In the end position, the pulp press develops considerable pressing forces of up to 1.5 / 2.5

tons, which are quite suitable for mutilating hands.

That is why this machine belongs not in children‘s hands !

If children should have access to your kitchen, please point them out several times

insistently on the danger. You can also signicantly reduce the risk if The press height adjust-

ment after each use turn far apart so that no damage can be done to a child‘s hand!

Please operate the press alone. Make sure that while pressing nobody is handling the press

area.

When transporting or setting up the press, keep in mind that the press has a weight of 25 kg

for type L and 45 kg for type XXL.

Handling

Place the shredder press on a stable, non-slip surface. As a right-handed person, it makes

sense to place the prepared schnitzel meat and the container for the nished schnitzel on

the right side. To place and remove the schnitzel, you need additional space left or right for

swiveling. To press, push the handle lever (8) down with both hands as far as it will go.

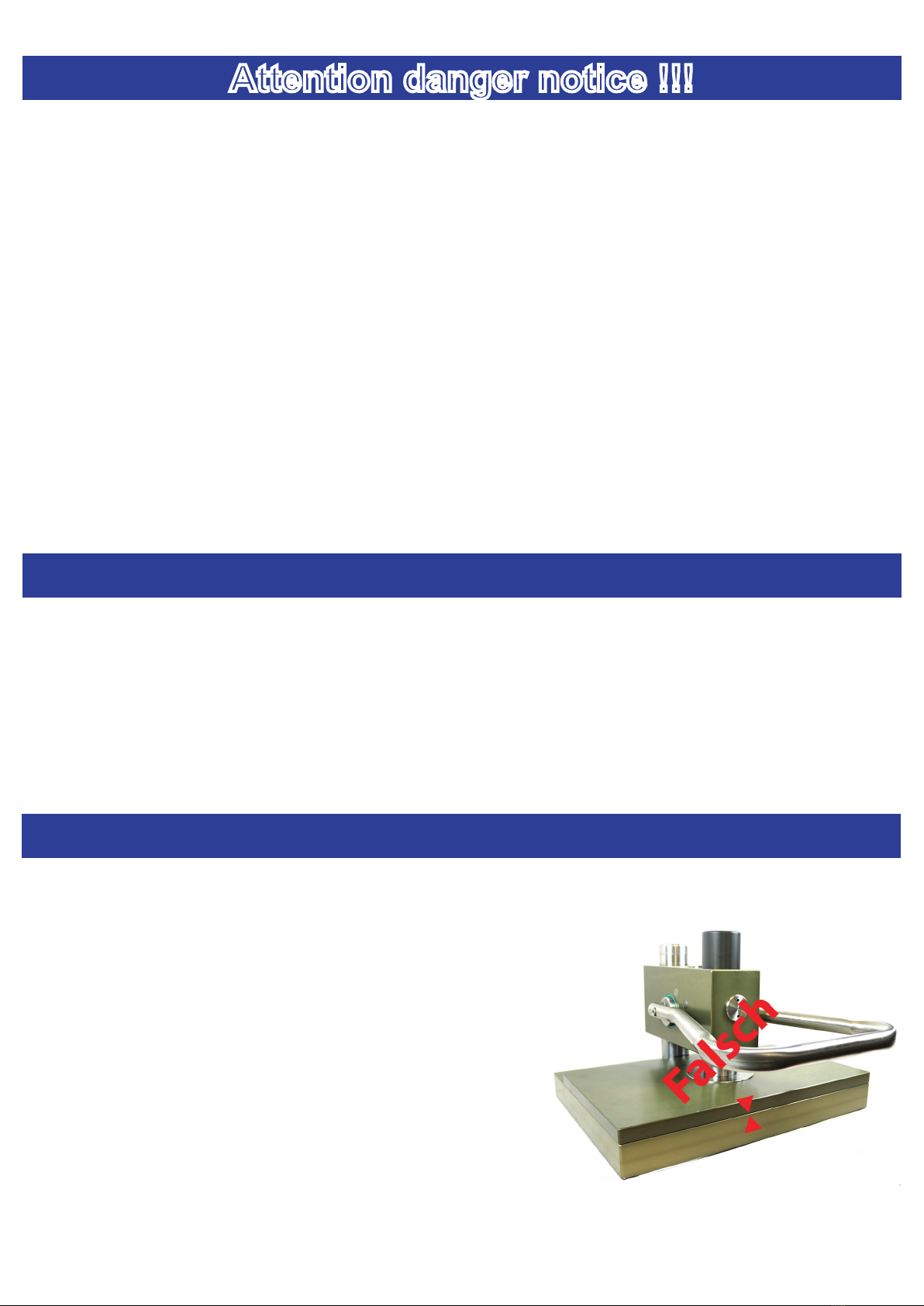

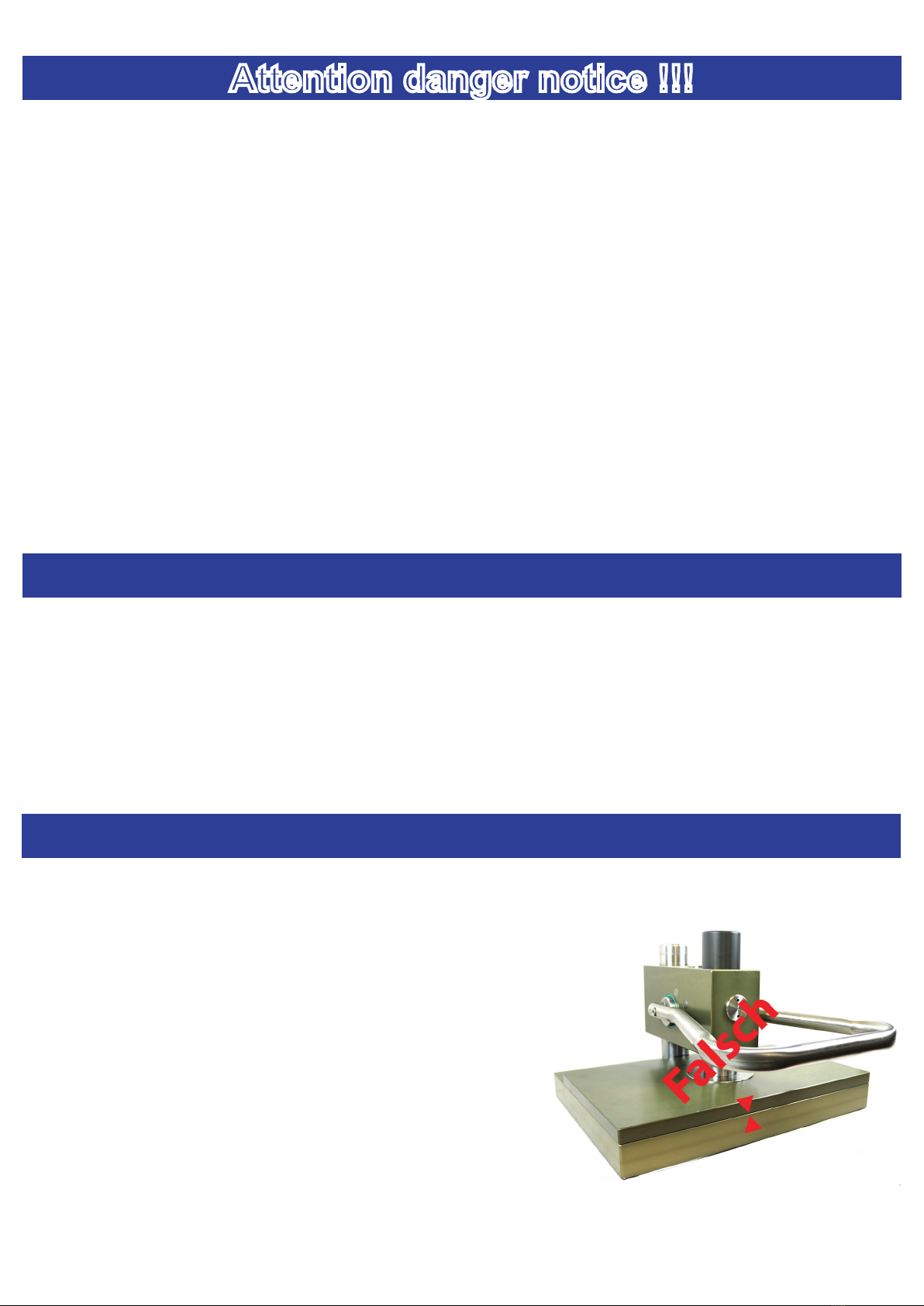

Setting the meat thickness

Before pressing your rst schnitzel, put the handle

lever (8) down (do not press!) And look at the gap

(9) between the press plate (6) and the base plate

(7). The gap distance (9) corresponds to the desired

meat thickness. If the pressed meat is too thin, turn

the height adjustment (2) behind the handle lever

to the right. You feel a click every 0.2 mm in height

when turning. If the pressed meat is too thick, turn

the height adjustment to the left until you have rea-

ched the desired meat thickness. When the rie le-

ver is pushed all the way down to the pressure plate,

you have reached the greatest pressing force. The

press plate and base plate should not touch each

other.

Attention danger notice !!!

wrong