Web: http://www.enviromaster.comEnviromaster International LLC 1

SpecificationS and performance

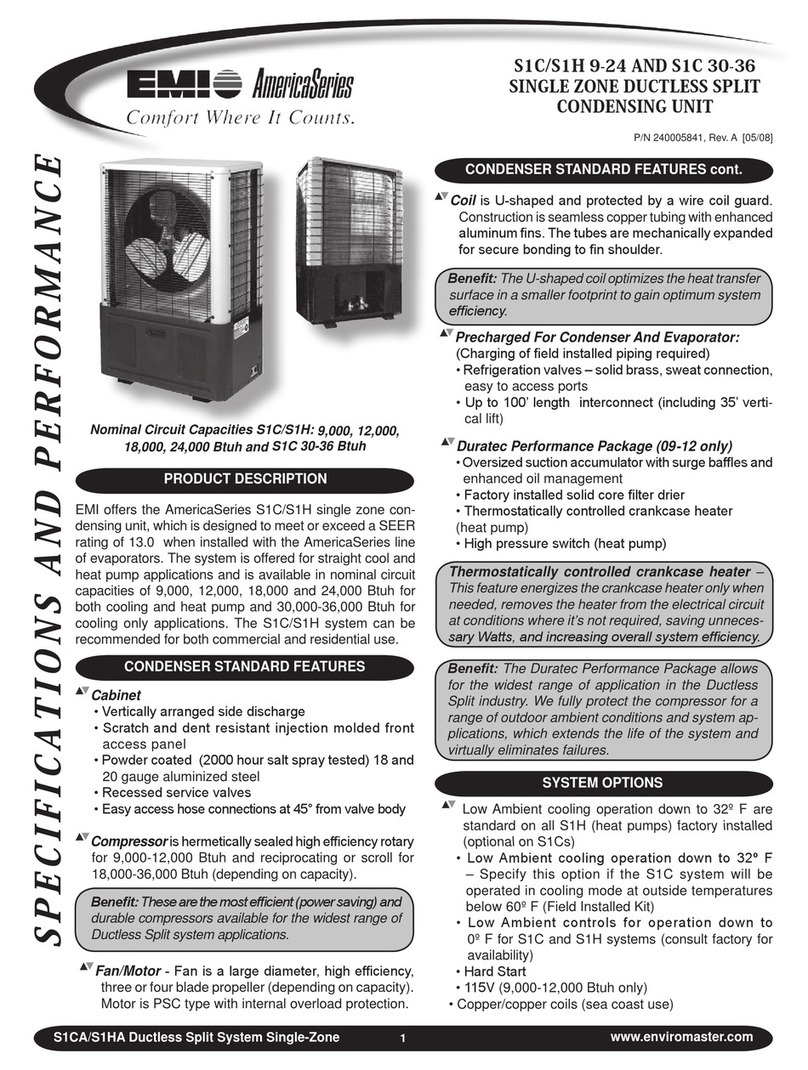

PRODUCT DESCRIPTION

The AmericaSeries WLC/WLH offers a contemporary

design, ductless type evaporator combining attractive

appearance in any decor and high efciency condition-

ing for small to medium size commercial or residential

spaces. The WLC/WLH is equipped with unit mounted

infrared compatible controls which also supports 24V

remote wall thermostat operation. Optional hand held

remote is available.

Heat Pump models provide up to a nominal 24,000 Btuh

ofcoolingandheating.Electricheatoptionsareavailable

for up to 5KW of supplemental heat.

This American-made evaporator offers ease of instal-

lation, operation, and service. It can be matched with

EMI’sS1C/S1H09-24andS1C 30-36 BtuhSingle-Zone

Condensing Units, the S2C side discharge Multi-Zone

CondensingUnit,ortheT2C,T3C,andT4Ctopdischarge

Multi-Zone Condensing Units.

Unit Mounted Control:

• Large LCD Backlit Display

• Singleunitmountedcontrolpackage, congurable

to either unit mount or remote wall thermostat

operation, reducing model number or SKU’s

required.

• Universal control can be used in cooling only,

coolingwithelectricheat,heatpump,or heatpump

with second stage electric heat applications.

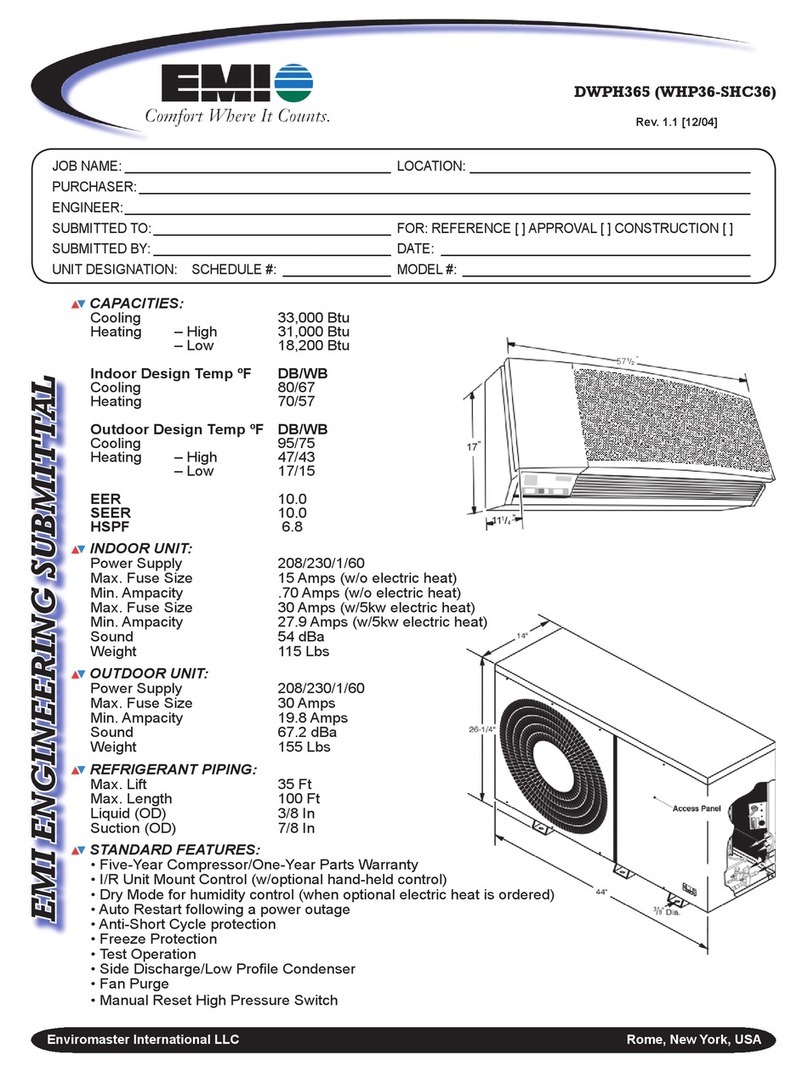

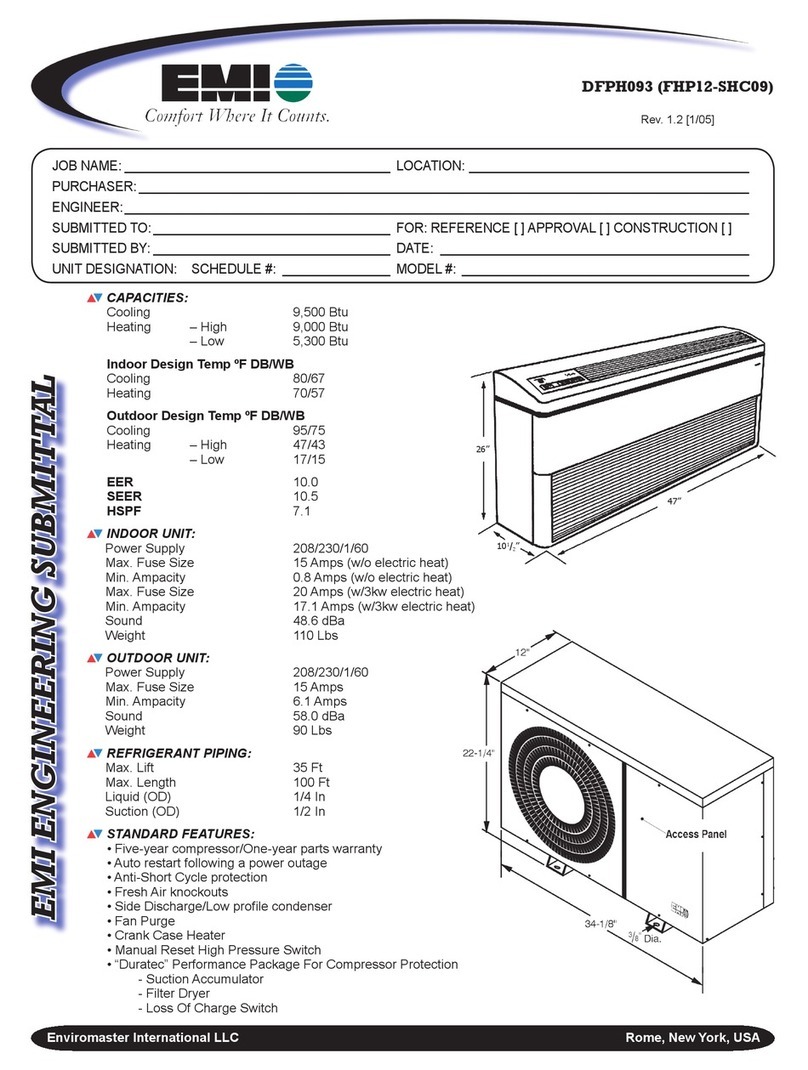

Straight cool/heat pump*

Nominal Circuit Capacities: WLH 9,000, 12,000,

18,000, 24,000 Btuh and WLC (only) 30,000 & 36,000 Btuh

* Heat Pump only available for 9,000-24,000 Btuh units.

Wlc/Wlh

high Wall eVaporator

• Operational range set point temperature

adjustable between 55°F and 90°F in one-degree

increments.

• Infra red compatible control allowsuseofoptional

IR hand held controller

NOTE:Unitmountedcontrolsarefullyfunctional

without the handheld remote.

• Operation modes includeHeat,Cool,Dry,Fanand

Auto Change-over.

• Fan Operation – Auto/On. High or Low speed fan

• Fan Purge – Fan remains on for 60 seconds after

Heat/Cool call is dropped for improved efciency

(Auto mode only)

• Room air sampling: Selectable time intervals

ensures the fan will cycle on periodically, in Auto

Fan Mode.

Benefit: Helps to eliminate room temperature

stratication.

• Selectable Fahrenheit (°F) or Centigrade (°C)

temperature scale.

• Dry mode – Operates cooling and electric heat

simultaneously to remove humidity. Optional

electric heat must be selected.

• Anti-Short Cycle Compressor Protection.

• Minimum on time for heating and cooling.

Benet: Helps eliminate room temperature drop

and system short cycling.

• Freeze Protection – Prevents evaporator freeze up.

• Test operation – Allows ease of testing after

installation (all timers are eliminated).

• Non-volatile back-up memory

Benefit: Control settings are maintained for an

indenite period during a power outage. When power

isrestoredtheequipmentwillresumeoperationafter

a three-minute compressor time delay.

• 7-day programmable with copy feature.

• Filter change indicator: A timer feature that

indicates the lter should be changed according to

the selected time.

• Motorized supply louver with optional sweep or

six stationary settings.

• Modulardesign – reducespartsrequiredforcontrol

STANDARD FEATURES

P/N 240005842, Rev. A [05/08]