EMTEST EFT 500 User manual

ELECTROMAGNETIC

COMPATIBILITY

CONSULTING

AND

SIMULATION

Version

Replaces

Filename

Printdate

(

5

?

EM

TEST

BURST

GENERATOR

Type

EFT

500

MANUAL

1.00

/

24.11

.

97

no

previous

version

EFTBA

-

A

5

.

DOC

8.02

.

01

SPECIFIC

PRECAUTIONS

<

3

EM

TEST

Observe

all

of

these

precautions

to

ensure

your

personal

safety

and

to

prevent

damage

to

the

test

equipment

of

our

product

range

.

The

generators

correspond

to

installation

category

(

overvoltage

category

)

II

.

Power

Source

The

equipment

is

intended

to

operate

from

a

power

source

that

will

not

apply

more

than

250

VRMS

between

the

supply

conductors

or

between

either

supply

conductor

and

ground

.

A

protective

ground

connection

,

through

the

grounding

conductor

in

the

power

cord

,

is

essential

for

safe

system

operation

.

Grounding

the

generators

The

generators

are

grounded

through

the

power

cord

.

To

avoid

electric

shock

,

plug

the

power

cord

into

a

properly

wired

receptacle

where

earth

ground

has

been

verified

by

a

qualified

service

person

.

Do

this

before

making

connections

to

the

input

or

output

terminals

of

the

test

equipment

.

Without

the

protective

ground

connection

,

all

parts

of

generators

are

potential

shock

hazards

.

This

includes

knobs

and

controls

that

may

appear

to

be

insulators

.

Use

the

Proper

Power

Cord

Use

only

the

power

cord

and

connector

specified

for

you

product

.

Use

only

a

power

cord

that

is

in

good

condition

.

Use

the

Proper

Fuse

To

avoid

fire

hazard

,

use

only

the

fuse

specified

in

the

parts

list

for

your

product

,

matched

by

type

,

voltage

rating

and

current

rating

.

Do

Not

Remove

Covers

or

Panels

To

avoid

personal

injury

,

do

not

operate

the

generators

without

the

panels

or

covers

.

Do

Not

Operate

in

Explosive

Atmospheres

The

generators

provides

no

explosion

protection

from

statistic

discharges

or

arcing

components

.

Do

not

operate

them

in

an

atmosphere

of

explosive

gases

.

Electric

Overload

Never

apply

generators

voltage

to

a

connector

which

is

not

specified

for

that

voltage

range

.

Read

carefully

the

following

operation

manual

!!

!

!

,

•

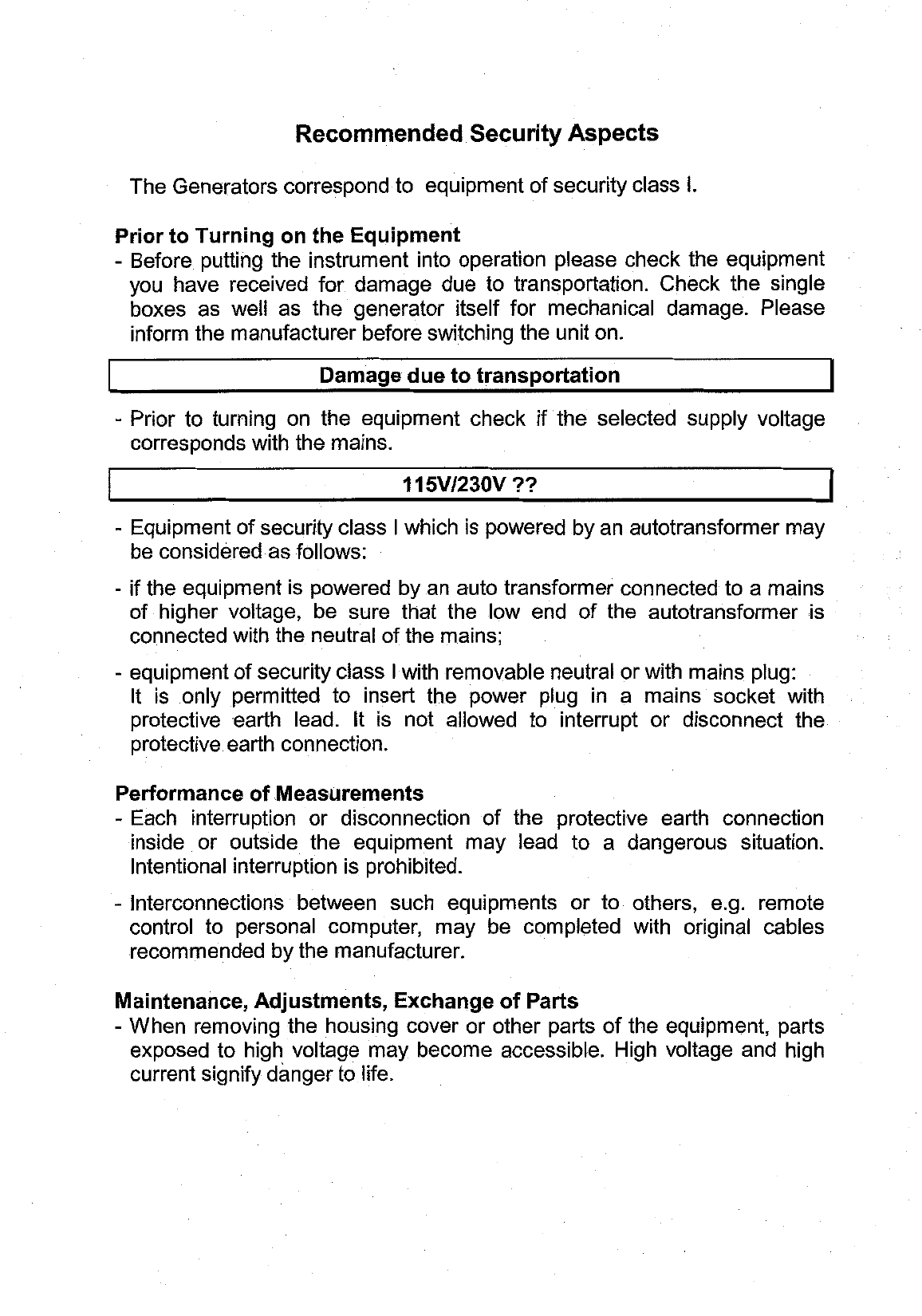

Recommended

Security

Aspects

The

Generators

correspond

to

equipment

of

security

class

I

.

Prior

to

Turning

on

the

Equipment

-

Before

putting

the

instrument

into

operation

please

check

the

equipment

you

have

received

for

damage

due

to

transportation

.

Check

the

single

boxes

as

well

as

the

generator

itself

for

mechanical

damage

.

Please

inform

the

manufacturer

before

switching

the

unit

on

.

Damage

due

to

transportation

-

Prior

to

turning

on

the

equipment

check

if

the

selected

supply

voltage

corresponds

with

the

mains

.

115

V

/

230

V

?

?

-

Equipment

of

security

class

I

which

is

powered

by

an

autotransformer

may

be

considered

as

follows

:

-

if

the

equipment

is

powered

by

an

auto

transformer

connected

to

a

mains

of

higher

voltage

,

be

sure

that

the

low

end

of

the

autotransformer

is

connected

with

the

neutral

of

the

mains

;

-

equipment

of

security

class

I

with

removable

neutral

or

with

mains

plug

:

It

is

only

permitted

to

insert

the

power

plug

in

a

mains

socket

with

protective

earth

lead

.

It

is

not

allowed

to

interrupt

or

disconnect

the

protective

earth

connection

.

Performance

of

Measurements

-

Each

interruption

or

disconnection

of

the

protective

earth

connection

inside

or

outside

the

equipment

may

lead

to

a

dangerous

situation

.

Intentional

interruption

is

prohibited

.

-

Interconnections

between

such

equipments

or

to

others

,

e

.

g

.

remote

control

to

personal

computer

,

may

be

completed

with

original

cables

recommended

by

the

manufacturer

.

Maintenance

,

Adjustments

,

Exchange

of

Parts

-

When

removing

the

housing

cover

or

other

parts

of

the

equipment

,

parts

exposed

to

high

voltage

may

become

accessible

.

High

voltage

and

high

current

signify

danger

to

life

.

I

-

Do

not

perform

maintenance

or

service

work

until

you

have

disconnected

the

equipment

from

the

mains

.

Be

sure

the

capacitors

or

other

voltage

-

carrying

parts

are

discharged

.

-

If

maintenance

or

service

work

is

necessary

,

it

must

be

performed

only

by

experts

who

are

familiar

with

the

existing

danger

.

-

It

has

to

be

assured

that

only

fuses

of

recommended

type

and

nominal

current

are

used

for

replacement

.

It

is

not

allowed

to

use

repaired

fuses

.

Failures

and

Overstressing

-

If

it

is

assumed

that

a

riskless

operating

mode

of

the

equipment

is

no

longer

possible

,

the

mains

connection

must

be

removed

and

the

equipment

secured

from

unintentional

use

.

-

It

may

be

assumed

that

an

endanger

operating

is

given

:

-

when

the

equipment

shows

recognisable

damages

;

-

when

the

equipment

is

not

working

;

-

after

severe

transportation

stress

;

-

after

longer

stock

-

keeping

under

disadvantageous

conditions

.

It

is

suggested

that

you

read

the

operating

manual

carefully

and

completely

.

It

is

absolutely

necessary

to

observe

and

comply

with

the

security

indications

.

Maintenance

The

generator

is

absolutely

maintenance

-

free

by

using

a

solid

state

semiconductor

switch

to

generate

the

test

events

.

Coupling

network

-

Due

to

the

various

national

safety

instructions

the

coupling

network

has

no

ON

/

OFF

key

as

well

as

no

internal

fuse

protection

.

The

EUT

must

be

fused

by

the

user

.

-

Special

supply

adapters

with

switch

and

fuse

protection

are

available

but

must

be

specified

by

the

user

.

-

Special

supply

cables

are

included

as

basic

equipment

.

Test

set

-

up

!

!

Attention

Immunity

Tests

!

!

Burst

test

is

an

immunity

test

on

electronic

equipment

.

Therefore

it

is

the

responsibility

of

the

user

to

avoid

critical

failures

and

risks

to

the

environment

and

operator

.

Long

and

distributed

lines

of

the

EUT

are

able

to

radiate

a

certain

energy

to

their

vicinity

.

Therefore

it

is

also

the

responsibility

of

the

user

to

decide

whether

it

is

allowed

to

conduct

immunity

tests

in

a

given

installation

.

Test

voltages

above

500

V

may

generate

spark

discharges

.

Therefore

it

is

forbidden

to

test

in

an

explosive

environment

.

National

and

international

recommendations

regarding

human

safety

must

be

followed

.

Handicapped

people

,

e

.

g

.

with

a

heart

defibrillator

,

should

be

excluded

from

testing

.

CONTENTS

1

.

Application

9

1.1

.

Introduction

9

1.2

.

Definitions

10

1.3

.

Sources

of

interference

11

2

.

Operating

Functions

...

13

2.1

.

Front

view

13

2.2

.

Rear

view

15

3

.

Operation

17

3.1

.

Description

of

the

menus

17

3.2

.

Quick

Start

19

3.3

.

User

test

routines

21

3.4

.

Test

routine

as

per

to

IEC

1000

-

4

-

4

.

..

.

26

3.5

.

Service

27

3.6

.

Set

-

up

28

4

.

Putting

into

Operation

.

29

4.1

.

Security

Aspects

,

.

29

4.2

.

Immunity

Tests

Burst

,

using

PC

’

s

29

4.3

.

Generator

function

check

32

5

.

Test

Equipment

EFT

500

34

5.1

.

Construction

34

5.2

.

Control

unit

35

5.3

.

High

voltage

unit

.

..

35

5.4

.

Coupling

network

..

.

.

36

6

.

Technical

Data

39

6.1

.

Pulse

forming

unit

39

6.2

.

Trigger

39

6.3

.

Burst

impulses

39

6.4

.

Output

39

6.5

.

Test

routines

40

6.6

.

General

data

40

7

.

Maintenance

.

41

7.1

.

General

41

7.2

.

Limiting

values

41

7.3

.

Coupling

network

41

8

.

Delivery

Groups

8.1

.

Basic

equipment

8.2

.

Accessories

and

options

9

.

Remote

Control

9.1

.

Interfaces

9.2

.

General

information

9.3

.

Parameter

of

the

remote

commands

9.4

.

E

commands

9.5

.

N

commands

SO

)

Ol

W

W

N

)

N

)

N

9.6

.

A

commands

47

9.7

.

Back

messages

..

48

10

.

Appendix

49

10.1

.

Declaration

of

CE

-

Conformity

49

10.2

.

Declaration

for

safety

requirements

49

10.3

.

List

of

sales

representatives

49

10.4

.

EFT

500

-

General

Diagram

49

10.5

.

EFT

500

-

Overview

49

1

.

Application

1.1

.

Introduction

With

more

complex

electronic

devices

and

systems

the

tendency

towards

lower

signal

levels

,

particularly

those

involving

microprocessors

,

has

increased

their

susceptibility

to

interference

,

as

the

ratio

between

wanted

and

unwanted

signals

becomes

increasingly

unfavourable

.

When

electronic

circuits

are

subjected

to

interference

,

their

performance

may

be

degraded

causing

malfunction

,

or

even

catastrophic

failure

.

The

most

common

factors

influencing

electronic

devices

may

be

described

as

follows

:

-

Compared

with

tube

-

equipped

instruments

having

mechanical

switches

,

modern

measuring

and

control

technology

incorporating

microprocessors

have

had

their

signal

and

measuring

levels

decreased

by

one

order

of

magnitude

,

while

frequencies

increased

by

a

factor

of

10

.

In

addition

,

present

process

automation

requirements

dictate

the

use

of

commercially

available

microprocessors

,

which

have

to

work

impeccably

-

often

online

-

under

these

hostile

environmental

conditions

.

The

end

is

not

yet

in

sight

:

newer

devices

will

soon

be

appearing

with

still

shrinking

geometry

and

escalating

sensitivity

.

-

Levels

of

interference

are

growing

due

to

new

technological

developments

.

-

More

and

more

plastic

material

is

being

used

for

case

designs

,

increasing

the

tendency

to

expose

vulnerable

electronics

to

interference

rich

environments

.

Further

developments

in

microelectronic

circuits

will

bring

about

a

marked

reduction

in

the

interference

thresholds

.

That

is

the

reason

why

greater

attention

must

be

drawn

towards

the

EMC

behaviour

of

individual

components

and

electronic

systems

.

National

and

international

standardisation

organisations

have

released

or

are

still

working

on

guidelines

and

recommendations

to

provide

engineering

with

a

greater

harmonisation

between

EMC

and

electronic

circuits

and

systems

.

9

1.2

.

Definitions

-

Electromagnetic

Compatibility

(

EMC

)

Ability

of

a

device

to

correctly

function

in

its

electromagnetic

environment

without

introducing

intolerable

disturbances

to

that

environment

or

to

other

equipment

.

-

Coupling

Interaction

between

circuits

,

transferring

energy

from

one

circuit

to

another

.

-

Electromagnetic

Interference

(

EMI

)

Electromagnetic

disturbance

which

manifests

itself

in

performance

degradation

,

malfunction

,

or

failure

of

electric

or

electronic

equipment

.

-

Immunity

Capability

of

a

device

,

equipment

or

system

to

be

unaffected

by

electromagnetic

disturbances

.

-

Surge

A

transient

wave

of

electric

current

,

voltage

or

power

in

the

circuit

lasting

from

a

few

nanoseconds

to

several

seconds

.

-

Sink

(

victim

)

An

electronic

equipment

which

causes

a

degradation

,

malfunction

,

or

failure

of

electric

or

electronic

equipment

.

-

Susceptibility

The

characteristic

of

electronic

equipment

to

procedure

an

undesirable

response

when

exposed

to

electromagnetic

energy

.

10

1.3

.

Sources

of

interference

Surges

result

from

the

redistribution

of

electromagnetic

energy

.

Such

redistributions

and

their

most

important

sources

are

listed

below

.

-

Stationary

and

non

-

stationary

transmitters

Both

stationary

high

power

radio

transmitters

and

non

-

stationary

walkie

-

talkies

operating

in

the

immediate

vicinity

of

systems

or

equipment

lead

to

uncontrolled

electromagnetic

irradiation

into

vulnerable

electronic

equipment

.

Parameters

:

narrow

-

band

,

continuous

electromagnetic

interference

(

modulated

)

.

-

Electrical

fast

transients

(

burst

)

Electromagnetic

influences

produced

in

the

neighbourhood

by

rapid

variation

of

voltage

and

current

as

a

result

of

the

abrupt

change

of

a

switch

from

a

non

-

conductive

to

a

fully

conductive

status

or

vice

versa

,

e

.

g

.

switching

inductive

loads

with

mechanically

moved

contacts

between

which

arcing

occurs

before

they

separate

.

Further

examples

are

provided

by

arc

-

overs

in

the

measuring

and

limiting

spark

gaps

used

in

high

voltage

test

facilities

.

Parameters

:

broad

-

band

pulse

interference

,

rise

time

of

pulses

of

a

few

nanoseconds

,

small

energy

content

and

high

repetition

rate

.

-

Atmospheric

discharges

,

lightning

and

switching

transients

Lightning

and

switching

transients

appearing

in

low

voltage

networks

of

industrial

installations

are

the

origin

of

pulse

-

cancelling

interferences

.

Parameters

:

range

of

voltage

some

tens

of

kV

,

range

of

current

some

tens

of

kA

,

high

-

energy

pulses

with

rise

times

in

the

microsecond

range

.

-

Breakdowns

,

power

failures

Fuse

blowing

as

the

result

of

a

short

-

circuit

may

affect

equipment

in

the

neighbourhood

in

the

following

way

:

a

)

power

failure

or

voltage

fluctuations

of

some

milliseconds

until

fuse

blows

.

b

)

whenever

there

is

an

abrupt

break

of

the

short

-

circuit

current

,

an

overvoltage

of

2

or

3

times

the

nominal

value

with

duration

up

to

1

ms

is

generated

.

11

-

Harmonic

frequency

disturbances

Generation

of

harmonics

takes

place

in

most

power

equipments

as

a

consequence

of

their

reactive

coupling

.

-

Electrostatic

discharge

Generation

of

an

electrostatic

charge

is

especially

favoured

by

the

combination

of

synthetic

fabrics

and

dry

atmosphere

.

There

is

a

big

variety

in

the

charging

process

.

A

common

situation

is

that

an

operator

walks

over

a

carpet

and

with

each

step

loses

electrons

from

his

body

to

the

fabric

.

Friction

between

the

operators

clothing

and

the

chair

can

also

produce

an

exchange

of

charges

.

The

operators

body

may

be

charged

either

directly

or

by

electrostatic

induction

;

in

the

latter

case

a

conducting

carpet

will

not

give

protection

unless

the

operator

is

adequately

earthed

to

it

.

The

effect

of

the

operator

discharge

may

be

a

simple

malfunction

of

the

equipment

or

damage

of

electronic

components

.

The

dominant

effects

can

be

attributed

to

the

discharge

current

(

<

100

A

)

and

voltage

(

<

30

kV

)

with

rise

times

in

the

nanosecond

range

.

12

2

.

Operating

Functions

2.1

.

Front

view

E

F T

500

EM

TEST

TESTSUPPLY

1

5

50

OHM

F

1

F

2

F

3

F

4

F

5

F

6

F

7

<

- -

>

.

00

EXIT

ESC

20

TESTON

G Q

0 7

CRO

.

8

®

Hh

-

@

L

11

(

§

)

©

—

II

—

(

p

)

N

©

—

II

—

(

§

j

)

PE

12

9

10

1

Display

2

’

’

Test

On

"

3

Function

keys

,

,

F

1

.

.

F

7

,

,

4

Cursor

keys

and

5

Knob

(

Inc

/

Dec

)

6

Exit

7

Escape

8

CRO

9

Coupling

mode

10

EUT

test

supply

11

HV

pulse

output

50

ohm

12

Ground

reference

1

Display

All

functions

and

parameters

are

displayed

(

8

lines

with

max

.

40

characters

)

.

2

Test

On

By

pressing

the

key

"

Test

On

"

the

test

procedure

is

initiated

with

the

preselected

parameters

.

The

red

LED

indicates

the

trigger

of

a

burst

event

.

3

Function

keys

"

F

1

.

.

F

7

”

Parameters

and

functions

,

displayed

in

the

lowest

line

,

can

be

selected

with

the

related

function

key

.

4

Cursor

keys

Parameters

and

functions

can

be

changed

online

.

The

selection

of

these

parameters

is

realised

with

the

cursor

moving

to

the

left

or

to

the

right

.

5

Knob

(

Inc

/

Dec

)

The

knob

increments

or

decrements

test

parameters

with

a

numeric

value

or

selects

from

a

list

of

parameters

.

13

6

Exit

Pressing

of

the

Exit

function

will

cause

a

reset

of

the

firmware

.

This

is

only

possible

if

no

test

routine

is

running

.

7

ESC

When

pressing

the

ESC

button

the

user

moves

back

one

page

in

the

menu

.

8

BNC

-

CRO

At

the

BNC

output

the

generator

trigger

can

be

checked

,

e

.

g

.

the

burst

duration

,

the

burst

repetition

rate

and

the

spike

frequency

(

+

15

V

rectangular

)

.

9

Coupling

mode

The

actual

coupling

mode

is

indicated

by

LED

.

10

EUT

test

supply

For

single

-

phase

EUT

the

coupling

/

decoupling

network

is

part

of

the

generator

.

The

EUT

is

powered

via

the

safety

banana

plugs

at

the

front

panel

of

the

simulator

.

11

HV

pulse

output

50

ohm

External

coupling

devices

such

as

the

capacitive

coupling

clamp

and

the

3

-

phase

coupling

network

are

connected

to

the

coaxial

50

ohm

output

.

Also

the

calibration

of

the

generator

is

handled

at

this

output

.

12

Ground

reference

During

test

or

calibration

procedure

the

burst

generator

must

be

grounded

at

the

reference

ground

plane

.

14

2.2

.

Rear

view

5

8

9

EXT

TRIGGER

2

0

fc

=

i

Wfca

4

m

RS

232

CN

O

©

1

©

6

©

11

O

)

FAIL

IEEE

0

FAIL

2

SAFETY

CIRCUIT

12

(

§

)

(

§

)

3

10

7

0

0

0

1

Test

supply

2

Phase

indication

3

Reference

earth

connection

4

External

trigger

5

Mains

selector

115

V

/

230

V

6

Power

on

7

Security

circuit

8

Serial

interface

RS

232

9

Remote

control

connector

10

Parallel

interface

IEEE

11

Fail

detection

"

Stop

"

12

Fail

detection

"

Pause

"

1

Test

supply

The

power

supply

for

the

EUT

is

connected

to

the

banana

connectors

L

/

N

/

PE

.

The

input

is

decoupled

by

the

coupling

/

decoupling

network

incorporated

in

the

generator

mainframe

.

2

Phase

indication

The

generator

is

synchronised

to

the

line

of

the

power

supply

connected

at

input

L

.

To

indicate

that

the

phase

is

connected

at

this

plug

the

lamp

must

be

on

.

3

Reference

earth

connection

The

generator

has

to

be

connected

to

the

reference

earth

plane

of

the

test

set

up

.

4

Externa

!

trigger

One

single

burst

can

be

released

.

Trigger

level

5

-

15

V

positive

going

.

5

Mains

selector

Selection

of

115

V

/

230

V

6

Power

on

switch

The

switch

is

part

of

the

mains

filter

.

Mains

fuses

are

part

of

the

filter

.

230

V

/

1

A

and

115

V

/

2

A

15

7

Security

circuit

Connector

for

external

security

circuit

.

8

Serial

interface

RS

232

interface

with

a

9

-

po

!

e

connector

.

9

Remote

control

connector

External

coupling

devices

are

controlled

via

this

remote

control

connector

.

10

Parallel

interface

IEEE

IEEE

488

interface

with

IEEE

connector

.

11

Fail

detection

FAIL

1

(

TEST

STOP

)

The

BNC

input

FAIL

1

can

be

used

for

failure

detection

at

the

EUT

.

If

the

input

is

set

to

ground

(

chassis

)

the

burst

generator

will

be

stopped

and

the

actual

test

routine

is

finished

.

It

is

not

possible

to

continue

this

test

routine

.

A

complete

restart

of

the

routine

is

necessary

.

A

message

of

FAIL

1

is

indicated

in

the

LCD

display

as

well

as

in

the

ISM

software

.

12

Fail

detection

FAIL

2

(

TEST

PAUSE

)

The

BNC

input

FAIL

2

can

be

used

for

failure

detection

at

the

EUT

.

If

the

input

is

set

to

ground

(

chassis

)

the

actual

test

routine

is

paused

as

long

as

the

low

level

signal

is

available

at

the

FAIL

2

input

.

Without

the

low

level

signal

the

test

procedure

continues

automatically

.

A

message

of

FAIL

2

is

indicated

in

the

LCD

display

as

well

as

in

the

ISM

software

.

16

3

.

Operation

3.1

.

Description

of

the

menus

The

simulator

is

handled

by

an

easy

menu

control

system

.

Seven

function

keys

are

available

to

select

parameters

and

functions

.

The

selected

parameters

can

be

changed

by

turning

the

knob

(

incr

/

decr

)

,

the

digit

to

be

changed

can

be

selected

with

the

cursor

.

Esc

will

bring

you

one

page

back

in

the

menu

and

Exit

will

reset

the

firmware

to

the

beginning

.

Esc

will

bring

you

one

page

back

in

the

menu

and

Exit

will

reset

the

firmware

to

the

beginning

.

All

functions

are

indicated

on

the

display

;

max

.

8

lines

and

40

characters

.

Start

up

display

EM

TEST

ident

Name

of

the

simulator

Version

-

and

serial

no

.

The

serial

number

and

the

version

number

SWN

are

used

for

traceability

reasons

.

These

numbers

are

listed

in

the

test

reports

and

calibration

certificates

.

These

numbers

also

are

listed

within

the

test

reports

generated

by

the

IEC

WIN

software

.

17

Page

1

(

Main

menu

)

MAIN

MENU

HHMttytVmiMUniHIMM

*

*

*

'

*

*

*****

**

*

*

^

*

<

n

UrtMrr

*

W

W

*

M

WW

WWWWIWiWI

»

MfrlffiW

*

MWIMWW

*

fMWWWISWWWW

*

l

>

W

#

WWW

#

*

WM

1

WIW

<

ll

*

^

F

1

:

Quick

Start

\

V

,

WVH

>

iw

.

vmr

r

^

nrAi

.

r

"

.

w

»

»

T

.

ww

>

ywr

.

ViwvrrtWbVyWA

.

W

V

W

/

WIVV

^

V

1

V

‘

>

“

«

F

2

:

User

test

routines

F

3

:

Test

routines

acc

.

to

I

EC

1000

-

4

-

4

/

61000

-

4

-

4

F

7

:

Service

F

1

F

2

F

3

F

4

F

5

F

6

F

7

F

1

Quick

Start

Easy

and

fast

operation

of

the

equipment

without

special

functions

(

memory

)

.

F

2

User

test

routines

The

user

can

save

and

recall

his

own

specific

test

routines

.

He

can

select

standard

routines

or

special

functions

such

as

automatic

change

of

voltage

or

frequency

during

a

test

routine

.

F

3

Test

routines

as

per

IEC

61000

-

4

-

4

(

prior

:

IEC

1000

-

4

-

4

)

The

user

can

call

up

the

standard

routines

as

per

to

IEC

1000

-

4

-

4

,

level

1

-

5

and

start

them

immediately

.

F

7

Service

Set

-

up

,

self

-

test

,

addresses

of

EM

Test

can

be

selected

and

displayed

.

18

3.2

.

Quick

Start

Easy

and

very

fast

operation

of

all

standard

functions

of

the

equipment

.

The

last

simulator

settings

are

stored

automatically

and

will

be

recalled

when

Quick

Start

is

next

selected

.

Page

2

(

Show

parameters

)

QUICK

START

V

=

2000

V

f

=

5.0

kHz

td

=

15.0

ms

tr

=

300

ms

kop

=

L

N

PE

+

/

-

=

+

T

=

5

:

00

min

START

CHANGE

PRINT

F

1

F

2

F

3

F

4

F

5

F

6

F

7

Press

START

and

the

test

routines

begin

to

work

.

Press

CHANGE

and

the

actual

parameter

can

be

changed

.

PRINT

will

cause

a

hard

copy

of

the

set

-

up

via

the

serial

interface

RS

232

.

EFT

/

Burst

Specification

IEC

61000

-

4

-

4

V

f

-

5

kHz

/

2

,

5

kHz

»

-

*

f

*

t

td

=

15

ms

tr

=

300

ms

T

>

1

min

tm

*

i

i

I

a

I

m

fai

»

«

i

»

i

#

T

&

>

M

fcl

MbYdn

+

iK

*

19

Page

3

(

Change

)

QUICKSTART

Voltage

V

:

200

V

-

4400

V

0.1

kHz

-

1000.0

kHz

Duration

td

:

0.1

ms

-

999.9

ms

Repetition

tr

:

10

ms

-

9999

ms

Test

time

T

:

0

:

01

min

-

99

:

59

min

U

f

td

tr

kop

+

/

-

T

200

5.0

15.0

300

L

N

PE

+

5

:

00

F

1

F

2

F

3

F

4

F

5

F

6

F

7

The

user

can

select

the

parameter

with

the

related

function

key

and

change

the

value

with

the

knob

.

The

cursor

allows

the

user

to

define

the

value

of

the

digit

to

be

changed

(

fast

or

slow

change

)

.

Pressing

of

the

Esc

button

will

bring

the

user

back

to

the

previous

level

from

where

the

test

can

be

restarted

with

new

levels

.

After

restart

the

actual

test

time

is

displayed

.

All

function

keys

except

F

2

(

manual

trigger

)

can

stop

the

test

routine

.

The

latest

setting

will

be

displayed

.

Any

pressing

of

a

function

key

will

indicate

the

functions

START

,

CHANGE

,

CONTINUE

or

PRINT

.

F

3

will

continue

the

same

test

routine

.

Also

the

test

time

will

continue

running

.

If

the

user

first

selects

START

,

CHANGE

or

PRINT

the

test

will

be

stopped

completely

.

The

blinking

value

can

be

changed

with

the

knob

inc

/

dec

.

To

select

other

values

use

the

cursor

keys

.

Print

prints

the

settings

of

the

actual

menu

.

20

Table of contents

Other EMTEST Portable Generator manuals

Popular Portable Generator manuals by other brands

King Canada

King Canada 1500W Gasoline Generator KCG-1500G Service manual

Champion

Champion 4000 Starting watts / 3500 Running watts owner's manual

Durapac

Durapac DPA-16 instruction manual

Itm

Itm Trade Series Operator's manual

Power

Power SUA8000iE quick start guide

Fischer Panda

Fischer Panda Panda 8000x PMS manual

MULTIQUIP

MULTIQUIP GA-2.3R2 Parts and operation manual

Caviblaster

Caviblaster 1325-D Operation & maintenance manual

PowerTech

PowerTech Promate 600 owner's manual

Generac Power Systems

Generac Power Systems 006001-0 owner's manual

Westinghouse

Westinghouse 10KPRO owner's manual

aFe Power

aFe Power 77-46318 instruction manual