EMPERO EMP.7FE010 User manual

1

ELECTRIC FRYERS

Kasap Tip Dik Buzdolapları

CONTENTS

A GENERAL INFORMATION Page 2

A1 PRODUCT DESCRIPTION Page 3

A2 TECHNICAL INFORMATION Page 3

A3 TRANSPORTATION Page 4

A4 UNPACKING Page 4

B INSTALLATION Page 4

C SAFETY INSTRUCTIONS Page 5

D OPERATION Page 6

E CLEANING & MAINTENANCE Page 7

F TROUBLESHOOTING Page 8

G SPARE PART LIST- EXPLODING DRAWING Page 9

H ELECTRIC CIRCUIT SCHEMA Page 17

2

ELECTRIC FRYERS

ELEKTRİKLİ FRİTÖZLER

Kasap Tip Dik Buzdolapları

A GENERAL INFORMATION

Before installing the appliance, read operation and maintenance instructions

carefully.Wrong installation and part changing may damage the product or may cause

injury on people.These are not in our company’s responsibility to damage the

appliance intentionally,negligence,detriments because of disobeying instructions and

regulations,wrong connections.Unauthorized intervention to appliance invalidates the

warranty.

1. This instruction manual should be kept in a safe place for future reference.

2. Installation should be made in accordance with ordinances and security rules of

that country by a qualified service personnel.

3. This appliance has to be used by trained person.

4. Please turn off the appliance immediately in the event of malfunction or failure.The

appliance should be repaired only by authorized service personnel.Please demand

original spare part.

3

ELECTRIC FRYERS

Kasap Tip Dik Buzdolapları

A1 PRODUCT DESCRIPTION

*The Professional Electric Fryers ,that provides high efficiency has been designed to be used

in industrial kitchens.

Product Code

Dimensions (mm)

Weight (kg)

Packaging

Dimensions (mm)

EMP.7FE010

400x730x285

23

480x800x590

EMP.7FE020

800x730x285

51

780x830x1050

EMP.9FE010

400x900x850

61

430x950x1050

EMP.9FE020

800x900x850

138

830x950x1050

A2 TECHNICAL INFORMATION

Product Code

Electric Entrance

Cable

(mm²)

Power

(KW)

Capacity

(lt)

EMP.7FE010

400 V. AC 3N PE

5x4

11

18

EMP.7FE020

400 V. AC 3N PE

5x4

22

2x18

EMP.9FE010

400 V. AC 3N PE

5x4

12

24

EMP.9FE020

400 V. AC 3N PE

5x6

24

2x24

4

ELECTRIC FRYERS

ELEKTRİKLİ FRİTÖZLER

Kasap Tip Dik Buzdolapları

A3 TRANSPORTATION

*This appliance can be moved by hand from area to area.Do not crash and drop the appliance

while transporting.

A4 UNPACKING

*Please unpack the package according to the security codes and ordinances of current

country and get rid from the pack.Parts which contacts with food are produced by stainless

steel.All plastic parts are marked by material’s symbol.

*Please check that all the parts of appliance had come completely and if they are damaged or

not during the shipping.

B INSTALLATION

*Please place the product to straight and sturdy ground,please take necessary steps against

possibility of overturn.

*Technician who will serve for installation and service for the appliance must be professional

on this subject and must have installation and service licenses by the company.

*Connection to Electric Power Supply must be done by authorized person.

*Please be sure that the voltage connected to appliance must be equal with the voltage which

is on appliance’s label.

This appliance must be connected to an earthed outlet in accordance with safety rules

and standards.

*Appliance’s earthing must be connected to earthing line on panel which is nearest to

electric installation.

*Connection to the main fuse and leak current fuse must be done in accordance with the

current regulations.

*If the location where electric fryers placed is covered with nonflammable heat insulation

material,the distance between them must be 5 cm.Otherwise it should be at least 20 cm.The

appliance shouldn’t be operated under chimney hood.

!

5

ELECTRIC FRYERS

Kasap Tip Dik Buzdolapları

C SAFETY INSTRUCTIONS

*Do not use the appliance in insufficient lighted place.

*Do not touch the moving attachments while the appliance operates.

*Do not install the appliance in the presence of flammable or explosive materials.

*Do not operate the appliance when the machine is empty.

*Do not load so less or more than appliance’s capacity.

*Do not attempt to use the appliance without suitable protective equipments.

*Because of any reason if there is a fire or flame flare where the appliance is

used,turn off all gas valves and electric contactor switch quickly and use fire

extinguisher .Never use water to extinguish the fire.

*All the damages because of not having earthing connection will not be on

warranty.

*Level of oil mustn’t be less than minimum level.Otherwise it can be ignited.

*Level of oil mustn’t be more than maximum level.Otherwise the oil that overflows

from fryer may cause combustion.

*Do not put the unstrained and frozen foods into the hot oil.

!

!

!

!

!

!

!

!

!

6

ELECTRIC FRYERS

ELEKTRİKLİ FRİTÖZLER

Kasap Tip Dik Buzdolapları

D OPERATION

*Control Panel;

A: Heat setting button

B: Indicator lamp

* Operating;

•Before operating the fryer,place filter and filter into the tank.

•Turn off the valve that is in fryer.

•Open the fryer’s lid and add oil into the tank.Pay attention to minimum and maximum

lines while adding oil.

•Plug in the appliance.

•Set the thermostat switch to desired heat in order to operate the appliance.

•Fryers are 2 type; sıngle-tank, double-tank.There are 2 resistances and thermostats in

every tank.If thermostat switch is set to on position,the heaters start to work and indicator

lamp that is on thermostat signals.

•When the oil temperature reaches indicator temperature,heaters are disabled through the

agency of limit thermostat.When the oil temperature is lower than indicator

temperature,the limit thermostat steps in and heaters start to work.

•Put the materials that will be fried into the tank in the basket during oil heating.

•After putting the materials into the tank close the lid and start to fry

•Add oil when the oil is at minimum level.

•After frying process,swtich the thermostat to (0) position and unplug the appliance.

•Open the lid and take off the basket from tank

•In order to remove the oil from fryer,first leave the oil to be cooled.Then attach the oil

drainage pipe to the oil drainage hole.

•Slide the slidiing sled to the right to remove the oil.

7

ELECTRIC FRYERS

Kasap Tip Dik Buzdolapları

E CLEANING & MAINTENANCE

➢CLEANING AND MAINTENANCE AFTER EVERY USE

•Always turn off the appliance and disconnect from the power supply before cleaning.

•Clean the outer surface of the appliance with a wet cloth and chrome shiner.

•Do not use abrasive cleaning chemicals as these can leave harmful residues.

•Do not clean the appliance by spraying water directly,otherwise electric motor may

get damaged.

•While cleaning the inside of the fryer,lift the heater handle,unsettle the heaters that

are in the tank and take them to vertical position.Take off the baskets and filter that

are in the tank.

➢PERIODIC CLEANING AND MAINTENANCE

•Maintenance should be done by qualified person.

•Get the periodic maintenance of the appliance once in every 15 days.

•Clean the oil tank in periodic times.Fill the tank with water and heat.This process will

help to remove frozen and sticked oil.

•Maintenance of the appliance’s contactor should be done by compressed air

according to frequency of use.

8

ELECTRIC FRYERS

ELEKTRİKLİ FRİTÖZLER

Kasap Tip Dik Buzdolapları

F TROUBLESHOOTING

THE APPLIANCE DOESN’T OPERATE

1. Check if the appliance is plugged in.

2. Check the electrical connections and

voltage.

3. Check the resistances.

THE APPLIANCE DOESN’T FRY WELL

1. Check the level of oil.

2. Check the thermostat switch.If the oil

can not be heated as desired,contact

with authorized service.

THE APPLIANCE STOPPED

1. If the oil temperature reaches to 230ºC

while the appliance is operating,limit

thermostat will stop the circuit.In this

situation the appliance can not be

operated.Leave the oil to be cooled to

operate again.Then take off the

thermostat switch that is on front panel

and press the red button with a thin tool.

2. The appliance can stop due to low

voltage.In this situation check the

voltage.

•If frying is not done at suitable quality

•If any function of security doesn’t work

➢Do not use the appliance.

*If these problems are still going on,contact with our authorized services.

9

ELECTRIC FRYERS

Kasap Tip Dik Buzdolapları

G SPARE PART LIST-EXPLODING DRAWING

EMP.7FE010

10

ELECTRIC FRYERS

ELEKTRİKLİ FRİTÖZLER

Kasap Tip Dik Buzdolapları

G SPARE PART LIST-EXPLODING DRAWING

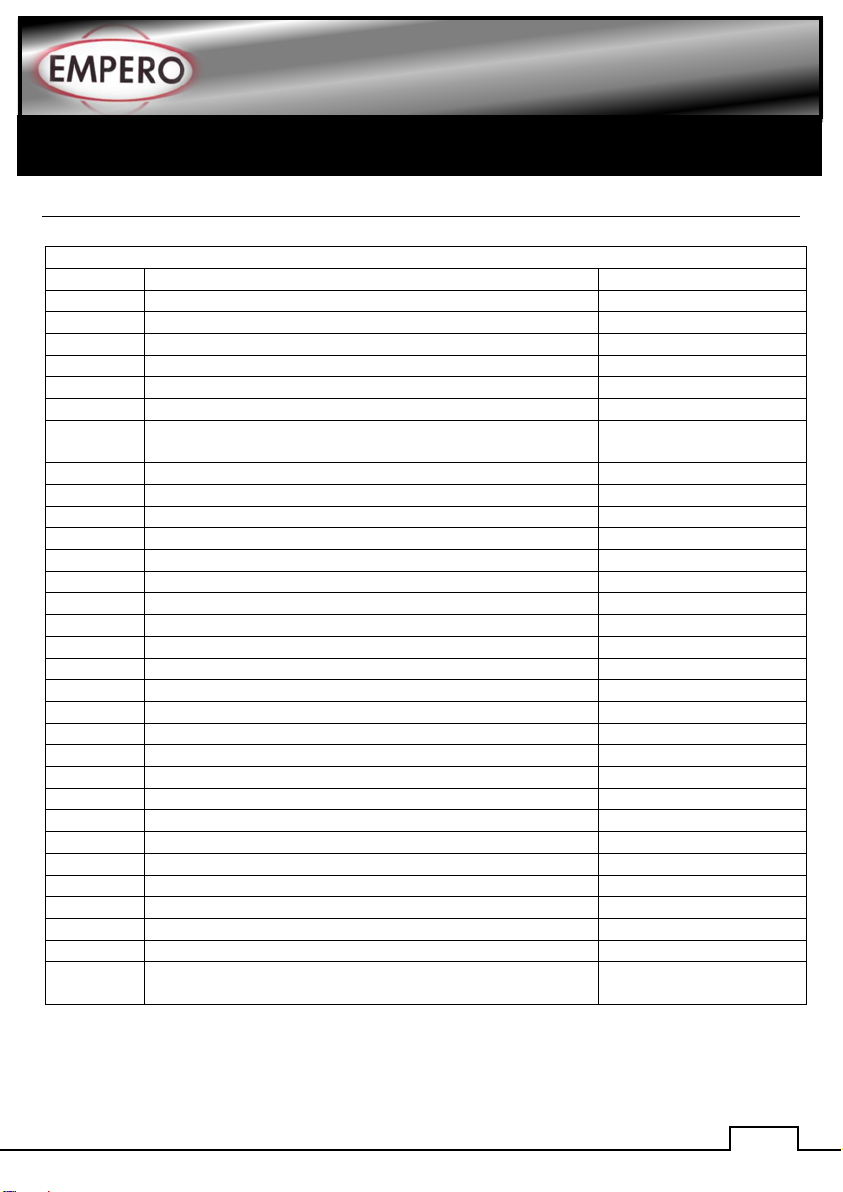

PRODUCT CODE:EMP.7FE010

NO

PRODUCT NAME

P.CODE

1

HANDLE

Y.EMP.7FE010.001

2

LID

Y.EMP.7FE010.002

3

BASKET HANGER SHEETMETAL

Y.EMP.7FE010.003

4

RESISTANCE

Y.EMP.7FE010.004

5

BASKET

Y.EMP.7FE010.005

6

BASKET BOTTOM SHEETMETAL

Y.EMP.7FE010.006

7

RESISTANCE CONNECTION MIDDLE TOP

SHEETMETAL

Y.EMP.7FE010.007

8

CONTACTOR MTF41

Y.EMP.7FE010.008

9

BASE FRAME

Y.EMP.7FE010.009

10

VALVE HANDLE

Y.EMP.7FE010.010

11

WARNING LAMP

Y.EMP.7FE010.011

12

YELLOW HINGE RING

Y.EMP.7FE010.012

13

BUTTON

Y.EMP.7FE010.013

14

EVACUATION HOSE

Y.EMP.7FE010.014

15

VALVE

Y.EMP.7FE010.015

16

SWITCH

Y.EMP.7FE010.016

17

CHROME HINGE RING

Y.EMP.7FE010.017

18

LOCK SPRING

Y.EMP.7FE010.018

19

RESISTANCE CONNECTION SHEETMETAL-RIGHT

Y.EMP.7FE010.019

20

LOCK CONNECTION YELLOW NUT

Y.EMP.7FE010.020

21

FEET

Y.EMP.7FE010.021

22

THERMOSTAT 135-180

Y.EMP.7FE010.022

23

LOCK HANDLE

Y.EMP.7FE010.023

24

BUTTON BUFFER

Y.EMP.7FE010.024

25

THERMO PART CONNECTION SHEETMETAL

Y.EMP.7FE010.025

26

RESISTANCE SUPPORT SHEETMETAL

Y.EMP.7FE010.026

27

HINGE LOCK- INNER

Y.EMP.7FE010.027

28

HINGE LOCK- OUTER

Y.EMP.7FE010.028

29

RESISTANCE CONNECTION SHEETMETAL-LEFT

Y.EMP.7FE010.029

30

RESISTANCE CONNECTION MIDDLE BOTTOM

SHEETMETAL

Y.EMP.7FE010.030

11

ELECTRIC FRYERS

Kasap Tip Dik Buzdolapları

G SPARE PART LIST-EXPLODING DRAWING

EMP.9FE010

12

ELECTRIC FRYERS

ELEKTRİKLİ FRİTÖZLER

Kasap Tip Dik Buzdolapları

G SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE: EMP.9FE010

NO

PRODUCT NAME

P.CODE

1

HANDLE

Y.EMP.9FE010.001

2

LID

Y.EMP.9FE010.002

3

BASKET HANGER SHEETMETAL

Y.EMP.9FE010.003

4

RESISTANCE

Y.EMP.9FE010.004

5

BASKET

Y.EMP.9FE010.005

6

BASKET HOLDER

Y.EMP.9FE010.006

7

RESISTANCE CONNECTION MIDDLE TOP

SHEETMETAL

Y.EMP.9FE010.007

8

CONTACTOR 3TF41

Y.EMP.9FE010.008

9

BASE FRAME

Y.EMP.9FE010.009

10

MAGNET,

Y.EMP.9FE010.010

11

WARNING LAMP

Y.EMP.9FE010.011

12

YELLOW HINGE RING

Y.EMP.9FE010.012

13

BUTTON

Y.EMP.9FE010.013

14

HINGE GROUP

Y.EMP.9FE010.014

15

VALVE

Y.EMP.9FE010.015

16

SWITCH

Y.EMP.9FE010.016

17

CHROME HINGE RING

Y.EMP.9FE010.017

18

LOCK SPRING

Y.EMP.9FE010.018

19

RESISTANCE CONNECTION MIDDLE BOTTOM

SHEETMETAL

Y.EMP.9FE010.019

20

LOCK CONNECTION YELLOW NUT

Y.EMP.9FE010.020

21

FEET

Y.EMP.9FE010.021

22

THERMOSTAT 135-180

Y.EMP.9FE010.022

23

LOCK HANDLE

Y.EMP.9FE010.023

24

BUTTON BUFFER

Y.EMP.9FE010.024

25

THERMOCUPL CONNECTION SHEETMETAL

Y.EMP.9FE010.025

26

RESISTANCE SUPPORT SHEETMETAL

Y.EMP.9FE010.026

27

HINGE LOCK- INNER

Y.EMP.9FE010.027

28

HINGE LOCK- OUTER

Y.EMP.9FE010.028

29

LID

Y.EMP.9FE010.029

30

HANDLE

Y.EMP.9FE010.030

31

VESSEL

Y.EMP.9FE010.031

32

FILTER

Y.EMP.9FE010.032

33

RESISTANCE CONNECTION SHEETMETAL-RIGHT

Y.EMP.9FE010.033

34

RESISTANCE CONNECTION SHEETMETAL-LEFT

Y.EMP.9FE010.034

13

ELECTRIC FRYERS

Kasap Tip Dik Buzdolapları

G SPARE PART LIST-EXPLODING DRAWING

EMP.7FE020

14

ELECTRIC FRYERS

ELEKTRİKLİ FRİTÖZLER

Kasap Tip Dik Buzdolapları

G SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE:EMP.7FE020

NO

PRODUCT NAME

P.CODE

1

HANDLE

Y.EMP.7FE020.001

2

LID

Y.EMP.7FE020.002

3

BASKET HANGER SHEETMETAL

Y.EMP.7FE020.003

4

RESISTANCE

Y.EMP.7FE020.004

5

BASKET

Y.EMP.7FE020.005

6

BASKET BOTTOM SHEETMETAL

Y.EMP.7FE020.006

7

RESISTANCE CONNECTION MIDDLE TOP

SHEETMETAL

Y.EMP.7FE020.007

8

CONTACTOR 3TF41

Y.EMP.7FE020.008

9

BASE FRAME

Y.EMP.7FE020.009

10

VALVE HANDLE

Y.EMP.7FE020.010

11

WARNING LAMP

Y.EMP.7FE020.011

12

YELLOW HINGE RING

Y.EMP.7FE020.012

13

BUTTON

Y.EMP.7FE020.013

14

DRAINAGE PIPE

Y.EMP.7FE020.014

15

VALVE

Y.EMP.7FE020.015

16

SWITCH

Y.EMP.7FE020.016

17

CHROME HINGE RING

Y.EMP.7FE020.017

18

LOCK SPRING

Y.EMP.7FE020.018

19

RESISTANCE CONNECTION SHEETMETAL-RIGHT

Y.EMP.7FE020.019

20

LOCK CONNECTION YELLOW NUT

Y.EMP.7FE020.020

21

FEET

Y.EMP.7FE020.021

22

THERMOSTAT 135-180

Y.EMP.7FE020.022

23

LOCK HANDLE

Y.EMP.7FE020.023

24

BUTTON BUFFER

Y.EMP.7FE020.024

25

THERMO PART CONNECTION SHEETMETAL

Y.EMP.7FE020.025

26

RESISTANCE SUPPORT SHEETMETAL

Y.EMP.7FE020.026

27

HINGE LOCK- INNER

Y.EMP.7FE020.027

28

HINGE LOCK- OUTER

Y.EMP.7FE020.028

29

RESISTANCE MIDDLE CONNECTION SHEETMETAL

Y.EMP.7FE020.029

30

RESISTANCE CONNECTION SHEETMETAL-LEFT

Y.EMP.7FE020.030

31

RESISTANCE CONNECTION MIDDLE BOTTOM

SHEETMETAL

Y.EMP.7FE020.031

15

ELECTRIC FRYERS

Kasap Tip Dik Buzdolapları

G SPARE PART LIST-EXPLODING DRAWING

EMP.9FE020

16

ELECTRIC FRYERS

ELEKTRİKLİ FRİTÖZLER

Kasap Tip Dik Buzdolapları

G SPARE PART LIST-EXPLODING DRAWING

PRODUCT CODE: EMP.9FE020

NO

PRODUCT NAME

P.CODE

1

HANDLE

Y.EMP.9FE020.001

2

LID

Y.EMP.9FE020.002

3

BASKET HANGER SHEETMETAL

Y.EMP.9FE020.003

4

RESISTANCE

Y.EMP.9FE020.004

5

BASKET

Y.EMP.9FE020.005

6

BASKET HOLDER

Y.EMP.9FE020.006

7

RESISTANCE CONNECTION MIDDLE TOP

SHEETMETAL

Y.EMP.9FE020.007

8

CONTACTOR 3TF41

Y.EMP.9FE020.008

9

BASE FRAME

Y.EMP.9FE020.009

10

MAGNET,

Y.EMP.9FE020.010

11

WARNING LAMP

Y.EMP.9FE020.011

12

YELLOW HINGE RING

Y.EMP.9FE020.012

13

BUTTON

Y.EMP.9FE020.013

14

HINGE GROUP

Y.EMP.9FE020.014

15

VALVE

Y.EMP.9FE020.015

16

SWITCH

Y.EMP.9FE020.016

17

CHROME HINGE RING

Y.EMP.9FE020.017

18

LOCK SPRING

Y.EMP.9FE020.018

19

RESISTANCE CONNECTION SHEETMETAL-RIGHT

Y.EMP.9FE020.019

20

LOCK CONNECTION YELLOW NUT

Y.EMP.9FE020.020

21

FEET

Y.EMP.9FE020.021

22

THERMOSTAT 135-180

Y.EMP.9FE020.022

23

LOCK HANDLE

Y.EMP.9FE020.023

24

BUTTON BUFFER

Y.EMP.9FE020.024

25

THERMOCUPL CONNECTION SHEETMETAL

Y.EMP.9FE020.025

26

RESISTANCE SUPPORT SHEETMETAL

Y.EMP.9FE020.026

27

HINGE LOCK- INNER

Y.EMP.9FE020.027

28

HINGE LOCK- OUTER

Y.EMP.9FE020.028

29

LID

Y.EMP.9FE020.029

30

HANDLE

Y.EMP.9FE020.030

31

VESSEL

Y.EMP.9FE020.031

32

FILTER

Y.EMP.9FE020.032

33

RESISTANCE MIDDLE CONNECTION SHEETMETAL

Y.EMP.9FE020.033

34

RESISTANCE CONNECTION MIDDLE BOTTOM

SHEETMETAL

Y.EMP.9FE020.034

35

RESISTANCE CONNECTION SHEETMETAL-LEFT

Y.EMP.9FE020.035

17

ELECTRIC FRYERS

Kasap Tip Dik Buzdolapları

H ELECTRIC CIRCUIT SCHEMA

EMP.7FE010

T1

LS

C1

L1

R1

Thermostat (135-180ºC)

Limit Switch

Contactor

Thermostat signal lamp

Resistance

18

ELECTRIC FRYERS

ELEKTRİKLİ FRİTÖZLER

Kasap Tip Dik Buzdolapları

H ELECTRIC CIRCUIT SCHEMA

EMP.7FE020

T1.T2

LS1.LS2

C1.C2

L1.L2

R1.R2

Thermostat (135-180ºC)

Limit Switch

Contactor

Thermostat signal lamp

Resistance

19

ELECTRIC FRYERS

Kasap Tip Dik Buzdolapları

H ELECTRIC CIRCUIT SCHEMA

EMP.9FE010

T1

LT

LS

C1

L1

R1.

Thermostat (135-

180ºC)

Limit thermostat

230ºC

Limit

Switch

Contactor

Thermostat

signal lamp

Resistance

20

ELECTRIC FRYERS

ELEKTRİKLİ FRİTÖZLER

Kasap Tip Dik Buzdolapları

H ELECTRIC CIRCUIT SCHEMA

EMP.9FE020

T1.T2

LT1.LT2

LS1.LS2

C1.C2

L1.L2

R1.R2.

Thermostat

(135-180ºC)

Limit

thermostat

230ºC

Limit

Switch

Contactor

Thermostat

signal lamp

Resistance

4000W 230V

This manual suits for next models

3

Table of contents

Other EMPERO Fryer manuals