Emtec SonoTT User manual

SonoTTTM Clamp-On Transducer

Operating Instructions

Copyright

All rights reserved, especially with respect to reproduction, distribution and translation.

These operating instructions or any part thereof must not be reproduced, saved, processed, duplicated or

distributed without the written consent of em-tec GmbH.

© Copyright 2022 em-tec GmbH Finning. -All rights reserved.

Subject to Technical Changes

Owing to our policy of continuous product development, the illustrations and technical data contained in

this document may differ slightly from the current version of the device.

Legal Manufacturer

em-tec GmbH

Lerchenberg 20

86923 Finning

GERMANY

Phone: +49 8806 9236-0

Fax: +49 8806 9236-50

E-mail: em-tec-info@psgdover.com

Internet: www.em-tec.de

EN

Table of Contents

English..................................................... 5

Deutsch..................................................... 26

DE

SonoTTTM Clamp-On Transducer

EN

Table of Contents

1 System Description............................................................................................................5

2 Description of the Measurement Principle..................................................................6

3 General Safety Information, Symbols and Units ...................................................... 7

3.1 Symbols Used in these Operating Instructions ...................................................7

3.2 Symbols on the SonoTTTM Clamp-On Transducer and on Packaging.............7

4 General Information Concerning these Operating Instructions.............................8

5 Intended Purpose, Restrictions and Limitations.......................................................8

5.1 Intended Purpose.........................................................................................................8

5.2 Contraindications......................................................................................................... 9

5.3 Usage Restrictions and Limitations........................................................................ 9

5.4 Liabilities and Responsibilities.............................................................................. 10

5.5 Notice Concerning Compulsory Registration..................................................... 10

5.6 Safety Instructions..................................................................................................... 10

5.7 Electromagnetic Compatibility .............................................................................. 10

5.8 Ultrasonic Safety Regarding Acoustic Output.....................................................11

5.9 Biocompatibility ..........................................................................................................11

5.10 Maintenance and Service..........................................................................................12

6 Installation, Use, and Disassembly of the

SonoTTTM Clamp-On Transducer....................................................................................13

6.1 General Safety Information .....................................................................................13

6.2 Connecting the SonoTTTM Clamp-On Transducer to the

SonoTTTM Ultrasonic FlowComputer.......................................................................13

6.3 Attaching the SonoTTTM Clamp-On Transducer to the Tube........................... 14

6.4 Use of the SonoTTTM Clamp-On Transducer.........................................................15

6.5 Disassembly and Storage of the SonoTTTM Clamp-On Transducer ............ 16

6.6 Cleaning and Disinfection of the SonoTTTM Clamp-On Transducer..............17

6.7 Changing the SonoTTTM Clamp-On Transducer .................................................17

7 Adjustment and Calibration of the SonoTTTM Clamp-On Transducer...................18

7.1 Adjustment................................................................................................................... 18

7.2 Calibration ................................................................................................................... 18

8 Troubleshooting ...............................................................................................................19

9 Environmental Protection and Disposal.....................................................................22

10 TechnicalSpecicationsoftheSonoTTTM Clamp-On Transducer.........................23

SonoTTTM Clamp-On Transducer

Page 4 D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Copyright em-tec GmbH

EN

1 System Description

The SonoTTTM Clamp-On Transducer, which is used in combination with, and powered by, the evaluation

device SonoTTTM Ultrasonic FlowComputer, measures the volumetric ow rate of uids based on the ultrasonic

transit time method. The SonoTTTM Clamp-On Transducer encloses exible tubes via a simple click-fastening

and operates non-invasively without physical contact to the medium, allowing it to meet even strict hygienic

requirements. In combination, the SonoTTTM Clamp-On Transducer and the SonoTTTM Ultrasonic FlowComputer

represent an independent system.

Established elds of application on extracorporeal tubing circuits for the SonoTTTM Clamp-On Transducer are,

for example:

• heart-lung machines (HLM)

• extracorporeal membrane oxygenation (ECMO)

• organ perfusion

• left and right ventricular bypasses

• cardiopulmonary support/bypasses

• venous extracorporeal support (e.g. for liver transplantation)

• shunts

ClassicationunderMDR(EUDirective2017/745)

The SonoTTTM Clamp-On Transducer is assigned to MDR Class I in accordance with Annex VIII, using Rule 13.

The SonoTTTM Clamp-On Transducer is an active device used to monitor the ow in extracorporeal tubing

circuits together with the SonoTTTM Ultrasonic FlowComputer. The Declaration of Conformity for the MDR is

based on this classication.

While a copy of the current version of the CE Declaration of Conformity, including RoHS and REACH, and

a copy of the CE certicate itself are not included in these operating instructions, they are available from

em-tec GmbH upon request.

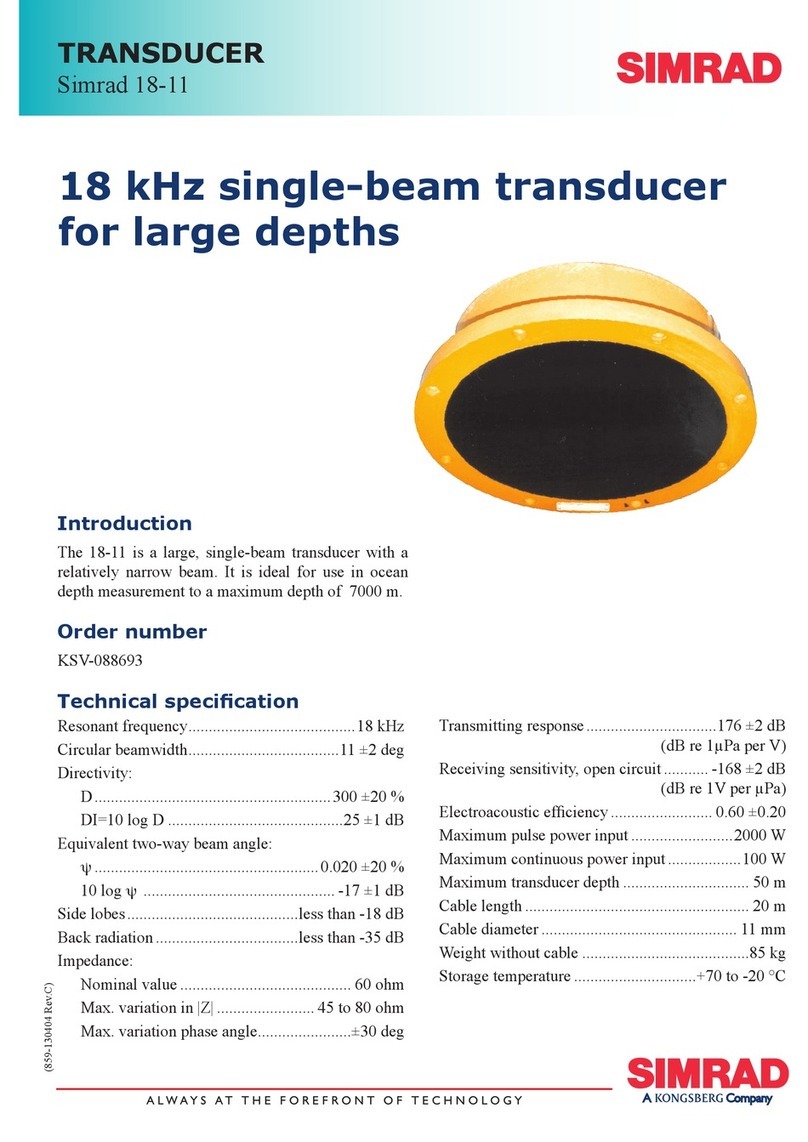

Figure 1: SonoTTTM FlowMeasurement System

SonoTTTM Clamp-On Transducer

Copyright em-tec GmbH D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Page 5

EN

2 Description of the Measurement Principle

The SonoTTTM Clamp-On Transducer is based on an acoustic measurement principle and utilizes the transit

time method to determine the ow. A typical transit time ow measurement system incorporates two

piezo ceramics that act as both ultrasonic transmitter and receiver. The measurement system, consisting

of the SonoTTTM Ultrasonic FlowComputer and the SonoTTTM Clamp-On Transducer, operates by alternately

transmitting and receiving an ultrasonic pulse between the piezo ceramics and measuring the transit time

difference that it takes for the pulse to travel between them.

This method determines the transit time difference of ultrasonic signals through a measuring section

and is used to estimate volumetric ow rates. There are at least two piezo ceramics required in order to

send and receive ultrasonic pulses both with and against the ow direction. For a higher accuracy, the

SonoTTTM Clamp-On Transducers incorporate two pairs of piezo ceramics, i.e. four piezo ceramics in total,

which are arranged in an X-conguration around the tube containing the measured ow.

When sending ultrasonic signals through the measuring section, the transit time difference depends on the

ow direction of the medium:

• The ultrasonic sound signals that are sent along the ow direction and volume ow of the medium, i.e.

downstream, need less time to travel the measuring section

than

• the ultrasonic sound signals that are sent against the ow direction, i.e. upstream.

Consequently, the transit time difference is measured for every pulse. The difference between upstream and

downstream measurements is proportional to the volumetric ow rate of the liquid in the tube. Therefore,

by accurately measuring the difference between upstream and downstream transit time Tup and Tdown, it is

possible to estimate the ow velocity. Subsequently, the volumetric ow rate is computed from the inner cross

section area of the tube and the instrument coefcient.

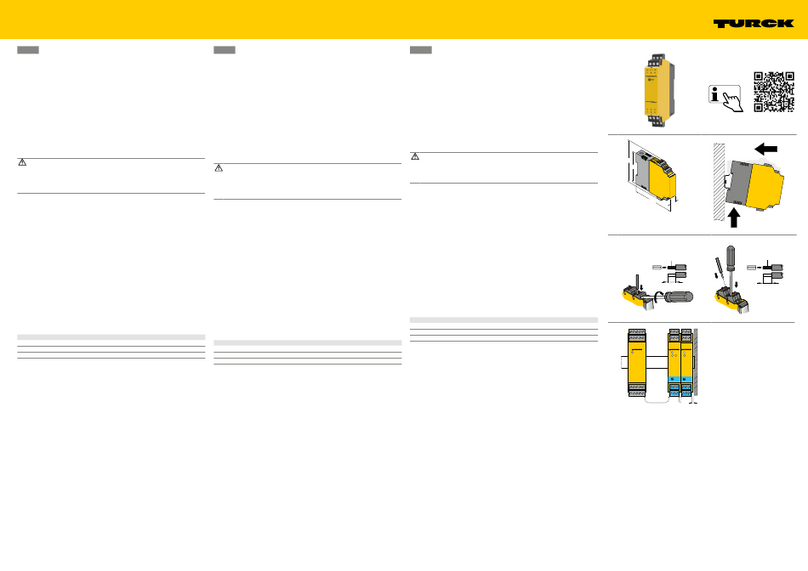

Figure 2: Sensor Structure

SonoTTTM Clamp-On Transducer

Page 6 D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Copyright em-tec GmbH

EN

3 General Safety Information, Symbols and Units

3.1 Symbols Used in these Operating Instructions

Symbol Meaning

Warning! This safety symbol precedes critical information that must be strictly

observed in order to prevent injuries and fatal hazards. This warning symbol is the

most important safety symbol.

Caution! Important information regarding correct handling. Must be observed and

strictly adhered to. If this information is not observed, malfunction or damage of

the product and its surroundings may occur.

3.2 Symbols on the SonoTTTM Clamp-On Transducer and on Packaging

Symbol Meaning

Read these operating instructions carefully before use. Keep them in an easily

accessible location for future reference. Replacement copies of these operating

instructions are available from the manufacturer.

Do not dispose of this device together with domestic waste!

The device as a whole as well as any parts must be disposed of in accordance with

WEEE Directive and national legislation.

Manufacturer:

em-tec GmbH · Lerchenberg 20 · 86923 Finning · Germany

Date of manufacture

Serial number

Order number

Temperature limit during storage and transport.

Moisture limit during storage and transport.

Air pressure limit

Classication Applied Part: BF according to EN 60601-1

IP67 IP (=Ingress Protection) Classication

SonoTTTM Clamp-On Transducer

Copyright em-tec GmbH D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Page 7

EN

4 General Information Concerning these Operating Instructions

• Read these operating instructions carefully before starting up the system!

→This document is intended for the SonoTTTM Clamp-On Transducer and describes

the use of the SonoTTTM Clamp-On Transducer in combination with the

SonoTTTM Ultrasonic FlowComputer.

• The user (= the person who connects the SonoTTTM Clamp-On Transducer to

the tubing circuit and measurement system) is responsible for any risk if the

SonoTTTM Clamp-On Transducer is not connected correctly.

• Inspect your SonoTTTM Clamp-On Transducer for completeness and damage when unpacking

it for the rst time.

• The customer must ensure that the persons involved in the integration and use of the

SonoTTTM Clamp-On Transducer and the system it is part of are adequately qualied. In

addition, the information in these operating instructions must be followed.

• Do not drop the SonoTTTM Clamp-On Transducer. It might break or become damaged, which

could impair the measurement.

These instructions contain important information concerning the safe and correct handling of the

SonoTTTM Clamp-On Transducer. Read these operating instructions carefully before using the product and keep

them in an easily accessible location. Familiarize yourself with all warning and safety information and observe

them. It is the responsibility of the operator to ensure that the SonoTTTM Clamp-On Transducer is used, inspected

and maintained in accordance with the operating instructions. This also applies for all subsequent revisions or

instructions from the manufacturer. The manufacturer reserves the right to modify technical data without

prior notice.

5 Intended Purpose, Restrictions and Limitations

5.1 Intended Purpose

The SonoTTTM Clamp-On Transducer (in combination with a SonoTTTM Ultrasonic FlowComputer) is indicated for

the bi-directional volumetric measurement of the liquid owing through tubing systems. The measurement

principle is the ultrasound transit-time method.

The medical use of the device is appropriate for extracorporeal applications together with the

SonoTTTM Ultrasonic FlowComputer such as:

• cardio-pulmonary bypass, hemodialysis, hemoltration, plasmapheresis

• ECMO (ExtraCorporeal Membrane Oxygenation) applications

• perfusion, infusion, transfusion

• several shunt-applications

Intended Users of the SonoTTTM Clamp-On Transducer

For reasons of patient safety, the device may only be used by qualied and trained medical professionals.

SonoTTTM Clamp-On Transducer

Page 8 D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Copyright em-tec GmbH

EN

Intended Patients of the SonoTTTM Clamp-On Transducer

The product is intended for the following patient population:

• patients who are undergoing a surgery, supervised by medically trained personnel.

• patients who are connected to an extracorporeal circulation system such as an ECMO device.

• patients who are treated within an hospital environment, e.g. an intensive care unit or operating room.

The product is not intended for the direct use on patients and should not come into direct contact with

them. In situations where skin contact cannot be ruled out or avoided, a pad, e.g. a gauze, should be placed

between the skin and the sensor.

A malfunction of the device is causing no additional health risk to the patient.

Intended Environment of the SonoTTTM Clamp-On Transducer

The SonoTTTM Clamp-On Transducer is designed for the continuous operation in intensive care units, operating

rooms and similar medical environments.

ClinicalBenets

Additional information for the attenting physician on the ow behavior of liquids in a patient-bound tubing

system.

The expected lifetime of the device is ten years.

5.2 Contraindications

This device and the accessories have been built and sold exclusively for the intended purpose mentioned

above.

The SonoTTTM Clamp-On Transducer and the SonoTTTM Ultrasonic FlowComputer are explicitly not intended

–to allow direct diagnosis or monitoring of vital physiological processes.

–for the monitoring of vital physiological parameters, where the variation could result in immediate

danger to the patient, for instance variations in cardiac performance, respiration, activity of the central

nervous system.

–as sole base for decisions regarding therapeutic methods. The values issued by this device have to

always be veried with other methods before any decisions regarding treatment are made.

It is the operator’s responsibility to use the device as described in the operating instructions and in any of its

following revisions. The use of clinical procedures and techniques lies in the physician’s area of responsibility.

5.3 Usage Restrictions and Limitations

The SonoTTTM Clamp-On Transducer is explicitly not intended

–for the use outside of medical environments.

–for the use inside means of medical transport (e.g. ambulance car or helicopter).

SonoTTTM Clamp-On Transducer

Copyright em-tec GmbH D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Page 9

EN

5.4 Liabilities and Responsibilities

The user is responsible to use, check and maintain the SonoTTTM Clamp-On Transducer according to these

operating instructions.

em-tec GmbH is neither liable nor responsible for any consequences arising from the use of the

SonoTTTM Clamp-On Transducer that does not comply with the operating instructions or specications in this

document.

5.5 Notice Concerning Compulsory Registration

Any major incidents in any ways connected to the product must be immediately reported to the manufacturer

and the appropriate authority of the member state in which the user and/or patient reside in.

5.6 Safety Instructions

If the SonoTTTM Clamp-On Transducer is part of a medical application, the user has to observe the following

instructions:

• The measured values of the SonoTTTM Clamp-On Transducer, supplied through the corresponding evaluation

device (i.e. the SonoTTTM Ultrasonic FlowComputer) only display the current ow rate (e.g. of an oxygenator

or blood pump).

• These values are neither to be used for the evaluation of a patient’s status nor for the basis of medical

actions without the conrmation of another approved medical measurement procedure.

• Should the unit be used to control the liquid volume ow, the user has to analyze the risk of the application

and, if necessary, take additional actions independent from the system to minimize this risk.

5.7 Electromagnetic Compatibility

Medical electronic devices are subjected to special precautions in terms of the electromagnetic compatibility

(EMC). Because of this, the SonoTTTM Clamp-On Transducer and SonoTTTM Ultrasonic FlowComputer have to be

installed and operated according to the following EMC information.

The SonoTTTM Ultrasonic FlowComputer and the SonoTTTM Clamp-On Transducer fulll the requirements of

the

IEC 60601-1-2 4

th

ed.

. Compliance with these requirements can only be guaranteed if the device is used

according to the operating instructions.

This device fullls the requirements of Class A according to CISPR 11 and should not be operated in home

care, industrial areas, or environments with strong electromagnetic elds or disturbances.

Portable RF communications equipment (including peripherals such as antenna cables and external

antennas) should be used no closer than 30 cm (12 inches) to any part of the SonoTTTM Clamp-On Transducer

or SonoTTTM Ultrasonic FlowComputer including the cables. Otherwise, degradation of the measurement

performance and stability of this equipment could result.

If an electric cautery comes in contact with the device or the SonoTTTM Ultrasonic FlowComputer, it might

cause a dysfunction which can lead to incorrect measurement values or other problems. This includes use

of HF surgery at the patient or crossing of lines. Increased emission or decreased electromagnetic noise

immunity can affect the measurements.

SonoTTTM Clamp-On Transducer

Page 10 D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Copyright em-tec GmbH

EN

They can be caused by the use of SonoTTTM Clamp-On Transducers or any devices and/or accessories that are

part of the measurement system but which are not mentioned in these operating instructions. Interference

of ultrasonic ow measurements by electromagnetic elds could be possibly identied by compromised

measured data, which are not related to the real ow. Please also note that the SonoTTTM Clamp-On Transducer

is not galvanically isolated.

The SonoTTTM Clamp-On Transducer performs without producing either unintended or excessive ultrasound

output nor unintended or excessive surface temperatures according to

IEC 60601-1-2 4

th

ed.

Electromagnetic

elds and electrostatic discharge cannot lead to unintended changes of the electronics causing hazardous

ultrasonic output. Nevertheless, it is important to ensure that the SonoTTTM Clamp-On Transducer and the

SonoTTTM Ultrasonic FlowComputer are not placed near any disturbance source that is not compliant with the

applicable standards, since this could inuence and negatively affect the measurement.

5.8 Ultrasonic Safety Regarding Acoustic Output

When in use, the connected SonoTTTM Clamp-On Transducers produce very low-power ultrasonic signals at

frequencies between 2.25 and 4 MHz. The emmited acoustic signals are declared in the technical specications

according to

IEC 61157 2

nd

ed.

and

IEC 60601-2-37 2

nd

ed.

If used properly, the acoustic signals produced by the SonoTTTM Ultrasonic FlowComputer and

SonoTTTM Clamp-On Transducer are, according to current knowledge, harmless for people and the environment.

5.9 Biocompatibility

The SonoTTTM Clamp-On Transducer is made from conventional materials which, with appropriate use, are

harmless for the patient and the user according to current knowledge.

SonoTTTM Clamp-On Transducer

Copyright em-tec GmbH D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Page 11

EN

5.10 Maintenance and Service

The service for the SonoTTTM Clamp-On Transducer may be carried out by

em-tec GmbH only. If these instructions are not followed, em-tec GmbH shall accept no liability for the

component and the warranty will be void.

In order to maintain the accuracy of the SonoTTTM Clamp-On Transducer, it is recommended to regularly carry

out re-calibrations. The time between calibrations should not exceed 24 months.

If you experience any trouble with the measurement despite following the operating instructions, or if your

SonoTTTM Clamp-On Transducer is damaged in any way, please contact our service department.

Please make a note of the serial number of the SonoTTTM Clamp on Transducer and the evaluation device

before you contact our staff.

If you need to return the SonoTTTM Ultrasonic FlowComputer or the SonoTTTM Clamp-On Transducer for

servicing, please follow the steps below:

1. Contact our service department at:

em-tec GmbH

Service Department

Am Graben 6-8

86923 Finning

Germany

em-tec-service@psgdover.com

2. Our service department will send you a RMA form.

3. Fill out the form and include it in your shipment.

SonoTTTM Clamp-On Transducer

Page 12 D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Copyright em-tec GmbH

EN

6 Installation, Use, and Disassembly of the

SonoTTTM Clamp-On Transducer

6.1 General Safety Information

• If the SonoTTTM Clamp-On Transdcuer is not used as intended, the user may be exposed to

risks that were not taken into account during its development.

• If the SonoTTTM Clamp-On Transducer is clamped onto a tubing circuit that is part of a

life-supporting device used to maintain a patient's bodily functions, to support the lives

of critically-ill patients, or during surgical interventions, these devices must be used and

monitored by qualied clinical professionals.

• Decisions regarding therapeutic methods must not be solely based on the measured ow

data.

• The values issued by the ow measuremet system including the SonoTTTM Clamp-On

Transducer have to always be veried with other methods before any decisions regarding

treatment are made.

• For the installation, all ambient conditions must meet the prescribed specications (see

chapter 10 “Technical Specications of the SonoTTTM Clamp-On Transducer”).

6.2 Connecting the SonoTTTM Clamp-On Transducer to the

SonoTTTM Ultrasonic FlowComputer

To connect the SonoTTTM Clamp-On Transducer to the SonoTTTM Ultrasonic FlowComputer, carefully attach the

15-pin high density D-Sub socket to the screw connection at the back of the SonoTTTM UltrasonicFlowComputer.

Once this is done, the sensor can be attached to the tube.

• The connector of the SonoTTTM Clamp-On Transducer must be dry when plugged in.

• Check the plug and the pins for damage before connecting the sensor.

• Do not use the SonoTTTM Clamp-On Transducer if any part of it is damaged.

• Check and make sure that the connector used ts and is actually compatible with the

measurement system.

SonoTTTM Clamp-On Transducer

Copyright em-tec GmbH D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Page 13

EN

6.3 Attaching the SonoTTTM Clamp-On Transducer to the Tube

• Before you clamp on the sensor, make sure that the tube is not deformed, damaged, or dirty.

• Air in the tube can lead to errors in the measurement or interrupt the ultrasound coupling.

• Ensure that there is no debris or dirt in the ow channel. If necessary, clean the ow channel

before attaching the SonoTTTM Clamp-On Transducer to the tube.

• While installing the SonoTTTM Clamp-On Transducer, be sure not to impair the function of

the tubing system.

• Ensure that the tube size and material used corresponds with the size and material the

SonoTTTM Clamp-On Transducer was calibrated and adjusted for.

• First, make sure that the arrow on the lid is aligned with the ow direction (positive ow

display).

Note: If the medium within the tube moves in the opposite direction of the arrow on the

lid, the ow value is displayed as negative value (e.g. -250 ml/min instead of 250 ml/min).

The accuracy and the ow range stated in chapter 10 "Technical Specications of the

SonoTTTM Clamp-On Transducer" remains the same for both positive and negative values.

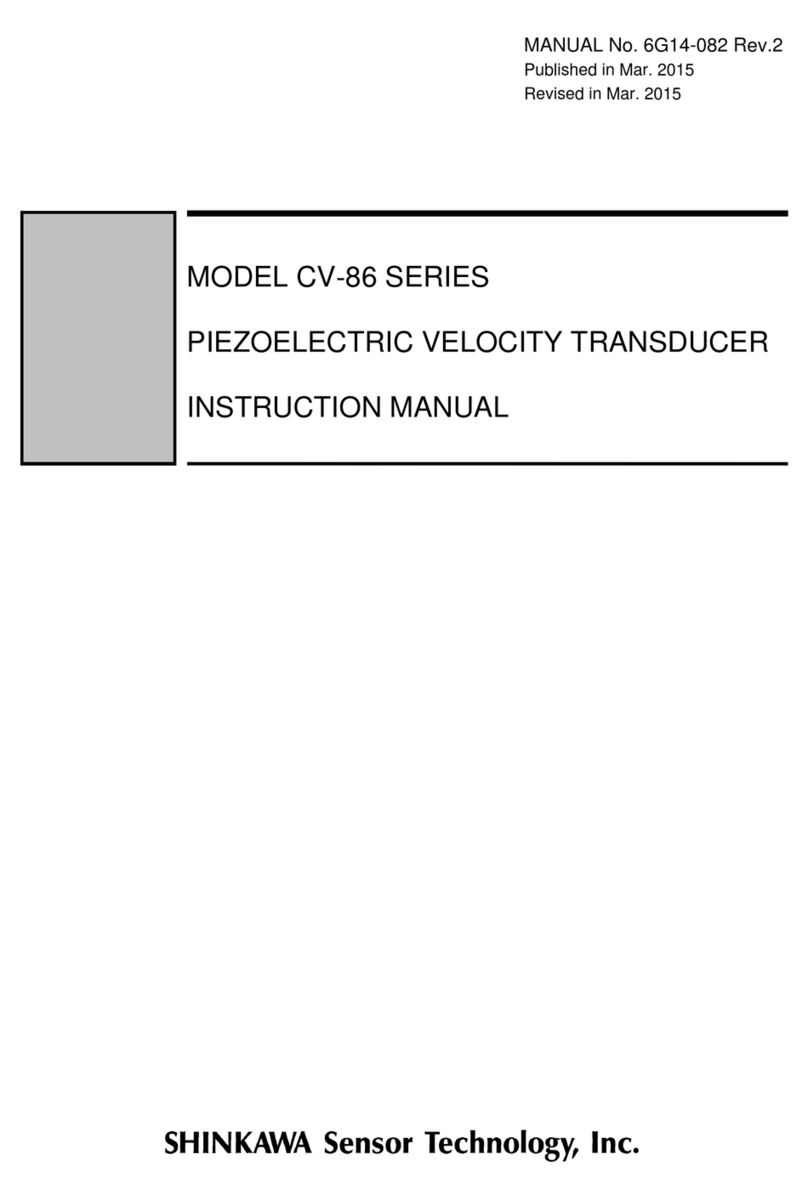

To clamp on the SonoTTTM Clamp-On Transducer, follow the steps illustrated below:

1. Open the spring-loaded lock and swing back the lid.

2. Insert the tube into the channel.

3. Close the SonoTTTM Clamp-On Transducer lid and secure it with the help of the spring-loaded lock.

• Do not use excessive force when closing the sensor lid; while the tube should be xed within

the channel, it must not be crammed into it as this might affect the measurement values or

damage the sensor.

• Ensure that the lid is fully closed as to avoid uctuating coupling and ow values.

• To avoid ow turbulances and associated measurement inaccuracies, it is necessary for the

tube to be straight in the area near the SonoTTTM Clamp-On Transducer.

• Ideally, the tube should be straight for a distance of at least 10 x the inner diameter (ID) of

the tube on either side of the sensor.

Figure 3: Clamping on the Sensor

Figure 4: Ideal Inlet Section

SonoTTTM Clamp-On Transducer

Page 14 D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Copyright em-tec GmbH

EN

For more information regarding the setup of the SonoTTTM Clamp-On Transducer and what to keep

in mind to maintain and optimize the accuracy of your flow measurementent, refer to our TechNote

"Optimizing Accuracy". The TechNote is available upon request, or for download on our website.

6.4 Use of the SonoTTTM Clamp-On Transducer

For more details on how to carry out the ow measurement, please refer to the operating

instructions of the evaluation device; in this case, the SonoTTTM Ultrasonic FlowComputer.

Make sure to follow the steps below and to heed the instructions included in them in order to

ensure the highest possible accuracy of measurement values as well as the highest possible

safety for the patient.

In addition, always ensure that

• the medium temperature is the temperature the sensor was calibrated and adjusted for.

• there is a zero ow adjustment performed before each measurement.

• the sensor is not permanently placed on the patient as this might lead to skin irritations.

Beforestartingtheowmeasurement:

1. Make sure that only tubes specied for the SonoTTTM Clamp-On Transducer are used as this is the tube type

the SonoTTTM Clamp-On Transducer is adjusted and calibrated for.

2. Before each measurement, the cables, connectors and pins must be checked for breaks or

damages as this could result in wrong measurements. If there are any damages, do not use the

SonoTTTM Clamp-On Transducer.

3. Ensure that the temperature of the medium is the one the SonoTTTM Clamp-On Transducer was adjusted

and calibrated for.

4. Ensure that no air bubbles are in the tube during the zero ow adjustment. Allow sufcient time for the

system to adapt to ambient conditions, then zero the ow. Only then is the system ready for measurement.

5. The coupling must be checked before each measurement.

6. Azeroowadjustmentmustbecarriedoutbeforeeachmeasurement to avoid possible offsets from the

measured values.

Beforethezeroowadjustment, allow the system sufcient time to adapt to ambient conditions.

Duringthezeroowadjustment,

–The sensor must be clamped on the correct position .

–The tube must be lled with liquid, but the liquid must not move.

–There must be no air bubbles inside the tube.

Duringtheowmeasurement:

• Ensure that the coupling is within the operating range of 60 % - 99%. If the coupling falls below 50 %, the

SonoTTTM Ultrasonic FlowComputer issues a warning as the low coupling might impair the measurement.

• It is important that any unwanted interruption of the extracorporeal patient circulation due to damage or

kinking of the tubing is avoided at all times.

• The stated measurement accuracy of the SonoTTTM Clamp-On Transducer is only valid if the specied tubes

are used and if the temperature of the medium is the one the sensor was adjusted and calibrated for.

• Any changes in the medium itself or its temperature can cause errors or anomalies in the measurement.

• It must be ensured that the correct calibration parameters are used.

SonoTTTM Clamp-On Transducer

Copyright em-tec GmbH D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Page 15

EN

While it is possible to carry out measurements outside of the specied ow range, em-tec GmbH cannot

guarantee that resulting ow values will be within the given accuracy range.

The parameters of the connected SonoTTTM Clamp-On Transducer and the selected calibration table are

displayed in the Settings-Menu of the SonoTTTM Ultrasonic FlowComputer as shown in the following example:

Calibration

Table Transdcuer

Serial No. Tube Size Tube

material Medium Medium

Temperature Maximum Measured Value

0 SN 12345 3/8" x 3/32" PVC Blood

(based on water) 37 °C (98.6 °F) 10000 ml/min

Pleasue ensure that the tube size and material used corresponds to that shown on the display of the SonoTTTM Ultrasonic FlowComputer.

6.5 Disassembly and Storage of the SonoTTTM Clamp-On Transducer

In order to not impair the measurement, it is best to disassemble the SonoTTTM Clamp-On

Transducer once the measurement process has been completed.

To disconnect the SonoTTTM Clamp-On Transducer, follow these steps:

1. Open the spring-loaded lock and swing back the lid.

2. Remove the tube from the channel.

3. Close the lid and carefully remove the 15-pin, high density D-Sub socket from the screw connection at the

back of the SonoTTTM Ultrasonic FlowComputer.

Once you have disconnected the SonoTTTM Clamp-On Transducer, check for any residue of the medium or

any other kind of dirt or grime and clean the sensor if necessary. Store the sensor according to storage

specications. Make sure to store it in a place where it cannot fall off or be dropped and ensure that the plug

is dry.

SonoTTTM Clamp-On Transducer

Page 16 D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Copyright em-tec GmbH

EN

6.6 Cleaning and Disinfection of the SonoTTTM Clamp-On Transducer

Make sure no detergents, disinfectants or other liquids can leak into the plug of the

SonoTTTM Clamp-On Transducer.

For the cleaning of the device, we recommend the use of common household detergents. In order to avoid

stains and dirt from drying out, grime residue should be removed after each application.

To clean the SonoTTTM Clamp-On Transducer, use a lint-free cloth. Be sure to remove any dirt in the clamping

area. Additionally, please follow the legal regulations valid in your country and the hygiene regulations for

your doctor’s ofce or hospital.

•The SonoTTTM Clamp-On Transducer may not be submerged into cleaning or disinfecting

solution.

•The SonoTTTM Clamp-On Transducer is not suited for cleaning processes using machines.

Sterilization processes, especially steam sterilization or autoclaving, may not be used.

•The SonoTTTM Ultrasonic FlowComputer and the SonoTTTM Clamp-On Transducer are used

in non-sterile areas in operating rooms. Due to this, cleaning and disinfection after every

use as well as before the rst use is essential.

The following surface disinfectant is recommended:

Name Manufacturer Contact

Bacillol® AF Hartmann www.hartmann.de

6.7 Changing the SonoTTTM Clamp-On Transducer

If the SonoTTTM Clamp-On Transducer was exchanged before switching on the

SonoTTTM Ultrasonic FlowComputer, then the new calibration parameters will be shown in the Settings Menu

of the SonoTTTM Ultrasonic FlowComputer after the next start-up sequence.

If the SonoTTTM Clamp-On Transducer is exchanged during the operation of the SonoTTTM Ultrasonic

FlowComputer, the alarm is activated with an error message. Once the new SonoTTTM Clamp-On Transducer is

connected, the alarm is reset and the calibration data can be seen in the Settings Menu.

• Make sure that the SonoTTTM Clamp-On Transducer is attached at a different place on the

tube each time to avoid deformation.

• Ensure that the calibration table used is the one needed for your respective application.

SonoTTTM Clamp-On Transducer

Copyright em-tec GmbH D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Page 17

EN

7 Adjustment and Calibration of the SonoTTTM Clamp-On Transducer

As the function of the SonoTTTM Clamp-On Transducer is based on an acoustic measurement principle,

parameters such as the tubing size and material, or the medium as well as its temperature can impact the

ultrasonic signal and thus the transit time difference between them. To take these factors into account and

to ensure the highest possible accuracy regarding the measured values, each sensor is individually adjusted

and calibrated prior to shipment.

The relevant parameters for the adjustment and calibration are:

–tubing material

–medium

–medium temperature

–flow range

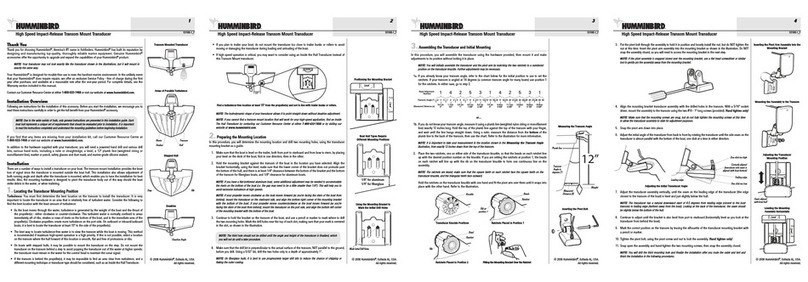

7.1 Adjustment

An act of modifying something, in this case to fit a certain standard, the sensor adjustment represents an

actual intervention in the measurement system. To ensure that the parameters stated above are factored

into the measurement and consequently into the ow values displayed by the SonoTTTM Ultrasonic

FlowComputer, parameters such as the amplitude of the ultrasonic signal or the length of the ultrasonic burst

are changed to t the tubing and the medium used during the application. .

As a result, the adjustment is an action that permantently alters the

device as the setting of the burst signal (scan window and amplitude)

and the sequential balance line are changed.

Since these parameters have a deep impact on the sensor‘s

performance, and since adjusting the sensor represents an intervention

of the measurement system, adjustments may only be carried out by

em-tec GmbH.

7.2 Calibration

The term ‘calibration‘, on the other hand, refers to the act of checking the accuracy of a measurement device

by comparing its measurement values with those of a device with a known accuracy. This comparison is

subject to a specied measurement setup and specied measurement conditions. During the calibration

process, neither the devices involved nor any of their parameters may be changed, manipulated, or altered

in any way.

Ideally, the SonoTTTM Clamp-On Transducers should be re-calibrated every 24 months. This can be carried out

by the customer on-site or by em-tec GmbH.

For more information regarding this process, please contact em-tec GmbH:

Figure 5: Ultrasonic Signal

SonoTTTM Clamp-On Transducer

Page 18 D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Copyright em-tec GmbH

EN

8 Troubleshooting

If there are any issues with the SonoTTTM Clamp-On Transducer, try the following suggestions. If the problem

cannot be solved this way, please contact your local distributor or em-tec GmbH directly.

Problem Possible Cause Action

Sensor lid does not

close.

• Sensor might be

damaged.

• Tube might be too

large.

1. Check if the sensor is damaged.

2. Check if the tube size is the one indicated for your

sensor.

3. If necessary, exchange the tube for the right one.

If the problem persists, return the sensor for servicing*.

Sensor does not

stay in place.

• Sensor might be

damaged.

• Tube might be too

small.

1. Check if the sensor is damaged.

2. Check if the tube size is the one indicated for your

sensor.

3. If necessary, exchange the tube for the right one.

If the problem persists, return the sensor for servicing*.

Sensor emits noise.

There might be

electromagnetic elds

inuencing the sensor.

1. Check if there are any electromagnetic elds or

disturbance sources that are not compliant with

the relevant standards and that could inuence the

sensor. Also check if the sensor or its cable came into

contact with an electric cautery.

2. Remove the source of the electromagnetic eld or

carry the measurement out somewhere else.

If the problem persists, return the sensor for servicing*.

Sensor is not

recognized.

There is no

measurement

possible.

The cable is damaged.

1. Check if the sensor is connected properly to the

device and if the sensor is damaged.

2. Check if the cable is damaged.

3. If the cable is damaged, return the sensor and cable

for servicing.

If the problem persists, return the sensor for servicing*.

The plug is damaged (e.g.

broken PIN).

1. Check if the sensor is connected properly to the

device and if the sensor is damaged.

2. Check if the plug is damaged and if there are any

broken PINs

3. If the plug is damaged, return the device for servicing.

If the problem persists, return the sensor for servicing*.

SonoTTTM Clamp-On Transducer

Copyright em-tec GmbH D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Page 19

EN

Problem Possible Cause Action

Sensor is not

recognized.

There is no

measurement

possible.

Storage might have been

damaged or deleted by

electromagnetic elds.

1. Check if the sensor is connected properly to the

device and if the sensor is damaged.

2. Check if there are any electromagnetic elds or

disturbance sources that are not compliant with

the relevant standards and that could inuence the

sensor.Also check if the sensor or its cable came into

contact with an electric cautery.

3. Remove the source of the electromagnetic eld or

carry the measurement out somewhere else.

If the problem persists, return the sensor to em-tec GmbH

for recalibration*.

The connected sensor is

the wrong sensor type.

1. Check if the correct sensor is connected and if the

connected sensor is not damaged.

2. If the sensor is correct, disconnect it.

3. Reconnect the sensor again.

If the problem persists, return the device and sensor for

servicing,

Acoustic coupling is

too low.

Sensor lid might not be

closed properly.

1. Check if the sensor lid is closed properly.

2. Close the lid.

If the problem persists, return the sensor for servicing*.

The tube size and/or

material is not the one

indicated for the sensor.

1. Check if the tube size and material are the ones the

sensor was adjusted and calibrated for.

2. If necessary, exchange the tube for the right one.

If the problem persists, return the sensor for servicing*.

There is dirt in the ow

channel.

1. Check if there is dirt in the ow channel.

2. If necessary, clean the ow channel.

If the problem persists, return the sensor for servicing*.

Sensor might be

damaged.

1. Check if the sensor or the sensor lid is damaged

(e.g. broken hinge).

2. If the sensor is damaged, stop the measurement and

return the sensor for servicing.

If the problem persists, return the sensor for servicing*.

There are air bubbles in

the tube.

1. Check if there are air bubbles in the tube.

2. Remove any air within the tube.

3. Repeat the ow measurement following the steps

described in chapter 6.4.

If the problem persists, return the sensor for servicing*.

SonoTTTM Clamp-On Transducer

Page 20 D162-700 SonoTTTM Clamp-On Transducer - Operating Instructions V3.0 Copyright em-tec GmbH

Table of contents

Languages:

Popular Transducer manuals by other brands

Setra Systems

Setra Systems 269 installation guide

novotechnik

novotechnik TP1 Series user manual

Balluff

Balluff BTL5-P1 Series user guide

Camille Bauer

Camille Bauer SINEAX I 538 operating instructions

Shinkawa

Shinkawa CV-86 Series instruction manual

Airmar

Airmar P79S Owner's guide & installation instructions

Electro-Voice

Electro-Voice 3-Inch High Frequency Neodymium Transducer... Technical specifications

Humminbird

Humminbird Transducer Installation

Honeywell

Honeywell IPT user manual

Airmar

Airmar P58 Owner's guide & installation instructions

OHIO SEMITRONICS

OHIO SEMITRONICS DCT Series operating instructions

Simrad

Simrad 710-36E - REV E datasheet