Rome, New York, USAEnviromaster International LLC 3

PART ONE “GENERAL”

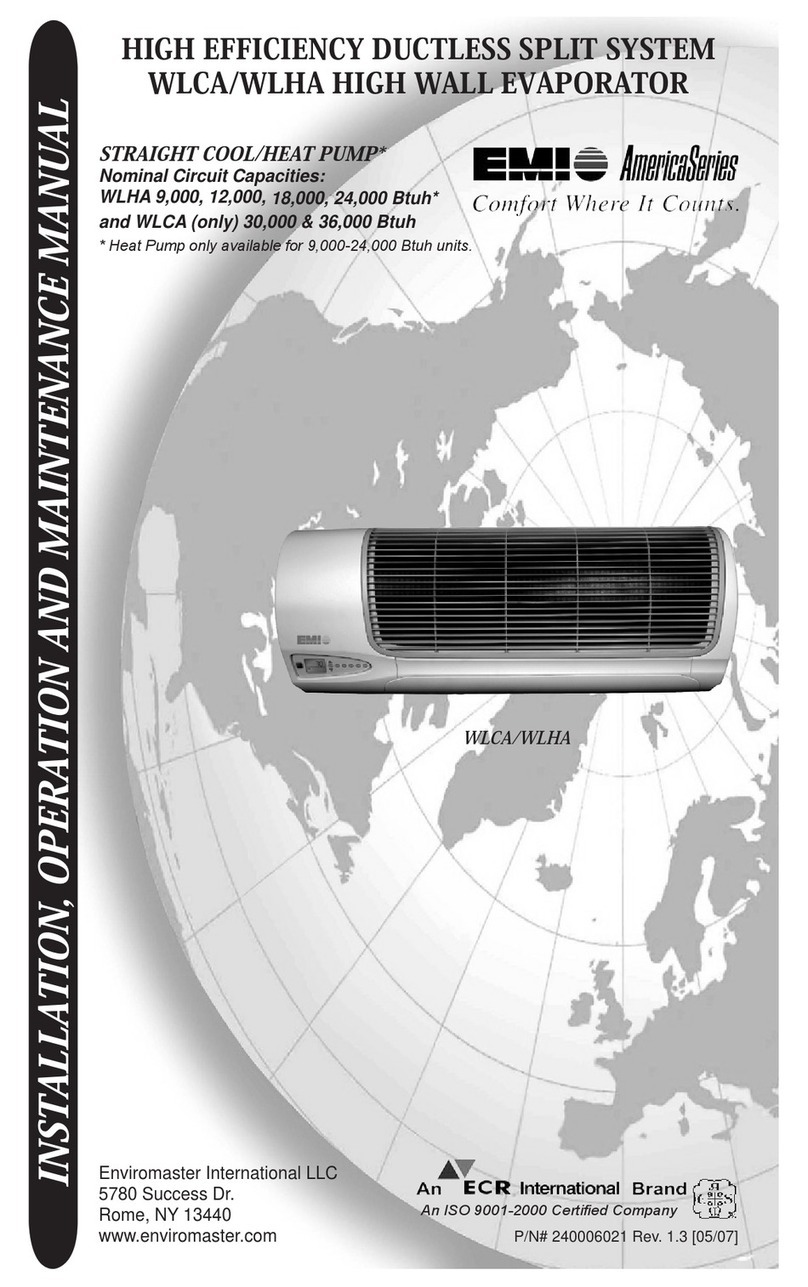

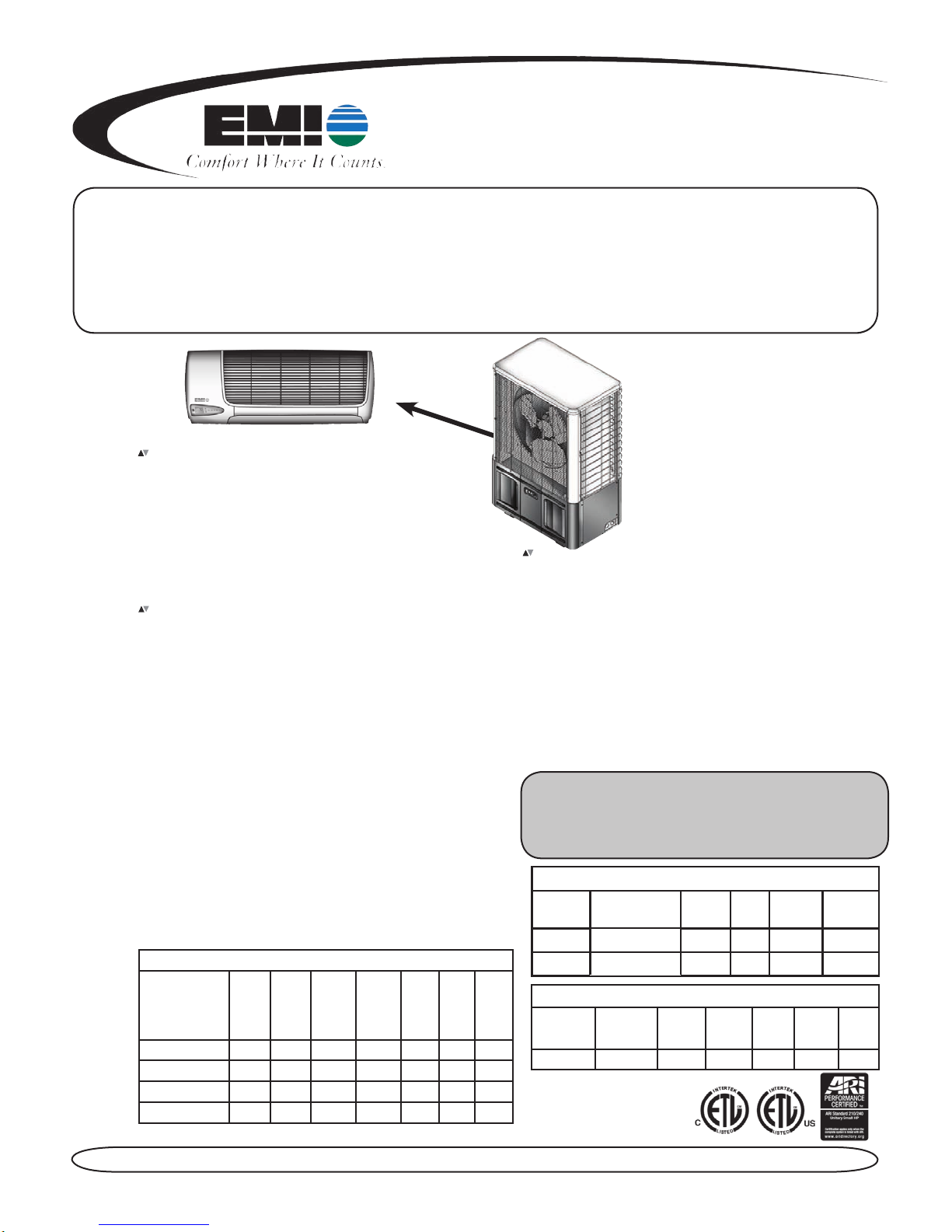

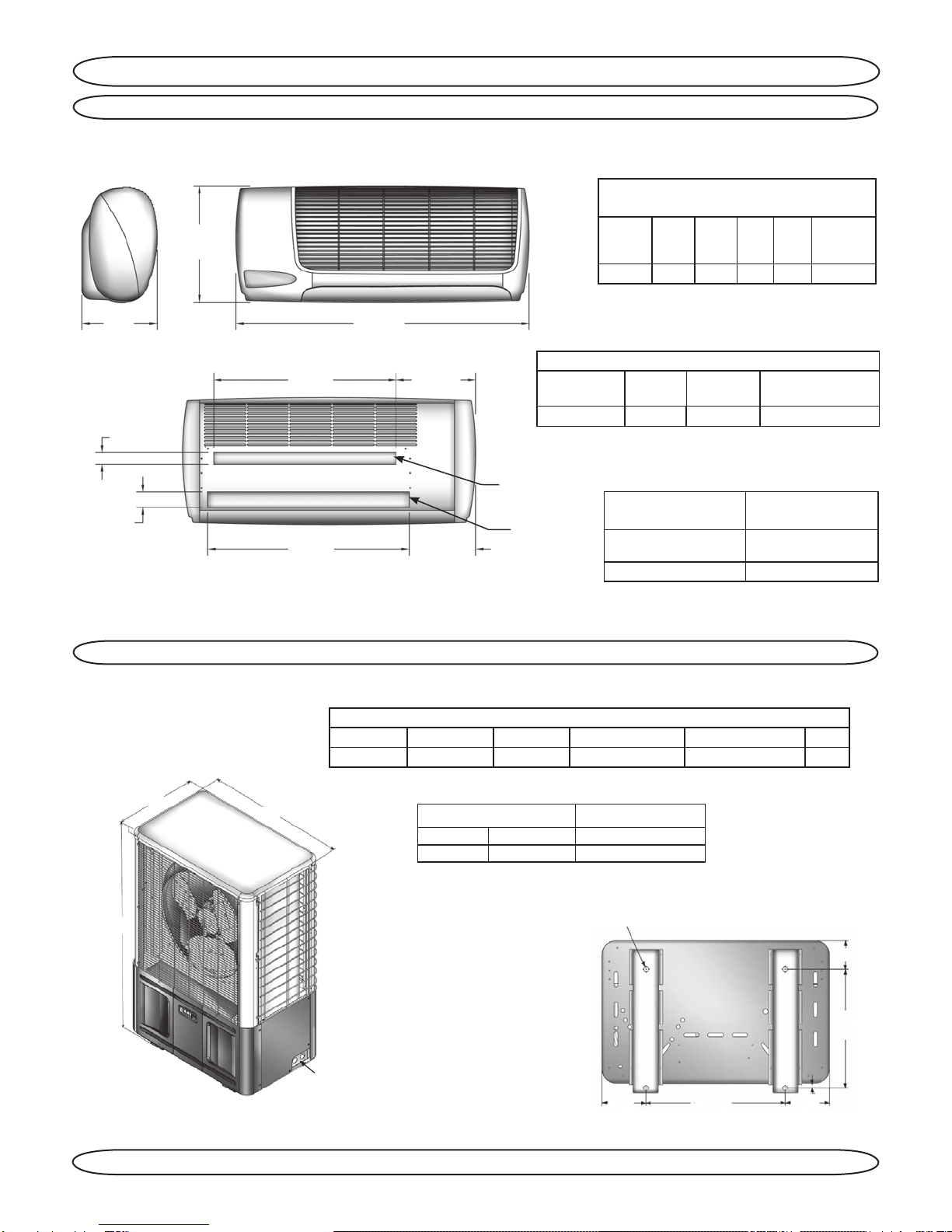

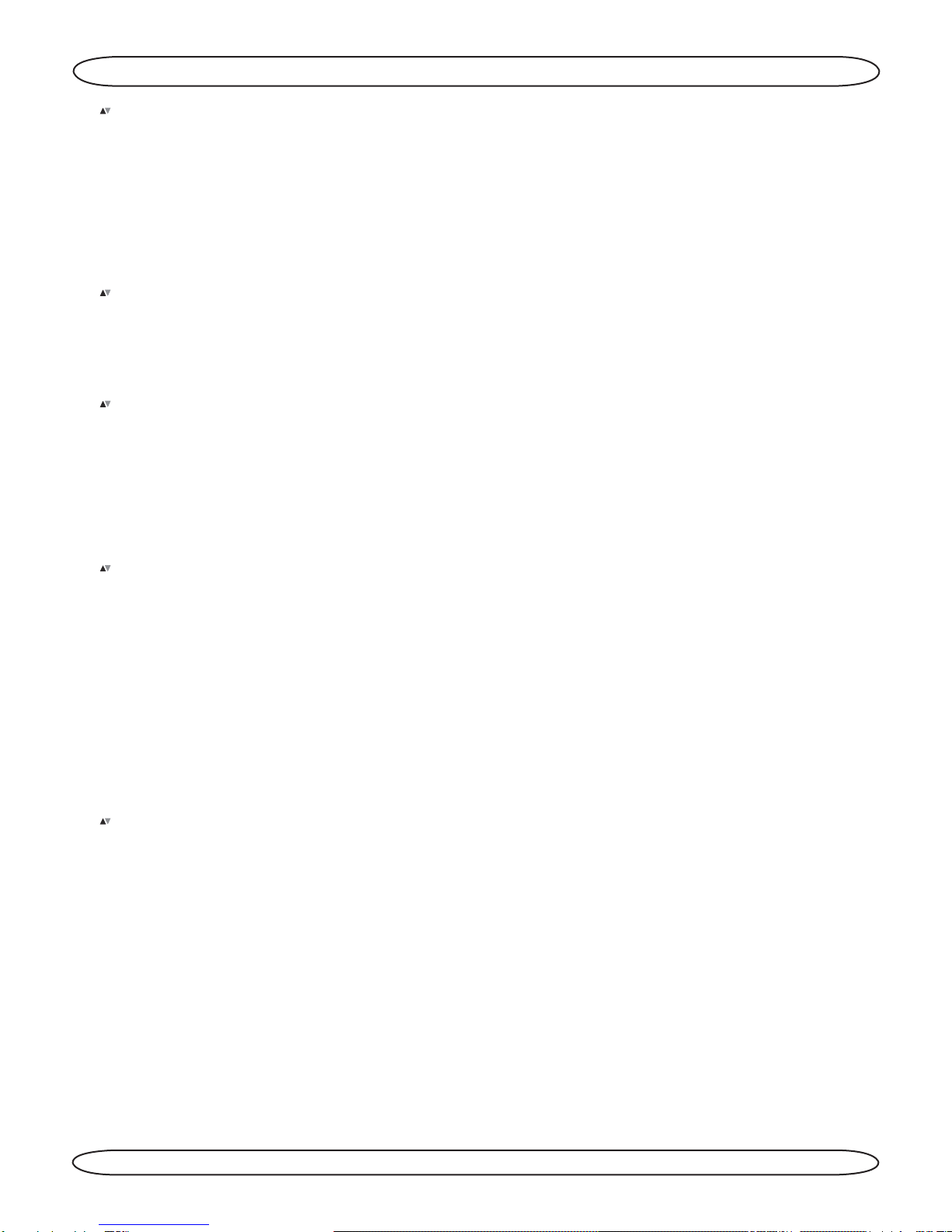

TheheatpumpairconditioningsystemsshallbeanEMIAmericaSeriessplitsystem.Thesystemshallconsistof

ahighwallmountedpackagedevaporatorsectionModelWLH12andmatchingAmericaSeriesoutdoorunitModel

S1H2.TheunitsshallbemadewithinNorthAmerica.TheunitsshallbelistedbyIntertekTestingService(ITS)and

beartheETLlabel.AllwiringshallbeinaccordancewiththeNationalElectricalCode(N.E.C.).Theunitsshallberated

inaccordancewithARIStandard210/240andbeartheARIlabel.Theunitsshallbemanufacturedinafacilitycertied

toISO9001,whichisaninternationalstandardusedtoprovideguidanceinthedevelopmentandimplementationofan

effectiveQualityManagementSystem.ThecondensingunitshallcontainR-22refrigerantchargefortheevaporator

sectionandcondensersection.Thesystemefciencyshallmeetorexceed2006FederalStandards.

PART TWO “WARRANTY”

Theunitsshallhaveamanufacturer’swarrantyforaperiodof(1)yearfromdateofinstallation.Thecompressorshall

haveawarrantyof(5)yearsfromdateofinstallation.If,duringthisperiod,anypartshouldfailtofunctionproperlydue

todefectsinworkmanshipormaterial,itshallbereplacedorrepairedatthediscretionofEnviromasterInternational

LLC.Thiswarrantydoesnotincludelabor.ManufacturershallhavetwentyyearsexperienceintheU.S.market.

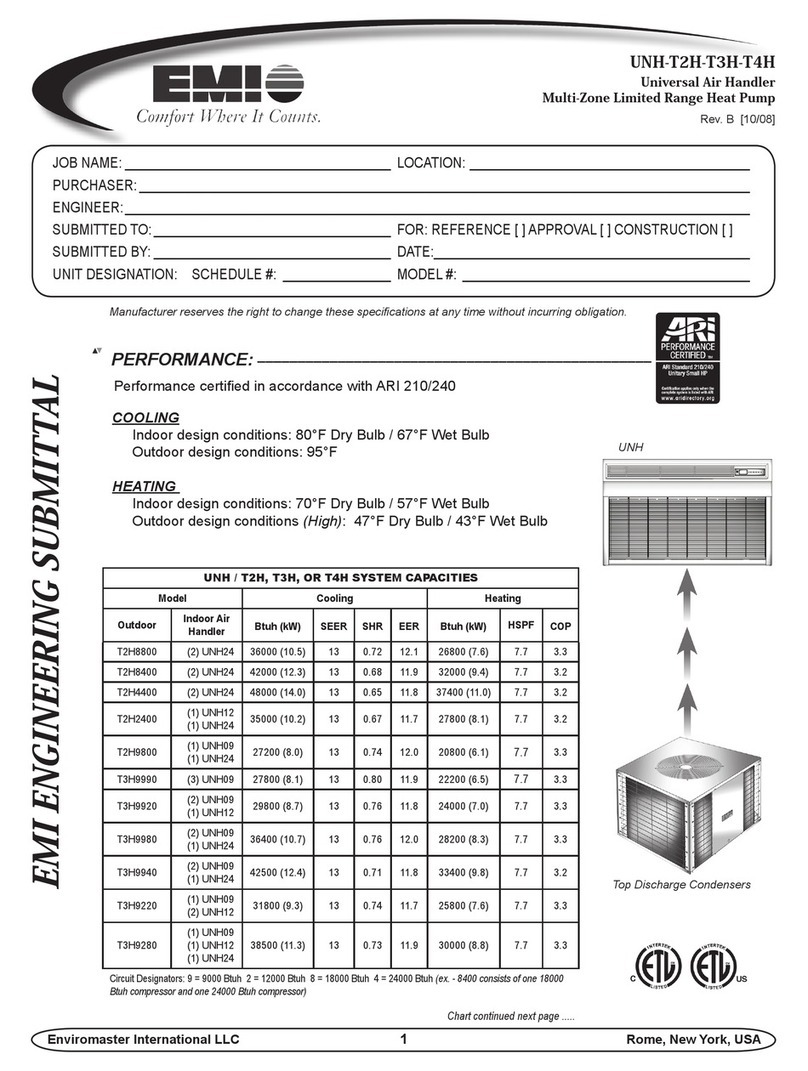

PART THREE “PERFORMANCE”

Eachindoorunitshallprovideattotalminimumcoolingcapacityof11,400BtuhwithaSEERof13.0andEERof11.5

atARIstandardconditions.Thesystemnetminimumtotalcoolingcapacityshallbe11,400Btuhandthenetminimum

sensiblecoolingcapacityshallbe8,760Btuhwithacirculatingairrateof400CFMat80°F(DB)/67°F(WB)entering

theindoorcoiland95°F(DB)airenteringtheoutdoorcoil.Thetotalpowerconsumptionofthecombinedsystemshall

notexceed992Wattsattheseconditions.Theindoorevaporatorshallhaveanairthrowof15feet.Thesystemshall

provideaheatingcapacityof10,600BtuhwithanHSPFof8.0andaCOPof3.4atARIstandardconditions.The

heatingcapacityat70°Findoorand17°Foutdoorshallbe6,200Btuh.

PART FOUR “INDOOR UNIT”

Theindoorunitshallbefactoryassembled,wiredandcontainalowVoltagetransformer.ThecabinetwillbeABS

plasticwithalightgraynishandhaveagalvanizedsteelsubchassis.Theevaporatorfanshallbeanassemblywith

lineowtangentialfandirectdrivenbyasinglemotor.Thefanshallbestaticallyanddynamicallybalancedandrunon

permanentlylubricatedbearings.Amotorizedlouvershallbeprovidedwiththeabilitytochangetheairowvertically.

Horizontal-manuallyadjustabledischargelouverswillbeprovidedthatcanbeplacedinaxedposition.Returnair

shallbelteredbymeansofawashable,reusablemeshlter.Theevaporatorcoilshallbeofnonferrousconstruction

withlouverednsbondedto riedcoppertubing.The tubingshallhave innergroovesforhighefciencyheatex-

change.Alltubejointsshallbebrazedwithphoscopperorsilveralloy.Thecoilshallbepressuretestedatthefactory.

Acondensatemanagementsystemwithover ow protection,condensatedrainpanwithanti-corrosioncoatingand

drainshallbeprovidedunderthecoil.Systemrefrigerantowshallbecontrolledbymeansofanoricepistoninthe

indoorunit.Theunitelectricalpowershallbe208/230or115Volts,1phase,60Hertz.Thesystemshallbecapableof

satisfactoryoperationwithintheVoltagelimitsof208/230or115+/-10%Volts.

PART FIVE “CONTROL SYSTEM”

Thecontrolsystemshallconsistofauniversal unit mounted, infrared compatible control package, congurable to

either unit mount or optional wall thermostat operation.Interconnectedlowvoltagewiringshallrunfromindoorunit

tooutdoorunitdirect,nosplices.Whenrunninglowvoltagewiringadoubleinsulated,18gagecableismandatoryor

useshieldedcable.Themicroprocessorshallbefactorywiredandlocatedwithintheindoorunit.Thecontrolunitwill

havealargeLCDbacklitdisplayandbecongurabletoeitherunitmountorremotewallthermostatoperation.Unit

mount-controloperationallowstheuseofanoptionalIRhandheldcontroller.Thecontrolshallhavethecapability

ofsensingreturnairtemperatureandindoorcoiltemperature.Theoperationalrangewillhaveadjustablesetpoints

from55°Fto90°Finonedegreeincrements.Theuniversalcontrolcanbeusedincoolingonly,coolingwithoptional

electricheat,heatpumporheatpumpwithoptionalsecondstageelectricheat.Operationmodesinclude,cool,heat,

fan,autochangeoveranddry.Fanoperationofauto(cycling),highandlow(constant),autofanoperationautomati-

callyselectsfanspeedaccordingtoheatingorcoolingdemand.Drymodeoperatescoolingandoptionalelectricheat

simultaneouslytoremovehumidity(optionalelectricheatrequired).Testmodeallowsforeaseoftestingafterinstal-

lation(alltimersareeliminated).Roomairsampling(fanautomode)cyclesthefanonperiodicallytoremovetem-

peraturestratication.Fanpurgerunstheindoorfanfor60secondsaftercallisdroppedforcool/heat,improvingunit

efciency.Unitprotectionfeaturesinclude,antishortcyclingcompressorprotection,minimumcompressorruntime,

freezeprotectiontopreventevaporatorfreeze,lterchangeindicator,condensatepanoverowswitch,andintegral

EMI ENGINEERING SUBMITTAL WLH12-S1H2000_101