4

General:

This manual should be seen as an integral part of the mixer and should be kept by the machine throughout its working life.

Beforethemachineiscommissioned,itisimportanttoreadtheseinstructionsthoroughly, particularly the section on user safety

.

The manufacturer may update the product manual without updating this copy of the manual.

The manufacturer will not be liable for faults caused by:

• Careless, improper or incorrect use of the mixer

• Non-standard use (not for the purposes described in the manual)

• Incorrect installation

• Incorrect power supply to the machine

• Failure to comply with maintenance instructions

• Modications to the machine

• Spare parts and accessories that are not original or specied for this model

• Failure to comply with instructions in this manual

In case of faults with the mixer, please contact the Lokal Authorized Service Agency.

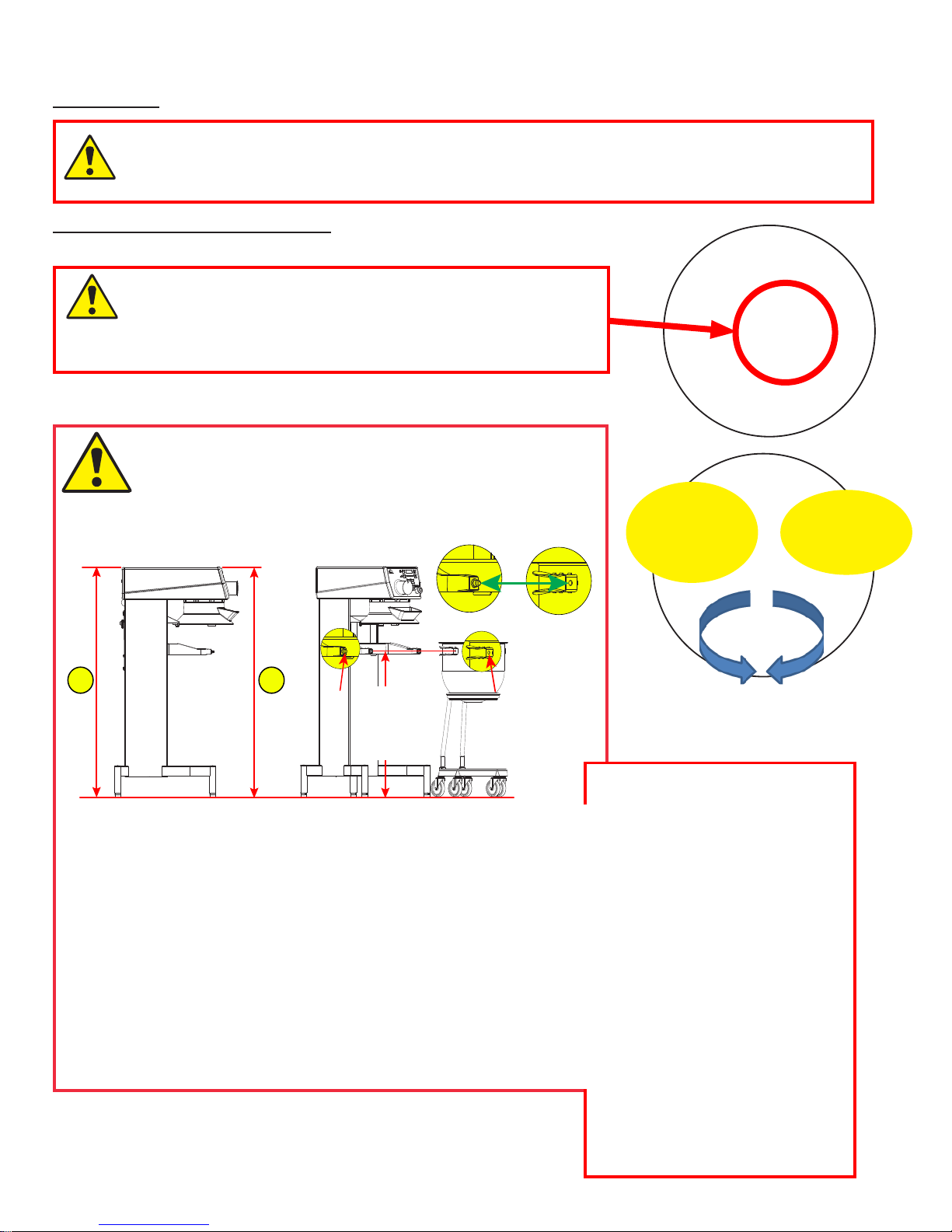

UnpackinG:

The machine should be unpacked and the packaging disposed of according to regulations applicable in the country concerned.

Before the mixer is removed from the pallet, check that all parts are present with the machine:

• Bowl Screen, Power cable, 32 mm xed spanner for legs, Bowl trolley

• Bowl, Whip, Beater, Hook and Scraper with blade, if these were selected with the order.

The machine can be released from the pallet by cutting the strips.

contents:

General: ............................................................................................................................................................4

UnpackinG: ............................................................................................................................................................ 5

transport: ............................................................................................................................................................5

installation and adjUstments: ..............................................................................................................................5

commissioninG:.......................................................................................................................................................6

recommended Use of the machine:.......................................................................................................................... 6

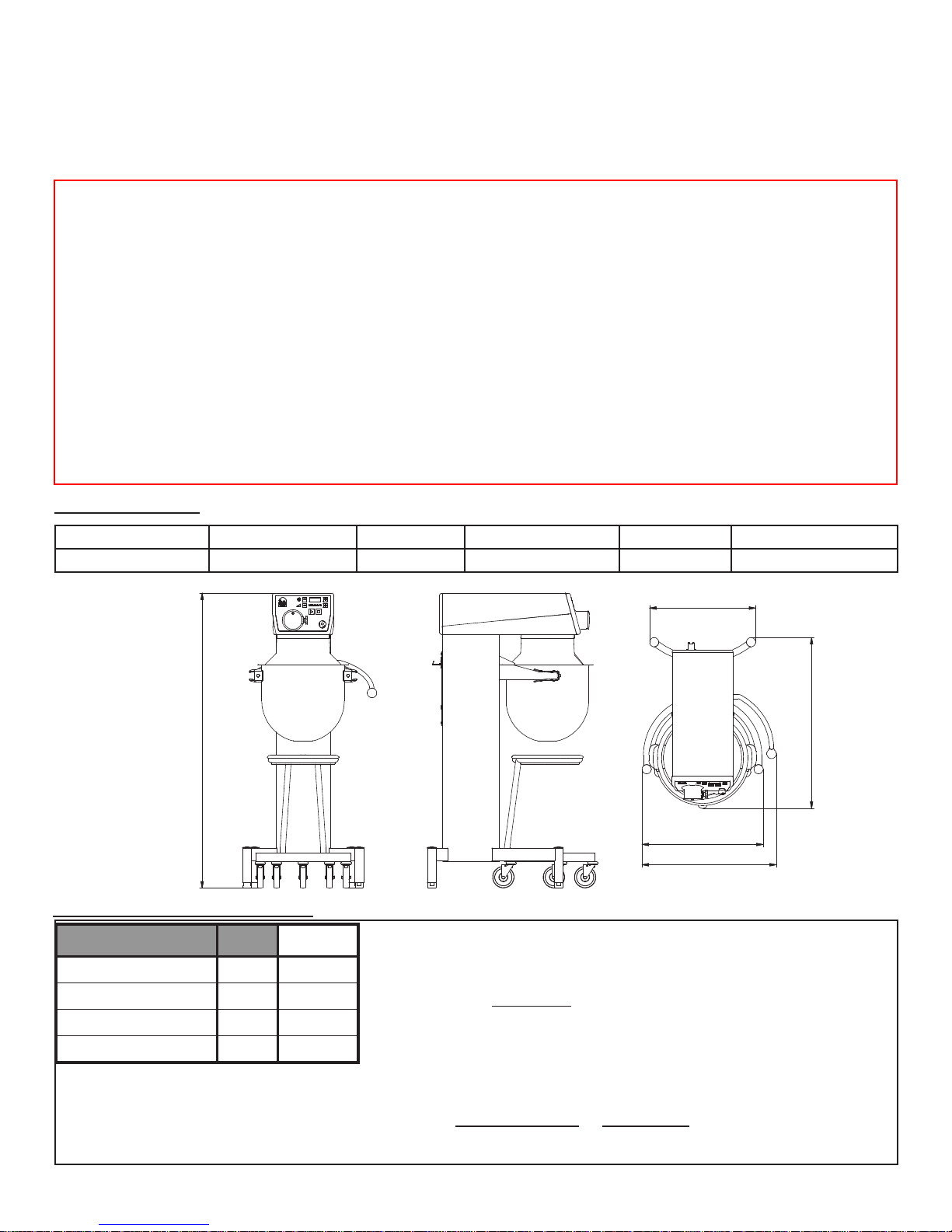

technical data: .....................................................................................................................................................6

max. capacity of the machine: ................................................................................................................................6

components of the machine: .................................................................................................................................. 7

safety: ............................................................................................................................................................8

adjUstments:.........................................................................................................................................................8

kodiak User-friendliness: ..................................................................................................................................9

operatinG the mixer:............................................................................................................................................ 10

overloadinG:....................................................................................................................................................... 11

procedUre in case of overloadinG:...................................................................................................................... 11

recommended max. speeds: .................................................................................................................................. 11

recommended max. speeds for attachment drive: ................................................................................................. 11

correct Use of tools:......................................................................................................................................... 11

cleaninG: .......................................................................................................................................................... 11

lUbrication and Grease types: ............................................................................................................................. 11

attachment drive:................................................................................................................................................ 11

display of mixer data ........................................................................................................................................... 12

error codes and possible solUtions:...................................................................................................................12

access to the fUse:.............................................................................................................................................13

example electrical connections:......................................................................................................................... 13

circUit diaGram: ..................................................................................................................................................14

mixer spare parts ................................................................................................................................................16