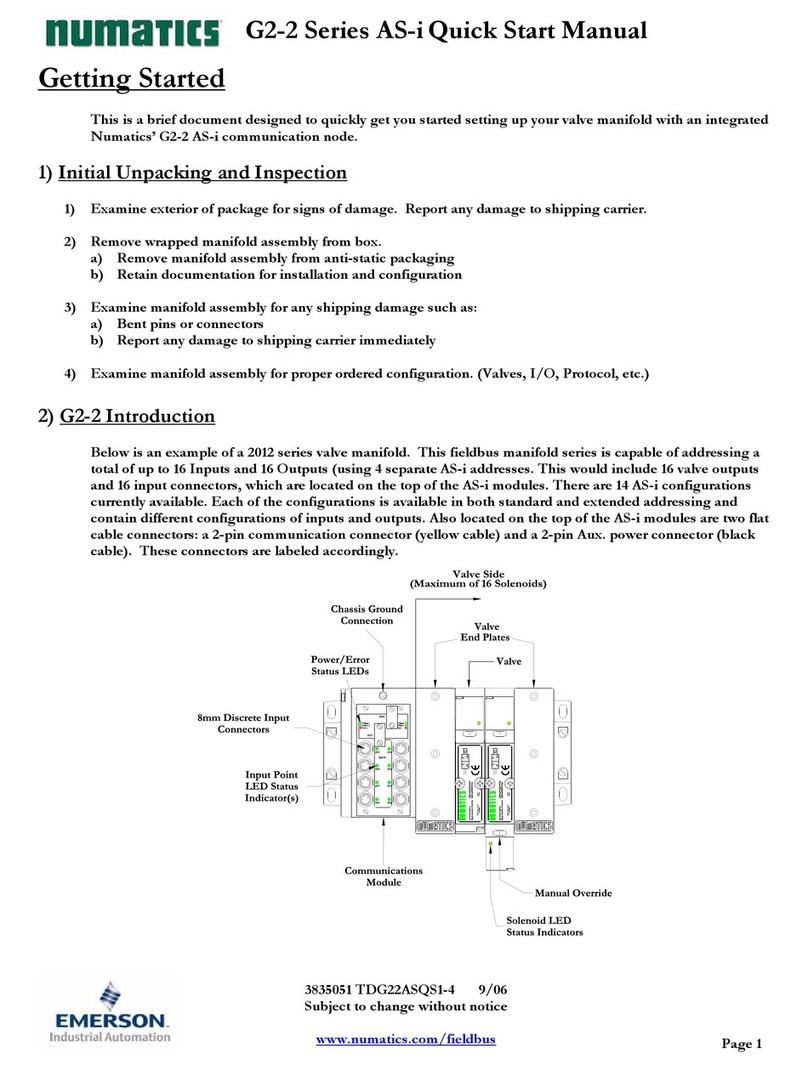

1. Switches 1 through 5 are used for setting

the device address. DIP switch 1 is the least

signicant bit (LSB) and switch 5 is the most

signicant bit (MSB). DIP switch addresses

0 through 31 are shown in Figure 4. Each

CoreSense Communications module that is daisy

chained and connected to a master controller

must have a unique node address (as determined

by the DIP switch settings).

2. Switch6denesthecommunicationbaudratefor

the CoreSense Communications module. If the

switch is “off”, the baud rate is 19200. If the switch

is “on” the baud rate is 9600. The baud rate of

each CoreSense Communications module should

be set to match the master controller baud rate.

3. Switch 7 denes the communications parity.

The default parity setting for the CoreSense

Communications module is no parity. If the switch

is set to “on” the module will communicate using

even parity. The parity setting must match the

parity setting of the master controller.

4. Switch 8 defines the control mode. The

default setting is standalone mode (off). If

communications with a master controller is

desired, switch 8 should be turned “on” to

network.

5. Switch9denesthethermistorconguration.If

the compressor has a voltage code of TE*, the

compressor has PTC and NTC thermistors for

motor and scroll temperature protection. If the

compressor voltage code is TW*, the compressor

has only PTC thermistors for motor and scroll

temperature protection. The default setting is “on”

for PTC and NTC thermistor types.

6. Switch 10 enables short cycling protection if

turned “on”. The default setting is “off”.

Jumper Setting

CoreSense Communications modules are shipped

with the jumper installed. For standalone operation

the jumper should remain installed. For daisy chained

applications the jumper should remain installed for

the modules on the ends of the daisy chain. All other

jumpers in the sequence of daisy chained modules

should be removed. The jumper can be removed using

miniature electronics needle nose pliers

PC Interface Software

PC interface software is available from Emerson Climate

Technologies, Inc. The PC interface software allows

the design engineer access to status, conguration,

history, and data logging via a computer. This method of

connecting and communicating with CoreSense is very

helpful during the unit development stage if CoreSense

is in stand-alone mode and not communicating with a

master controller.