3

IPT User’s Manual Contents

1 Introduction.....................................................................................................................................................4

1.1 Overview..................................................................................................................................................4

2 Specifications.................................................................................................................................................4

2.1 Block Diagram .........................................................................................................................................4

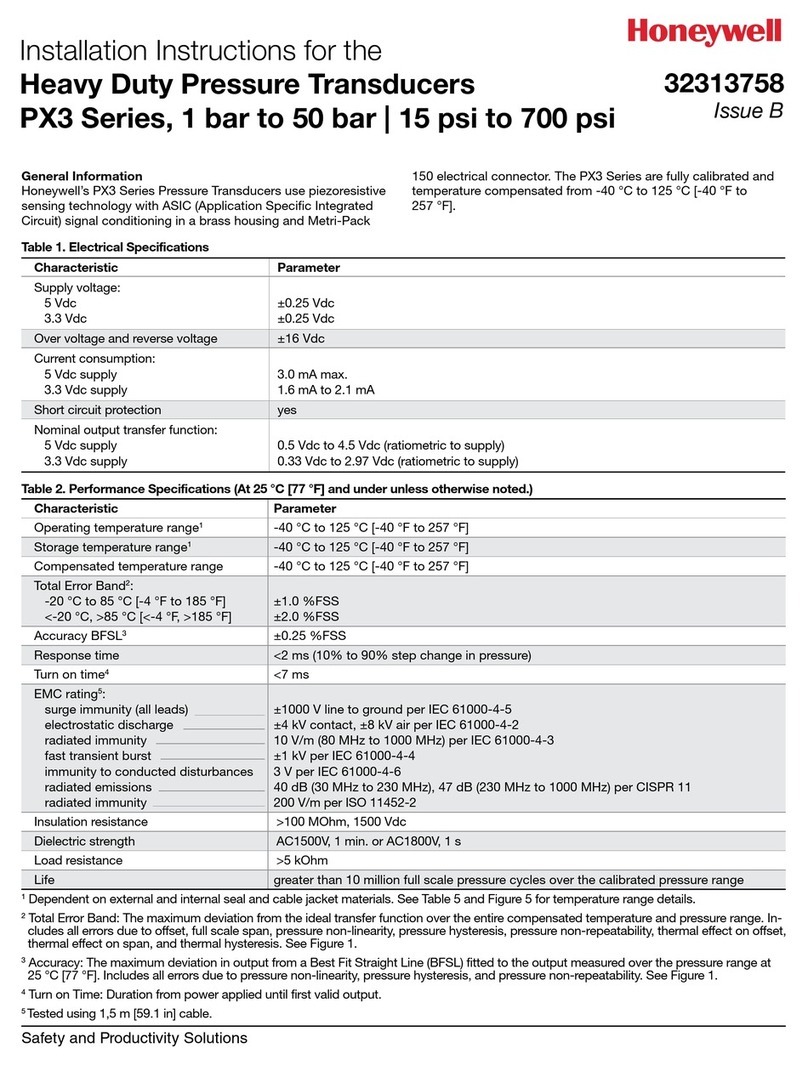

2.2 Specifications/Performance .....................................................................................................................5

2.3 Outline/Dimensions (inches)....................................................................................................................6

2.4 Electrical Connections .............................................................................................................................7

2.4.1 Connector.........................................................................................................................................7

3 Operation........................................................................................................................................................8

3.1 Commands and Format...........................................................................................................................8

3.1.1 Initialization.......................................................................................................................................8

3.1.2 Normal Operation (Polling)..............................................................................................................10

3.1.3 Other Modes...................................................................................................................................11

3.2 Correction Algorithms ............................................................................................................................12

3.2.1 Pressure .........................................................................................................................................12

3.2.1.1 Algorithm #1.................................................................................................................................12

3.2.1.1.1 Horner’s Method, Algorithm #1..................................................................................................12

3.2.1.2 Algorithm #2.................................................................................................................................13

3.2.1.2.1 Horner’s Method, Algorithm #2..................................................................................................13

3.2.2 Pressure Sensor Temperature........................................................................................................14

3.2.2.1 Algorithm......................................................................................................................................14

3.2.2.1.1 Horner’s Method........................................................................................................................14

3.3 EEPROM Storage..................................................................................................................................15

3.3.1 EEPROM Format............................................................................................................................15

3.3.2 Contents .........................................................................................................................................15

4 Installation Recommendations......................................................................................................................19

4.1 Installation Examples.........................................................................................................................19

4.1.1 Flexible Tubing and Double-wire Hose Clamps..........................................................................19

4.1.2 Static Radial O-ring Seals ..........................................................................................................20

4.1.3 Static Radial and Face O-ring Seals...........................................................................................20

5 Marking ........................................................................................................................................................20

6 Fletcher Checksum.......................................................................................................................................21

6.1 Calculation.............................................................................................................................................21