Safety instructions

4Endress+Hauser

1 Safety instructions

1.1 Designated use

The product is designed for the cyclic cleaning of ion-selective sensors with compressed air in municipal

sewage treatment plants. The cleaning intervals are controlled by the connected transmitter.

Any other use than the one described here compromises the safety of persons and the entire measuring

system and is not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

1.2 Installation, commissioning and operation

Please note the following items:

• Installation, commissioning, operation and maintenance of the measuring system must only be

carried out by trained technical personnel.

Trained personnel must be authorized for the specified activities by the system operator.

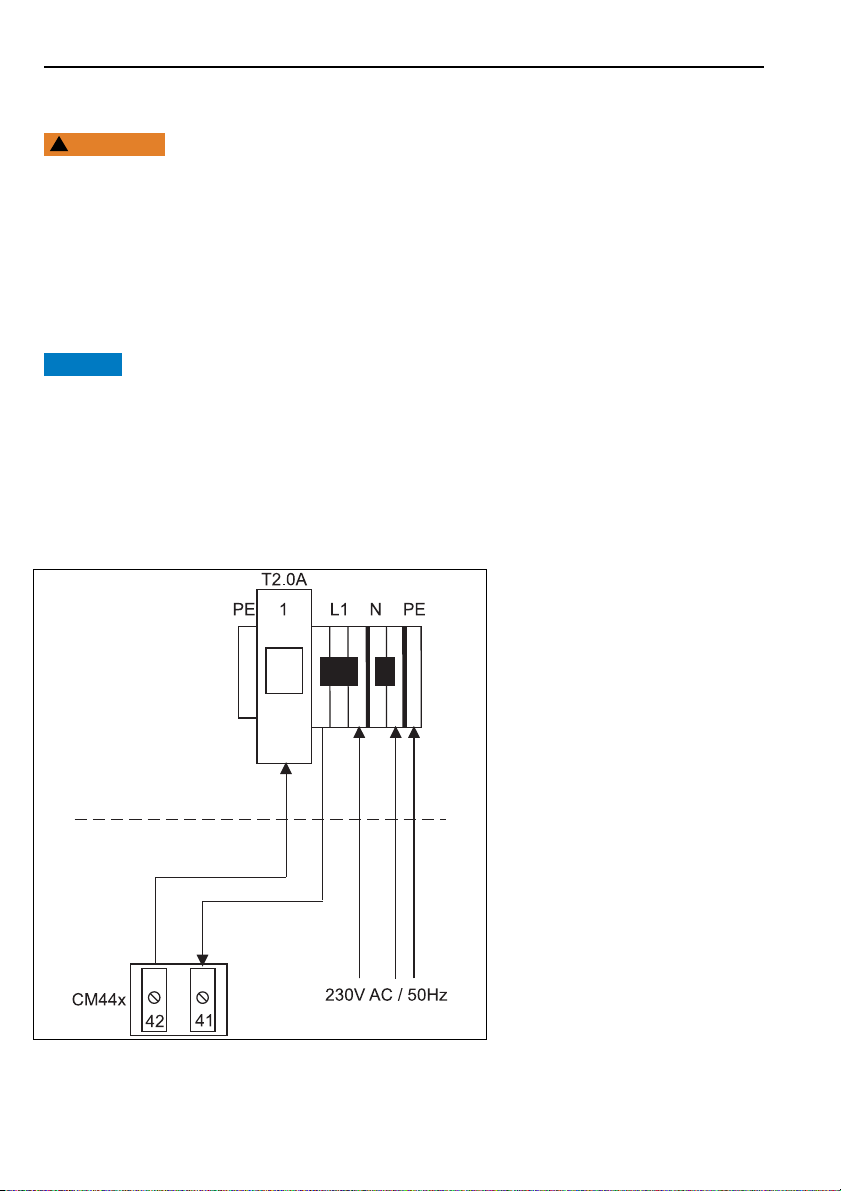

• Electrical connection must only be carried out by a certified electrician.

• Technical personnel must have read and understood these Operating Instructions and must adhere

to them.

• Before commissioning the entire measuring point, check all the connections. Ensure that electrical

cables and hose connections are not damaged.

• Do not operate damaged products and secure them against unintentional commissioning. Mark the

damaged product as being defective.

• Measuring point faults may only be rectified by authorized and specially trained personnel.

• If faults can not be rectified, the products must be taken out of service and secured against

unintentional commissioning.

• Repairs not described in these Operating Instructions may only be carried out at the manufacturer’s

or by the service organization.

1.3 Operational safety

The product is designed to meet state-of-the-art safety requirements, has been tested and left the factory

in a condition in which it is safe to operate. Relevant regulations and European standards have been

observed.

As the user, you are responsible for complying with the following safety conditions:

• Installation instructions

• Local prevailing standards and regulations.

1.4 Return

If the device has to be repaired, please return it cleaned to the sales center responsible.

Please use the original packaging, if possible.