Endo HR-2000 Series User manual

Supply this manual to the user.

INSTRUCTION MANUAL

HOSE REEL

HR-2000 SERIES

HR-3000 SERIES

・Read this manual before use.

・Keep this manual available.

ENDO KOGYO CO., LTD

RM-10661a

Issued on Mar. 2020

Copied digital data

from http://www.endo-kogyo.co.jp/

Copyright and liabilities

The copyright for this manual belongs to Endo Kogyo Co., Ltd.

The manual is provided for the limited purpose of supporting the safe and proper use of

the product. It cannot be used for other purposes.

The customer may not use or make copies of this manual, in whole or in part, outside of

this purpose without receiving prior consent from Endo Kogyo Co., Ltd.

The customer is also prohibited from translating or modifying the content of the manual,

in whole or in part.

The content described in the manual is subject to change without advance notice.

Please note this in advance.

November 2019 ENDO KOGYO CO., LTD.

Copied digital data

from http://www.endo-kogyo.co.jp/

SAFETY ALERT SYMBOL AND ALERT SIGNS

Please read this manual carefully and follow its instructions.

The SAFETY ALERT SYMBOL ( ), WARNING, CAUTION,

and NOTE carry special messages.

This SAFETY ALERT SYMBOL is used to call your attention

to items or operations that could be dangerous to you or other persons using

this equipment.

Please read these messages and follow these instructions carefully.

: WARNING indicates a hazardous situation which,

if not avoided, could result in death or serious injury.

:CAUTION indicates a hazardous situation which,

if not avoided, could result in minor or moderate

injury,

damage or destruction of the equipment and others.

NOTE:NOTE indicates a special instruction in operation or maintenance.

Copied digital data

from http://www.endo-kogyo.co.jp/

Scope of warranty and liabilities for the equipment

1. We will repair or replace the product free of charge if a failure due to manufacturing defects

occurs under proper usage during the warranty period.

For details, contact us or your dealer.

2. The warranty will be void in the following cases:

1) Change in ownership.

2) Repair, adjustment, or modification performed by a party other than the manufacturer, agents,

or dealers.

3. The warranty period is one (1) year from the date of purchase except for consumables.

4. Repairs applicable to any of the following shall be charged even during the warranty period:

1) Failure/damage caused by incorrect use.

2) Failure/damage caused by use of non-genuine parts.

3) Failure/damage caused by fire, earthquake, natural disaster, or other unexpected incident.

4) Incident caused by fall, shock, negligence, or by inadequate storage.

5) Failure/damage caused by use of parts or other equipment that are not included in this product.

6) Replacement of consumables.

7) Usage in violation of dangers or cautions stipulated in this Instruction Manual or the warning

labels.

8) Failure/damage caused by any reason that is not attributable to the manufacturer.

5. Warranty exclusions such as mechanical loss.

Either during or after the warranty period, mechanical loss, damage to anything other than our

product(s), or other duties incurred on you/your customer as a result of the failure of our product(s)

are outside the scope of the warranty.

Copied digital data

from http://www.endo-kogyo.co.jp/

Contents

1. Safety instruction··························································1

2. Terminology definitions ····················································································4

3. Product description ·························································································5

3-1. Models and specifications

3-2. Names of main parts

4. Installation ·································································································8

4-1. Checks before installation

4-2. Installation

5. Hose connection ···························································································9

5-1. Calculation of required hose length on winding side

5-2. Hose connection

6. Spring tension adjustment ··············································································· 11

6-1. Relationship between winding torque and drum turns

6-2. Standard value of initial spring turns and calculation for upper limit of initial spring turns

6-3. Initial tension setting

7. Measures against uneven winding ······································································ 13

7-1. Checks before adjustments

7-2. Adjustments

8. Safety instructions on use ··············································································· 14

9. Special accessories ······················································································ 14

10. Periodic inspections ···················································································· 16

10-1. Visual inspections

10-2. Leakage inspection

10-3. Storage

11. Troubleshooting ························································································ 17

12. O-ring replacement ····················································································· 17

13. Spring replacement ····················································································· 19

13-1. Disassembly of bracket

13-2. Disassembly and reassembly according to spring structure

13-3. Common reassembly method

13-4. Spring disposal1

14. Parts list ································································································· 28

Copied digital data

from http://www.endo-kogyo.co.jp/

- 1 -

1. Safety instructions

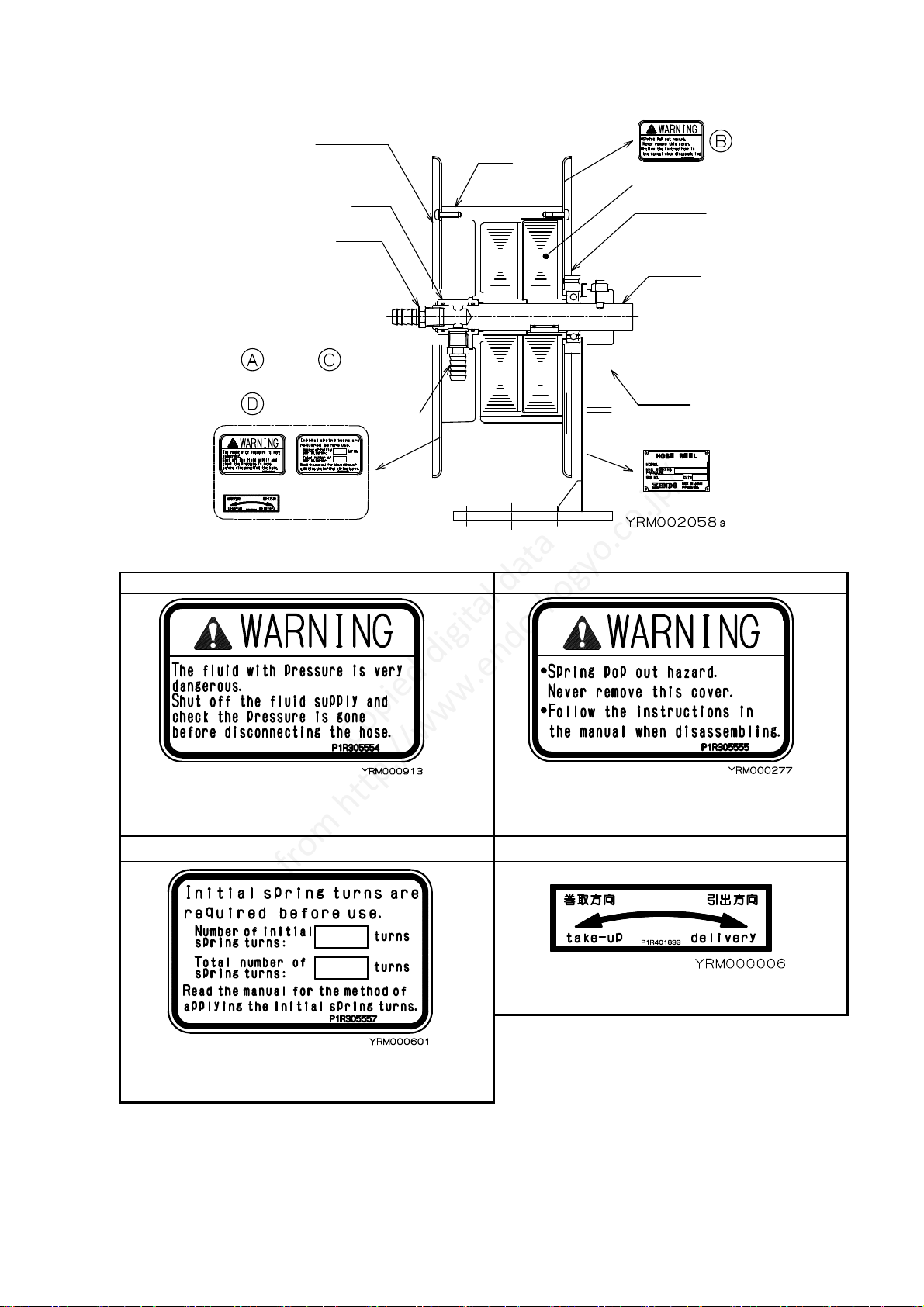

Regarding name plates, warning labels and labels:

・Never remove or deface any name plates, warning labels or labels which are

attached to the body.

The operator should always observe them.

Regarding installation (page 8):

・Take sufficient care not to knock or drop the reel when handling.

Never use the arm of the guide roller (special accessories) to lift the reel.

Regarding hose connection (page 9):

・Fluid leakage hazard.

Stop supplying the fluid to the hose reel before the work.

・Do not install hose to drum over winding length plus dead turn (2-3 turns).

Make free space in drum, otherwise hose could spill out from drum cover.

If hose spilled, it causes accidents as a hose cutting.

・Connect hose securely to prevent the fluid leakage from connected part.

Regarding initial tension setting (page 12):

・Never let go of the drum during any work.

When released, the drum suddenly rotates, possibly causing personal injury.

・After setting the initial tension, hose connection requires more than 2 people to

secure the drum and connect the hose.

Copied digital data

from http://www.endo-kogyo.co.jp/

- 2 -

Safety instructions on use (page 14):

・Never approach the moving parts during operation.

There is a danger of being caught up.

・Before supplying defferent fluid into the hose, take maker’s advise.

If there is no specification request on the type of fluid application, the product

will be for air, water (less than 80℃), lubricating oil (mineral type),

grease (lithium type).

If you are applying different kinds of fluid from standard fluid type, teke

maker’s advise.

・Shut off the fluid supply immediately in case of any trouble to avoid the problem

escalating.

・Never use the reel when damaged or abnormal sound/vibration occurs.

・Never alter the reel or its accessories.

・Never let go of or unfasten the hose from the fixed points when the hose is pulled

out.

The hose will rewind suddenly, possibly causing personal injury.

・Use within the rated values of maximum working pressure (1.5 MPa {15kgf/cm

2

}).

・Never pull out the hose past the winding length.

Always leave 2 - 3 dead turns on the drum. (To the sign of red tape)

Put sign (red tape) on the 2 - 3 dead turns when installing or replacing the hose.

Regarding periodic inspections (page 16):

・Periodically inspect the reel and replace any worn or damaged parts.

Carefully check the hose has no damage.

・If a malfunction is found during a periodic inspection, never reuse the reel but

repair immediately.

・Allow the hose to fully wind onto the drum to give the minimum winding tension

before carrying out inspections.

・Fluid leakage hazard.

Stop supplying the fluid to the hose reel before carrying out any work.

・Always put up instruction signs ("Equipment being inspected", "Do not open the

valve", etc.) before carrying out periodic inspections or repair.

・Always use genuine parts for replacement.

・Test the fluid leakage on the hose and reel after the reel has been stored for a long

time.

Copied digital data

from http://www.endo-kogyo.co.jp/

- 3 -

Regarding with O-ring replacement (page 17):

・High pressured fluid on hose reel is very dangerous.

Shut off the fluid supply and set 0 pressure in the hose.

・Allow the hose to fully wind onto the drum to give the minimum winding tension

before carrying out replacement.

・Always put up instruction signs ("Equipment being inspected", "Do not open the

valve", etc.) before carrying out O-ring replecement.

・After finishing O-ring replacement, carry out the fluid leakage test on joint and

each connection part.

Regarding spring replacement (page 19):

・High pressured fluid on hose reel is very dangerous.

Shut off the fluid supply, and set 0 pressure in the hose.

・If the winding side hose is disconnected from mating equipment, the drum may

suddenly rotate.

Allow the hose to fully wind onto the drum to give the minimum winding tension,

and work with more than 2 people divided into the person who secure the drum

and the person who disconnect the hose.

Allow the disconnected hose to wind around the drum, and slowly turn the drum

until the winding tension in the drum is released.

・Never disassemble the reel until winding tension is released.

The spring will burst out and cause personal injury.

Even if the spring seems to be broken, never disassemble before ensuring no

winding tension remains by rotating the drum by hand.

・Never disassemble the reel using any other disassembly procedure.

If disassembled incorrectly, the spring will burst out and cause personal injury.

・Never remove the spring from the spring case.

If removed, the spring will expand explosively and cause personal injury.

・Follow the instructions for handling and disposing of the spring.

・Always put up instruction signs ("Equipment being inspected", "Do not open the

valve", etc.) before carrying out spring replecement.

Copied digital data

from http://www.endo-kogyo.co.jp/

- 4 -

2. Terminology Definitions

The terminology used in this manual will be explained here.

If there is any terminology which is unclear or not included in this section, please contact our company.

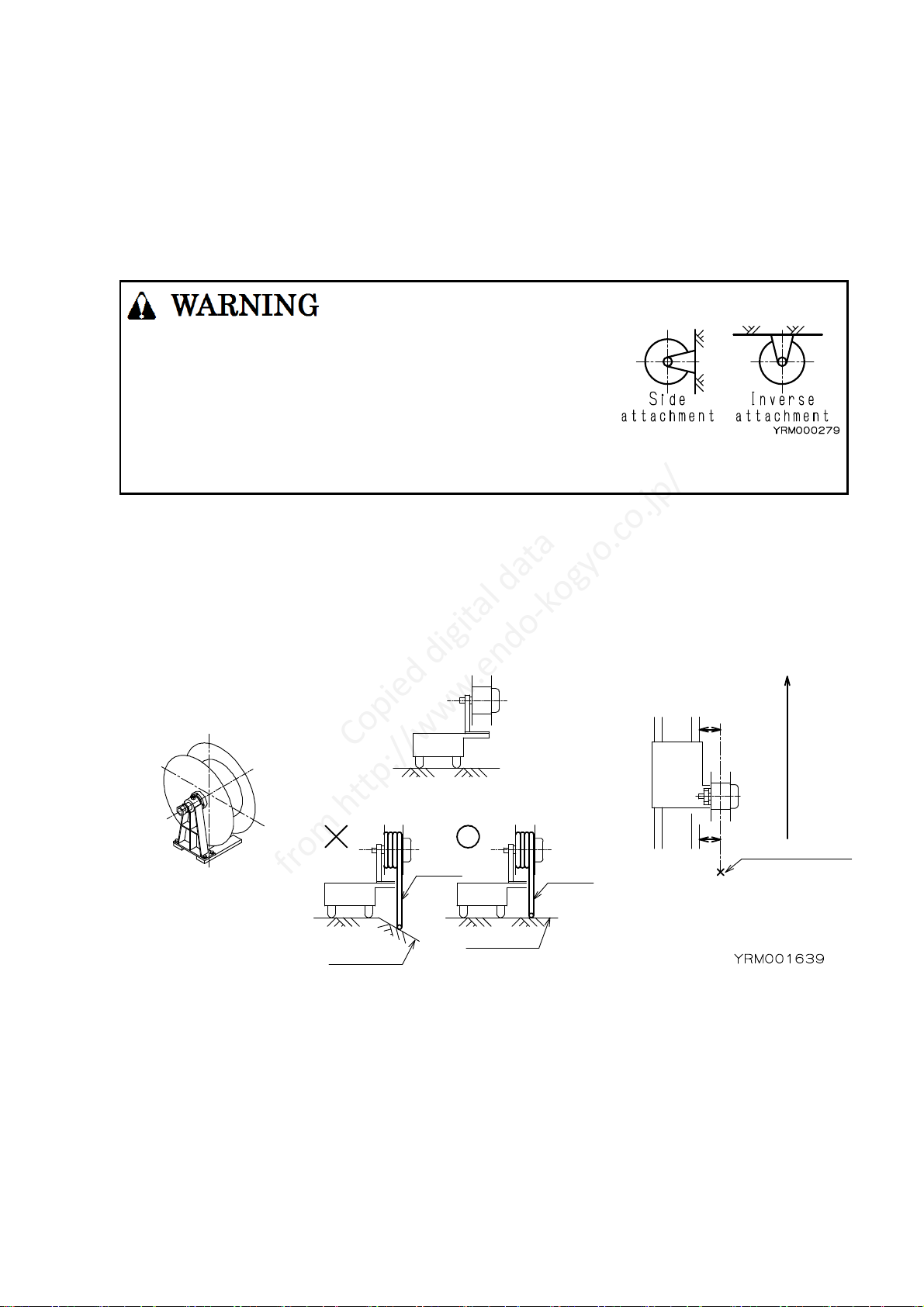

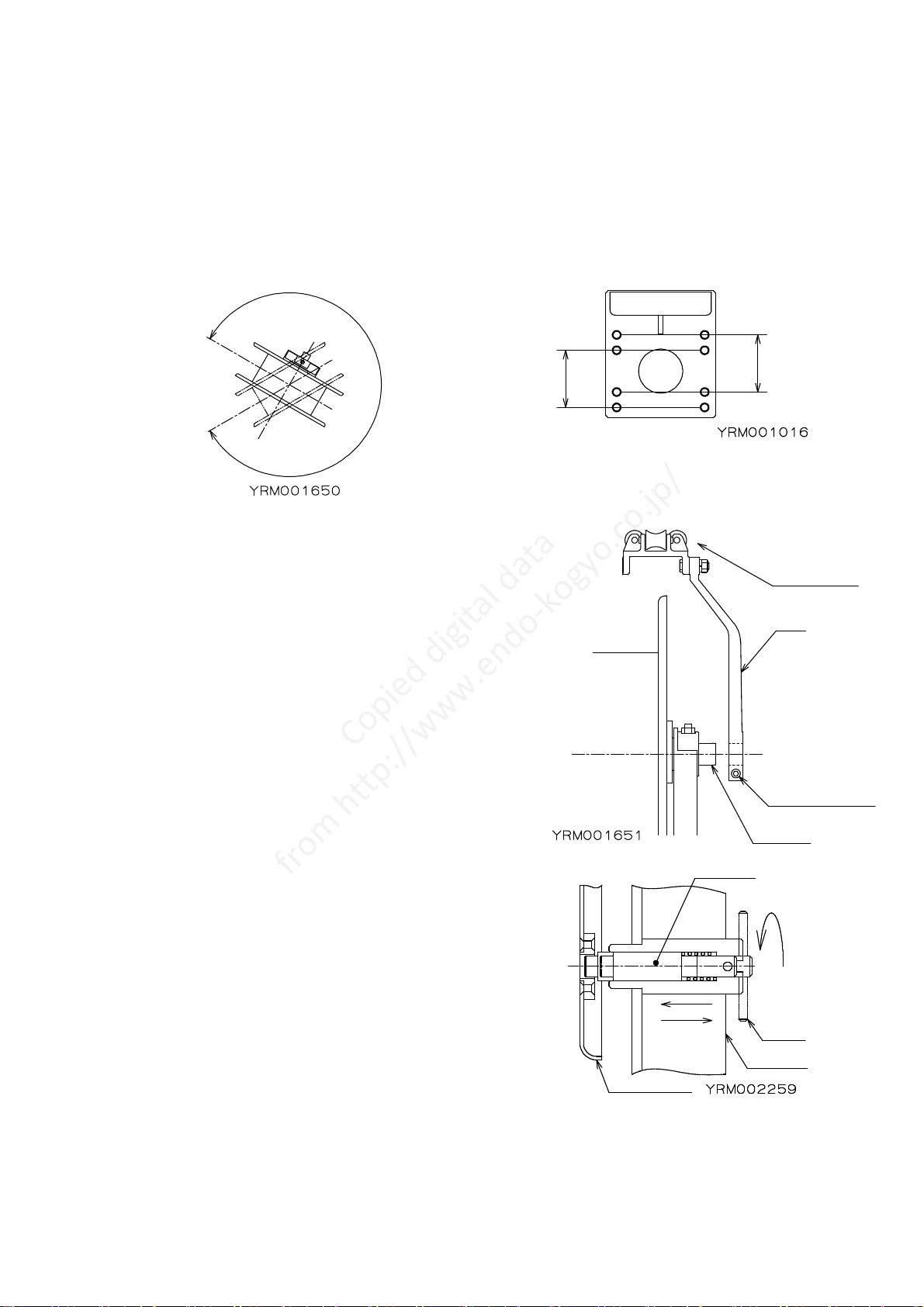

Winding methods: Figure 1

Forward winding: The winding direction when

viewed from the bracket side is

right (clockwise).

Reverse winding: The winding direction when

viewed from the bracket side is

left (counterclockwise).

Forward seating: The installation plate (base plate) is cated

under the drum.

Reverse seating: The installation plate (base plate) is

located on the opposite side of the drum.

Dead turn: The 2-3 turns of hose wrapped around the drum other

than the used winding length.

Initial spring turn: The applied initial tension to the spring.

The initial tension is required for winding the hose on the drum.

Horizontal drag ,two-way payout

Vertical

lift

Moving reel Fixed reel

Horizontal retrieve

Horizontal stretch

Vertical

retrieve

Vertical

lift

Horizontal retrieve ,two-way payout

Horizontal drag

Horizontal stretch

Vertical

retrieve

View from

the bracket

side.

Forward

winding

(Clockwise)

Reverse

winding

(Counter

clockwise)

Figure 2

Reverse

seating

Forward

seating

Figure 3

Copied digital data

from http://www.endo-kogyo.co.jp/

- 5 -

3. Product Description

3-1. Models and specifications

(1) Models

Please observe the name plate attached to the main body.

Refer to Figure 5 (page 7) for the attached location.

MODEL: The product model is shown.

Please check if this manual matches

with the product.

MAX. WORKING PRESSURE:

Maximum working pressure is

shown.

■Model description

HR - 2A 2 05 W - 1 R

Series Drum size Drum cover Spring Spring Installation Winding

name and width size type combination plate direction

Drum size and width (mm) Drum cover size (mm)

Code 2 2A 3 3A Code 2 3 4 5

Size 200 200 230 230

Size 292 350 440 510

Width 75 110 75 110

Spring type

Spring code 05 10 09 16

Number of springs 05×1 05×2 09×1 16×1

Total spring torque

N・m {kgf・m} 4.9

{0.5} 9.8

{1.0} 8.8

{0.9} 15.6

{1.6}

Spring combination Installation plate

Code None W

None 1

number of sets 1 2 Forward seating Reverse seating

Winding direction

None R

Forward winding Reverse winding

Manufactured date

Serial

Model

Max. working pressure

Figure 4

Copied digital data

from http://www.endo-kogyo.co.jp/

- 6 -

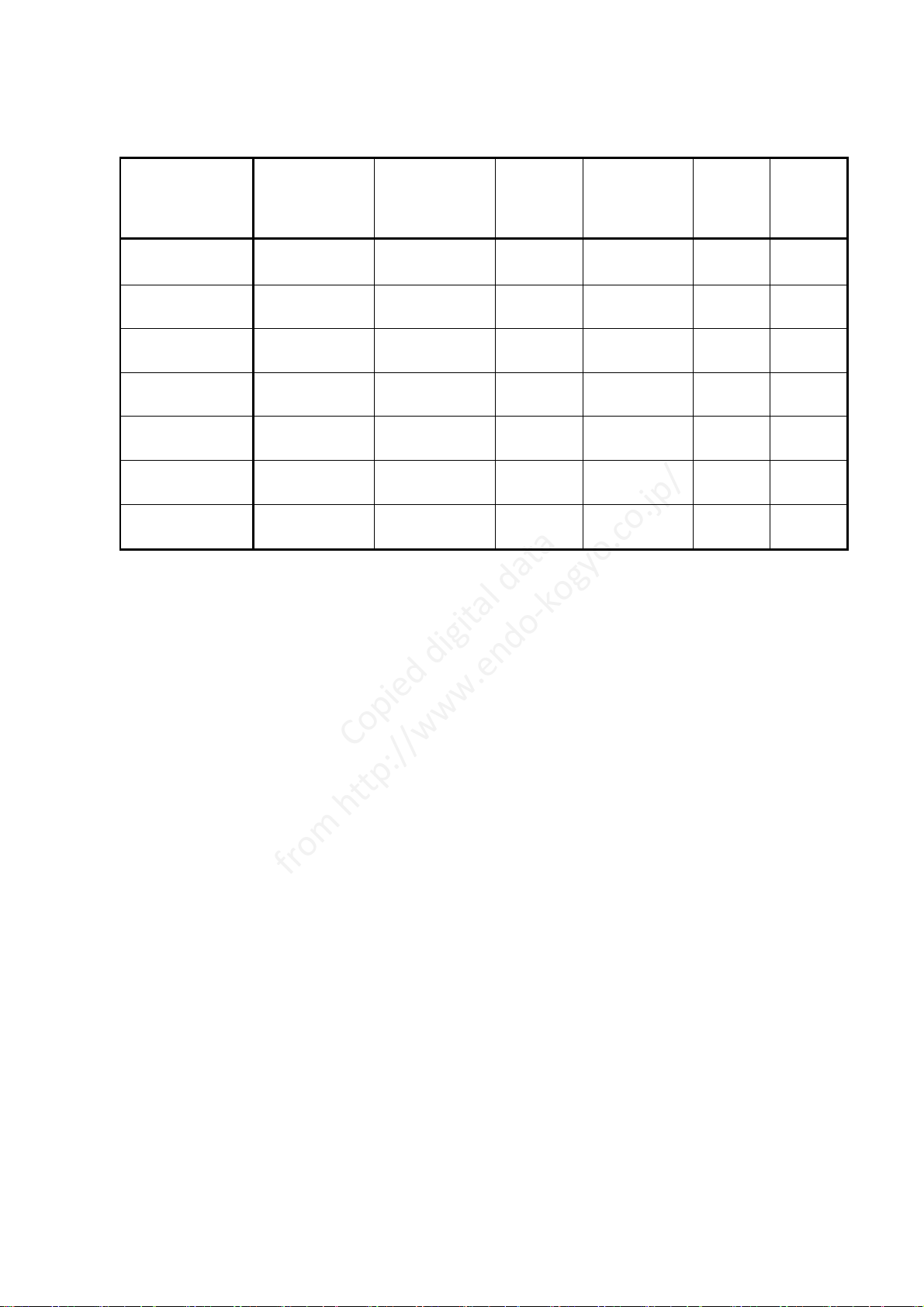

(2) Specifications

Table 1

Model Maximum

spring torque

N・m {kgf・m}

Calculated

maximum

spring tension

N{kgf}

Conection

size

{Rc}

Total number

of spring turns

※

Spring

structure

Reference

Mass

{kg}

HR-2205

HR-2250-R 4.9

{0.5} 49

{5.0} Rc 3/8 20 A 8

HR-2305

HR-2305-R 4.9

{0.5} 49

{5.0} Rc 3/8 20 A 9

HR-2A305W

HR-2A305W-R 4.9

{0.5} 49

{5.0} Rc 3/8 39 C 11

HR-3416

HR-3416-R 15.6

{1.6} 132

{13.5} Rc 1/2 13 A 12

HR-3A409W

HR-3A409W-R 8.8

{0.9} 73

{7.5} Rc 1/2 38 C 16

HR-3A416W

HR-3A416W-R 15.6

{1.6} 132

{13.5} Rc 1/2 26 C 16

HR-3A516W

HR-3A516W-R 15.6

{1.6} 132

{13.5} Rc 1/2 26 C 20

NOTICE: The reference mass shown in the table does not include accessories such as

guide rollers, turn table and ratchet mechanism.

※The method for spring replacement is different depending on the spring structure.

Refer to Chapter 13. "Spring Replacement" (page 19).

■Available fluid

Fluid: Air, Water (less than 80ºC), Lubricating oil (Mineral type), Grease (Lithium type)

Maximum working pressure: 1.5MPa {15kgf/cm2}

■Application

Application area : general outside conditions

Ambient temperature: -10ºC to +50ºC

Copied digital data

from http://www.endo-kogyo.co.jp/

- 7 -

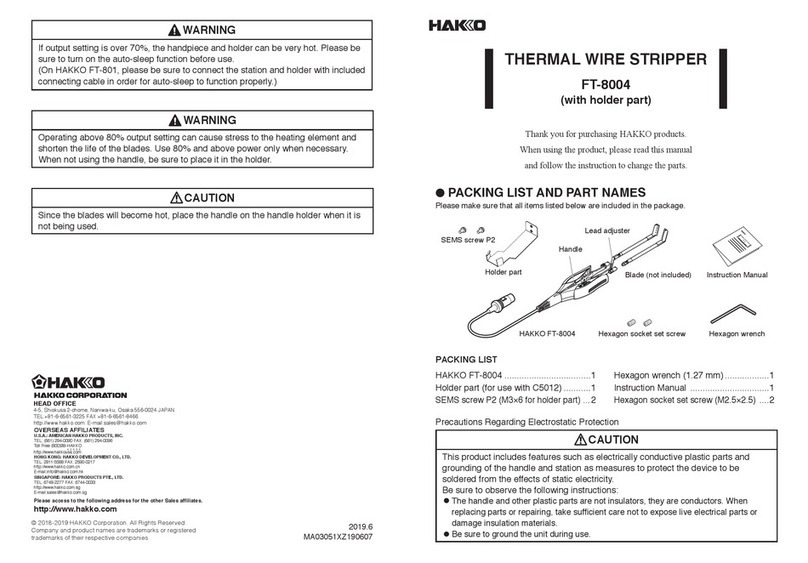

3-2. Names of main parts

Figure 5

Regarding the accessories, refer to Chapter 9. "Accessories" (page 14).

( A ) Warning label ( B ) Warning label

A warning is displayed regarding

fluid pressure hazards.

A warning is displayed regarding

spring ejection hazards.

( C ) Label ( D ) Label

The required number of initial

spring turns is displayed.

The winding direction is displayed.

Bracket

Drum cover

Nipple

Nipple

Drum

Spindle

Drum cover

Joint

Spring

Figure 4(See page 5)

Copied digital data

from http://www.endo-kogyo.co.jp/

- 8 -

4. Installation

4-1. Checks before installation

・Please check whether the items ordered were received.

(Check the name plate.)

・Check there is no damage to the product caused during transportation.

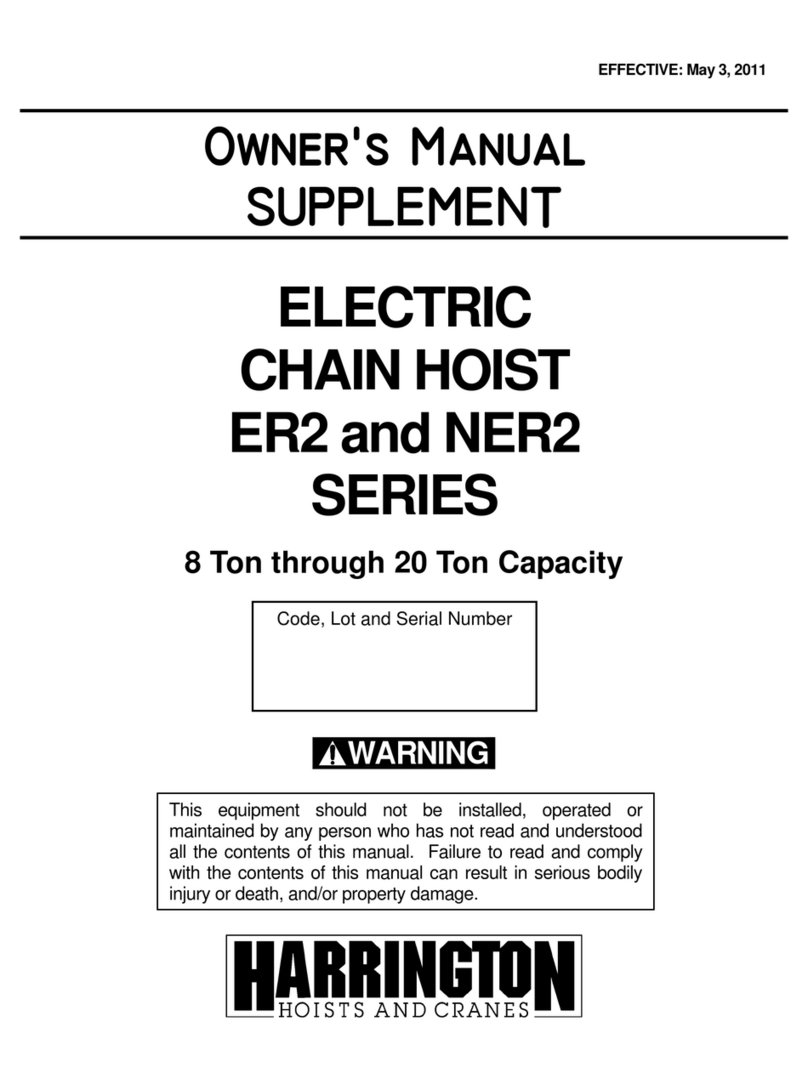

4-2. Installation

Figure 6

・Take sufficient care not to knock or drop the reel

when handling.

When lifting the reel, wrap the belt sling around

the drum at least twice, and lift in stable conditions.

・Never use the arm of the guide roller

(special accessories) to lift the reel.

・For side attachment or inverse attachment, use bolts with a strength

classification above 10.9.

・Place the main body in the fixing location and anchor the bracket securely with 4 bolts.

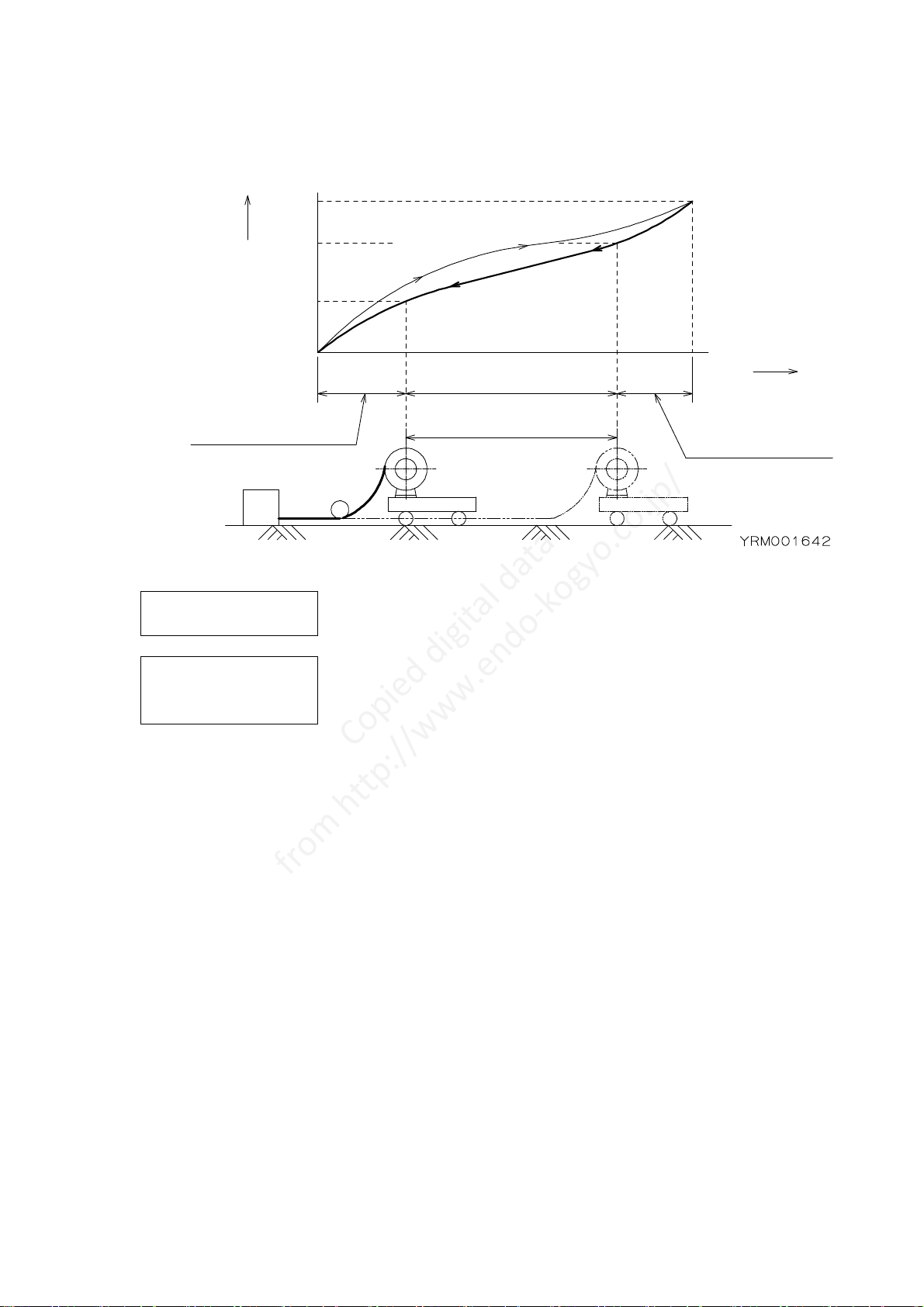

NOTE: In order to correctly wind the hose adjust the reel position as shown in Figure 7.

Try to adjust so the center of the drum width lines up with the hose's fixed point

on the mating equipment.

The surface the hose lies on should be horizontal.

Figure 7

X axis

Y axis

Moving direction

The Xaxisshould

behorizontal.

TheY axisshouldbeparallel

withthedirectiono

f

the

hosepayoutandmotion

oftheequipment.

Lineupthecenter ofthe

drumwidthwiththehose’s

fixedpointon the

matingequipment.

Fixed point

Hose Hose

Thesurface thehoselieson

should behorizontal.

Surface

Surface

Copied digital data

from http://www.endo-kogyo.co.jp/

- 9 -

5. Hose Connection

5-1. Calculation of required hose length on winding side

Figure 8

Hose length on winding side = Winding length + Extension length + Connection length

+ Dead turn length + Connection length inside reel.

Winding length = The length wound onto the drum.

Extension length = The length from the hose's fixed point to the end of the winding,

which is not wound onto the drum.

Connection length = The length required to connect the mating equipment to the hose's fixed point.

Dead turn length = The length of the 2-3 dead turns.

Required dead turn length = (Drum diameter + Hose diameter) × π×2 ~ 3

Number of dead turns

The length of 1 drum turn

5-2. Hose connection

・Fluid leakage hazard.

Stop supplying the fluid to the hose reel before the work.

・Do not install hose to drum over winding length plus dead turn (2-3 turns).

Make free space in drum, otherwise hose could spill out from drum cover.

If hose spilled, it causes accidents as a hose cutting.

・Connect hose securely to prevent the fluid leakage from connected part.

Winding length

Hose’s fixed point

Mating

equipment

E

x

t

e

n

s

i

o

n

l

e

n

g

t

h

Connection

length

Copied digital data

from http://www.endo-kogyo.co.jp/

- 10 -

Figure 9

■Winding side hose (Refer to Figure 9)

(1) Pass the hose through the drum part from the drum side.

(2) Connect the hose to joint.

NOTE: For hose without fitting, use and tie the sliding band.

Remove nipple for hose with fitting.

Then use seal tape around the screw part of hose fitting.

(Refer to 10)

Figure 10

■Fixed side hose

(1) Attach the hose to spindle.

NOTE: For hose without fitting, use and tie the sliding band.

Remove nipple for hose with fitting.

Then use seal tape around the screw part of hose fitting.

(Refer to Figure 10)

Drum cover

Drum curl part

Joint

Spindle

Fix side hose

Winding side hose

Without fitting With fitting

Hose Hose

Nipple

Hose band Roll seal tape

Bush Bush

JointJoint

YRM001647a

(1)Bush is attached

by specifications.

(2)Use one or two

hose bands

by specification.

(1) (1)

(2)

REMARKS

Copied digital data

from http://www.endo-kogyo.co.jp/

- 11 -

6. Spring Tension Adjustment

6-1. Relationship between winding torque and drum turns

Figure 11

Number of initial

spring turns means the number of spring turns which provides the initial tension

required for winding the hose onto the drum.

Number of spare

spring turns

means the number of remaining spring turns when the hose is fully paid out.

A shortage of spare spring turns shortens the spring life and causes spring

breakage.

Winding length

Number of drum turns Spring turns

( Drum turns )

Number of initial

spring turns

R

e

c

o

v

e

r

i

n

gt

h

eh

o

s

e

(R

e

l

e

a

s

i

n

gt

h

es

p

r

i

n

g)

P

a

y

i

n

go

u

tt

h

eh

o

s

e

(w

i

n

d

i

n

gt

h

es

p

r

i

n

g)

MAX

MAX

Winding torque

Number of spare

spring turns

Copied digital data

from http://www.endo-kogyo.co.jp/

- 12 -

6-2. Standard value of initial spring turns and calculation for upper limit of initial

spring turns.

(1) Check the total number of spring turns using Table 1 (page 6).

(2) Rotate the drum by hand until the hose of the winding length is fully

retracted, checking the number of drum turns.

(3) Check the standard value of initial spring turns and the number of spare

spring turns using Table 2.

Table 2

Spring

combination Number of sets Standard value of

initial spring turns Number of

spare spring turns

None 1 1 to 3 times 1.5 or more

W 2 2 to 6 times 3 or more

Upper limit of initial spring turns = Total number of spring turns

- (Number of drum turns + Number of spare spring turns)

Example) Model HR-2A305W for the case of 20 drum turns

According to Table 1, Total number of spring turns = 39.

According to Table 2, Standard value of initial spring turns = 2 - 6

Number of spare spring turns = 3 or more

Upper limit of initial spring turns = 39 - (20 + 3) = 16

Then the allowable number of initial spring turns = 2 - 16

6-3. Initial tension setting

・Never let go of the drum during any work.

When released, the drum suddenly rotates, possibly causing personal injury.

・After setting the initial tension, hose connection requires more than

2 people to

secure the drum and connect the hose.

(1) Wind the whole hose around the drum before connecting to the mating equipment.

NOTE: Take care not to twist the hose around the drum.

(2) With the hose still wrapped around the drum, rotate the drum by hand in the payout direction the same

number of turns as “standard value of initial spring turns” (Refer to Table 2).

This becomes "initial spring turn".

(3) Without letting the drum rotate, unwind the hose to the connection length plus the extension length

and connect the hose to the mating equipment.

Check there are no twists in the hose before connection.

(4) Pull out the hose to the winding length, then let the hose wind around the drum.

Ensure the drum can recover the hose full length.

(5) If the drum stops during recovery, the initial spring tension is insufficient.

Disconnect the hose from the mating equipment and increase the number of initial spring turns in the

same manner.

NOTE: Set the initial tension as small as possible and never exceed the upper limit of the initial spring

turns.

Over - tensioning could cause a spring breakage.

Copied digital data

from http://www.endo-kogyo.co.jp/

- 13 -

7. Measure against Uneven Winding

Uneven

winding

means the hose is wound on mainly one side of the drum width.

The uneven winding will cause the hose to drop from the drum or recovery problems,

resulting in damage to the hose.

7-1. Checks before adjustments

(1) Check the reel position is correct.

Refer to Section 4-2. "installation" (page 8).

Adjust the X and Y axes of the reel.

(2) Check there are no twists in the winding side hose.

If the hose is twisted, disconnect the hose from the mating equipment and

remove any twists.

※If uneven winding still exists after the above checks, adjust according to

the next section.

7-2. Adjustments

(1) Initial tension modification.

Increase the number of initial spring turns one by one without exceeding the upper limit.

If there is no improvement, set the initial tension back to the first value.

(2) X axis modification.

Tilt the X axis at a small angle by inserting a spacer under the bracket.

Figure 12

(3) Y axis modification

Tilt the Y axis at a small angle after adjusting the X axis.

Figure 13

Spacer

Spacer

Copied digital data

from http://www.endo-kogyo.co.jp/

- 14 -

8. Safety Instructions on Use

・Never approach the moving parts during operation.

There is a danger of being caught up.

・Before supplying different fluid into the hose, take maker's advise.

If there is no specification request on the type of fluid application, the product

will be for air, water (less than 80ºC), lubricating oil (Mineral type),

grease (lithium type).

If you are applying different kinds of fluid from standard fluid type,take

maker's advise.

・Shut off the fluid supply immediately in case of any trouble to avoid the

problem

escalating.

・Never use the reel when damaged or abnormal sound/vibration occurs.

・Never alter the reel or its accessories.

・Never let go of or unfasten the hose from the fixed points when the hose is

pulled

out.

The hose will rewind suddenly, possibly causing personal injury.

・Use within the rated value of maximum working pressure (1.5Mpa {15kgf/cm2}).

・Never pull out the hose past the winding length.

Always leave 2-3 dead turns on the drum. (To the sign of red tape)

Put sign (red tape) on the 2-3 dead turns when installing or replacing the hose.

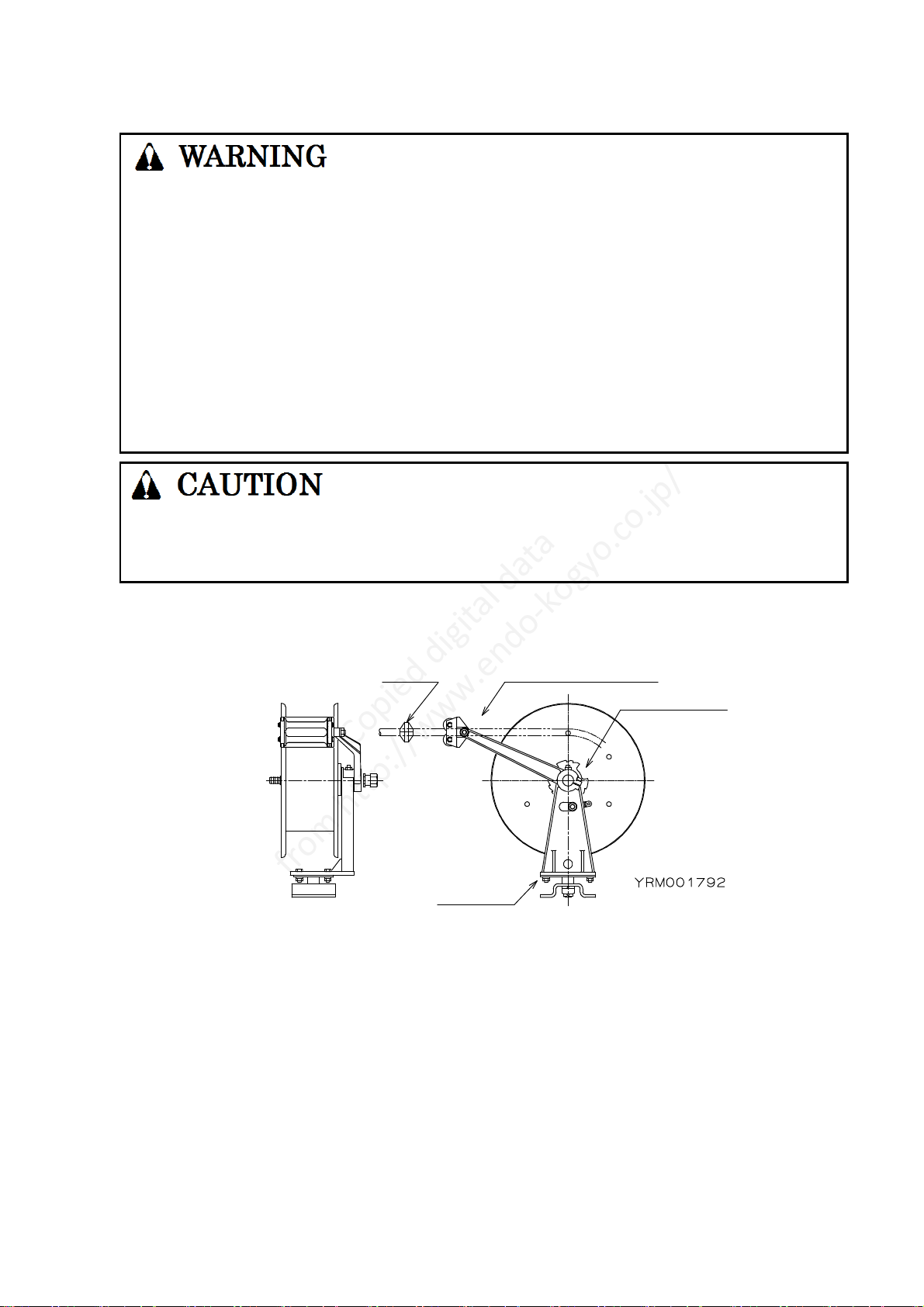

9. Special Accessories

Figure 14

Ratchet device

Turn table

Arm type guide rollerStopper

Copied digital data

from http://www.endo-kogyo.co.jp/

- 15 -

(1) Turn table

This can swivel the reel up to 300゜(Refer to Figure 15).

When turned, take care the fixed side hose is not put under excessive force or contacts the reel or

surrounding objects.

An arm type guide roller is required together with the turn table.

The fixing position varies depending on the drum width.

Confirm the model name indicated on the name plate, then check the drum code and width. Refer to

Section 3-1. "Model and specifications" (page 5).

Fix the turn table to the bracket with the enclosed 4 bolts and nuts referring to Figure 16.

Figure 15 Figure 16

(2) Arm type guide roller Figure 17

This is required when the reeling direction angle varies

during operation.

Attach the arm to the spindle and fix with the hexagon

socket head cap screw.

(3) Stopper (Hose the attached)

This will stop the hose at the attached location during a

winding operation when used with the arm type guide

roller.

(4) Drum stopper

The rotation of the drum can be locked at 90° intervals.

Pull the lever, turn the stopper and insert it in the hole

of the drum cover. Pull the lever and set it on the

shallow slit for releasing the lock.

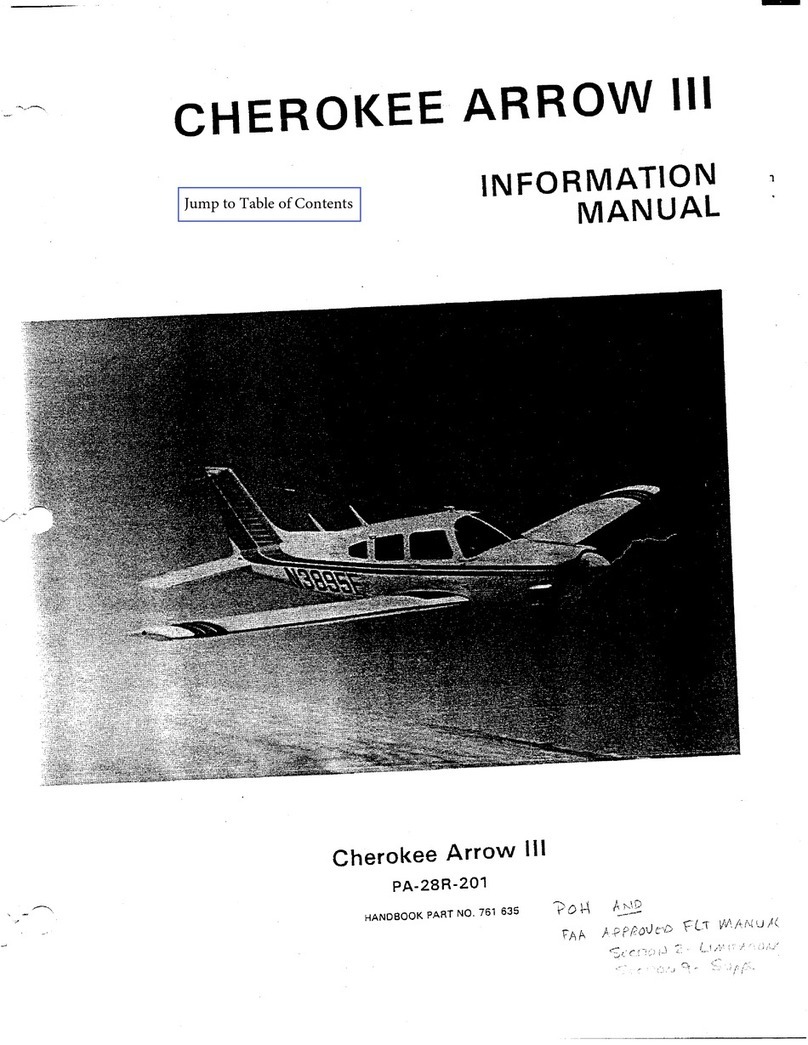

(5) Ratchet device (Use for pulling the hose manually) Figure 18

This is used when the winding operation stops and the

hose is still paid out.

To stop the drum, pull out the hose slightly then let it

return.

To release the drum, pull out the hose so as to rotate

the drum by 1/4 turn.

U

pt

o3

0

0

゜

For drum code

of 2A or 3A

For drum code

of 2 or 3

Gude roller

Arm

Spindle

Hexagon spcket

head cap screw

Drum cover

lever

S

t

o

p

p

e

r

Bracket

Copied digital data

from http://www.endo-kogyo.co.jp/

This manual suits for next models

1

Table of contents

Other Endo Tools manuals

Popular Tools manuals by other brands

Huskie Tools

Huskie Tools SL- 610 Operation manual

RIDGID

RIDGID PH-60C Swiv-L-Punch Head instructions

Hilti

Hilti SMD 50 Operating instructions and owner's manual

Hakko Electronics

Hakko Electronics FT-8004 manual

Harrington Hoists

Harrington Hoists ER2 Series Owner's manual supplement

Piper

Piper CHEROKEE ARROW III Information manual