5ENGLISH | Operating Instructions

Additional clamping can be used, but may not be necessary.

Please be sure to exercise good judgment when securing your

vise to the mounting surface. Be sure your vise is secured and

will not move when applying the machine pressure.

Operating Instructions

For proper vise operation place the handle on to the hex end of

the vise. Rotate clockwise to clamp and counterclockwise to un-

clamp your vise. is handle combined with the correct amount

of torque will provide you with all the clamping force you will

need to machine your parts. A high quality calibrated torque

wrench can be used if needed.

DO NOT use any other type of pressure to open or close your

vise.

e uses of handle extensions, air impact wrenches, breaker

bars or hammer strikes are not recommended and will void

the warranty if used. is will also cause damage to the thrust

bearing and screw threads. If you need more clamping force you

may need to upgrade to a larger vise.

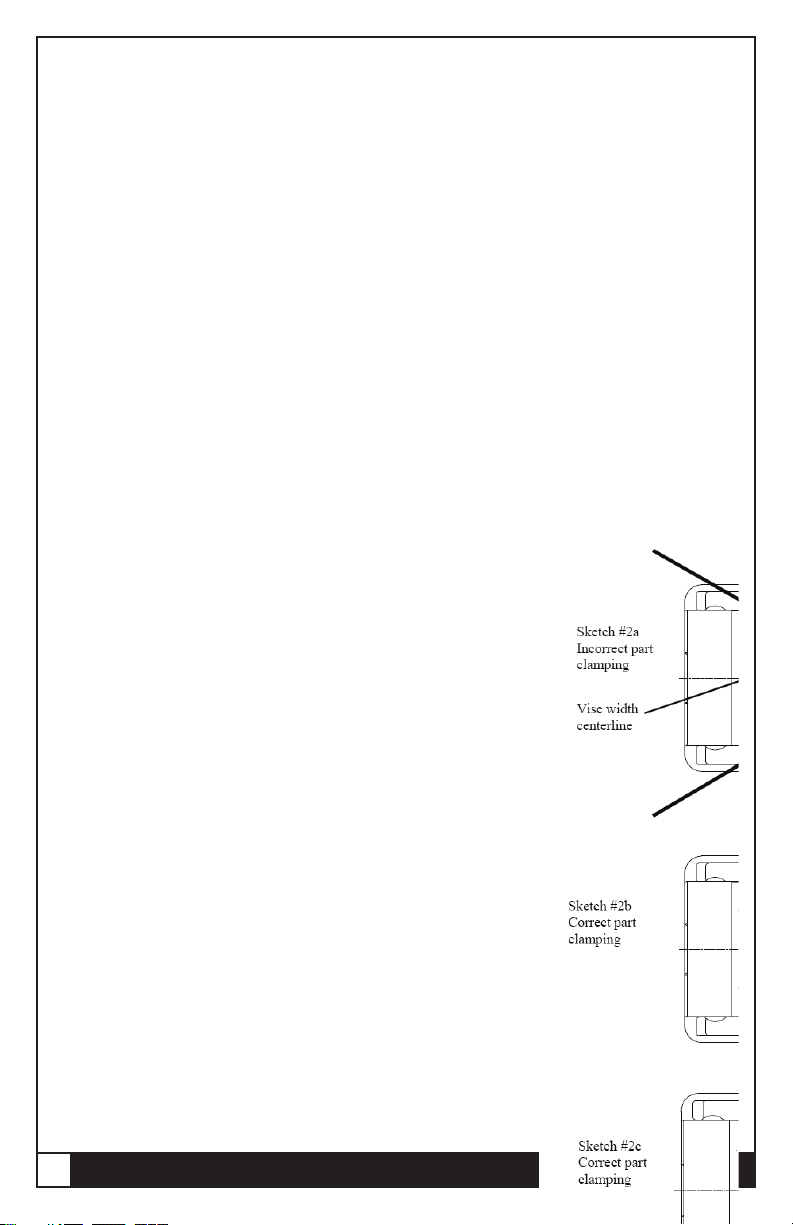

To properly clamp a part in your Kurt vise you should place

the part in the center of the jaws resting on the ways of the vise.

Clamping only on one side or above the movable and stationary

jaws can result in jaw li or loss of accuracy. (See Fig. on next

page)

If one-sided clamping is necessary you MUST use a dummy part

on the other side. When using parallels or step jaws you must se-

lect a size that keeps the bottom of the clamped part at or below

the top of the movable and stationary jaws. Always use jaw plates

for clamping. If jaw plates are not used,the mounting surface of

the movable and stationary jaw will be damaged. is will result

in reduced clamping accuracy and repeatability.