Endo CRL-4000 Series User manual

Supply this manual to the user.

INSTRUCTION MANUAL

CABLE REEL

CRL - 4000 SERIES

CRL - 5000 SERIES

CRL - 6000 SERIES

CRL - 7000 SERIES

・

・・

・Read this manual before use.

・

・

・

・Keep this manual available.

ENDO KOGYO CO., LTD

RM-10547a

Issued on Apr 2013

Copied digital data

from http://www.endo-kogyo.co.jp/

Copyright and liabilities

The copyright for this manual belongs to Endo Kogyo Co., Ltd.

The manual is provided for the limited purpose of supporting the safe and proper use of

the product. It cannot be used for other purposes.

The customer may not use or make copies of this manual, in whole or in part, outside of

this purpose without receiving prior consent from Endo Kogyo Co., Ltd.

The customer is also prohibited from translating or modifying the content of the manual,

in whole or in part.

The content described in the manual is subject to change without advance notice.

Please note this in advance.

November 2019 ENDO KOGYO CO., LTD.

Copied digital data

from http://www.endo-kogyo.co.jp/

SAFETY ALERT SYMBOL AND ALERT SIGNS

Please read this manual carefully and follow its instructions.

The SAFETY ALERT SYMBOL ), WARNING, CAUTION,

and NOTE carry special messages.

This SAFETY ALERT SYMBOL is used to all your attention

to items or operations that ould be dangerous to you or other persons using

this equipment.

Please read these messages and follow these instru tions arefully.

: WARNING indi ates a hazardous situation whi h,

if not avoided, ould result in death or serious injury.

: CAUTION indi ates a hazardous situation whi h,

if not avoided, ould result in minor or moderate injury,

damage or destru tion of the equipment and others.

NOTE:

::

:NOTE indi ates a spe ial instru tion in operation or maintenan e.

Copied digital data

from http://www.endo-kogyo.co.jp/

Contents

1. Safety instru tion ························································ 1

2. Terminolo y definitions ·························································································· 4

3. Product description ································································································ 5

3-1. Models and specifications

3-2. Names of main parts

4. Installation ············································································································8

4-1. Checks before installation

4-2. Installation

4-3. Ground connection work

5. Cable connection ····································································································9

5-1. Calculation of required cable len th on windin side

5-2. Cable connection

6. Sprin tension adjustment ····················································································13

6-1. Relationship between windin torque and drum turns

6-2. Standard value of initial sprin turns and calculation for upper limit of

initial sprin turns.

6-3. Initial tension settin

7. Measures a ainst uneven windin ·········································································14

7-1. Checks before adjustments

7-2. Adjustments

8. Safety instructions on use ·····················································································15

9. Special accessories ·······························································································16

10. Periodic inspections ····························································································17

10-1. Visual inspections

10-2. Slip rin inspections

10-3. Stora e

11. Troubleshootin ··································································································20

12. Brush and slip rin replacement ··········································································20

12-1. Brush replacement

12-2. Brush holder replacement

12-3. Slip rin replacement

13. Sprin replacement ····························································································23

13-1. Disassembly of slip rin assembly and bracket

13-2. Disassembly and reassembly accordin to sprin structure

13-3. Common reassembly method

13-4. Sprin disposal1

14. Parts List ···········································································································38

Copied digital data

from http://www.endo-kogyo.co.jp/

-

1

-

1. Safety instru tions

Re ardin name plates, warnin labels and labels:

・

・・

・Never remove or defa e any name plates, warning labels or labels whi h are atta hed to

the body.

The operator should always observe them.

Re ardin installation (pa e 8):

・

・・

・Never use in ignitable or explosive atmospheres.

・

・・

・Take suffi ient are not to kno k or drop the reel when handling.

Never use the arm of the guide roller (spe ial a essories) to lift the reel.

Re ardin round connection work (pa e 9):

・

・・

・Ele tri sho k hazard.

Do the ground onne tion work.

・

・・

・Never onne t the earth line to the following:

Gas pipes, et . : Danger of ignition or an explosion.

Phone lines / lightning rods : Danger of being stru k by lightning.

Along plasti water pipes : Does not a t as an earth.

Re ardin cable connection (pa e 10):

・

・・

・Ele tri sho k hazard.

Turn off the power before arrying out any work.

・

・・

・Do not install able to drum more than 2-3 times round.

(2-3 times means winding length & initial spring turns)

Make free spa e in drum, otherwise able ould spill out from drum over.

If able spilled, it auses a idents as a able utting.

・

・・

・When used for verti al lift or horizontal stret h appli ation, in order to

prevent severing of the able and then a fall in ase of a spring breakage, prote t the able

by wrapping rubber or the like around the able portion whi h onta ts with the oblong

hole in the drum over.

・

・・

・Che k the wire onne tions are sound and there are no wiring errors.

・

・・

・Never allow the able (leads) onne ted to the slip rings to protrude over 10mm from the

terminal plate upper surfa e for slip ring apa ities of 10A, 20A and 50A, or over 30mm

from the top of the lead bolt for slip ring apa ities of 100A and 150A.

・

・・

・Leave suffi ient room for onne ting the able (leads) to the brushes so as not to apply

ex essive for e to the brushes.

・

・・

・Never obliquely atta h the terminal lugs to the brush holder. If obliquely atta hed, the

insulator length will be insuffi ient, resulting in poor insulation.

・

・・

・Se urely tighten the ross re essed head s rews to atta h the dust proof over and the

onne tor nut to prevent rain penetration.

Take suffi ient are not to damage the seal ring during any work.

Copied digital data

from http://www.endo-kogyo.co.jp/

-

2

-

Re ardin initial tension settin (pa e 14):

・

・・

・Never let go of the drum during any work.

When released, the drum suddenly rotates, possibly ausing personal injury.

・

・・

・After setting the initial tension, wire onne tion requires more than 2 people to se ure

the drum and onne t the able.

Safety instructions on use (pa e 15):

・

・・

・Never approa h the moving parts during operation.

There is a danger of being aught up.

・

・・

・Turn off the power immediately in ase of any trouble to avoid the problem es alating.

・

・・

・Never use the reel when damaged or abnormal sound/vibration o urs.

・

・・

・Never alter the reel or its a essories.

・

・・

・Never let go of or unfasten the able from the fixed points when the able is pulled out.

The able will rewind suddenly, possibly ausing personal injury.

・

・・

・Use within the rated values of the operating voltage and urrent.

Refer to the name plate atta hed to the body.

・

・・

・Never pull out the able past the winding length. Always leave 2 - 3 dead turns

on the drum. (To the sign of red tape)

Put sign (red tape) on the 2 – 3 dead turns when installing or repla ing the able.

Re ardin periodic inspections (pa e 17):

・

・・

・Periodi ally inspe t the reel and repla e any worn or damaged parts.

Carefully he k the able has no damage.

・

・・

・If a malfun tion is found during a periodi inspe tion, never reuse the reel but repair

immediately.

・

・・

・Allow the able to fully wind onto the drum to give the minimum winding tension before

arrying out inspe tions.

・

・・

・Ele tri sho k hazard.

Turn off the power before removing the dust proof over.

・

・・

・Verify safety using some kind of ele tri al test sensor before arrying out inspe tions.

・

・・

・Always put up an instruction sign ("Equipment being inspected", "Do not turn on the power",

etc.) before carrying out periodic inspections or repair.

・

・・

・Ta e care as the slip ring assembly can still be very hot even if the power is cut.

・

・・

・Always use genuine parts for replacement.

・

・・

・Test the insulation after the reel has been stored for a long time.

Copied digital data

from http://www.endo-kogyo.co.jp/

-

3

-

Regarding brush and sli ring re lacement ( age 20):

・

・・

・Electric shoc hazard.

Turn off the power and verify safety using some ind of electrical test sensor before carrying out

replacement.

・

・・

・Allow the cable to fully wind onto the drum to give the minimum winding tension before

carrying out replacement.

・

・・

・Always put up an instruction sign ("Equipment being inspected", "Do not turn on the power",

etc.) before carrying out replacement.

・

・・

・Take are as the slip ring assembly an still be very hot even if the power is ut.

・

・・

・After part repla ement, test the insulation before onne ting the able.

・

・・

・Che k the ondu tion of ea h able ore after able onne tion.

Re ardin sprin replacement (pa e 23):

・

・・

・Ele tri sho k hazard.

Turn off the power and verify safety using some kind of ele tri al test sensor before

arrying out repla ement.

・

・・

・When dis onne ting the mating equipment side wiring on the able winding side, the drum

may suddenly rotate.

Allow the able to fully wind onto the drum to give the minimum winding tension, then

dismantle the mating equipment side wiring with more than 2 people to se ure the drum

and dismantle the wiring.

・

・・

・Allow the dismantled able to wind around the drum, slowly turning the drum until the

winding tension in the drum is released.

Never disassemble until the reel's winding tension is released.

The spring will burst out and ause personal injury.

・

・・

・Never disassemble using any other disassembly pro edure.

If disassembled in orre tly, the spring will burst out and ause personal injury.

・

・・

・Never remove the spring from the spring ase.

If removed, the spring will expand explosively and ause personal injury.

・

・・

・Treat and dispose of the spring a ording to the instru tions.

・

・・

・Always put up an instruction sign ("Equipment being inspected", "Do not turn on the power",

etc.) before carrying out periodic inspections or repair.

Copied digital data

from http://www.endo-kogyo.co.jp/

-

4

-

2. Terminology definitions

The terminolo y used in this manual will be explained here.

If there is any terminolo y which is unclear or not included in this section, please contact

our company.

Windin methods: Fi ure 1

Forward windin : The windin direction when Fi ure 2

viewed from the bracket side is

ri ht (clockwise).

Reverse windin : The windin direction when

viewed from the bracket side is

left (counterclockwise).

Forward seatin : The installation plate (base plate)

is located under the drum.

Reverse seatin : The installation plate (base plate) Fi ure 3

is located on the opposite side of the drum.

C-class round,

connection work: applied to non-char in parts of electric

equipment or cable metal jackets, the round

resistance of which should be 10 ohms or less.

Dead turns : The 2-3 turns of cable wrapped around the drum other than the used

windin len th.

Initial sprin turns : The applied initial tension to the sprin .

The initial tension is required for windin the cable on the drum.

Reverse

seating

Forward

seating

View from

the bracket

side.

Forward

winding

(Clockwise)

Reverse

winding

(Counter

clockwise)

Horizontal drag ,two-way payout

Vertical

lift

Horizontal retrieve

Horizontal stretch

Vertical

retrieve

Vertical

lift

Horizontal retrieve ,two-way payout

Horizontal drag

Horizontal stretch

Vertical

retrieve

Moving reel Fixed reel

Copied digital data

from http://www.endo-kogyo.co.jp/

-

5

-

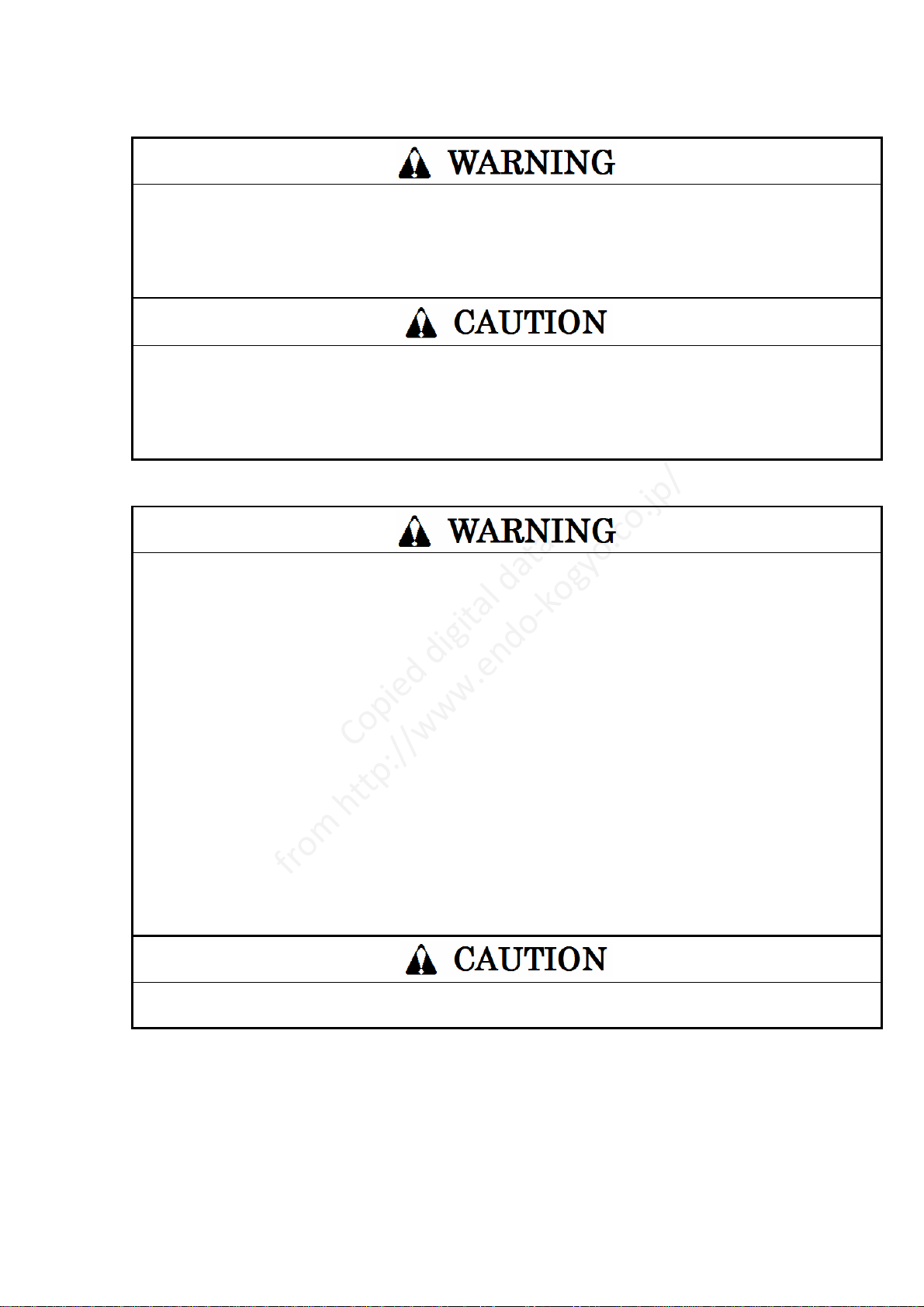

3. Produ t Des ription

3-1. Models and specifications

(1) Models

Please observe the name plate attached to the main body.

Refer to Fi ure 5 (pa e 7) for the attached location.

Fi ure 4

MODEL: The product model is shown.

Please check if this manual

matches with the product.

Refer to Table 1.

CAP'Y: The slip rin capacity is shown.

■ Model description

CRL - 6M 7 112 W - R

Series Drum size Drum cover Sprin Sprin Windin

name and width size type combination direction

Drum size and width (mm)

Code 4M

4 4A

5M

5 5A

6M

6 6A

7M

7 7A

Size 280

280

280

360

360

360

440

440

440

550

550

550

Width 127

165

217

127

165

217

172

220

275

172

220

275

Drum cover size (mm)

Code 4 5 6 7 8 9

Size 440

510

630

750

870

1000

Sprin type

Sprin code 24 48 36 72 55 110 56 112 75 150

Number of sprin s

24×1

24×2

36×1

36×2

55×2

55×2

56×1

56×2

75×1

75×2

Total sprin torque

N・m {k f・m}

23.5

{2.4}

47.0

{4.8}

35.3

{3.6}

70.6

{7.2}

53.9

{5.5}

107.8

{11.0}

54.9

{5.6}

109.0

{11.2}

73.5

{7.5}

147.0

{15.0}

Sprin combination

Code None

W T F V

Number of sets 1 2 3 4 5

Windin direction

None R

Forward windin

Reverse windin

Slip ring capacity

Manufactured date

Serial

Model

Copied digital data

from http://www.endo-kogyo.co.jp/

-

6

-

(2) Specifications

Table 1

Model

Maximum

sprin

torque

N・m

{ k f・m }

Calculated

maximum

sprin

tension

N { k f }

Total

number of

sprin

turns

Sprin

structure

Reference

mass

k

CRL-4M424

CRL-4M424-R

23.5

{ 2.4 }

166

{ 17.0 } 13 E 28

CRL-4424W

CRL-4424W-R

23.5

{ 2.4 }

166

{ 17.0 } 26 G 34

CRL-4424T

CRL-4424T-R

23.5

{ 2.4 }

166

{ 17.0 } 39 G 40

CRL-4424F

CRL-4424F-R

23.5

{ 2.4 }

166

{ 17.0 } 52 G 46

CRL-4524T

CRL-4524T-R

23.5

{ 2.4 }

166

{ 17.0 } 39 G 42

CRL-4524F

CRL-4524F-R

23.5

{ 2.4 }

166

{ 17.0 } 52 G 48

CRL-5M636

CRL-5M636-R

35.3

{ 3.6 }

196

{ 20.0 } 13 E 42

CRL-5636W

CRL-5636W-R

35.3

{ 3.6 }

196

{ 20.0 } 26 G 52

CRL-5636T

CRL-5636T-R

35.3

{ 3.6 }

196

{ 20.0 } 39 G 62

CRL-5636F

CRL-5636F-R

35.3

{ 3.6 }

196

{ 20.0 } 52 G 72

CRL-5655W

CRL-5655W-R

53.9

{ 5.5 }

294

{ 30.0 } 24 G 57

CRL-5655T

CRL-5655T-R

53.9

{ 5.5 }

294

{ 20.0 } 36 G 70

CRL-6756F

CRL-6756F-R

54.9

{ 5.6 }

245

{ 25.0 } 48 G 97

CRL-6756V

CRL-6756V-R

54.9

{ 5.6 }

245

{ 25.0 } 60 G 110

CRL-6775W

CRL-6775W-R

73.5

{ 7.5 }

333

{ 34.0 } 24 G 85

CRL-6775T

CRL-6775T-R

73.5

{ 7.5 }

333

{ 34.0 } 36 G 100

CRL-6775F

CRL-6775F-R

73.5

{ 7.5 }

333

{ 34.0 } 48 G 115

CRL-6M7112W

CRL-6M7112W-R

109.0

{ 11.2 }

490

{ 50.0 } 24 G 100

CRL-7875T

CRL-7875T-R

73.9

{ 7.5 }

264

{ 27.0 } 36 G 115

CRL-7875F

CRL-7875F-R

73.9

{ 7.5 }

264

{ 27.0 } 48 G 130

NOTICE : The reference mass shown in the table is for a slip rin capacity of 50A×3P,

and does not include accessories such as the uide rollers, turn table and

ratchet mechanism.

※ The method for sprin replacement is different dependin on the sprin structure.

Refer to chapter 13. (pa e 23) "Sprin replacement".

■ Workin conditions

Application area : eneral outside conditions

Surroundin temperature : - 10℃ to + 50℃

Copied digital data

from http://www.endo-kogyo.co.jp/

-

7

-

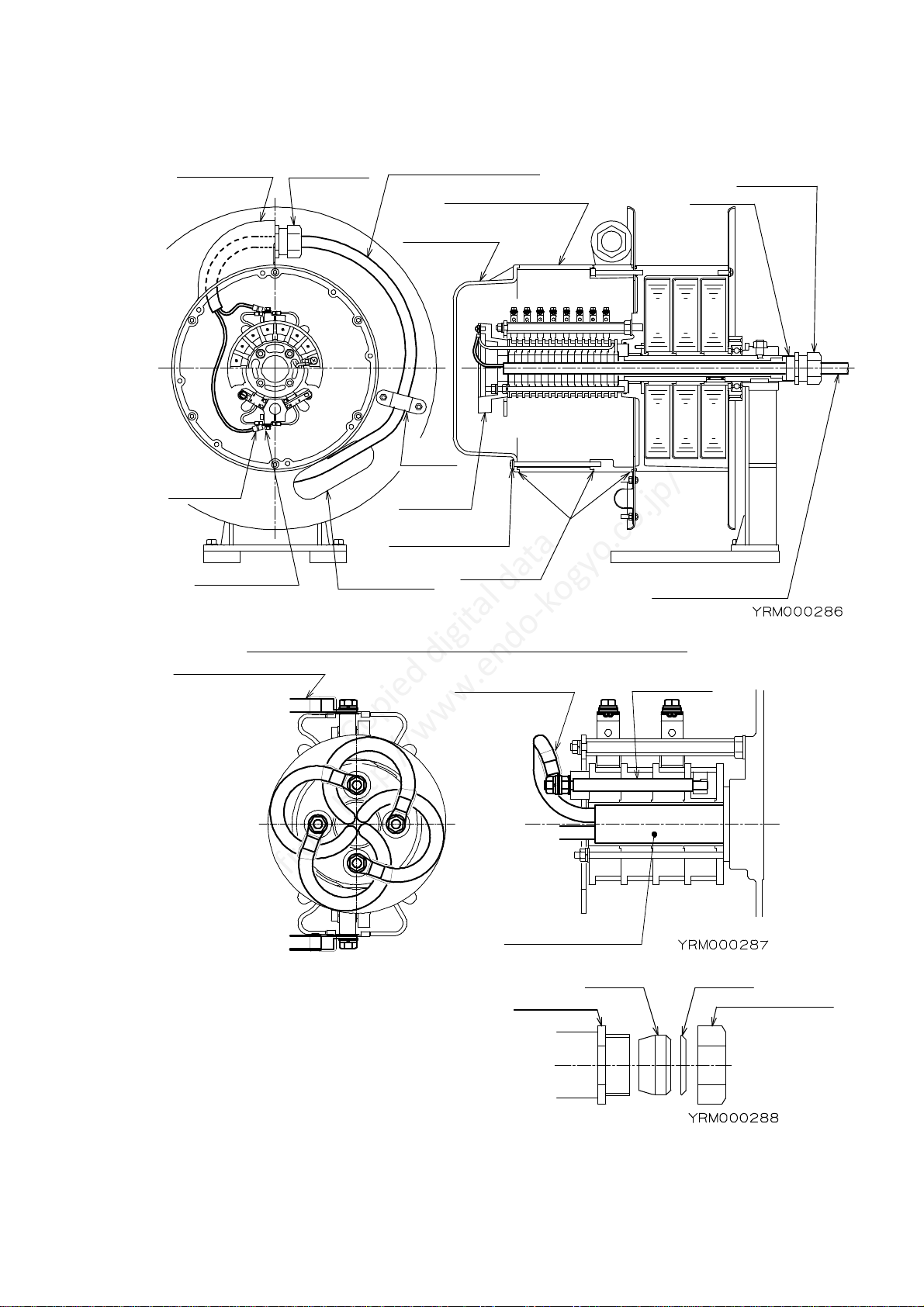

3-2. Name s of main parts

Fi ure 5

Re ardin the accessories, refer to chapter 9. "Accessories" (pa e 16).

(A) Warnin label (B) Warnin label

A warnin is displayed re ardin electric

shock hazards.

A warnin is displayed re ardin sprin

ejection hazards.

(C) Label (D) Label

The required number of initial sprin turns

is displayed.

The windin direction is displayed.

See to

figure 4(page 5).

Being attached

depending on

the slip ring

specifications.

Connector

Dust proof

spacer

Drum

Drum cover

Spring

Spindle

Connector

Bracket

Base plate

Drum cover

Saddle

Cable guide

Slip ring

Dust proof

cover

Copied digital data

from http://www.endo-kogyo.co.jp/

-

8

-

4. Installation

4-1. Checks before installation

・Please check whether the items ordered were received.

(Check the name plate.)

・Check there is no dama e to the product caused durin transportation.

4-2. Installation

Fi ure 6

・

・・

・Never use in ignitable or explosive atmospheres.

・

・

・

・Take suffi ient are not to kno k or drop the reel when

handling.

When lifting the reel, wrap the belt sling around the

drum at least twi e, and lift in stable onditions.

・

・・

・Never use the arm of the guide roller (spe ial a essories) to lift the reel.

・

・・

・For side atta hment or inverse atta hment, use bolts with a strength lassifi ation

above 10.9.

・Place the main body in the fixin location and anchor the bracket securely with 4 bolts.

・The bracket base plate can be chan ed as shown in Fi ure 7

fi ure 7.

NOTE: In order to correctly wind the cable, adjust the

reel position as shown in fi ure 7.

Try to adjust so the center of the drum width

lines up with the cables fixed point on the

matin equipment.

The surface the cable lies on should be

horizontal.

Fi ure 7

Side

attachment

Inverse

attachment

The Y axis should be parallel

with the direction of the

cable pay out and motion

of the equipment.

Line up the center of the

drum width with the cable’s

fixed point on the

mating equipment.

The X axis should

be horizontal.

Moving direction

The surface the cable lies on

should be horizontal.

X axis

Y axis

Cable

Surface

Surface

ixed point

Cable

Forward

seating

Base plate

Hexagon

head bolt

Reverse

seating

Copied digital data

from http://www.endo-kogyo.co.jp/

-

9

-

4-3. Ground connection work

・

・・

・Ele tri sho k hazard.

Do the ground onne tion work.

・

・・

・Never onne t the earth line to the following:

Gas pipes, et . : Danger of ignition or an explosion.

Phone lines / lightning rods : Danger of being stru k by lightning.

Along plasti water pipes : Does not a t as an earth.

For earth connection, connect the earth line to the hole installed in the bracket.

Fi ure 9

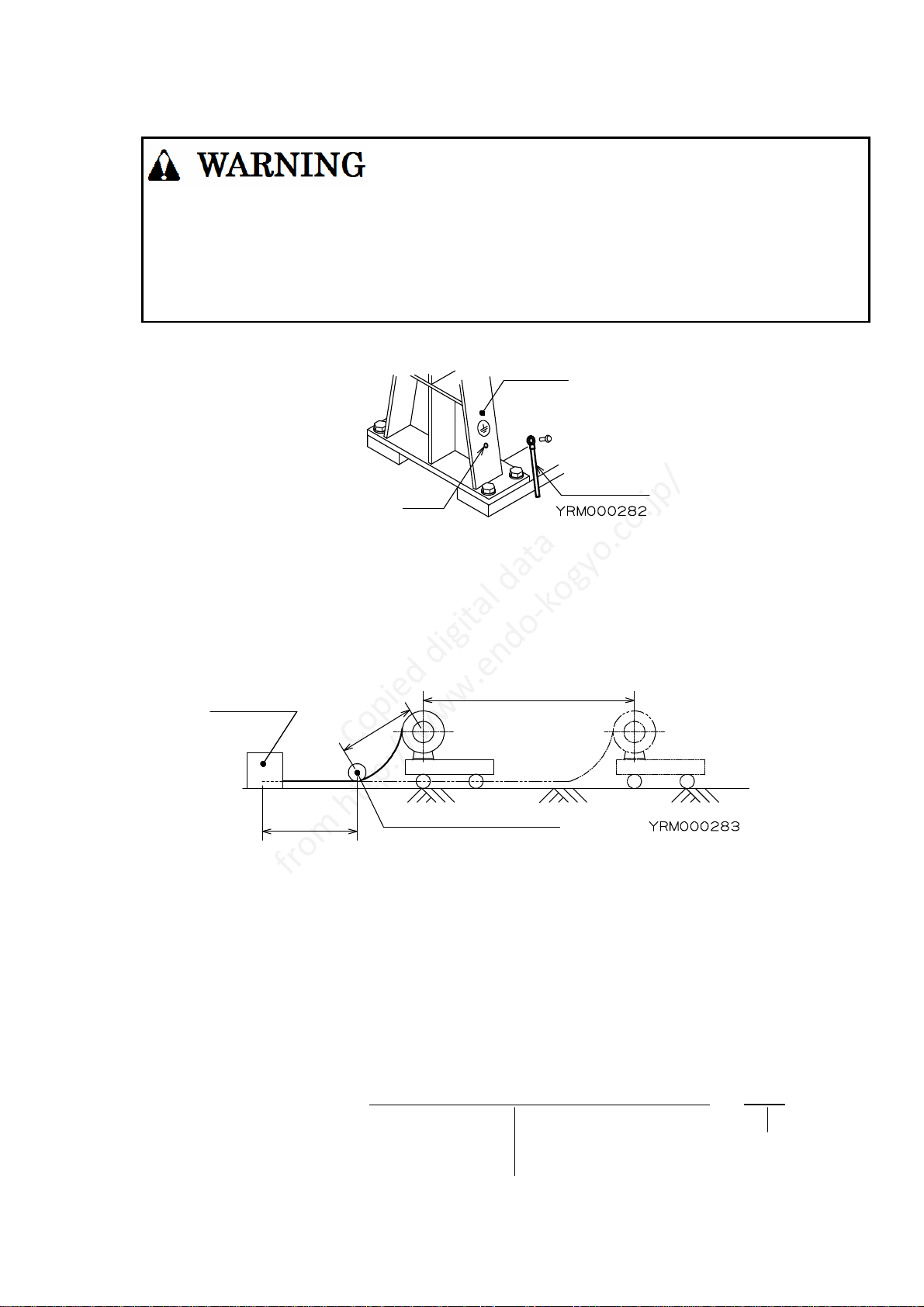

5. Cable onne tion

5-1. Calculation of required cable len th on windin side

Fi ure 10

Cable len th on windin side = Windin len th + Extension len th + Connection len th

+ Dead turns len th + Connection len th inside reel.

Windin len th = The len th wound onto the drum.

Extension len th = The len th from the cable's fixed point to the end of the windin ,

which is not wound onto the drum.

Connection len th = The len th required to connect the matin equipment to the

cables fixed point.

Dead turns len th = The len th of the 2-3 dead turns.

Connection len th inside reel = Approx 1m.

Required dead turns len th = (Drum diameter + Cable diameter) × π × 2 –

3

Numbers of dead turns

The len ths of 1 drum turn

Bracket

Earth line

Hole

M8

Connection

length

Winding length

E

x

t

e

n

s

i

o

n

l

e

n

g

t

h

Mating

equipment

Cable’s fixed point

Copied digital data

from http://www.endo-kogyo.co.jp/

-

10

-

5-2. Cable connection

・

・・

・Ele tri sho k hazard.

Turn off the power before arrying out any work.

・

・・

・Do not install able to drum more than 2-3 times round.

(2-3 times means winding length & initial spring turns)

Make free spa e in drum, otherwise able ould spill out

from drum over.

If able spilled, it auses a idents as a able utting.

・

・・

・When used for verti al lift or horizontal stret h appli ation,

in order to prevent severing of the able and then a fall

in ase of a spring breakage, prote t the able by wrapping

rubber or the like around the able portion whi h onta ts with the oblong hole (F) in

the drum over (See figure 11).

・

・・

・Che k the wire onne tions are sound and there are no wiring errors.

・

・・

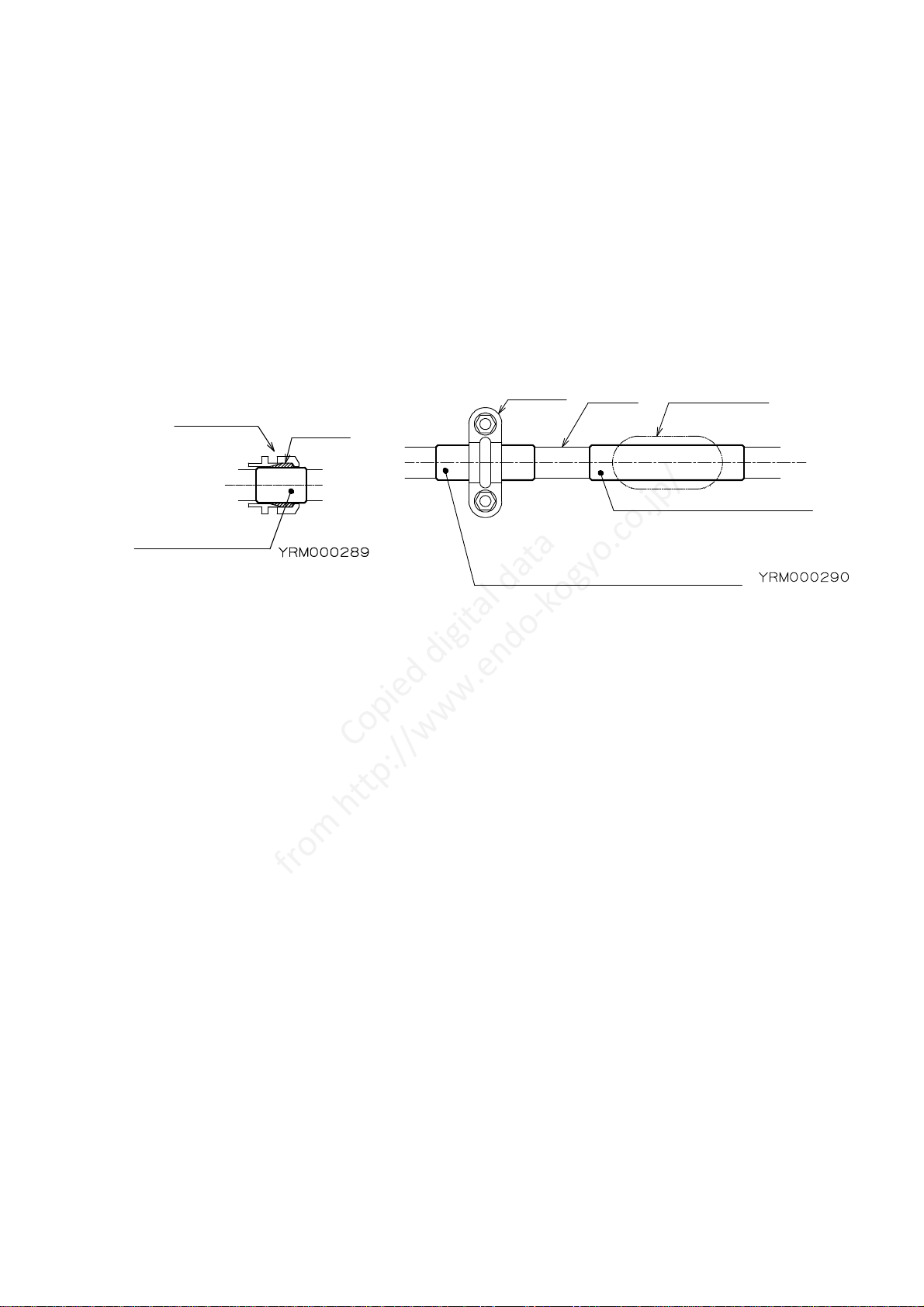

・Never allow the able (leads) onne ted to the slip rings to protrude over 10mm from the

terminal plate upper surfa e for slip ring apa ities of 10A, 20A and 50A, or over 30mm

from the top of the lead bolt for slip ring apa ities of 100A and 150A

(see figures 12 and 13).

If protruding out too far, the fixed side able and the dust proof over will onta t,

damaging the able insulation due to the drum rotation, ausing a spark.

Fi ure 12 Fi ure 13

・

・・

・Leave suffi ient room for onne ting the able (leads) to the brushes so as not to apply

ex essive for e to the brushes.

・

・・

・Never obliquely atta h the terminal lugs to the brush holder.

If obliquely atta hed, the insulator length will be insuffi ient, resulting in poor

insulation.

・

・・

・Se urely tighten the ross re essed head s rews to atta h the dust proof over and the

onne tor nut to prevent rain penetration.

Take suffi ient are not to damage the seal ring during any work.

10mmWithin

Dust proof cover

Fixed side cable

Terminal plate

10A,20A,50A

Lead bolt

Dust proof cover

Fixed side cable

30mmWithin

100A,150A

Figure 11

Copied digital data

from http://www.endo-kogyo.co.jp/

-

11

-

Fi ure 14

Fi ure 15

■ Windin side cable (See fi ure 14,15) Fi ure 16

(1) Loosen the cross recessed head screws

and remove the dust proof cover and

dust proof spacer.

NOTE: The dust proof cover and dust proof

spacer will fall when the cross recessed

head screws are loosened.

Take care not to drop them into the slip rin assembly.

(2) Remove the saddle and the connector nut on the cable uide side.

(3) Pass the cable throu h the oblon hole in the drum cover from the drum side.

Attach the removed nut, washer and sleeve to the cable (See fi ure 16).

Connector nut

Connector

Sleeve Washer

Cross recessed

head screw

Terminal

plate

Saddle

Spindle

Oblong hole

Brush holder Seal ring

Winding side cable

Dust

proof cover

Dust proof spacer

Cable guide

Fixed side cable

Terminal

lug

Connector

Connector

100A,150A connection diagram

Winding side cable

Insulation cap Lead bolt

Fixed side cable

Copied digital data

from http://www.endo-kogyo.co.jp/

-

12

-

(4) Peel the required len th of jacket from the cable, and pass the cable throu h the

cable uide.

Decide on the required len th for peelin to allow sufficient room for connectin the cable

core to the farthest brush holder from the cable uide exit.

(5) Ti hten the connector nut to secure the cable while leavin sufficient room for connectin

each cable core to the brush.

This is important to prevent rain penetration into the slip rin assembly.

NOTE: If the cable cannot be secured by ti htenin the connector nut, make the cable

diameter bi er by wrappin thick tape around the cable, then secure with the

connector nut (See fi ure 17).

Fi ure 17 Fi ure 18

(6) Wrap thick tape around the cable portion which contacts with the oblon hole in the

drum cover, and fix with the saddle.

If the cable cannot be secured by the saddle, make the cable diameter bi er by wrappin

thick tape around the cable (See fi ure 18).

(7) Attach the terminal lu s to each cable core.

(8) Connect the terminal lu s to the brush holders.

■ Fixed side cable (See fi ure 14, 15 (pa e 11))

(1) Remove the connector nut on the spindle side.

Attach the connector nut, washer and sleeve to the cable.

(2) Peel the jacket from the cable, and pass the cable throu h the spindle.

The peelin len th should be 100mm for slip rin capacities of 10A, 20A and 50A, and

300mm for slip rin capacities of 100A and 150A.

(3) Connect each cable core to the terminal plate or the lead bolts.

NOTE: Check the conduction of each cable core to ensure there are no wirin errors.

(4) Ti hten the connector nut to secure the cable.

This is important to prevent rain penetration into the slip rin assembly.

NOTE: If the cable cannot be secured by ti htenin the connector nut, make the cable

diameter bi er by wrappin thick tape around the cable, then secure with the

connector nut (See fi ure 17).

(5) Attach the dust proof spacer and dust proof cover.

Connector Sleeve

Make the cable

diameter bigger.

For vertical lift or horizontal stretch

application, protect the cable by wrapping

rubber or the like around the cable.

Make the cable diameter bigger.

Wrap at least two turns.

Oblong holeCable

Saddle

Copied digital data

from http://www.endo-kogyo.co.jp/

-

13

-

6. Spring tension adjustment

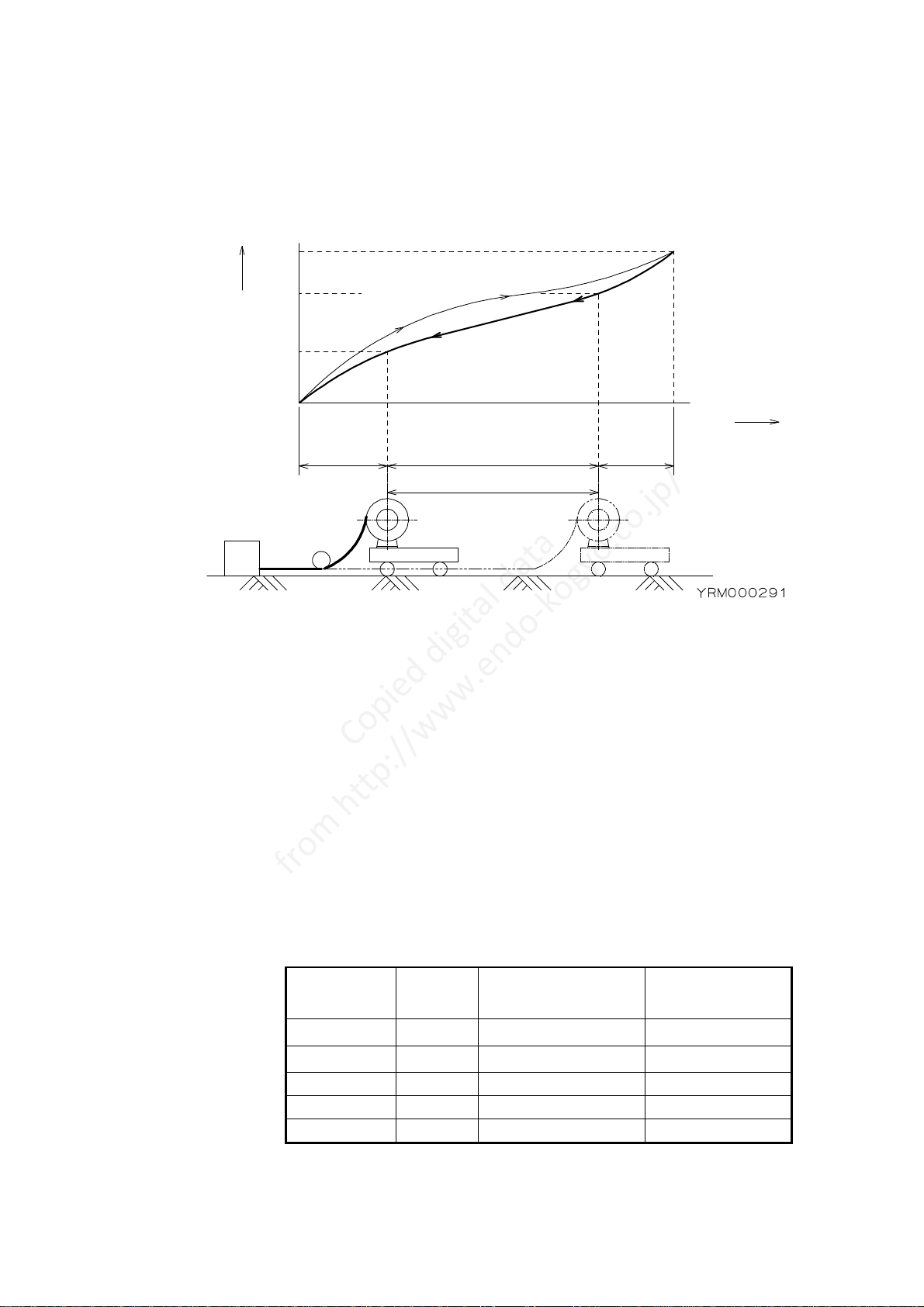

6-1. Relationship between windin torque and drum turns

Fi ure 19

"Number of initial sprin turns" means the number of sprin turns which provides the

initial tension required for windin the cable onto the drum.

"Number of spare sprin turns" means the number of remainin sprin turns when the

cable is fully paid out.

A shorta e of spare sprin turns shortens the sprin life and causes sprin breaka e.

6-2. Standard value of initial sprin turns and calculation for upper limit of

initial sprin turns

(1) Check the total number of sprin turns usin table 1(pa e 6).

(2) Rotate the drum by hand until the cable of the windin len th is fully retracted, checkin

the number of drum turns.

(3) Check the standard value of initial sprin turns and the number of spare sprin turns

usin table 2.

Sprin

combination

Number

of sets

Standard value of

Initial sprin turns

Number of spare

Sprin turns

None 1 1 to 3 1.5 or more

W 2 2 to 6 3 or more

T 3 3 to 9 4.5 or more

F 4 4 to 12 6 or mor

Table 2

V 5 5 to 15 7.5 or mor

Upper limit of initial sprin turns = Total number of sprin turns - (Number of drum turns

+ Number of spare sprin turns)

Winding

torque

MAX

Winding length

Number of

drum turns Spring turns

(Drum turns)

MAX

P

a

y

i

n

go

u

tt

h

ec

a

b

l

e

(

W

i

n

d

i

n

gt

h

es

p

r

i

n

g

)

R

e

c

o

v

e

r

i

n

gt

h

ec

a

b

l

e

(

R

e

l

e

a

s

i

n

gt

h

es

p

r

i

n

g

)

Number

of initial

spring

turns

Number

of spare

spring

turns

Copied digital data

from http://www.endo-kogyo.co.jp/

-

14

-

Example) Model CRL-6M7112W, for the case of 12 drum turns

Accordin to table 1, total number of sprin turns = 24.

Accordin to table 2, standard value of initial sprin turns = 2 - 6,

Number of spare sprin turns = 3 or more.

Upper limit of initial sprin turns = 24 - (12 + 3) = 9.

Then the allowable number of initial sprin turns = 2 - 9.

6-3. Initial tension settin

・

・・

・Never let go of the drum during any work.

When released, the drum suddenly rotates, possibly ausing personal injury.

・

・・

・After setting the initial tension, wire onne tion requires more

than 2 people to se ure the

drum and onne t the able.

(1) Before wire connection, wind the whole cable around the drum.

NOTE: Take care not to twist the cable durin windin .

(2) With the cable still wrapped around the drum, rotate the drum by hand in the payout

direction the same number of turns as the standard value of initial sprin turns.

This becomes "initial sprin turns".

(3) Without lettin the drum rotate, unwind the cable to the extension len th plus the

connection len th and connect the cable to the matin equipment.

Check there are no twists in the cable before connection.

(4) Pull out the cable to the windin len th, then let the cable wind around the drum.

Ensure the drum can recover the cable's full windin len th.

(5) If the drum stops durin recovery, the initial sprin tension is insufficient.

Disconnect the cable from the matin equipment and increase the number of initial

sprin turns in the same manner.

NOTE: Set the initial tension as small as possible and never exceed the upper limit of the

initial sprin turns.

Over-tensionin could cause a sprin breaka e.

7. Measures against uneven winding

"Uneven windin " means the cable is wound on mainly one side of the drum width.

The uneven windin will cause the cable to drop from the drum or recovery problems,

resultin in dama e to the cable.

7-1. Checks before adjustments

(1) Check the reel position is correct.

Refer to chapter 4, section 4-2. "Installation".

Adjust the X and Y axes of the reel.

(2) Check there are no twists in the windin side cable.

Disconnect the cable from the matin equipment and remove any twists.

※ If uneven windin still exists after the above checks, adjust accordin to the next section.

Copied digital data

from http://www.endo-kogyo.co.jp/

-

15

-

7-2. Adjustments

(1) Initial tension modification

Increase the number of initial sprin turns one by one without exceedin the upper limit.

If there is no improvement, set the initial tension back to the first value.

(2) X axis modification

Tilt the X axis at a small an le by insertin a spacer under the bracket.

Fi ure 20

(3) Y axis modification

Tilt the Y axis at a small an le after adjustin the X axis.

Fi ure 21

8. Safety instructions on use

・

・・

・Never approa h the moving parts during operation.

There is a danger of being aught up.

・

・・

・Turn off the power immediately in ase of any trouble to avoid the problem es alating.

・

・・

・Never use the reel when damaged or abnormal sound/vibration o urs.

・

・・

・Never alter the reel or its a essories.

・

・・

・Never let go of or unfasten the able from the fixed points when the able is pulled out.

The able will rewind suddenly, possibly ausing personal injury.

・

・・

・Use within the rated values of the operating voltage and urrent.

Refer to the name plate atta hed to the body.

・

・・

・Never pull out the able past the winding length.

Always leave 2 - 3 dead turns on the drum. (To the sign of red tape)

Put sign (red tape) on the 2 – 3 dead turns when installing or repla ing the able.

Spacer

Spacer

Copied digital data

from http://www.endo-kogyo.co.jp/

-

16

-

9. Spe ial a essories

Fi ure 22

(J) Warnin label

A warnin not to use the uide roller to

lift the reel is displayed.

Never employ a swivel base or a standard turn table for side atta hment or inverse

atta hment.

(1) Turn table Fi ure 23

This can swivel the reel up to 300゜.

When turned, take care the fixed side cable is not put

under excessive force or contacts the reel or surroundin

objects.

An arm type uide roller or pipe type uide roller is required

to ether with the turn table.

Please contact our company in case of side attachment or

inverse attachment, the specifications differ from the standard ones.

(2) Swivel base

This will freely swivel the reel.

An arm type uide roller or pipe type uide roller is required to ether with the

swivel base.

The swivel base is not available for side attachment or inverse attachment.

For installation and so forth, refer to the swivel base instruction manual.

Pipe type guide roller

Stopper

Arm type guide roller

Stopper

Ratchet device

Turn table Swivel base

Ratchet device

Up to 300

Copied digital data

from http://www.endo-kogyo.co.jp/

This manual suits for next models

43

Table of contents

Other Endo Tools manuals

Popular Tools manuals by other brands

Constructor

Constructor CTCID144LI2-3IN1-BM Original instructions

Nederman

Nederman 865 series Original user manual

FAR

FAR RAC 230 Operating instructions and spare parts list

Clarke

Clarke IT1500 Operation & maintenance instructions

pela tools

pela tools 494220 instructions

ACCU-SYSTEMS

ACCU-SYSTEMS DD manual