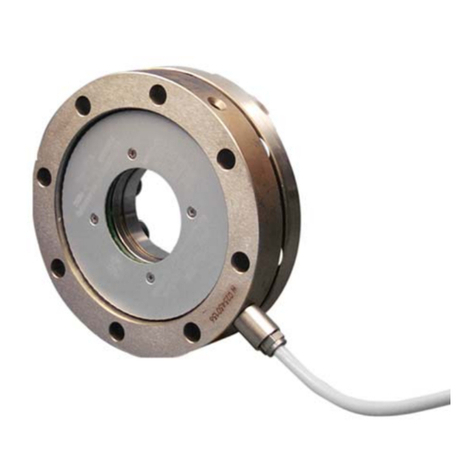

HBM P8AP User manual

Other HBM Transducer manuals

Popular Transducer manuals by other brands

ProMinent

ProMinent Dulcometer DMT operating instructions

MKS

MKS MicroPirani 925 Series Short form manual

WIKA

WIKA WU-20 operating instructions

Alcatel Vacuum Technology

Alcatel Vacuum Technology BARATRON 622A instruction manual

Camille Bauer

Camille Bauer SIRAX CH-5610 operating instructions

WIKA

WIKA F2802 operating instructions

Veris Industries

Veris Industries PW Series installation guide

Simrad

Simrad ES120-7C - REV D Dimensions

Airmar

Airmar M260 Owner's guide & installation instructions

Spirax Sarco

Spirax Sarco ITV1030 Installation and maintenance instructions

halstrup-walcher

halstrup-walcher PU10 instruction manual

Balluff

Balluff BTL5-P user guide