EMGA SANTOS 18 Owner's manual

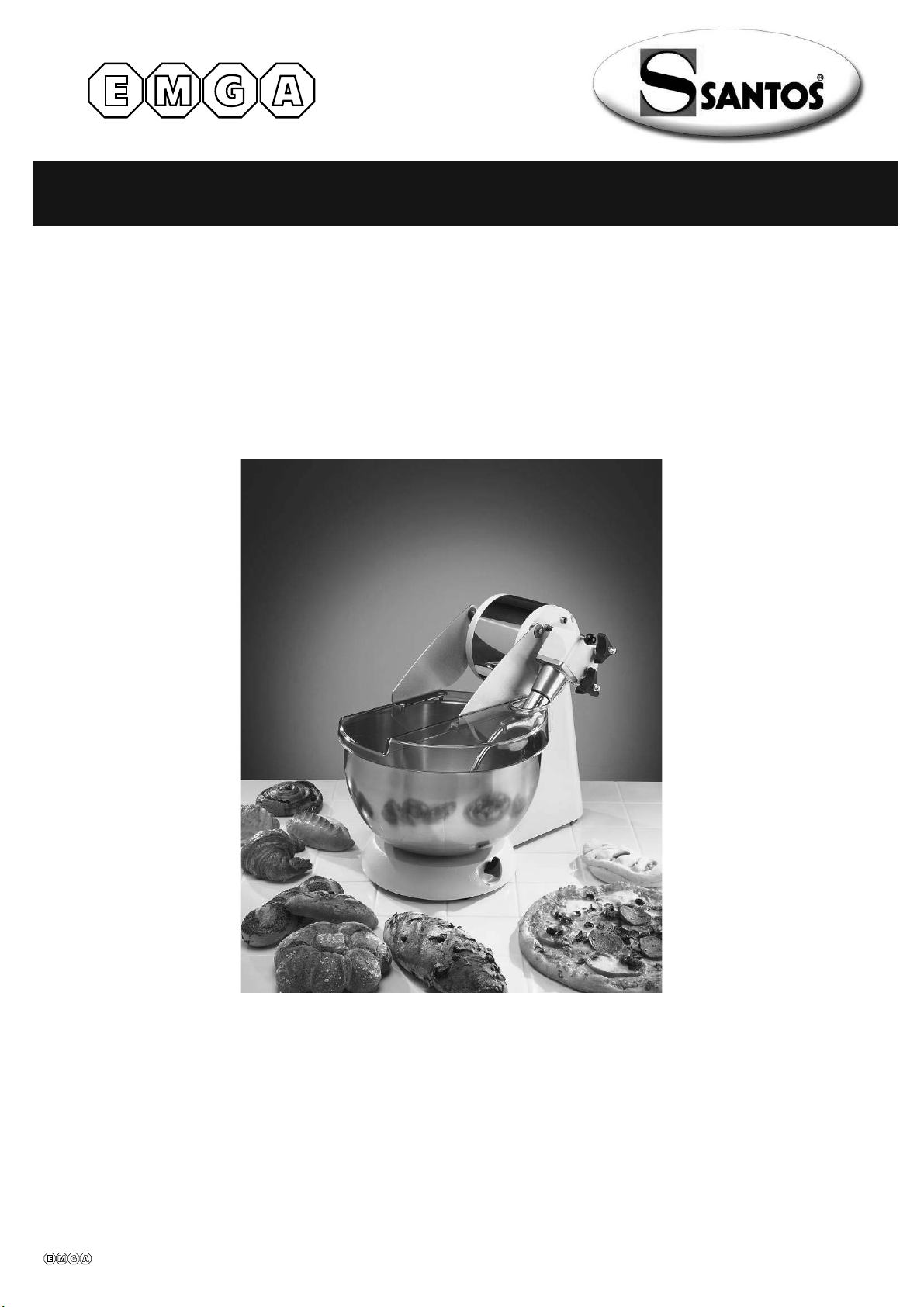

10-LITRE DOUGH MIXER No. 18

OPERATING AND SERVICING MANUAL

IMPORTANT: documents in this manual to be kept carefully:

• “CE” DECLARATION OF COMPLIANCE

• GUARANTEE CERTIFICATE

*408.015

Model No. 18

408015 en ma 2010.12 1/20

98 118 US 3.4 - 12 2010 2 / 20 www.santos.fr

CONTENTS

“CE” DECLARATION OF COMPLIANCE..................................................................................4

IMPORTANT SAFEGUARDS ........................................................................................................5

INSTALLATION AND HANDLING.................................................................................................5

IMPROPER USE .............................................................................................................................5

ELECTRICAL CONNECTION........................................................................................................6

COMMISSIONING..........................................................................................................................6

RECYCLING THE PRODUCT AT THE END OF ITS SERVICE LIFE..........................................6

YOUR No. 18 DOUGH MIXER.......................................................................................................7

DESCRIPTION OF THE MACHINE ..............................................................................................7

OPERATION OF THE MACHINE ................................................................................................8

START-UP .......................................................................................................................................8

Assembly and preparation ...........................................................................................................8

OPERATION....................................................................................................................................8

Adjust the brake so that the dough mixing proceeds correctly: ......................................................8

STOPPING OF THE MACHINE.....................................................................................................8

FRENCH BREAD............................................................................................................................9

CLEANING......................................................................................................................................9

SAFETY SYSTEMS / MAINTENANCE......................................................................................10

MOTOR OVERLOAD SAFETY SYSTEM......................................................................................10

TOOL ACCESS SAFETY SYSTEM................................................................................................10

MAINTENANCE............................................................................................................................11

Spare parts: ................................................................................................................................11

TROUBLE-SHOOTING.................................................................................................................12

The machine does not start ........................................................................................................12

The machine stops at an overload..............................................................................................12

The motor makes noise..............................................................................................................12

The bowl does not rotate............................................................................................................12

The bowl rotates too fast............................................................................................................12

The machine stops while mixing...............................................................................................12

Flour falls out of the bowl..........................................................................................................13

TECHNICAL CHARACTERISTICS OF THE MACHINE.......................................................14

TECHNICAL CHARACTERISTICS...............................................................................................14

408015 en ma 2010.12 2/20

98 118 US 3.4 - 12 2010 3 / 20 www.santos.fr

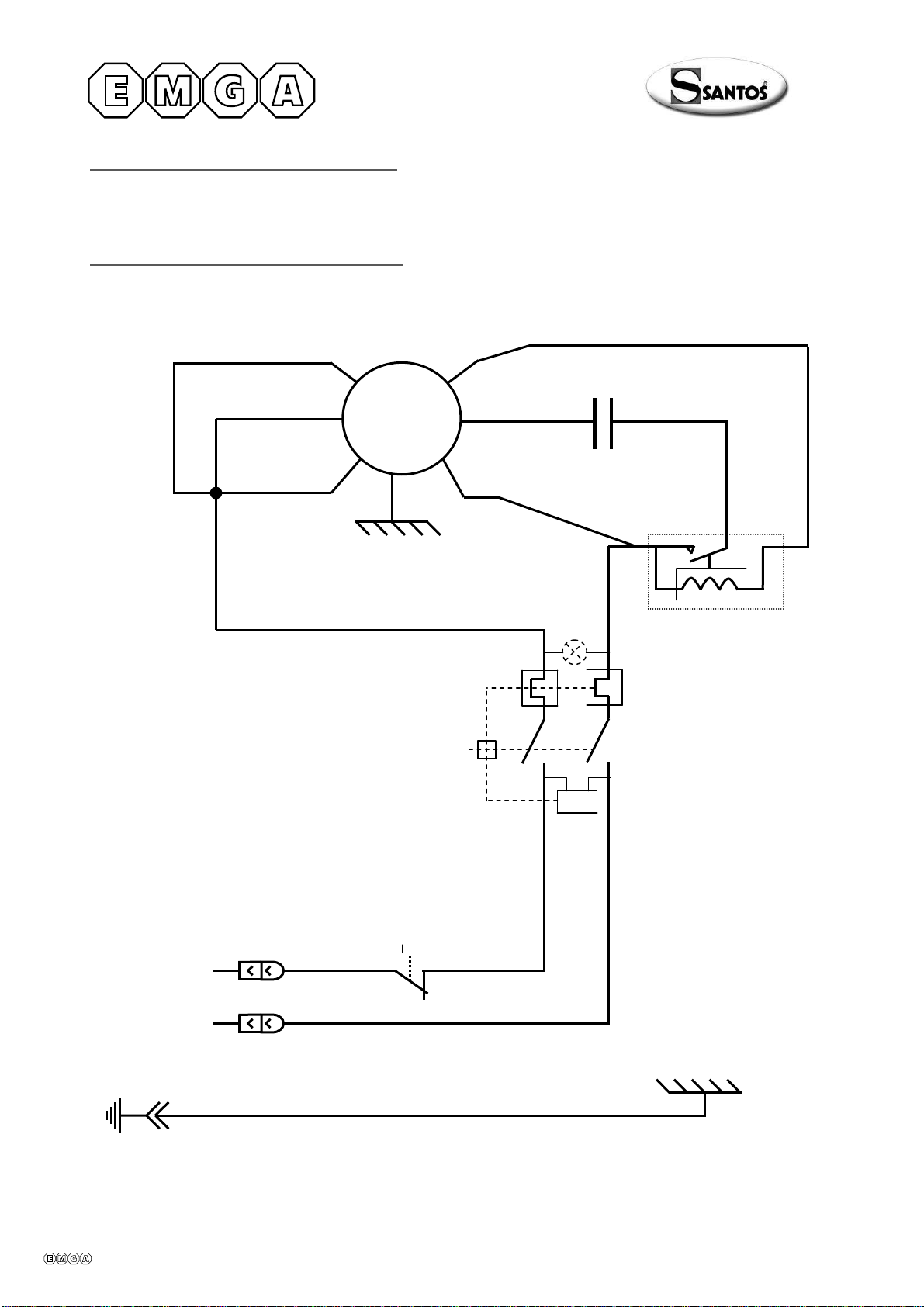

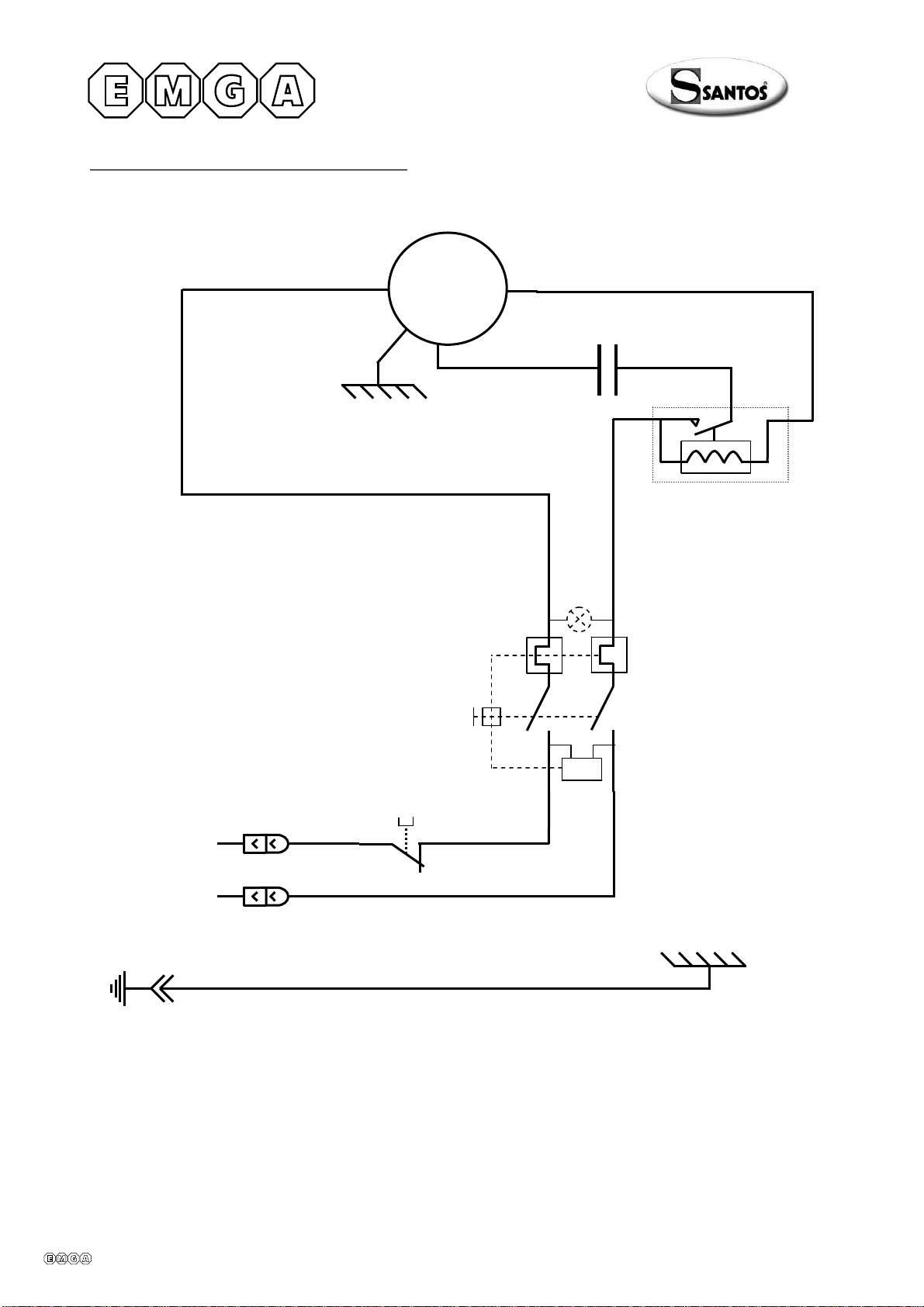

ELECTRICAL WIRING DIAGRAMS.............................................................................................15

Wiring diagram 100-120V~ 50/60Hz ............................................................................................15

Wiring diagram 220-240V~ 50/60Hz ...........................................................................................16

Component identification table

....................................................................................................17

Figures .......................................................................................................................................18

WARRANTY CERTIFICATE

.....................................................................................................20

APPLIANCE IDENTIFICATION PLATE

................................................................................20

408015 en ma 2010.12 3/20

98 118 US 3.4 - 12 2010 4 / 20 www.santos.fr

“CE” DECLARATION OF COMPLIANCE

SANTOS SAS - 140-150, Av. Roger SALENGRO 69120 VAULX-EN-VELIN (LYON)

FRANCE

declares that the appliance intended for the professional market described below:

Description: DOUGH MIXERS

Type number: 18

complies with:

xthe statutory provisions defined in appendix 1 of the European "machines" directive

n°2006/42/CE and the national legislation transposing it

xthe statutory provisions of the following European directives and regulations:

oN° 2006/95/CE (low voltage directive)

oN° 2004/108/CE (EMC directive)

oNo. 2002/95/CE (RoHS directive)

oNo. 2002/96/CE (WEEE directive)

oN° 1935/2004/CE (regulation) relating to materials and articles intended to

come into contact with foodstuffs

Harmonised European standards used to give presumption of conformity with the essential

requirements of the above-mentioned directives:

xNF EN 453+A1: 2010, Food processing machinery – DOUGH MIXERS - Safety

and hygiene requirements.

This European standard is a type-C standard as defined in EN ISO 12100. When the provisions of

this type-C standard differ from those stated in the type-A or B standards, the provisions of the type-

C standard override the provisions of the other standards. This standard provides the means to

comply with the requirements of the "machines" directive n°2006/42/CE, (see appendix ZA)

xNF EN ISO 12100 -1 and 2:2004: Safety of machinery - General principles for

design

xNF EN 60204-1: 2006 : Safety of machinery - Electrical equipment of machines-

General requirements

xNF EN 1672-2: 2005, Food processing machinery – Basic concepts – Hygiene

requirements

Drawn up in VAULX-EN-VELIN on: 01/01/2010

Signatory’s position: CHIEF EXECUTIVE OFFICER

Signatory’s name: Aurélien FOUQUET

Signature:

408015 en ma 2010.12 4/20

98 118 US 3.4 - 12 2010 5 / 20 www.santos.fr

IMPORTANT SAFEGUARDS

When using, cleaning or maintaining the machine, always follow these instructions:

Read all instructions

INSTALLATION AND HANDLING

Just one person is required for handling the appliance. For ease of use, it is recommended

that the machine is placed on a table or work surface so a to have the control panel in

front of you (recommended height: 90 cm, to be adapted to suit the user).

CAUTION:

For any handling operation, including unpacking of the machine, do

not hold or lift the machine by the protective cover (1). (fig. A)

CAUTION:

Check that the cover (1) is in the closed position before plugging the power

cord (10) into the mains socket (fig. C).

IMPROPER USE

This machine is exclusively meant to be used by qualified personnel in the context of a

professional job and NOT in the context of private work.

Any use of the machine which does not observe the instructions in this manual must be

considered as unsuitable and thus dangerous.

1. Do not use this machine for mixing anything other than foodstuffs.

2. Do not use this machine for mixing frozen products.

3. Do not overload the machine beyond the limits of its bowl capacity,

i.e. 2.5 kg of flour plus 1.5 kg of water (4 kg of stiff dough).

4. Cleaning with a water jet or under pressure is not allowed.

5. For electrocution risk protection reasons, never plunge the base

into water or any other liquid.

6. Unplug the appliance before carrying out any work on it: cleaning,

maintenance or repair.

!

!

Note: To facilitate understanding of the following paragraph, consult the diagrams

located at the end of the manual.

These photographs and images are given as an example and are non-contractual. Santos

reserves the right to change them at any moment.

!

7. The use of spare parts other than certified SANTOS original parts is

prohibited.

408015 en ma 2010.12 5/20

98 118 US 3.4 - 12 2010 6 / 20 www.santos.fr

ELECTRICAL CONNECTION

xThe electric power supply for the machine is available in 2 single-phase voltages:

1. 110-120 V 50/60 Hz: Model 18V1

2. 220-240 V 50/60 Hz: Model 18

Line protection: the machine should be connected to a standard 2-pole + earth electric

socket. The system should be fitted with an RCD and a fuse rated at 16A. The appliance

must be earthed (fig. B).

CARE:

xBefore connecting the machine, check that the mains electrical voltage is the same

as the voltage for your appliance. Its value is shown:

¾either on the identification plate (11) under the machine.

¾or on the identification plate on the last page of this manual.

xIf the power cable (10) is damaged, it should be replaced by a special assembly

available from approved SANTOS dealers or from SANTOS.

COMMISSIONING

Carefully clean the parts entering into contact with the foodstuffs (fig. B).

xClean the protective cover (1), the bowl (3) and the mixing fork (7) using a non-

abrasive sponge and a standard washing liquid.

RECYCLING THE PRODUCT AT THE END OF ITS SERVICE LIFE

This equipment is marked with the selective sorting symbol relating to

wastes from electrical and electronic equipment. It signifies that this product

should be taken over by a selective collection system conforming to the

Guideline 2002/96/EC (WEEE) – part Professional Equipment – so that it

can be either recycled or dismantled in order to reduce any impact on the

environment.

For more information, please contact your Retailer or the SANTOS.

For eliminating or recycling components of equipment, please contact a specialized

company or contact SANTOS.

The electronic products not undergoing a selective sorting are potentially dangerous for

the environment.

The damaging materials should be eliminated or recycled according to the regulations in

force.

!

408015 en ma 2010.12 6/20

98 118 US 3.4 - 12 2010 7 / 20 www.santos.fr

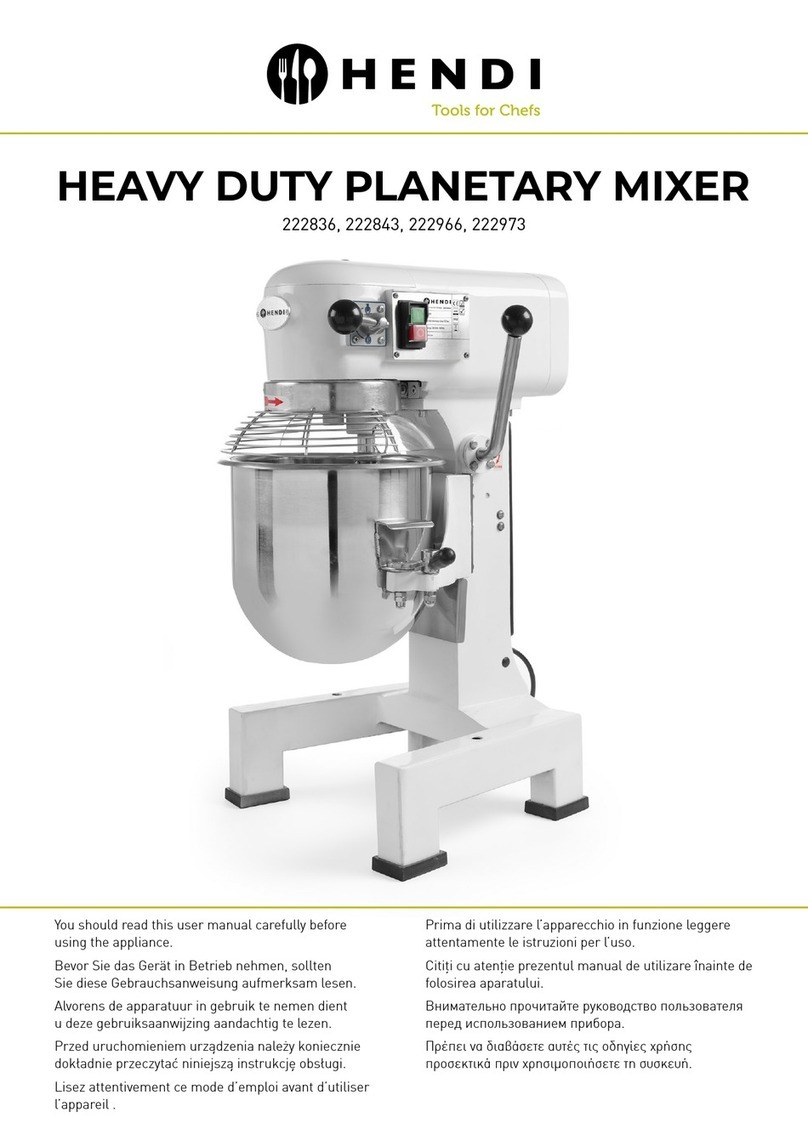

YOUR No. 18 DOUGH MIXER

xThis sturdily built cast aluminium dough mixer with a stainless steel bowl and mixing

fork and a polycarbonate protective cover is designed for professional use: HOTELS,

RESTAURANTS, COMMUNITIES, PIZZERIAS, BAKERIES, MANUFACTURERS

OF DIETING PRODUCTS, etc.

xThe dough mixer is particularly suitable for preparing stiff dough such as that used

for bread, tart bases and pizzas. Its bowl has a capacity of 10 litres and can be used

for preparing 4 kg of stiff dough (2.5 kg of flour). DO NOT overload the mixer with a

quantity of more than 4 kg !

xThe No. 18 dough mixer is ideal for preparing all types of pastries, minces, etc.

xDuring operation, the tool rotates at constant speed and rotation of the bowl is

ensured by mixing of the dough. A brake adjustable by a knob (5) can be used to set

the rotation speed of the bowl during mixing.

DESCRIPTION OF THE MACHINE

1. Tilting protective cover (1) (fig. B)

2. Lock pin (2) for tilting of the reduction gear (6) and fork assembly, after the two

screws (4) have been loosened.

3. Two screws for locking the reduction gear and fork (7) assembly.

4. On/Off luminous switch (13) operating without voltage with a manually reset thermal

circuit breaker.

5. Brake adjusting knob (5) to set the bowl rotation speed.

408015 en ma 2010.12 7/20

98 118 US 3.4 - 12 2010 8 / 20 www.santos.fr

OPERATION OF THE MACHINE

START-UP

Assembly and preparation

(fig. B)

1. The protective cover (1) is hinged.

The lower position is the work position.

The upper position gives complete access to the bowl and fork. In this position:

2. The reduction gear (6)is fitted around the motor shaft; the reduction gear is

tightened by the 2 screws (4). The stable positions are ensured by a pin (4).

3. Installation of the bowl (3): (fig. D) The bowl rotates freely around the base pin

and can be removed by raising it (first raise the cover (1), the reduction gear (6) and

the fork (7))

4. Installation of the fork (7): (fig. E) protective cover (1) raised, reduction gear (6)

up, install the fork (7) so that the bayonets are aligned with the fork groove.

OPERATION

1. Switch on the power by plugging the power cord (10) into the mains.

2. Place the fork (7) on the reduction gear output shaft (align the bayonet with the

groove.

3. Swivel the reduction gear (6) and align it with its lower position (fork in the bowl).

4. Lock and fasten the reduction gear by the screws (4).

5. Fill the bowl (3) with the necessary ingredients (see the counter-indications).

6. Lower the protective cover (1).

7. Actuate the On/Off switch (13) to begin the dough mixing.

8. The bowl is not driven by the motor and it is advisable to help it to turn by hand until

all the flour is wet.

Adjust the brake so that the dough mixing proceeds correctly:

xIf the bowl is too free, it turns too fast and the fork tends to make a hole in the

dough instead of mixing it. Tighten the brake (5)

xIf the bowl is too tight it turns too slowly and the dough tends to climb to the

top of the fork. Loosen the brake (5)

When the dough is mixed, loosen the two screws (4), raise the fork and remove it if

necessary.

The bowl is removed from its pin and can be easily transported.

408015 en ma 2010.12 8/20

98 118 US 3.4 - 12 2010 9 / 20 www.santos.fr

1. actuating the On/Off switch (13),

2. or raising the protective cover (1),

3. or unplugging the power cord (10) from the mains.

FRENCH BREAD

To mix 4 kg of stiff dough, use: 2.5 kg of baker's flour, 1.5 l of water (60 % of the weight of

the flour), 45 g of salt (30 g per litre of water), 45 g of baker's yeast (30 g per litre of

water).

Very important: the temperature of the water, in normal ambient conditions, must be about

14 °C. Use warmer water if the ambient temperature is lower (e.g. for an ambient

temperature of 5°C, use water at 30°C).

Slowly mix the flour, the water and the yeast; knead for 10 to 12 min. Add the salt only 3

minutes before the end: the dough obtained must be "STIFF" (about 24°C after mixing).

Allow the dough to rest after mixing for about 30 minutes minimum.

Shape your loaves and allow them to rise for about 2 hours.

For baking, use an appropriate oven and load at 220°C.

The duration of the baking will be 1 hour per kg of bread (20 min. for a 300 g baguette).

CLEANING

IMPORTANT:

xIn all cases, stop the machine and unplug its power cord (10).

It is advisable to clean the machine as soon as the mixing is completed.

Cleaning will be easier before the foodstuffs dry in the bowl (3), on the protective cover

(1) or on the mixing fork (7).

The base (8) should be cleaned with a damp sponge and then dried.

!

STOPPING OF THE MACHINE

The machine is stopped by:

408015 en ma 2010.12 9/20

98 118 US 3.4 - 12 2010 10 / 20 www.santos.fr

SAFETY SYSTEMS / MAINTENANCE

MOTOR OVERLOAD SAFETY SYSTEM

The On/Off switch (13) switches automatically to « 0 ».

REMARKS: Mixing dough requires heavy work from the motor. It is thus normal for the

motor to heat up. It has been designed for the purpose. It is however protected by a

thermal circuit-breaker built into the On/Off switch (13). Should there be an overload or

jamming, for example, this circuit-breaker will trip.

In this case, remove the cause of the trouble and allow the motor to cool, wait for a few

moments for automatic resetting of the circuit breaker then operate the On/Off switch

to start the motor.

If the problem persists, switch off the machine (unplug the power cord from the mains (10))

and call a technician of the maintenance department or contact an approved SANTOS

retailer.

TOOL ACCESS SAFETY SYSTEM

The machine can start only if the protective cover (1) is lowered.

xthe opening of the cover (1) stops the machine and all its moving parts.

xInterruption of the power supply stops the machine.

Restarting of the machine requires a fresh action on the switch (13).

For safety reasons, it is prohibited to insert a finger or part of one's hand into the opening

for adding ingredients (Fig. F).

408015 en ma 2010.12 10/20

98 118 US 3.4 - 12 2010 11 / 20 www.santos.fr

MAINTENANCE

Before carrying out any work on the machine, it must be unplugged from the mains and

the motor start capacitor discharged.

Discharging the capacitor:

Using a screwdriver with an insulated handle, touch the 2 capacitor

connections (9). You should see an electric arc which means that the

capacitor has been discharged.

Spare parts:

IMPORTANT:Use of spare parts other than certified original SANTOS

parts is prohibited

This machine requires no specific maintenance. The bearings are lubricated for life.

If work is required to replace worn parts such as the grindstones or the electric or other

components, refer to the parts list (see exploded view at the end of the manual).

For all spare part orders (see references in the exploded view at the end of the

manual), state:

¾the type,

¾the machine serial number and

¾the electrical specifications (16)

recorded under the machine.

!

!

!

408015 en ma 2010.12 11/20

98 118 US 3.4 - 12 2010 12 / 20 www.santos.fr

TROUBLE-SHOOTING

Identify the exact cause for stopping of the machine.

In all cases, if the problem persists, switch off the machine (disconnect the

power cord (10)) and call a technician from the maintenance department or

contact an approved SANTOS retailer.

The machine does not start

xCheck: the mains power supply and the state of the power cord (10).

xWithin the machine, check the state of the electric wires and connections (at the

grommet (12), at the On/Off switch (13)) (fig. F).

xCheck the electrical components and replace them one at a time (switch, capacitor,

protective cover, starting relay, motor).

The machine stops at an overload

A foreign body in the bowl (3) or intense operation can result in an overload of the motor.

Under these conditions, the over-current protection system (13) can go into action and

stop the operation of the machine.

xSee the "motor overload safety" part.

The motor makes noise

Check the tightening of the reduction gear (6). If the reduction gear is not correctly

tightened, this results in premature wear of the reduction gear wheel and worm screw.

Note: Always replace the gear wheel and worm screw at the same time.

xTighten the 2 reduction gear securing screws (4).

The bowl does not rotate

The bowl is not driven by the motor. It rotates under the dough mixing action. When mixing

begins, it is necessary to help the bowl to turn manually. As soon as all the flour is "wet",

the system operates alone and it is then necessary to brake the bowl to ensure correct

mixing.

The bowl rotates too fast

To ensure correct mixing, it is necessary to brake the bowl.

xTurn the butterfly screw (5) located on the side of the bowl to lock it. And/or slow

the rotation of the bowl by holding it with both hands.

!

408015 en ma 2010.12 12/20

98 118 US 3.4 - 12 2010 13 / 20 www.santos.fr

xCheck the correct position of the protective cover (1).

xIf the bowl is overloaded (too much flour in the bowl), during rotation of the fork,

too much stiff dough could gather around the fork and slightly raise the protective

cover (1) thus stopping the machine.

xClear the fork or lower the cover to start the motor.

Flour falls out of the bowl

If the bowl is too heavily loaded, before the flour is completely wet, a small quantity can be

ejected from the bowl.

xReduce the load (quantity of flour in the bowl).

The machine stops while mixing

408015 en ma 2010.12 13/20

98 118 US 3.4 - 12 2010 14 / 20 www.santos.fr

TECHNICAL CHARACTERISTICS OF THE MACHINE

TECHNICAL CHARACTERISTICS

Model18 Single-phase

Power supply voltage (VAC) 220-240 100-120

Fre

q

uenc

y

(

Hz

)

50/60 50/60

Motor: Power

Power consumption (W) 600 650

Motor speed: (rpm) 1450 at 50Hz 1700 at 60Hz

Tool (fork) speed: (rpm) 70 at 50Hz 84 at 60Hz

Bowl content (l) 9.9

Maximum useful content of the bowl (kg) 4

Dimensions: Height (mm) 420

Width (mm) 350

Depth (mm) 500

Weight: Net weight (kg) 17

Packed weight (kg) 19

Noise: (2) (dBA) 65

(1) These values are given as an example. The exact electrical characteristics of your machine

are noted on its identification plate.

(2) Noise level measured as acoustic pressure of the machine under load at 1 m from its axis,

according to standard EN 31201.

408015 en ma 2010.12 14/20

98 118 US 3.4 - 12 2010 15 / 20 www.santos.fr

ELECTRICAL WIRING DIAGRAMS

Wiring diagram 100-120V~ 50/60Hz

Starting relay

43

2

Blue

~

On/Of

f

White

White

White

White

Capacitor

M

Y

ellow Brown

Black

White Red

White

Black

U<

P2

3

P1

4

Black

Cover safety system

White

Green / yellow

408015 en ma 2010.12 15/20

98 118 US 3.4 - 12 2010 16 / 20 www.santos.fr

Wiring diagram 220-240V~ 50/60Hz

43

2

Starting relay

Black

M

Brown

White

~

On/Of

f

White

White

White

White

Capacitor

U<

P2

3

P1

4

Cover safety

system

White

Green / Yellow

408015 en ma 2010.12 16/20

98 118 US 3.4 - 12 2010 17 / 20 www.santos.fr

Component identification table

ITEM Description

1Protective cover

2Lock ping

3Bowl

4Reduction gear securing screw

5Adjustable brake

6Reduction gear

7Mixing fork

8Base

9Capacitor

10 Power cord

11 Identification plate

12 Grommet

13 Switch

14 Cover safety switch

408015 en ma 2010.12 17/20

3

13

1

Fig. B

Fig. D

7

14

Fig. C 10

Fig. A

8

9

5

4

3

2

6

1

408015 en ma 2010.12 18/20

98 118 US 3.4 - 12 2010 19 / 20 www.santos.fr

Fig. F

Fig. E

These photographs and images are given as an example and are non-contractual. Santos

reserves the right to change them at any moment.

408015 en ma 2010.12 19/20

WARRANTY CERTIFICATE

WARRANTY

APPLIANCE IDENTIFICATION PLATE

SPECIMEN

For all the documents not delivered

with the appliance.

Printed, Faxed, Downloaded

Since the 01.01.95, all our appliances comply with CE and possess the CE label. Our guarantee is of

12 months from the manufacturing date mentioned on the descriptive plate. Warranty is strictly

limited to the free replacement of any part of origin recognized by us as defective due to a defect or

building default and identified as belonging to the concerned appliance. Warranty does not apply to

damages resulting from installation or use non-complying with our appliance data sheet (user’s

manual) or in case of an evident lack of maintenance or disrespect of elementary security electric

rules. It does not apply in case of regular wear and tear.Any replacement of parts under warranty will

be realized after return of the defective part in our workshops, postage paid, supported by a copy of

a conformity statement on which appears the serial number of the appliance. Every appliance is

equipped with a descriptive plate conforming to the EC recommendations and of which a duplicate

exists in the conformity statement (serial number, manufacturing date, electrical characteristics …).

In case of serious damage judged repairable only in our workshops, and after prior consent from our

departments, any appliance under guarantee is sent by the Distributor, carriage paid. In case of

repairs or reconditioning of appliances not under guarantee, the round trip transport is payable by the

distributor. The parts and workforce are invoiced at the current rate. A preliminary estimate can be

supplied.

Coffee grinder not using SANTOS original burrs are not taken under guarantee. The warranty

conditions, repairs, reconditioning, of the espresso coffee grinder are the object of a specific note.

Our guarantee does not extend to the payment of penalties, the repair of direct or indirect damages

and notably to any loss of income resulting from the nonconformity or the defectiveness of products,

SANTOS's global responsibility being limited to the sale price of the delivered product and to the

possible repair of the defective products.

In case of revelation of an imperfection during the warranty period, the Distributor has to, unless a

different written agreement of SANTOS, indicate to his customer to stop any use of the defective

product. Such a use would release SANTOS of any responsibility.

408015 en ma 2010.12 20/20

Table of contents

Other EMGA Mixer manuals