Instruction Manual

D103628X012

CVX Blowdown Fixture

June 2017

4

4. Inspect the bonnet guiding surfaces and gasket mating surfaces. Light damage on the guiding surface may be

repaired with an emery cloth or other suitable material. Damage to the gasket mating surface may require bonnet

replacement to avoid leakage.

5. Remove the plug assembly (key 22, 23, and 53) as a single unit by grasping the valve stem (key 23) and pulling the

assembly from the body cavity. The plug assembly contains sensitive guiding and sealing surfaces on its outside

diameter and care must be taken in its handling. The plug should be temporarily stored on a clean wooden or cloth

surface.

6. Remove the cage (key 21) from the valve body. Remove and discard the upper and lower cage gaskets (key 43).

Reference the CVX valve instruction manual for guidance in performing this disassembly. The cage contains

sensitive guiding surfaces on its outside diameter and care must be taken during handling. The cage should be

temporarily stored on a clean wooden or cloth surface.

7. Clean and inspect the guiding and sealing surfaces of the plug assembly. For balanced plug designs, inspect the

piston ring (key 45) and Bore Seal ring (key 46) for signs of excess wear or damage and replace if necessary. The

piston ring is a two piece design with an outer seal ring and an inner expander ring. The outer ring diameter should

be expanded beyond the diameter of the plug in its free state. It can be shifted within its groove to inspect for

uneven wear around its circumference. The piston ring should require some compression when installing the plug

into the cage. Lack of required compression indicates that the piston ring has worn or relaxed and should be

replaced. Vertical marks in the axial orientation also indicates wear that requires replacement of the ring. The Bore

Seal ring has a C‐shaped cross section with the open portion of the C‐shape facing the stem side of the plug for

flow‐up designs and the open portion of the Cshape facing the seating surface of the plug for flowdown designs.

Any uneven marks around the circumference of the ring or any flattening of the ring shape at its outside diameter

are indications of wear and require replacement. Contact your Emerson sales office or Local Business Partner for

Bore Seal ring replacement.

8. Clean and inspect the inside diameter surfaces of the cage. The entire length of the cage inside diameter is either a

sealing and/or guiding surface and any measurable wear requires that the cage be replaced.

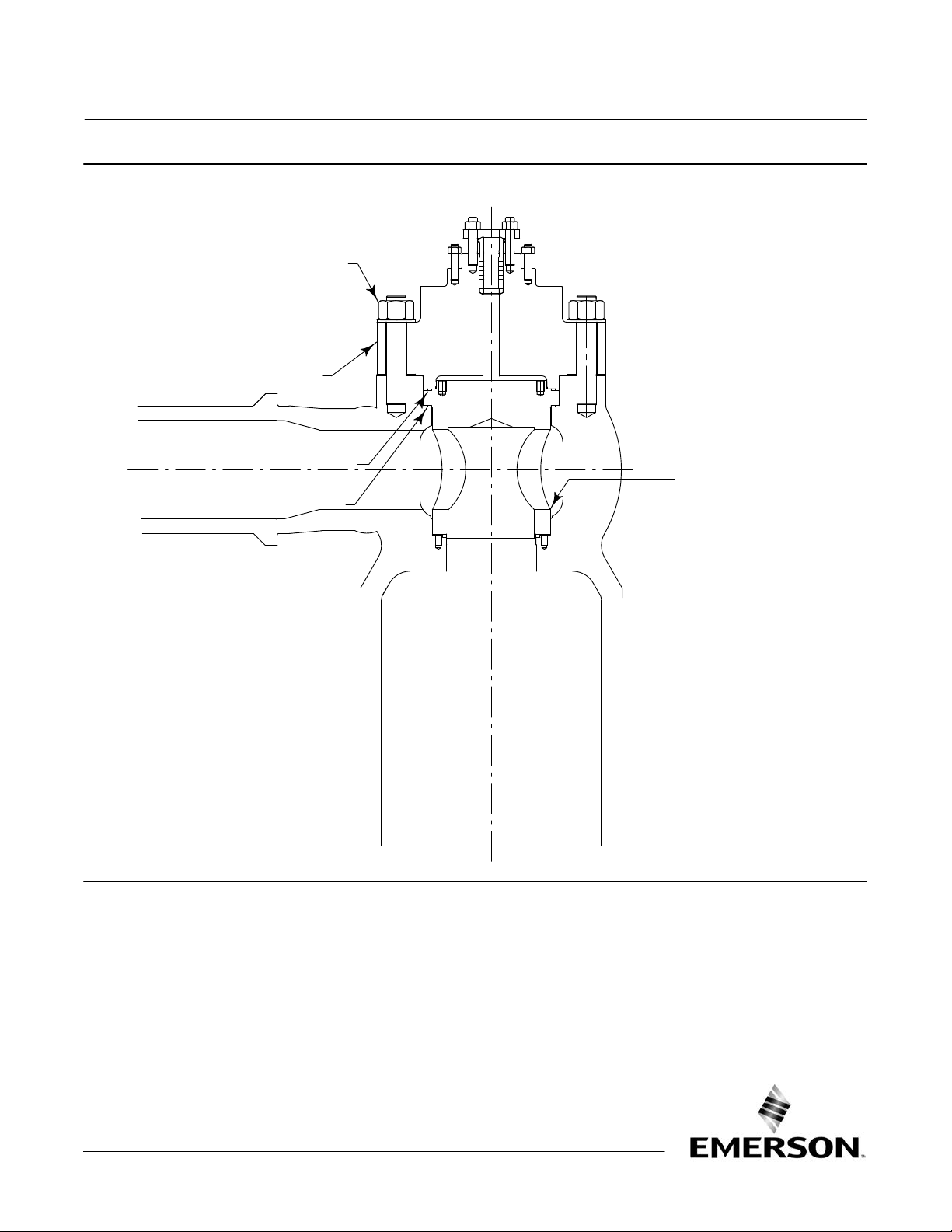

9. Bolted Seat Ring Removable Diffuser Only: The bolted seat ring and seat diffuser must be removed. Loosen the seat

ring bolts, (key 76) using an even and opposing pattern (for example, if the first nut loosened is at the 1 o'clock

position, the next nut to be loosened would be at the 7 o'clock position). This will prevent uneven loading of the

seat ring studs, which may cause binding. Individual bolts should not be completely loosened while the remaining

bolts are tight. It is suggested that at least two stages of loosening be used to avoid overloading the last few

remaining studs. Reference the CVX instruction manual for guiding on removing the bolted seat ring and seat

diffuser (key 77). Discard lower diffuser gaskets (key 75). The bolted seat ring and seat diffuser contain sensitive

guiding and gasket surfaces on its outside diameter and care must be taken in their handling. The seat ring and seat

diffuser should be temporarily stored on a clean wooden or cloth surface.

10. Remove all used gaskets and foreign matter from the interior of the valve and from the inlet and outlet openings.

Remove any foreign matter that may be in the valve trim. Inspect all valve body guiding and sealing surfaces for any

signs of wear.

Visual Inspection

Visually inspect the interior of the valve for abnormal wear, signs of erosion, or scoring if the valve has been in service.

All scores and scratches should be removed by grinding or filing to remove any interference of the clearance zones

between the internal bores and the mating parts. The affected area should be sanded with 100 grit or finer paper. Do

not attempt to completely remove the score, only the interference should be removed and sanded.

The gasket surfaces of the valve body and bonnet should be inspected to verify that they are not damaged and are free

of imbedded gasket material.