Table of contents

4 / 75 ELDRO-EdEx-Montageanleitung-607338-EN.docx

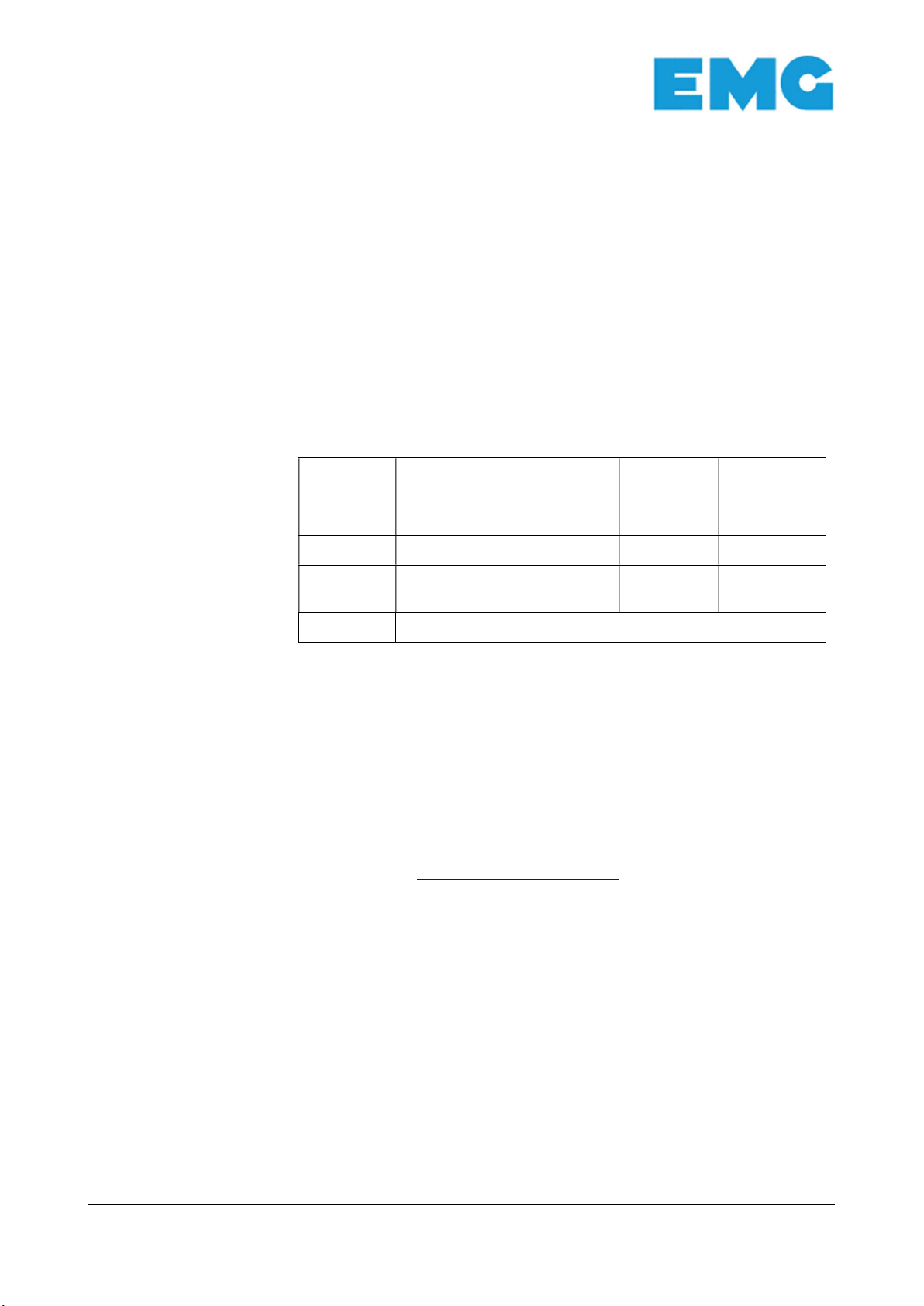

3.6 Dimensions .......................................................................................................................... 31

3.6.1 Type EdEx ............................................................................................................................. 31

3.6.2 Type EdEx-HV....................................................................................................................... 32

3.7 Electrical system ................................................................................................................. 33

3.7.1 Voltage and frequency .......................................................................................................... 33

3.8 Operating fluid ..................................................................................................................... 33

3.9 Airborne sound emissions ................................................................................................. 34

3.10 Operating conditions .......................................................................................................... 34

3.10.1 Ambient temperature ............................................................................................................. 34

3.10.2 Air humidity ............................................................................................................................ 34

3.10.3 Aggressive ambient conditions ............................................................................................. 34

3.10.4 Installation height .................................................................................................................. 34

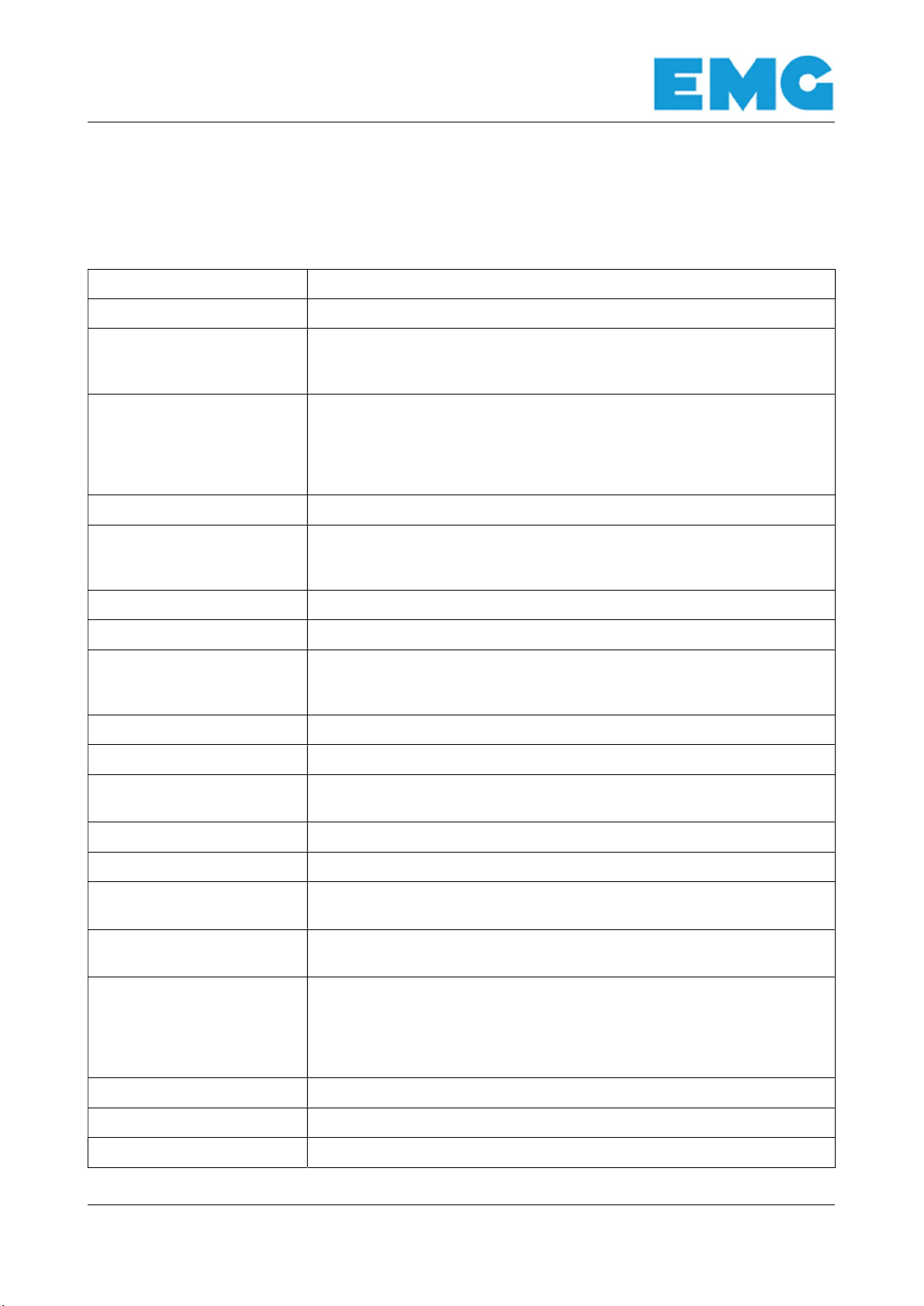

4 Functional description............................................................................... 35

4.1 Mechanical layout ............................................................................................................... 36

4.2 Electrical equipment ........................................................................................................... 37

4.2.1 Motor ..................................................................................................................................... 37

4.2.2 Operating modes ................................................................................................................... 37

4.2.3 Junction box .......................................................................................................................... 37

4.3 Electrical and mechanical additional equipment ............................................................. 38

4.3.1 Lift, lowering or throttle valve (H, S, D) ................................................................................. 38

4.3.2 Brake spring – C-spring ........................................................................................................ 38

4.3.3 Regulating spring – R-spring ................................................................................................. 38

4.4 Function sequence ............................................................................................................. 39

5 Transport and storage ............................................................................... 40

5.1 Transport .............................................................................................................................. 40

5.1.1 Transport sketch ................................................................................................................... 41

5.2 Storage ................................................................................................................................. 42

6 Assembly and installation ......................................................................... 43

6.1 Assembly ............................................................................................................................. 43

6.1.1 Permissible installation positions .......................................................................................... 45

6.1.2 Installing the EdEx thruster ................................................................................................... 45

6.2 Electrical connection .......................................................................................................... 47

6.2.1 Junction box and terminal diagram ....................................................................................... 49

6.2.2 Earthing conductor connection.............................................................................................. 51

6.2.3 Power supply connection ...................................................................................................... 51

6.3 Adjusting the valves ........................................................................................................... 53

6.3.1 Installation location of the regulating screw .......................................................................... 54

6.3.2 Changing the set time and the reset time ............................................................................. 55

6.4 Completing assembly ......................................................................................................... 55

7 Notes on operation .................................................................................... 56