European Safety Systems Ltd.

Impress House, Mansell Road, Acton, London W3 7QH

Document No. D211-00-671-IS

Issue 3

20-08-22

Sheet 3 of 8

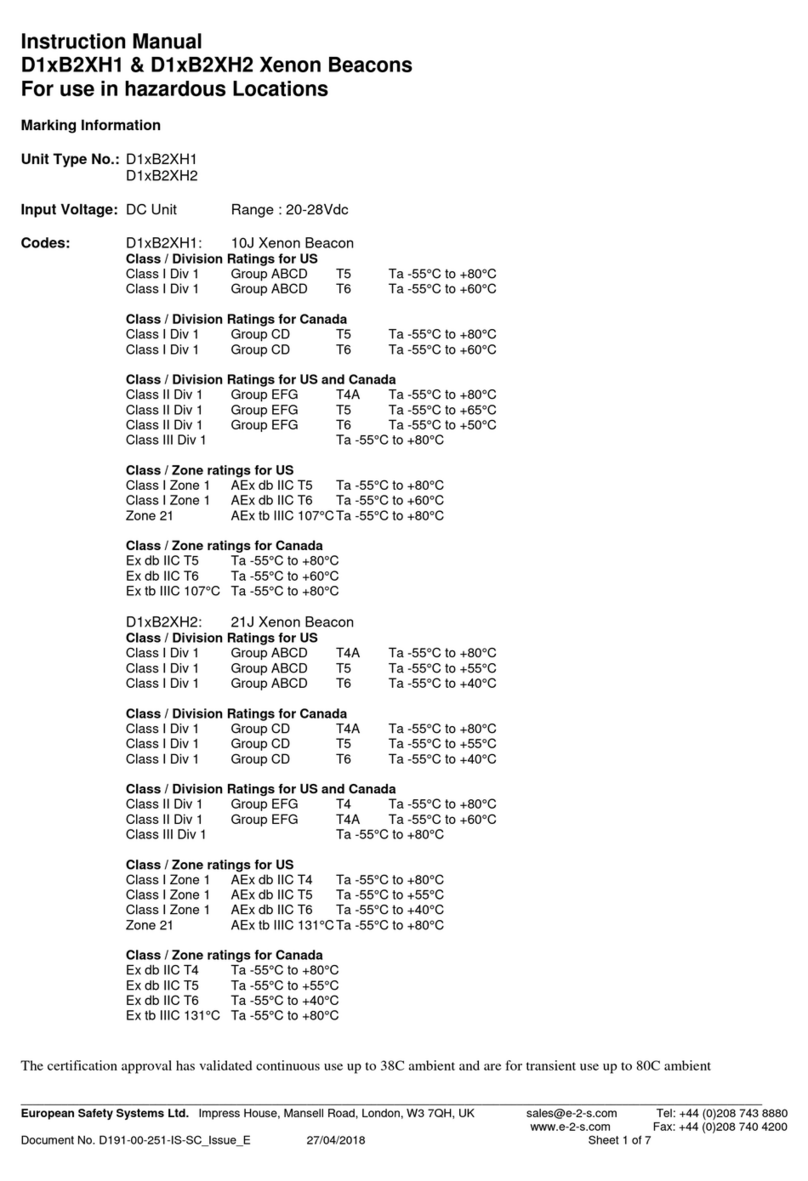

Beacon

Cover

M4 Screws

(4-off)

147,0mm [5,73in.]

116,0mm [4,52in.]

213,3mm [8,32in.]

165,6mm [6,46in.]

9,7mm [0,38in.]

6,7mm [0,26in.]

Ø6,9mm [Ø0,27in.]

310,3mm [12,10in.]

125,0mm [4,88in.]

168,0mm [6,55in.]

Sounder

Cover

M4

Screws

5) Special Conditions for Safe Use

Special Condition for safe Use as stated on the Type

Examination Certificate DEMKO 14 ATEX 4786493904X /

CoC/IECEx ULD 14.0004X / UL21UKEX2131X:

When used for a Group III application, the surface of the

enclosure may store electrostatic charge and become a

source of ignition in applications with a low relative humidity

<~30% relative humidity where the surface is relatively free of

surface contamination such as dirt, dust, or oil.

Guidance on protection against the risk of ignition due to

electrostatic discharge can be found in EN TR50404 and IEC

TR60079-32.

End user shall adhere to the manufacturer’s installation and

instruction when performing housekeeping to avoid the

potential for hazardous electrostatic charges during cleaning,

by using a damp cloth.

To maintain the ingress protection rating and mode of

protection, the cable entries must be fitted with suitably rated,

certified cable entry and/or blanking devices during

installation.

The equipment shall only be used in an area of at least

pollution degree 2, as defined in IEC 60664-1.

6) Product Mounting and Access

6.1. Location and Mounting

The location of the combined alarm horn and beacon should

be made with due regard to the area over which the warning

signal must be visible and audible. It should only be fixed to

services that can carry the weight of the unit.

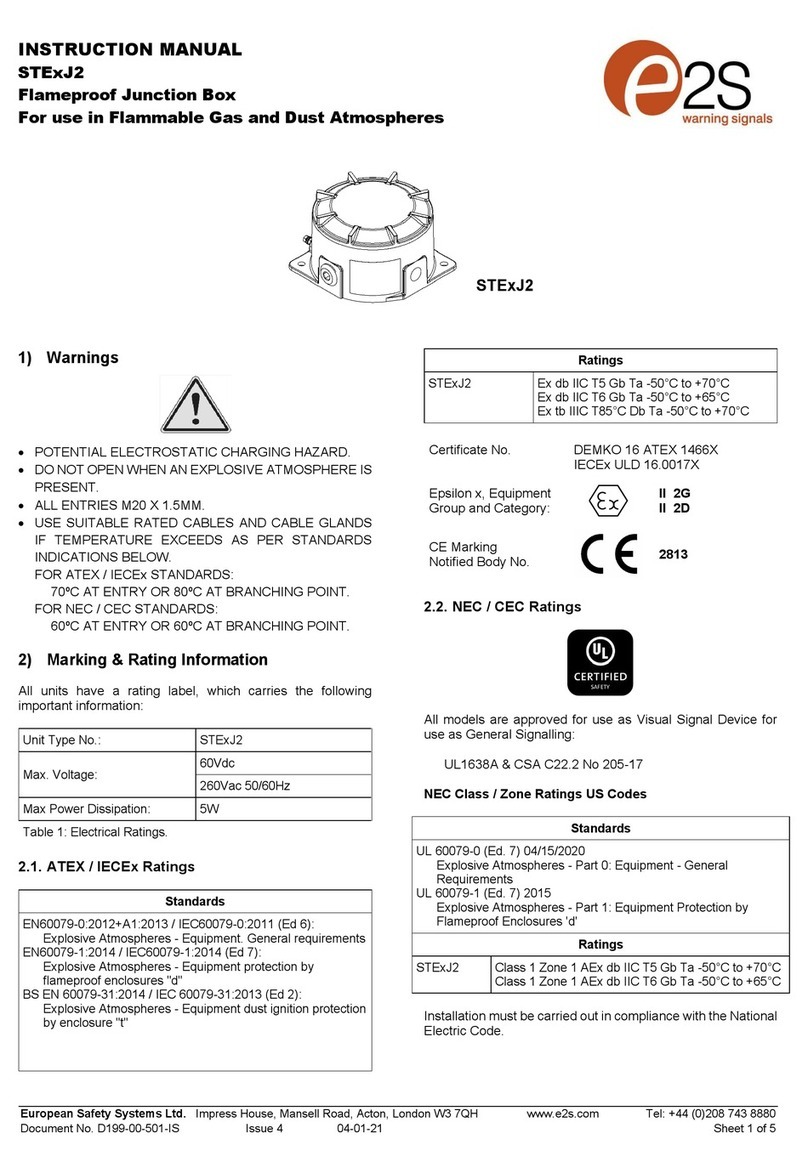

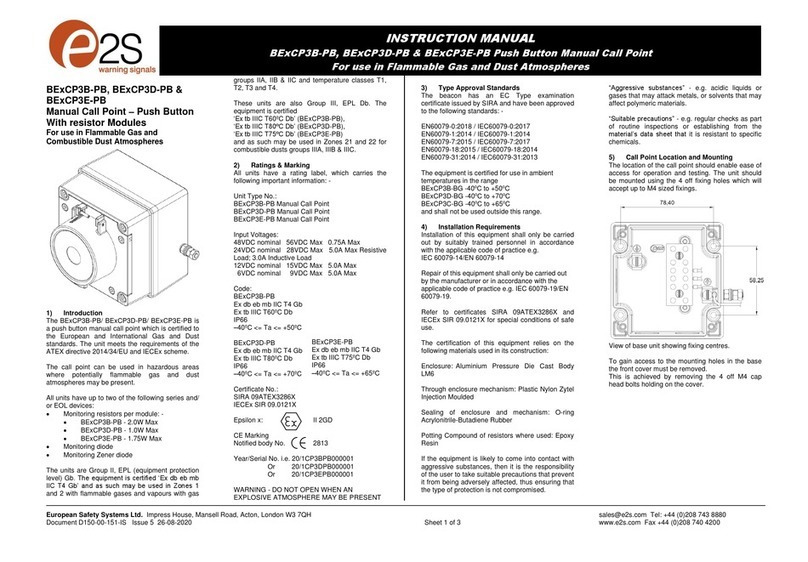

DxC2 Alarm Horn and Strobe to a flat surface via the two 9.7

x 6.7mm, 147mm pitch fixing holes in the mounting feet of the

sounder section and the two 7mm fixing holes in the feet of

the base.

The equipment is not to be mounted with the horn facing

upwards.

Fig. 1 Fixing locations.

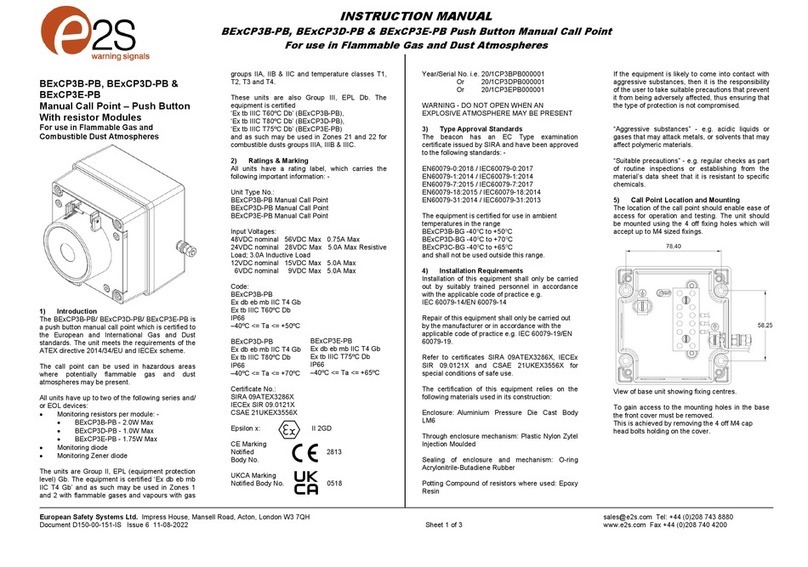

6.2. Access to the Enclosure

Warning – High voltage may be

present, risk of electric shock.

DO NOT open when energised,

disconnect power before opening.

Warning – Hot surfaces. External

surfaces and internal components

may be hot after operation, take

care when handling the equipment.

To access the enclosures, loosen the four M4 posi pan head

screws of the beacon and loosen the four M4 posi pan head

screws of the sounder and withdraw the covers.

Fig. 2 Accessing the Enclosures.

To replace covers, check that the ‘O’ ring seals are in place.

Carefully push the covers in place. Insert M4 screws with fibre

washers and tighten to 3Nm torque.

7) Selection of Cable, Cable Glands, Blanking

Elements & Adapters

When selecting the cable size, consideration must be given to

the input current that each unit draws (see Table 1), the number

of units on the line and the length of the cable runs. The cable

size selected must have the necessary capacity to provide the

input current to all of the sounders connected to the line.

When selecting the cable size consideration must be given to

the voltage drop over the length of the cable run to ensure the

min. input voltage at the point of use (voltage range, see section

15)

The voltage drop depends on:

- The total current draw of the devices installed on this

cable run

- The wire size and total length of the cable run,

determining the total resistance of this cable run

- The minimum output voltage supplied by the power

supply

The voltage drop and input voltage at the point of use can be

calculated as follows:

Total Wire resistance =

Wire resistance / 1000ft x length of cable run x 2

(length of cable run needs to be multiplied by two to account for

two wires going to and from the unit)

Total current draw =

Current draw per unit x number of units

Voltage Drop = Total current draw x Total wire resistance

Minimum output of power supply =

Min. voltage at point of use + voltage drop

The entries are available as one of the following options:

2-off M20 x 1.5 thread & 1-off ¾” NPT thread;