EmpireCovers Carport 122008R User manual

122008R Part List

Shelter Assembly Manual

Normal Model # Carport 122008R

Specication:

Width: 12’ Length: 20’ Height: 8’

12’

8’

Part Code Description Qty Box

1Male Bent Tube 6 B

2Female Bent Tube 6 B

3 Stake Peg for back door frame 2 C

3a Stake Peg for front door frame 2 C

4 Stake Peg for middle arch frame 8 C

5 Male Horizontal Connecting Tube 20 C

6 Female Horizontal Connecting Tube 5 C

7Diagonal Bracing Tube 2 B

9 Duckbill Nail 6 B

10 12x1000mm Steel Rod 1 C

11 U bolt 6 B

13 Roof Cover 1 A

14 Front and Back Door Cover 2 A

15 Bolt M8*80mm 30 B

16 Bolt M8*50mm 2 B

17 Bungee 6 B

18 42mm Plastic Plug 12 B

19 28mm Plastic Plug 10 B

20 Rope 2 B

IMPORTANT - READ MANUAL FIRST

READ ALL INSTRUCTIONS BEFORE ASSEMBLY

EQUIPMENT AND TOOLS FOR INSTALLATION

Improper site preparation, Assembly and Maintenance may invalidate warranty and cause

unnecessary and costly mistake. If you have any questions contact your local dealer. For User

Friendly assembly we have identied each individual component with the part code as indicated in the

parts list. Please refer to the part code numbers and drawing to ensure problem free assembly.

It’s necessary to tighten the roof fabric enough to avoid “hammocks” on the roof and also re-tighten

once or twice again after a few months of use. This is important when assembly in cold weather

(autumn and winter) because the fabric is stiff then and when we got the sun and warm weather

afterwards it will make the fabric “slack” again and need to be re-tighten before next winter.

It’s the owners responsibility to take of snow immediately if not slide off by itself.

1. Keep work area clean. Cluttered areas invite injuries. Do not set up near snow drifts, in slippery

places, in high winds, or wet location.

2. Keep children away. All children should be kept away from the work area.

3. Don’t over reach. Keep proper footing and balance at all times.

4. Do not assemble in under the inuence of alcohol or drugs. Read warning labels on prescriptions

to determine if your judgment or reexes are impaired while taking drugs. If there is any doubt, do

not assemble.

5. Be aware of possible windy conditions; fasten the bases in concrete if these conditions are likely

to occur. Remove the cover during hurricane.

6. Be careful with power and heat sources. Do not keep heat sources near the tarpaulin. Do not

expose to open ame.

7. Be aware of personal safety during assembly and use. Be careful not to pinch ngers with clips

and tubes when assembling: when using makes sure there is adequate ventilation for exhaust and

other dangerous fumes.

1. Measuring tape

2. String for alignment

3. Step ladder

4. Welder

5. Sledge hammer

6. Wrench

7. Scissors

INSTALLATION PROCESS

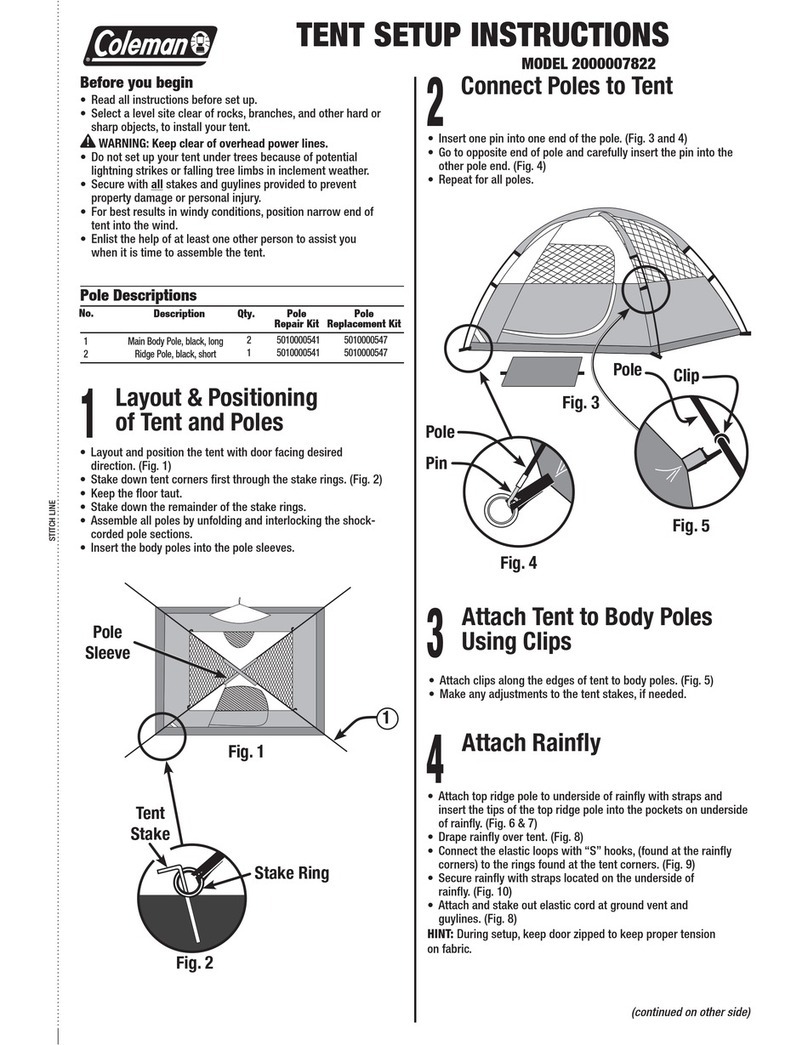

A. Arch Frame Installation

1. (Part No. 1* 1 unit + part No. 2 * 1 unit +

part No. 3A* 2 unit) Please nd the 1 piece

of Male Bent Tubes (part No. 1), one piece

of Female Bent Tubes (part No. 2) and

2 pieces of Stake Peg for front wall (part

No. 3A). Connect them to make one group

arch.

2. (Part No. 1* 1 unit + part No. 2 * 1 unit +

part No. 4* 2 unit) Please nd the 1 piece

of Male Bent Tubes (part No. 1), one piece

of Female Bent Tubes (part No. 2) and 2

pieces of Stake Peg for middle arch frame

(part No. 4). Connect them to make the

second group arch. By turns, there are 6

groups of arches.

1

2

3

12

3a

3a

10

11

15

15

18

19

4

7

6

11

5

9

INSTALLATION PROCESS

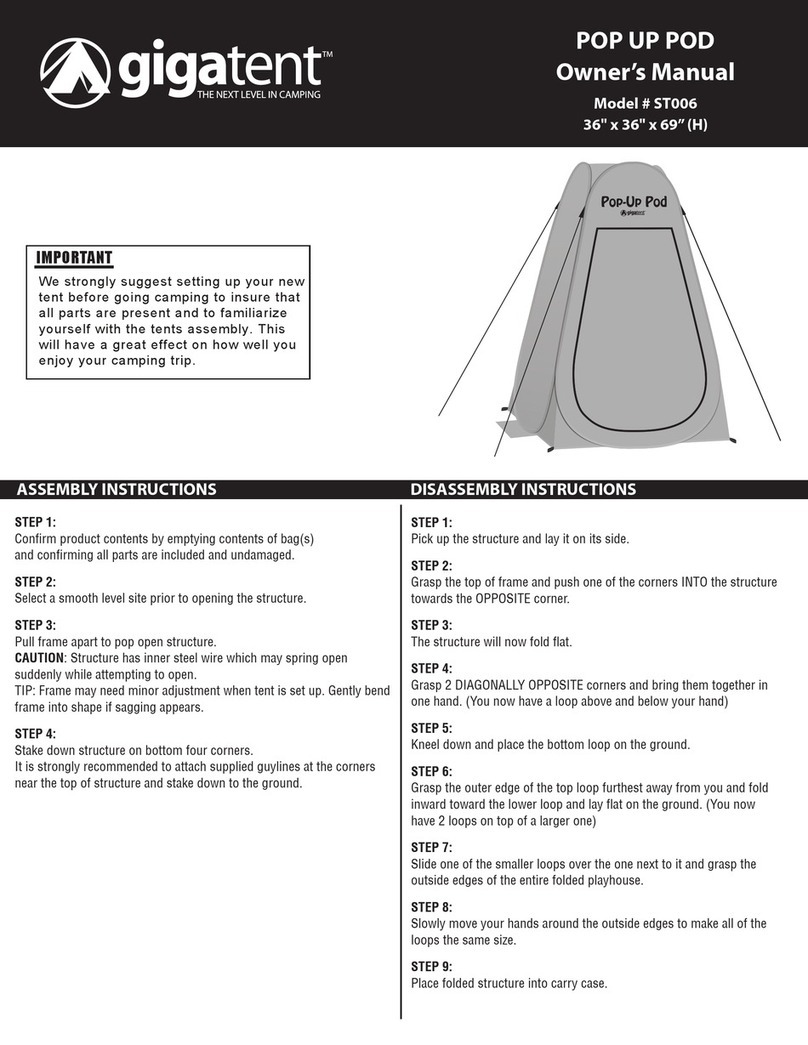

B. Connect the Arch Frame

NOTE:

Please check

and reference the

Frame Figure.

1. Please connect the rst and second group

of arches by using Female Horizontal

Connecting Tube (part No.6) and Bolt

M8*80mm (part No.15), there are 5 pieces of

female horizontal connecting tubes between

them. Which make the front door group arch.

(Please NOTE the direction of the bolt. DO

NOT install the bolt on the top of the truss

where the fabric will rest.)

2. By turn, connect the other group arches

by using Male Horizontal Connecting Tube

(part No.5) and Bolt M8*80mm (part No.15)

Please make the Horizontal Connecting

Tube under the arch frame, the roof cover

could be supported beautifully.

3. Install the Diagonal Bracing Tube (part No.7) by using Bolt M8*50mm (part No.16) and Bolt

M8*80mm (part No.15).

4. Finally install all the Plastic Plug (part No. 18 and No. 19) in the suitable tubes.

INSTALLATION PROCESS

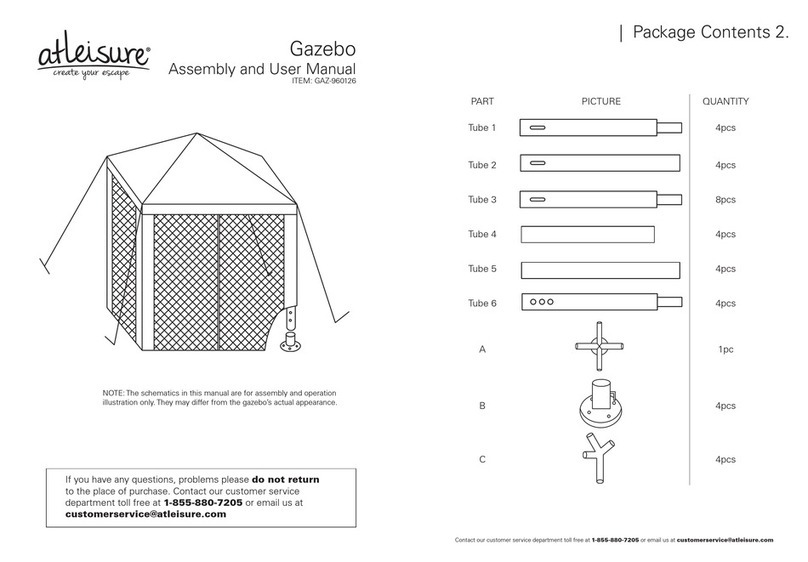

C. Cover Installation

1. Put on the Front Door cover (part

No.14) from the inside of the door

frame to the outside and nd the

suitable holes to pass through all

the tubes. Fix them using Rope

inside of the door cover and tie it

on the bottom of the door frame.

Then put on the back door cover

like it.

2. Put on the Roof Cover (part

No.13).

3. Knit the Roof Cover and the Lowest

Horizontal Connecting Tubes by

using the Rope (part No. 20).

Spin from inside out

13

20

14

17

INSTALLATION PROCESS

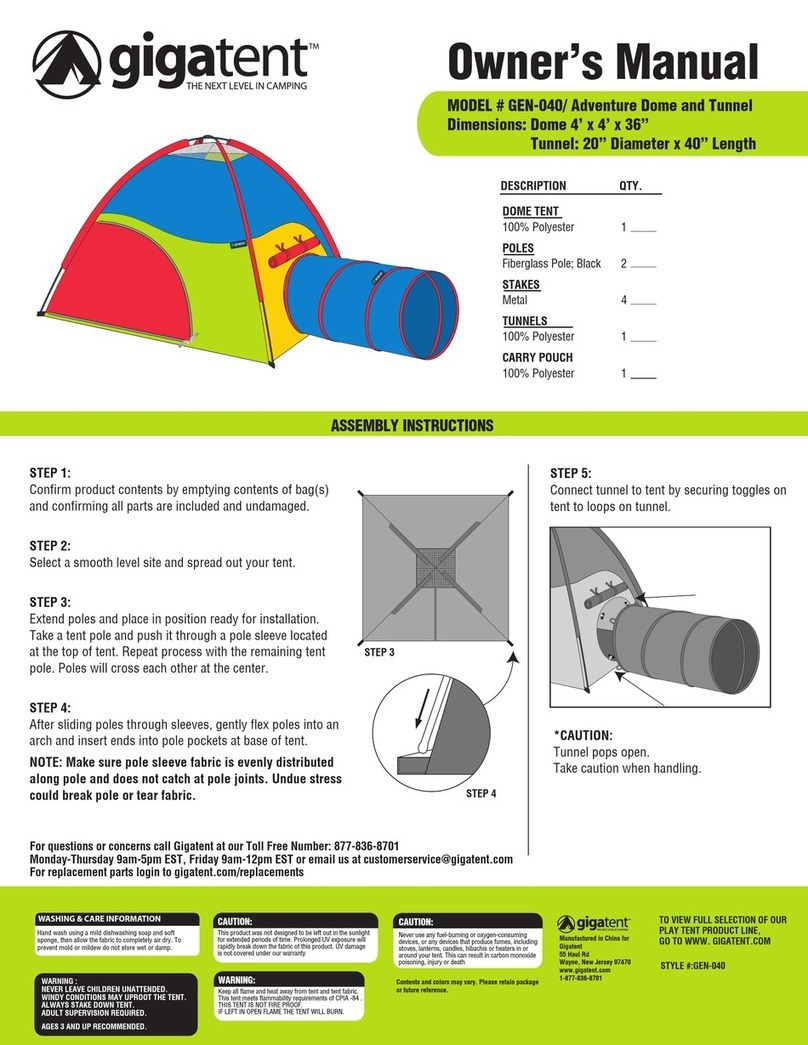

D. Duckbill Nail Installation

4. Finally adjust the frame and rope,

make sure the cover is binding and

smooth.

Insert the 12mm Steel Rod (part No.10) into one Duckbill Nail (part No.9) and use electric

hammer to sink the nail into the earth deeply. Then x it to the lower of frame tube using U

bolts (part No.11). There are 6 duckbill nails.

NOTE:

DO NOT LEAVE THE ROOF COVER UNATTACHED UNDER ANY

CIRCUMSTANCES UNTIL THE FINAL ASSEMBLY AND TIGHTENING

HAS BEEN COMPLETED. THE PROCESS IS QUITE EASY, BUT SOME

TIGHTENING ADJUSTMENTS WILL BE NECESSARY TO PRODUCE A

FLAT, TENSIONED ROOF COVER. PLEASE ADJUST THE ROOF

COVER EVERY MONTH.

Table of contents