enea ED100 User manual

Enea

Analogue-addressable fire detectors

ED100 - optical smoke detector

ED200 - temperature detector

ED300 - multicriteria detector

ATTENTION!

For information regarding device placement, coverage and method of installation, refer

to the established standard regulations and codes relating to Automatic fire-detection

systems. Enea series detectors are compliant with EN54-7: Smoke detectors – Point

detectors using the scattered light principle, light transmission or ionization (ED100 and

ED300 models only) and EN54-5: Heat detectors – point detectors (for ED200 and

ED300 models only), EN54-17 short-circuit isolators.

Product description

Enea series detectors are capable of sensing a number of combustion products suspended in the atmosphere and

thus the onset of fires.

The operating parameters of these detectors can be changed, via the connected control panel, to suit specific

environment conditions. These detectors are connected to the fire control panel via a 2 pole twisted-shielded

cable. The cable carries the power supply to the various devices and also the two-way digital transmission data.

Each detector has a short-circuit isolator that, in the event of short-circuit between the two poles and the control

panel (loop), is capable of interrupting the negative pole, thus isolating the section involved in the short-circuit

event. For the isolator specification, please refer to the “ILP Specification” document.

INIM Electronics offers three Enea series analogue fire-detectors, which can be identified by the Technical

specifications/ Serial number sticker on the back of the device.

ED100

Optical detector equipped with a reference chamber based on the

scattered light principle (Tyndall effect). The detector must be installed in

draught and obstacle free place which guarantees appropriate air-flow

into the reference chamber.

The detector will trigger an alarm when the level of smoke inside the

reference chamber reaches the alarm values set for the detector in the

control panel:

•0.08dB/m

•0.10dB/m

• 0.12 dB/m (pre-set mode)

•0.15dB/m

ED200

Heat detector with heat-sensitive element capable of sensing the

temperature within the protected environment.

The programmable operating modes are:

• “A1R” (pre-set); the detector signals alarm status when the temperature

within the protected environment exceeds 58 °C or when the temperature

undergoes anomalous changes.

• “B”; the detector signals alarm status when the temperature within the

protected environment exceeds 72°C.

• “A2S”; the detector signals alarm status when the temperature within in the

protected environment exceeds 58°C.

• “BR”; the detector signals alarm status when the temperature within the

protected environment exceeds 72° or when it senses a rapid temperature

rise.

ATTENTION!

The operating modes of the “A2S” and “BR” are not certified.

ED100

ADDRESSABLE

SMOKE DETECTOR

EN54-7:2000

EN54-17:2005

2010/09

FW.01.01

*00000004*

ED100 00000004 ED100 00000004

0832-CPD-1448 991d/01

00000004

ED200

ADDRESSABLE

HEAT DETECTOR

HEAT DETECTOR CLASS P

EN54-5:2000

EN54-17:2005

2010/09

FW.01.01

*00000005*

ED200 00000005 ED200 00000005

0832-CPD-1450 991f/01

00000005

DCMIIN4AED-R100-20110519

0832-CPD-1448

0832-CPD-1450

0832-CPD-1446

991d/01

991f/01

991b/01

2

Enea

ED300

Opto-heat detector with and optical reference chamber and heat sensitive

element. The combination of values provides (in accordance with the

operating mode selected via the control panel) high immunity to nuisance

alarms and an exceptionally sensitive detector which is capable of swift

response to developing fires characterized by low smoke emission.

The operating modes, programmable via the control panel are:

• “PLUS” (pre-set); the detector signals alarm status when smoke in the protected

environment exceeds the programmed threshold (programmed as described for

the ED100 model) or when the temperature within the protected environment

exceeds the programmed threshold (programmed as described for the model

ED200). Furthermore, in the event of a rise in temperature within the protected

environment, the sensitivity of the smoke chamber will be increased. This

operating mode, characterized by high sensitivity, allows detection of fires which

produce a large amount of flames but low smoke emission (e.g. combustion of

alcohol or similar highly-inflammable products) .

• “OR”; the detector signals alarm status when smoke in the protected environment exceeds the programmed threshold

(programmed as described for the ED100 model) or when the temperature within the protected environment exceeds the

programmed threshold (programmed as described for the ED200 model). This operating mode, characterized by medium-

high sensitivity, allows detection of fires which generate a substantial amount of smoke but low heat emission (slow

burning fires) as well as fires which generate high temperatures and low smoke emission (chemical products).

• “AND”; the detector signals alarm status when the smoke and temperature in the protected environment exceed the

programmed thresholds simultaneously (programmed as described for the ED100 model and ED200 respectively). This

operating mode, characterized by a low sensitivity, lowers the false alarm rate and is useful in applications where either the

smoke or heat values in the protected environment may increase without the risk of fire.

ATTENTION!

Given the limited response, consider the conditions in the protected environment

carefully before selecting this operating mode.

• “SMOKE”; the detector assumes the characteristics of the ED100 model.

• “HEAT”; the detector assumes the characteristics of the ED200 model.

Installation

ATTENTION!

The detectors are supplied with protective covers which help to protect them against

minor damage and dust contamination which may occur during the installation phase.

The covers should not be removed until the system is ready to start up.

Enea series detectors can be used with one of the following compatible mounting bases:

•

EB0010

; standard base

An example of installation using standard bases is shown opposite.

•

EB0020

; relay base

Appropriate when the detector is to be connected to an intrusion control panel or to a control panel using 4 wires. For the

respective wiring instructions, refer to the leaflet supplied with the EB0020.

ATTENTION!

The two removable serial-number stickers should be taken off and one should be

attached to the mounting base and the other to the installation layout.

TECHNICAL SPECIFICATIONS ED100 ED200 ED300

Power supply 19-30 Vdc

Average current draw in standby 200PA

Average current draw in alarm 10 mA @27.6V

Current draw by the “R” output

(internally limited) Max 14mA

Reference Standards

for smoke detectors

EN54-7:2000+A1:2002

+A2:2006

EN54-7:2000+A1:2002

+A2:2006 and CEA4021

Reference Standards

for temperature detectors EN 54-5:2000+A1:2002 EN 54-5:2000+A1:2002

and CEA4021

Reference Standards

for short-circuit isolator EN 54-17:2005

Operating temperature -5°C / +40°C

Humidity (without condensation) 95% RH

Height (standard base included) 46mm 54mm

Diameter (standard base included) 110mm

Weight (standard base included) 160gr

Weight (without base) 91gr

ED300

ADDRESSABLE

SMOKE/HEAT DETECTOR

HEAT DETECTOR CLASS P

EN54-7:2000

EN54-5:2000

EN54-17:2005

2010/09

FW.01.01

*00000006*

ED300 00000006 ED300 00000006

0832-CPD-1446 991b/01

00000006

Analogue-addressable fire detectors

3

A

Detector

H

Cover removing hooks

B

Base

I

Optical chambre removing

hooks

C

Red/yellow/green LED

L

“+” terminal

D

Optical chamber

M

“-” terminals

E

Thermal probe

N

“R” terminal

F

Technical specifications/

serial-number sticker

O

Short-circuit reed

G

Removable serial-number

stickers

P

Screw locations

A

C

E

F

I

L

M

N

O

B

D

A

C

H

H

D

E

CP

P

G

I

4

Enea

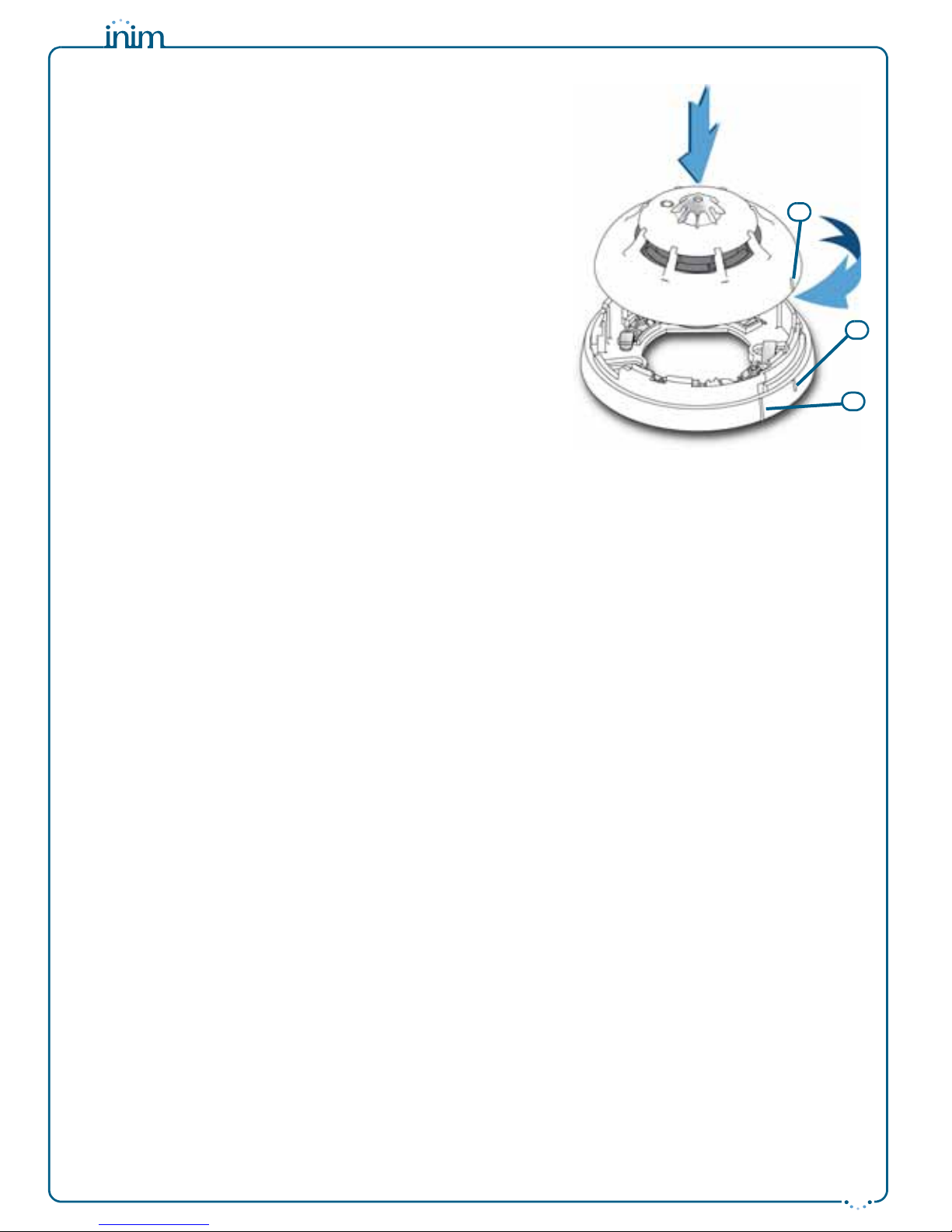

Once the base is located properly in its placement, place the detector

unit onto the base and, with minimum force, turn it clockwise until

notch “A” aligns with notch “B” (in order to attach the detector to the

base); turn it still further until notch “A” aligns with notch “C” (in

order to allow the base to engage with the detector contacts).

When installation of all the loop devices is complete, proceed with

the addressing phase. Refer to the respective section in the control

panel installation and programming manual.

Testing and maintenance

After installation and during periodic maintenance inspections, you

must carry out the following operations on each detector:

•

Check the LED

; if the yellow LED is On solid, the detector is in fault

status. The detector may simply require cleaning, however, if after

cleaning, this condition persists, you should remove the faulty detector

and replace it with a new one. The control panel will allow you to trace

and identify the cause of the fault.

•

Optical smoke detector test

; smoke detectors should be tested

immediately after installation and periodically during maintenance

inspections in accordance with the established standard regulations and

codes in force. To test smoke detectors, use an approved test aerosol

strictly in accordance with the accompanying instructions.

Ensure that the smoke inlet ports to the smoke detection chamber are not

blocked. Check the contamination level of the smoke detection chamber

via the control panel. If the contamination level is high (above 50%),

detach the detector from its mounting base, open the device and, using a

small, soft-bristle brush or hand-held vacuum cleaner remove all dust

particles from inside and around the smoke detection chamber and free

the protection net from all contaminants.

•

Heat detector test

; using a suitable device (e.g. hairdryer), create heat in the vicinity of the detector, then work through

the steps described in the device instruction sheet. During each periodic maintenance inspection, ensure that the heat

element is intact and that is not obstructed by dust or paint. If it is, using a small, soft-bristle brush or hand-held vacuum

cleaner remove all contaminants.

Operating mode

The three-colour LED (360° viewing) indicates the detector status, as follows:

• Green blinking at 15-second intervals; the detector is in standby status (i.e. operating properly).

• Green On solid; the LED has been activated manually from the control panel. This operation allows easy identification of

the detector.

• Yellow On solid; the detector is in fault status or has detected a short-circuit in the succeeding wiring section (short-circuit

isolator open). Further details regarding the fault can be obtained through the control panel.

• Red On solid; the detector is in alarm status. Further details regarding the alarm can be obtained through the control panel.

Each detector has an output (terminal “R”), for the connection of an alarm repeater LED. This LED will activate in

accordance with programming carried out via control panel. The detector is also capable of discerning whether its

repeater LED has been connected. This function provides indications (on the control panel) regarding the

detectors with connected LEDs, and also fault signals in the event of disconnection.

Using the EITK-DRV driver

The EITK-DRV driver allows you to change the operating parameters of the detectors, check the contamination

level of the smoke chambers and also obtain accurate diagnostic data. It can operate through the USB port of a

computer furnished with the relative software programme, or can function autonomously by way of the battery

housed inside.

Each detector is capable of retaining memory (smoke and/or temperature depending on the model) of the 5

minutes prior to an alarm. Therefore, if an alarm occurs, it will be possible to obtain information regarding the

onset of the fire by simply connecting the EITK-DRV driver to the detection line.

For further information and details regarding use of the EITK-DRV driver, refer to the respective handbook.

Warnings and limitations

Enea series detectors must be used exclusively with fully compliant, compatible control panels. Detectors may

not provide timely warning of fire if coverage is limited by large obstructions (pillars, large machinery, etc.).

When installing or working on a fire detection system, always refer to and comply with the established standard

regulations and codes. Appropriate fire-risk assessment should be undertaken to determine the type of detectors

required and their placements.

A

B

C

INIM Electronics reserves the right to change the

technical specifications of this product without

prior notice.

INIM Electronics s.r.l.

via Fosso Antico, Centobuchi

63033, Monteprandone, (AP) Italy

Tel. +39 0735 70 50 07

Fax + 39 0735 70 49 12

www.inim.biz [email protected]

This manual suits for next models

2

Table of contents

Popular Fire Alarm manuals by other brands

Tracon Electric

Tracon Electric SD133A user manual

Horing LIH

Horing LIH VIVID32 operating manual

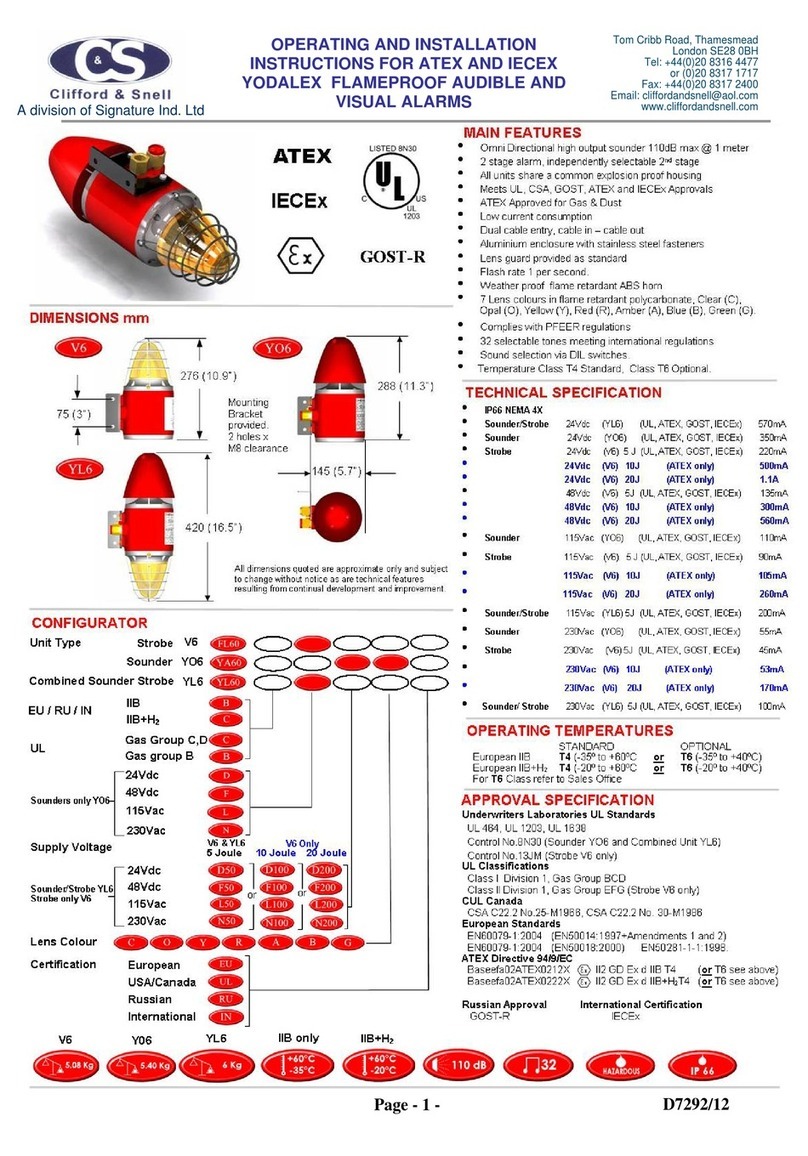

C&S

C&S YA60BD Operating and installation instructions

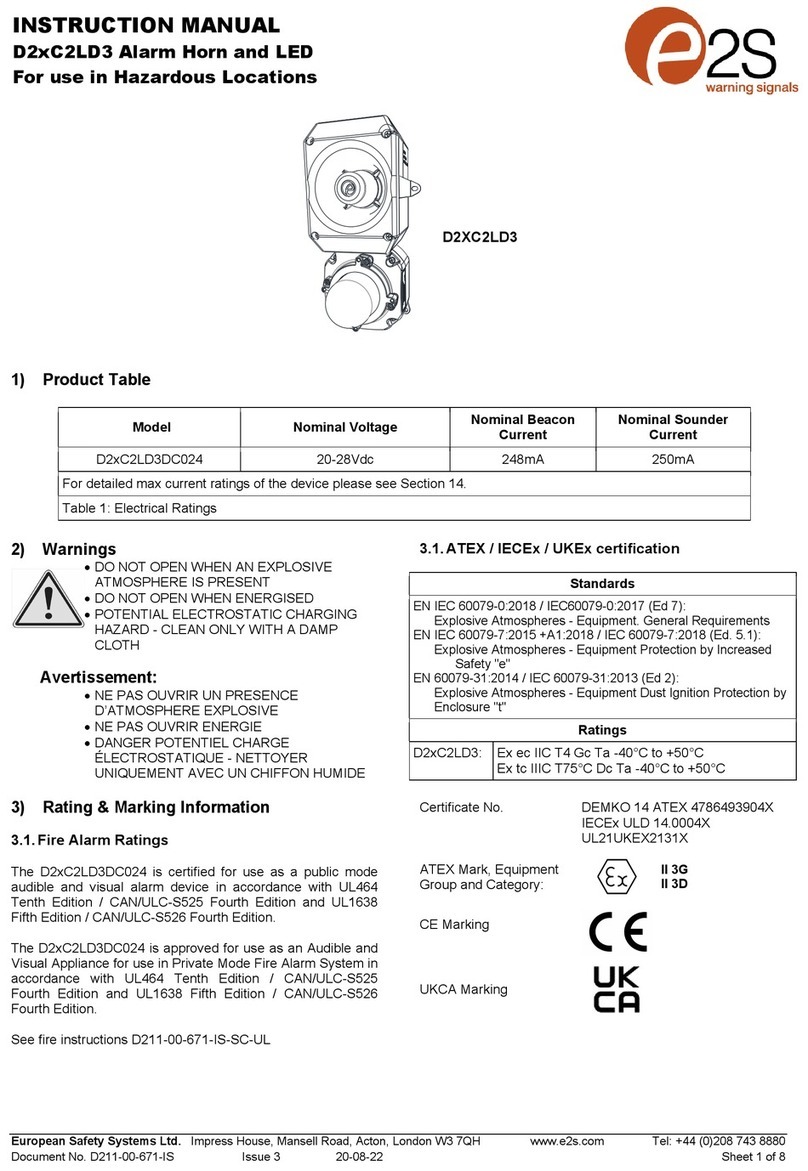

E2S

E2S D2xC2LD3 instruction manual

olympia electronics

olympia electronics BSR-100 Series Quick Installation Guide & Generic Design

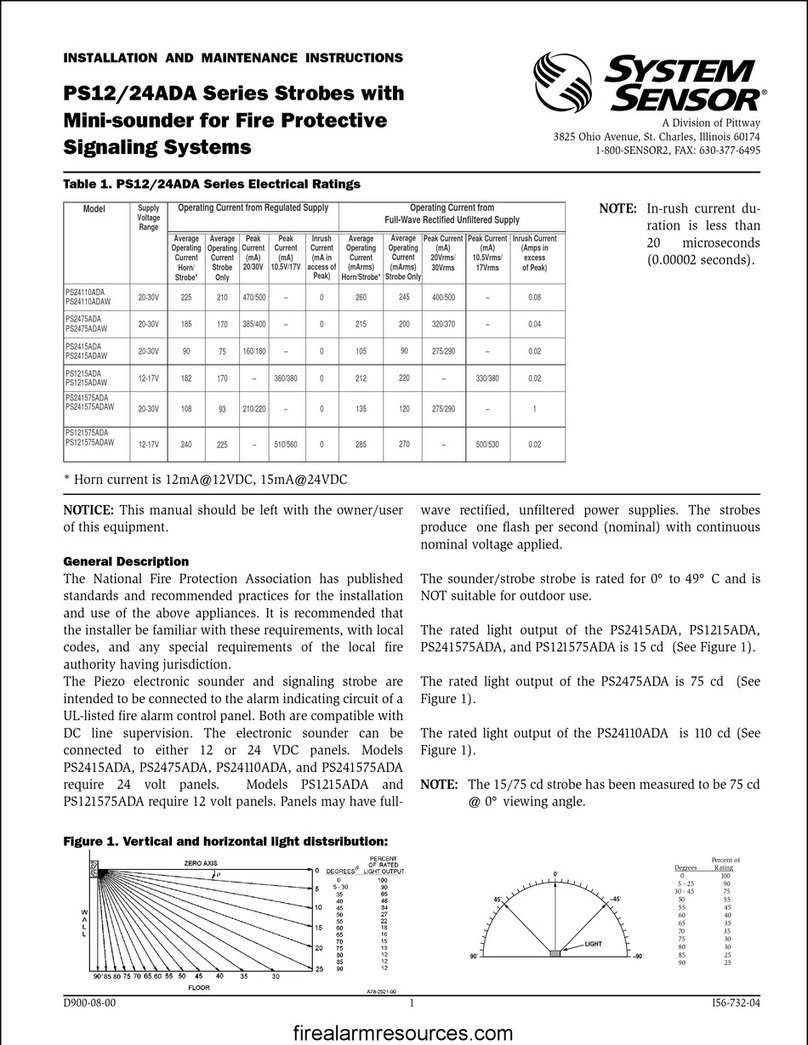

System Sensor

System Sensor PS12/24ADA Series Installation and maintenance instructions

Notifier

Notifier LCD-80F manual

Zeta

Zeta INFINITY ID2 User manual, maintenance guide & log book

Cooper

Cooper FX range Installation and user manual

usi

usi UNIVERSAL 5304CN instructions

Simplex

Simplex LifeAlarm 4005 Series Programming instructions

FireClass

FireClass Prescient III Application, Installation & Commissioning