Emotron AB 01-3694-01r2 3

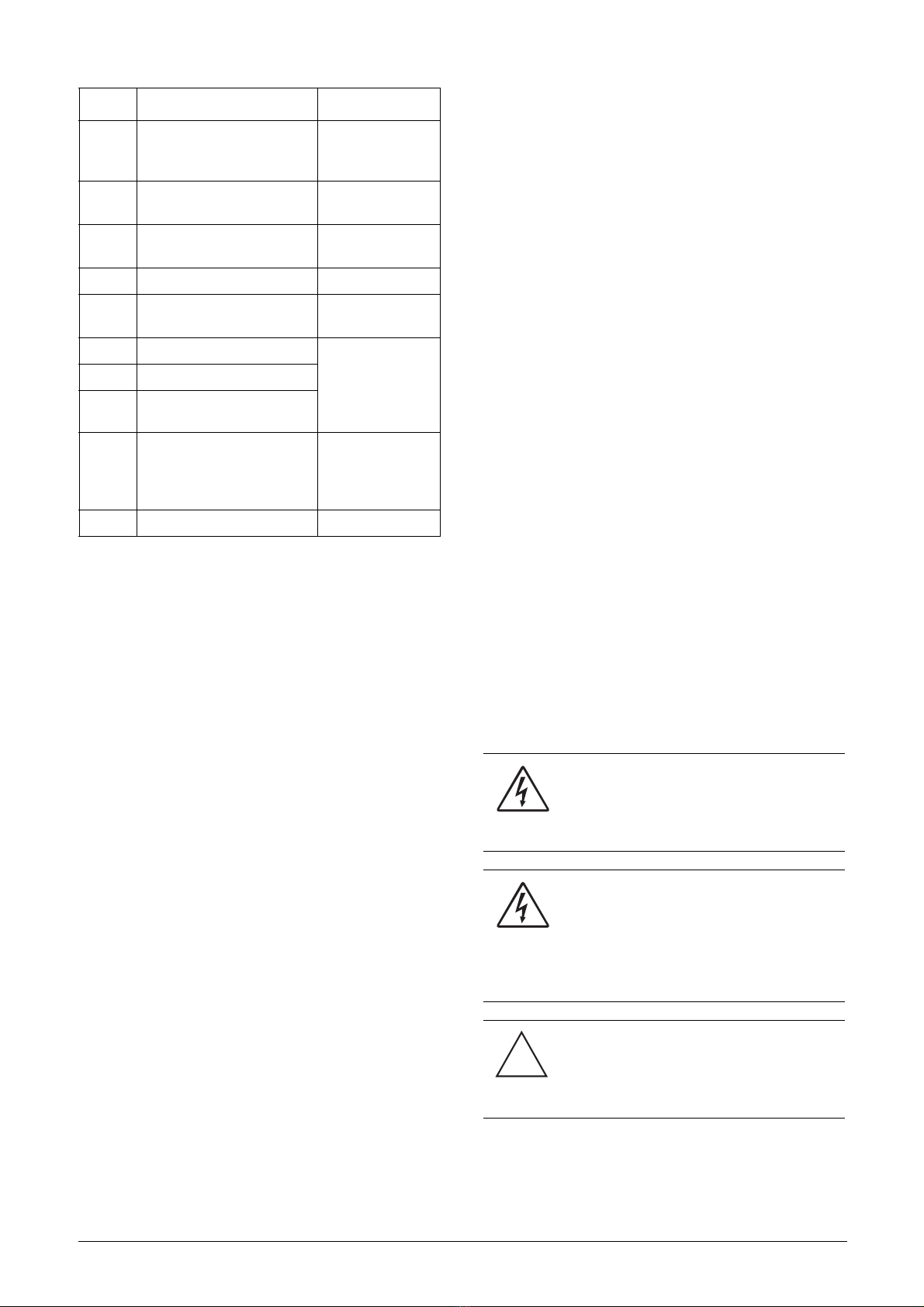

Contents

1. Introduction..................................................... 5

1.1 Delivery and unpacking ............................................ 5

1.2 Using of the instruction manual............................... 5

1.3 Type number.............................................................. 5

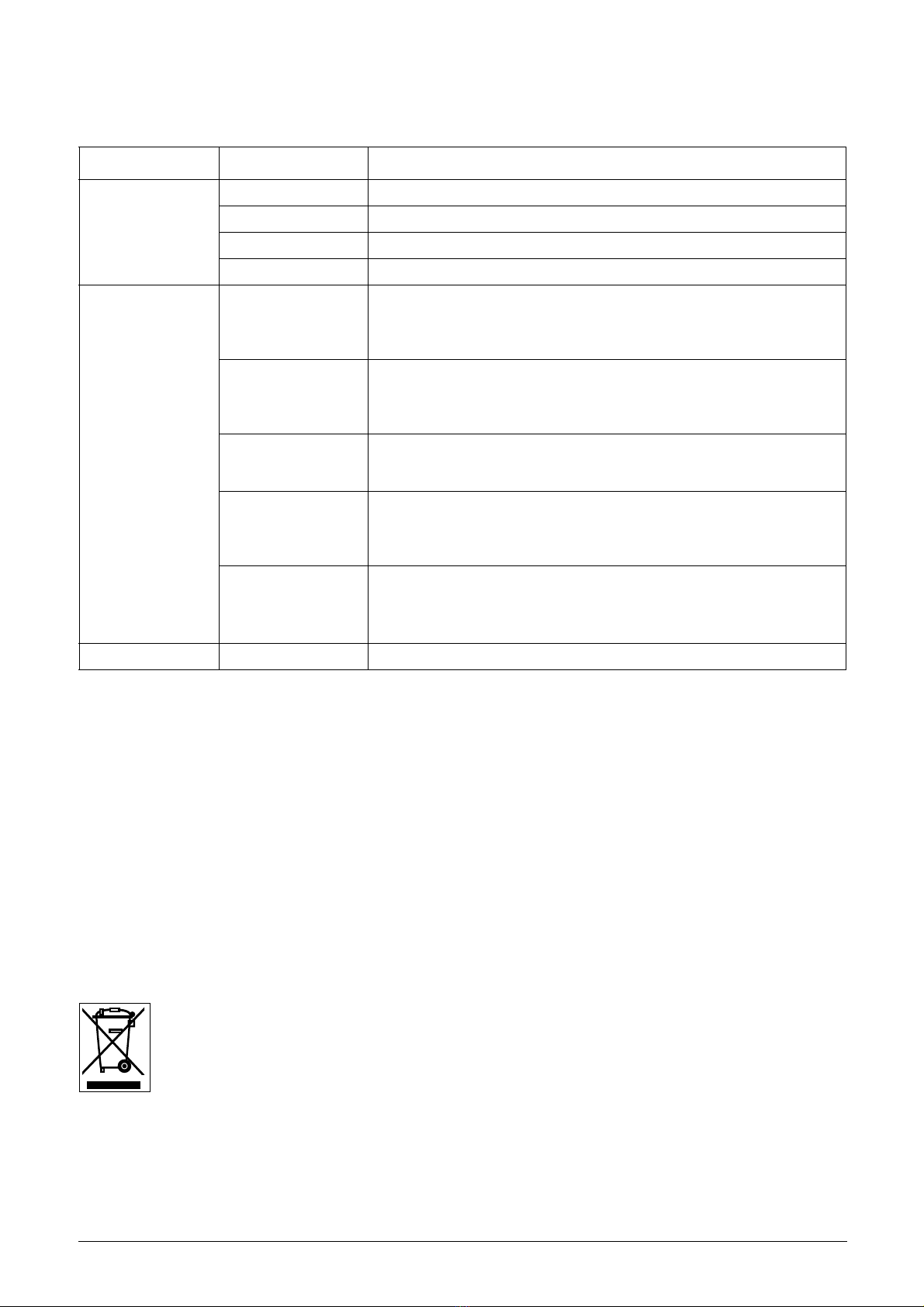

1.4 Standards .................................................................. 6

1.4.1 Product standard for EMC ........................................ 6

1.5 Dismantling and scrapping....................................... 7

1.5.1 Disposal of old electrical and electronic

equipment ................................................................. 7

1.6 Glossary ..................................................................... 8

1.6.1 Abbreviations and symbols....................................... 8

1.6.2 Definitions.................................................................. 8

2. Mounting ......................................................... 9

2.1 Lifting instructions..................................................... 9

2.2 Stand-alone units .................................................... 10

2.2.1 Cooling ..................................................................... 10

2.2.2 Mounting schemes.................................................. 11

2.3 Cabinet mounting.................................................... 13

2.3.1 Cooling ..................................................................... 13

2.3.2 Mounting schemes.................................................. 13

3. Installation ................................................... 17

3.1 Before installation................................................... 17

3.2 Cable connections................................................... 17

3.2.1 Motor cables............................................................ 17

3.2.2 Mains cables ........................................................... 19

3.3 Cable specifications................................................ 19

3.4 Stripping lengths ..................................................... 19

3.4.1 Dimension of cables and fuses.............................. 20

3.4.2 Tightening torque for mains and motor cables..... 20

3.5 Connect motor and mains cables .......................... 20

3.6 Thermal protection on the motor ........................... 21

3.7 Motors in parallel .................................................... 21

4. Control Connections.................................... 23

4.1 Control board........................................................... 23

4.2 Terminal connections ............................................. 24

4.3 Connection example ............................................... 25

4.4 Inputs configuration with the switches.................. 26

4.5 Connecting the Control Signals.............................. 26

4.5.1 Cables ...................................................................... 26

4.5.2 Types of control signals .......................................... 27

4.5.3 Screening................................................................. 27

4.5.4 Single-ended or double-ended connection? ......... 27

4.5.5 Current signals ((0)4-20 mA).................................. 28

4.5.6 Twisted cables......................................................... 28

4.6 Connecting options ................................................. 28

5. Getting Started ............................................ 29

5.1 Connect the mains and motor cables.................... 29

5.1.1 Mains cables ........................................................... 29

5.1.2 Motor cables............................................................ 29

5.2 Connect control cables ........................................... 29

5.3 Using the function keys .......................................... 30

5.4 Remote control........................................................ 30

5.4.1 Switch on the mains ............................................... 30

5.4.2 Set the Motor Data.................................................. 30

5.4.3 Run the VSD ............................................................ 30

5.5 Local control............................................................ 31

5.5.1 Switch on the mains ............................................... 31

5.5.2 Select manual control............................................. 31

5.5.3 Set the Motor Data.................................................. 31

5.5.4 Enter a Reference Value......................................... 31

5.5.5 Run the VSD ............................................................ 31

6. Applications.................................................. 33

6.1 Application overview ............................................... 33

6.1.1 Pumps...................................................................... 33

6.1.2 Fans ......................................................................... 33

6.1.3 Compressors ........................................................... 34

6.1.4 Blowers .................................................................... 34

7. Main Features .............................................. 35

7.1 Parameter sets........................................................ 35

7.1.1 One motor and one parameter set ........................ 36

7.1.2 One motor and two parameter sets....................... 36

7.1.3 Two motors and two parameter sets..................... 36

7.1.4 Autoreset at trip ...................................................... 36

7.1.5 Reference priority.................................................... 36

7.1.6 Preset references.................................................... 37

7.2 Remote control functions ....................................... 37

7.3 Performing an Identification Run........................... 39

7.4 Using the Control Panel Memory............................ 40

7.5 Load Monitor and Process Protection [400]......... 40

7.5.1 Load Monitor [410]................................................. 40

7.6 Pump function ......................................................... 42

7.6.1 Introduction ............................................................. 42

7.6.2 Fixed MASTER ......................................................... 43

7.6.3 Alternating MASTER ................................................ 43

7.6.4 Feedback 'Status' input .......................................... 43

7.6.5 Fail safe operation .................................................. 44

7.6.6 PID control ............................................................... 45

7.6.7 Wiring Alternating Master....................................... 46

7.6.8 Checklist And Tips................................................... 47

7.6.9 Functional Examples of Start/Stop Transitions .... 48

8. EMC and Machine Directive........................ 51

8.1 EMC standards........................................................ 51

8.2 Stop categories and emergency stop .................... 51

9. Operation via the Control Panel.................. 53

9.1 General .................................................................... 53

9.2 The control panel .................................................... 53

9.2.1 The display............................................................... 53

9.2.2 Indications on the display....................................... 54

9.2.3 LED indicators ......................................................... 54

9.2.4 Control keys............................................................. 54