ENERCORP HEATSTAR HS4040 Assembly instructions

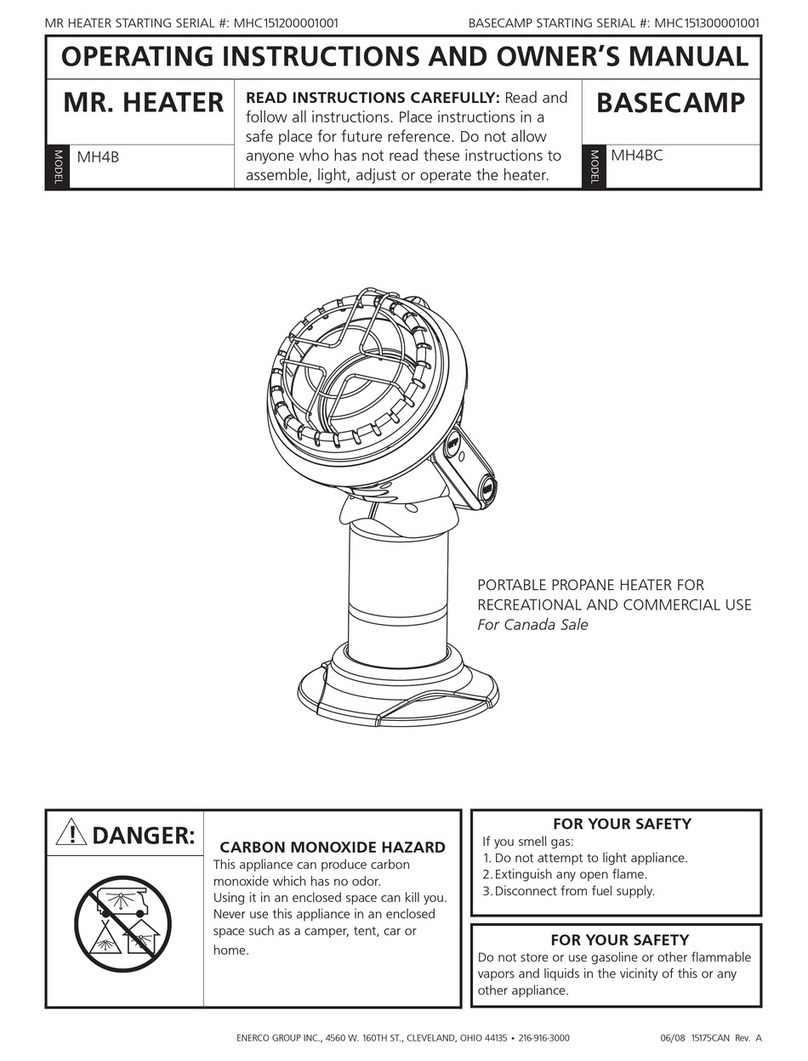

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all

instructions. Place instructions in a safe place for future

reference. Do not allow anyone who has not read these

instructions to assemble, light, adjust or operate the heater.

HEATSTAR High-Intensity Infrared Heaters

HS4040 HS9100S

HS8060 HS9120

MODELS

Installer: Leave this manual with the appliance. Consumer: Retain this manual for future reference.

If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

WARNING:

— Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Shutoffgassupply

• Donottrytolightappliance

• Donottouchanelectricalswitch;donotuseanyphoneinyourbuilding

• Immediatelycallyourgassupplierfromaneighbor’sphone.

Followthegassupplier’sinstructions

• Ifyoucannotreachyourgassupplier,calltheredepartment

—Installationandservicemustbeperformedbyaqualiedinstaller,serviceagencyorthegas

supplier.

Thisisanunventedgas-redheater.Itusesair(oxygen)fromtheareainwhichitisused.Adequate

combustion and ventilation air must be provided. Refer to page 4.

ENERCOGROUPINC.,4560W.160THST.,CLEVELAND,OHIO44135•216-916-3000

4000 & 8000 Models 9000 Models

18650 Rev. A 06/08

2

Enerco Group, Inc. |Gas-Fired Infra-Red Space Heaters OperatingInstructionsandOwner’sManual

CONTENTS

General Information.......................................................... 3

Clearances ........................................................................ 3

Gas Supply........................................................................ 3

Gas Pressure ..................................................................... 3

Electrical ........................................................................... 4

Thermostat & Location...................................................... 4

Ventilation ........................................................................ 4

Operations ........................................................................ 4

Cleaning Information ........................................................ 4

Connection diagram for flame rod current

foramerecticationsystems...................................... 5

Thermostat ....................................................................... 5

Replacement parts ............................................................ 7

Control system replacement parts................................... 10

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause property

damage, injury or death. Read the installation, opera-

tion, and maintenance instructions thoroughly before

installing or servicing this equipment. For assistance

oradditionalinformationconsultaqualiedinstaller,

service agency, or gas supplier.

WARNING: When used without fresh air, heater

may give off CARBON MONOXIDE, an odorless poi-

sonous gas. OPEN WINDOW AN INCH OR TWO FOR

FRESH AIR WHEN USING HEATER.

WARNING: This heater is equipped with a PILOT

LIGHT SAFETY SYSTEM. DO NOT TAMPER WITH PILOT

LIGHT SAFETY SYSTEM.

WARNING: If heater shuts off, do not relight

until you provide fresh air. If heater keeps shutting off,

have it serviced. Keep burner and control clean. Open

door for 5 minutes.

Maintain clearances as shown in Figure 1 or on heater nameplate.

•DONOTUSEMATCHOROTHERFLAME

FOR LEAK TESTING.

•DONOTEXCEED1/2PSIINLETPRESSURETOHEATER.

DANGER:

Carbonmonoxidepoisoningmayleadtodeath.

Carbon Monoxide Poisoning:

Earlysignsofcarbonmonoxidepoisoningresemble

the flu, with headaches, dizziness, or nausea. If you

have these signs, the heater may not be working

properly. Get fresh air at once! Have heater serviced.

Somepeoplearemoreaffectedbycarbonmonoxide

than others. These include pregnant women, persons

with heart or lung disease or anemia, those under the

influence of alcohol, and those at high altitudes.

CAUTION:

•Neverconnectgasvalveorthermostattolinevoltage

or a transformer.

•Iftheinfra-redcolorofthegridbecomesdullwhen

the building furnace is operating, consult gas supplier

on correct gas supply piping sizes.

•Thisheaterisforindoorinstallationonly!

NOTE Gasket binder material used in this heater assem-

bly will temporarily emit an odor and/or vapor. This

conditionwillclearupinapproximately20minutes

and thereafter will not reoccur. Refer to page 4 for

ventilation.

THE STATE OF CALIFORNIA REQUIRES THE

FOLLOWING WARNING:

WARNING: Combustion by-products produced

whenusingthisproductcontaincarbonmonoxide,

a chemical known to the State of California to cause

cancerandbirthdefects(orotherreproductiveharm).

3OperatingInstructionsandOwner’sManualEnerco Group, Inc. | Gas-Fired Infra-Red Space Heaters

1. GENERAL INFORMATION

Your heater comes fully assembled and is tested ata.

the factory for proper gas and input as stated on

the name plate.

Before proceeding with the installation, be sure tob.

inspect for damages. Freight company must be noti-

edofanydamagesandrequestthataninspection

be made by the freight company. HEAT STAR will send

replacement parts for damaged parts only after receiv-

ing a signed inspection report to prove the liability of

the freight company.

Do not attempt to operate heater with any other gasc.

than that indicated on the heater name plate.

The installation of heater must conform with locald.

building codes or, in absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1a/NFPA54. In

Canada, refer to Can 1-B146.1 and B149.2.

Plugged 1/8” N.P.T. Test Gage Connection is locatede.

on the Heater Gas Control or a ¼” N.P.T. Connection is

located on the outside of the Cast Venturi.

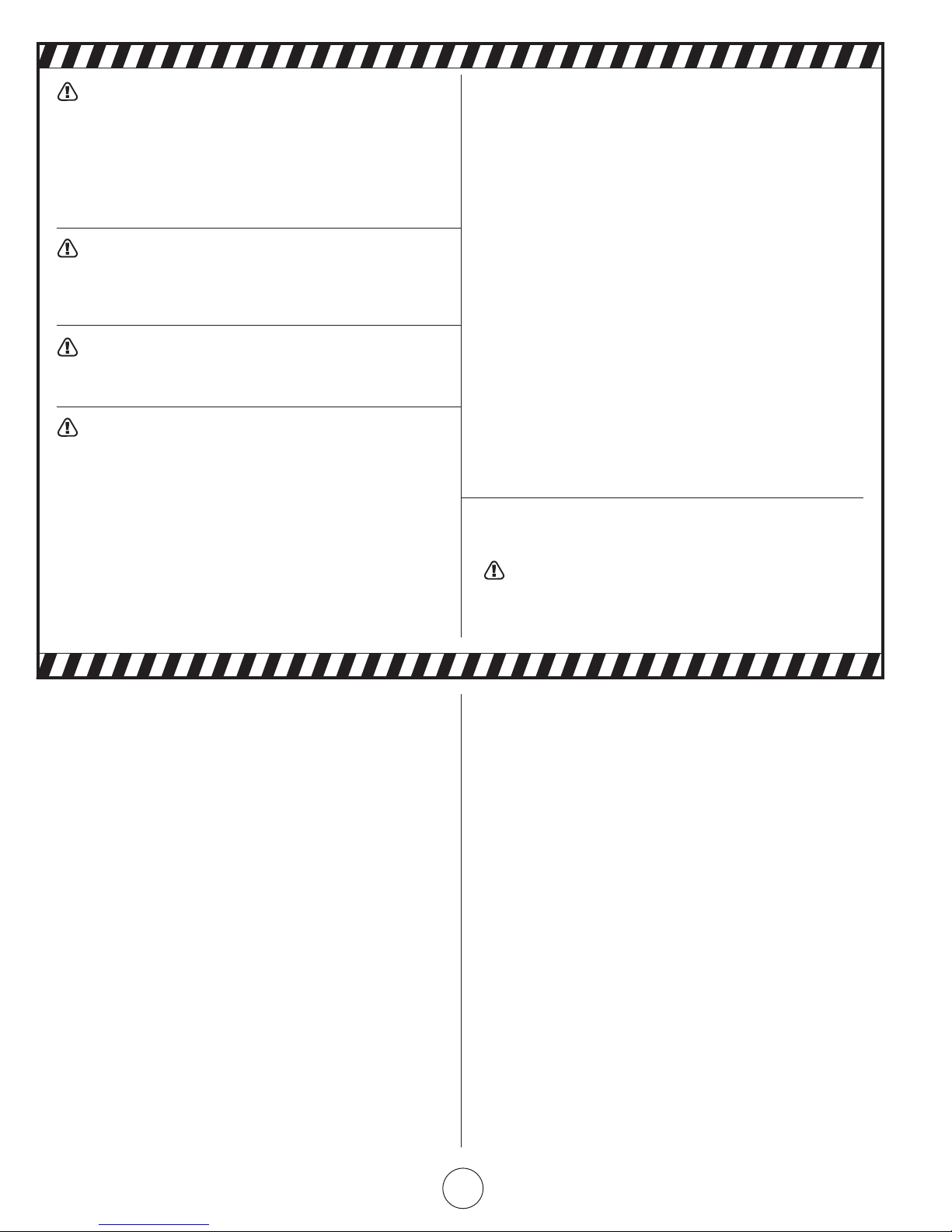

2. CLEARANCES Minimum clearances to combustibles.

(Refer to Figure 1)

Provide adequate clearance to combustibles, Figure 1,

between control end of heater for servicing and mini-

mum on top and sides for ventilation and combustion

air supply.

Aminimumclearanceof8’aboveoorforpublic

garages in accordance with ANSI/NFPA No. 88 most re-

centeditionorFigure1;whicheverislarger.InCanada

refer to Can 1-B149.1 and B149.2 Installation codes for

Gas burning appliances.

Aminimumclearanceof10’fromthebottomofheater

to top of wing, or engine enclosure, where aircraft are

housed,and8’aboveoorinotherareasofthehang-

er in accordance with ANSI/NFPA No. 409 most recent

FIGURE 1

MODEL NO.

BTU/HR. RATING NORMAL

MOUNTING

POSITION

CLEARANCES TO COMBUSTIBLES

GAS

NATURAL PROPANE TOP SIDES BACK BELOW

4030** 30,000 30,000 Horiz.-45° 30” 30” 30” 54”

4040* 40,000 40,000 Horiz.-45° 34” 30” 30” 68”

8050** 50,000 50,000 Horiz.-45° 36” 30” 30” 78”

8060* 60,000 60,000 Horiz.-45° 40” 30” 30” 84”

8070** 70,000 – Horiz.-45° 40” 30” 30” 84”

9080** 80,000 80,000 Horiz.-45° 46” 40” 40” 104”

9090** 90,000 90,000 Horiz.-45° 46” 46” 46” 114”

9100S* 100,000 100,000 Horiz.-45° 48” 46” 46” 118”

9100** 100,000 100,000 Horiz.-45° 44” 40” 40” 104”

9120* 120,000 120,000 Horiz.-45° 46” 46” 46” 114”

9140** 140,000 – Horiz.-45° 16” 46” 46” 114”

edition,orFigure1;thelargerdimensionofANSI/NFPA

No. 409 or Figure 1 is to be used. In Canada refer to

CCA B149-1-M91 and B149.2.

WARNING: MAINTAIN CLEARANCES AS SHOWN

IN FIGURE 1 OR ON HEATER NAMEPLATE, IN GARAGE

INSTALLATIONS WHERE PARKED VEHICLES ARE DI-

RECTLY BELOW THE HEATER.

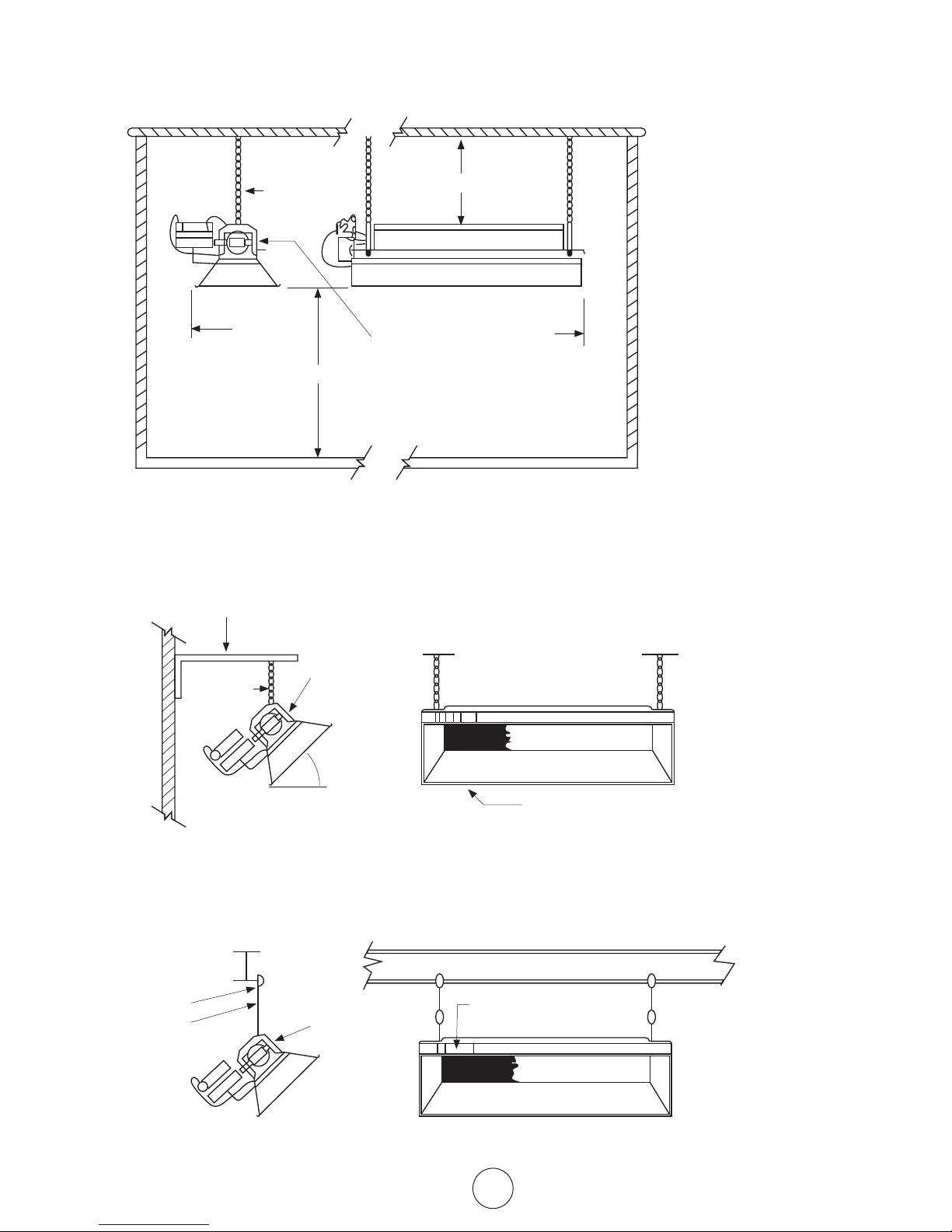

3. SUSPENSION

Heater has four mounting holes, two on each end, for

attaching rod or angle iron brackets and shall be safely

andadequatelyxedinpositionindependentofgas

and electric supply lines. Refer to Figures 4, 5, and 7 on

pages 13 and 14 for recommended suspensions.

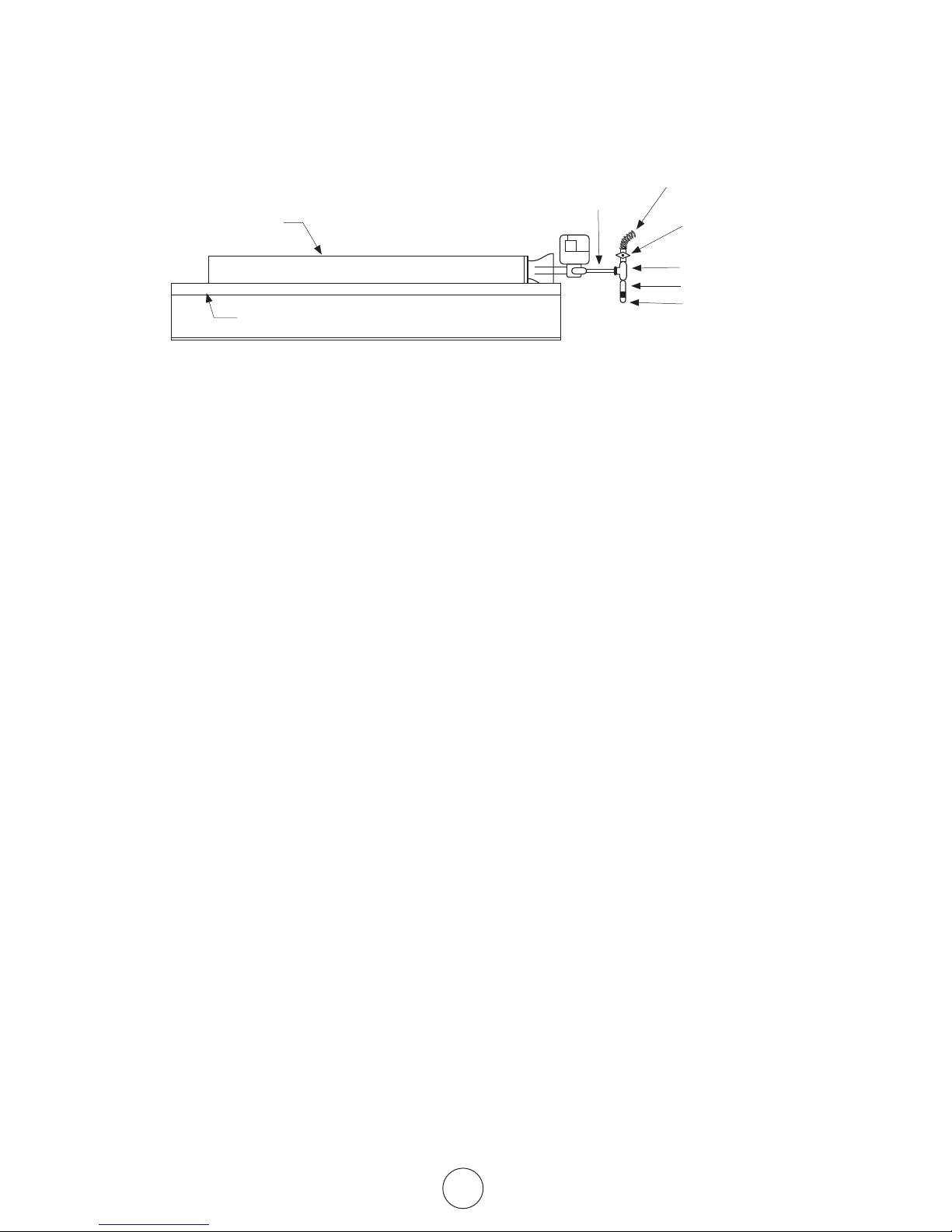

4. GAS SUPPLY

Provide adequate gas supply for rated input of each

heater using American Standard Installation of gas

piping and gas appliances in building ANSI/223. 1a/

NFPA54 Pamphlet, Table C-3 shows capacity of pipe of

different diameters and lengths in cubic feet per hour

for Natural Gas with pressure drop of 0.3 inches specify

gravityof0.60.ForliqueedPetroleumGas(LP)capac-

ity refer to Table C-3 and C-15 of the same pamphlet.

For recommended heater gas connection refer to

Figure No. 5, Page 15. In Canada refer to Can 1-B149.1

and B149.2, and CSA sto. B63.

If gas lines are to be pressure tested with compressed

air, disconnect each heater to prevent control damage

and cap outlets. After reconnecting all heaters, purge

gas lines of air and check all connections for leaks us-

ing soap solution.

WARNING: DO NOT USE MATCH OR OTHER

FLAME FOR LEAK TESTING.

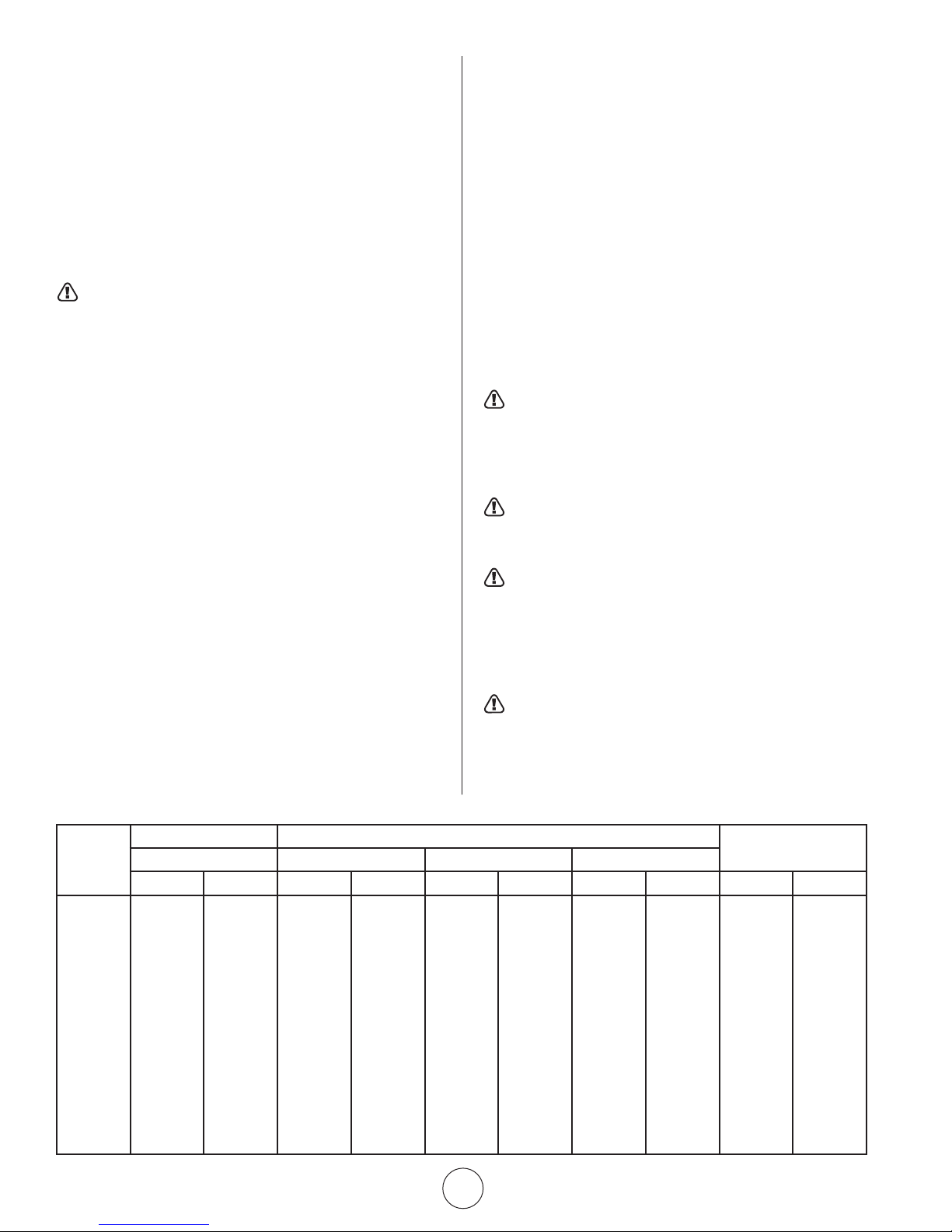

5. GAS PRESSURE

Whenahigherthanthemaximumrecommended

gas pressure is being maintained at the main gas line,

*High Intensity Heaters are only sold as 4040, 8060, 9100S, and 9120

**Differentmodelnumbersareachievedbyusingsupplementaloricesincludedwithheaterstochangeheatoutput.

4

Enerco Group, Inc. |Gas-Fired Infra-Red Space Heaters OperatingInstructionsandOwner’sManual

a separate regulator must be installed ahead of the

heater.RefertoFigure2formaximumallowablepres-

sure for stated model and gas.

See heater rating plate for minimum gas supply pres-

sure “For the Purpose of Input Adjustment”

On a multiple heater installation it may be possible to

use one large capacity regulator or an individual regula-

tor for each heater. Nevertheless, it is recommended

practice to make the entire pipe system a loop. Contact

your local representative or the factory for proper gas

pressure reducing design stage.

WARNING: DO NOT EXCEED ½ P.S.I. INLET PRES-

SURE TO HEATERS SHOWN IN FIGURES 1 AND 2

6. ELECTRICAL

Allexternalwiringmustbeinaccordancewiththe

existingelectricalcode.Usewiringdiagramfurnished

with heater. Be sure electric supply characteristics

match those called for on the name plate. The unit

must be electrically grounded in accordance with the

National Electrical Code, ANSI/NFPA70, latest revision.

In Canada refer to Canadian electrical code CSA C22.1

7. THERMOSTAT & LOCATION

Make sure that the electrical characteristics of the

thermostat match those of the heater controls. For best

results thermostat should be positioned 5 ft. above

floor where air can circulate freely around it. DO NOT

MOUNT directly to cold-side wall, in direct drafts or

directly beneath the infra-red heater.

8. VENTILATION

a.Theminimumintakeandexhaustairopeningsshallpro-

vide for not less than 400 CFM for every 100,000 BTU

inputexceptthattheinltrationareamaybeincluded

intheintakearea.Theexhaustfanmustbeinterlocked

withtheheaterthermostat.Ifapowerexhaustfan

is used, it should be controlled by the thermostat or

humidistat

b.Wherenatural(gravity)ventilationisprovidedfor

exhaust,theopeningsmustbedistributedabovethe

heaters(preferablyatthepeakoftheroof)andthe

areas of openings shall not be less than 300 square

inches for every 100,000 BTU input.

9. OPERATIONS

Upon completion of electrical wiring, gas piping and

purging of gas lines to heaters, refer to the lighting

instruction plate attached to heater for proper lighting

procedure.

10. CLEANING INFORMATION

Blow out Venturi and burner face with compressed

air(25#max.pressure);alsocleanorices(seeFigure

2forcorrectsizedrill).Fordetailedmaintenanceand

cleaning instructions contact your local representative

or factory.

WARNING: GASKET BINDER MATERIAL USED

IN THIS HEATER ASSEMBLY WILL TEMPORARILY EMIT

ANODORAND/ORVAPOR.USEVENTILATION(aOR

b)ANDTHISCONDITIONWILLCLEARUPINAPPROXI-

MATELY 20 MINUTES AND WILL NOT REOCCUR.

WARNING: DO NOT ATTEMPT TO IGNITE THE

PILOT BY HAND ON HEATERS EQUIPPED WITH AUTO-

MATIC SPARK IGNITION.

WARNING: THE STATE OF CALIFORNIA REQUIRES

THE FOLLOWING WARNING: COMBUSTION BY-PROD-

UCTS PRODUCED WHEN USING THIS PRODUCT CON-

TAIN CARBON MONOXIDE, A CHEMICAL KNOWN TO

THE STATE OF CALIFORNIA TO CAUSE CANCER AND

BIRTHDEFECTS(OROTHERREPRODUCTIVEHARM).

NOTE: USE LATEST EDITION FOR ALL ANSI STAN-

DARD AND CANADIAN STANDARDS.

FIGURE 2

MODEL

NO.

BTU/HR. RATING GASSUPPLYPRESSURE(W.C.) ORIFICE SIZE

GAS MIN. MAX. MANIFOLD

NATURAL PROPANE NAT. L.P. NAT. L.P. NAT. L.P. NAT. L.P.

4030 30,000 30,000 6.6” 11” 14” 14” 5.6” 10” 43 52

4040 40,000 40,000 6.8” 11” 14” 14” 5.8” 10” 37 49

8050 50,000 50,000 7.0” 11” 14” 14” 4.3” 10” 30 45

8060 60,000 60,000 7.0” 11” 14” 14” 5.8” 10” 29 43

8070 70,000 – 7.0” – 14” – 6.0” – 28 –

9080 80,000 80,000 7.0” 11” 14” 14” 5.8” 10” 37 49

9090 90,000 90,000 7.0” 11” 14” 14” 5.0” 10” 32 47

9100S 100,000 100,000 7.0” 11” 14” 14” 5.0” 10” 31 46

9100 100,000 100,000 7.0” 11” 14” 14” 4.3” 10” 30 45

9120 120,000 120,000 7.0” 11” 14” 14” 5.8” 10” 29 43

9140 140,000 – 7.0” – 14” – 5.5” – 28 –

5OperatingInstructionsandOwner’sManualEnerco Group, Inc. | Gas-Fired Infra-Red Space Heaters

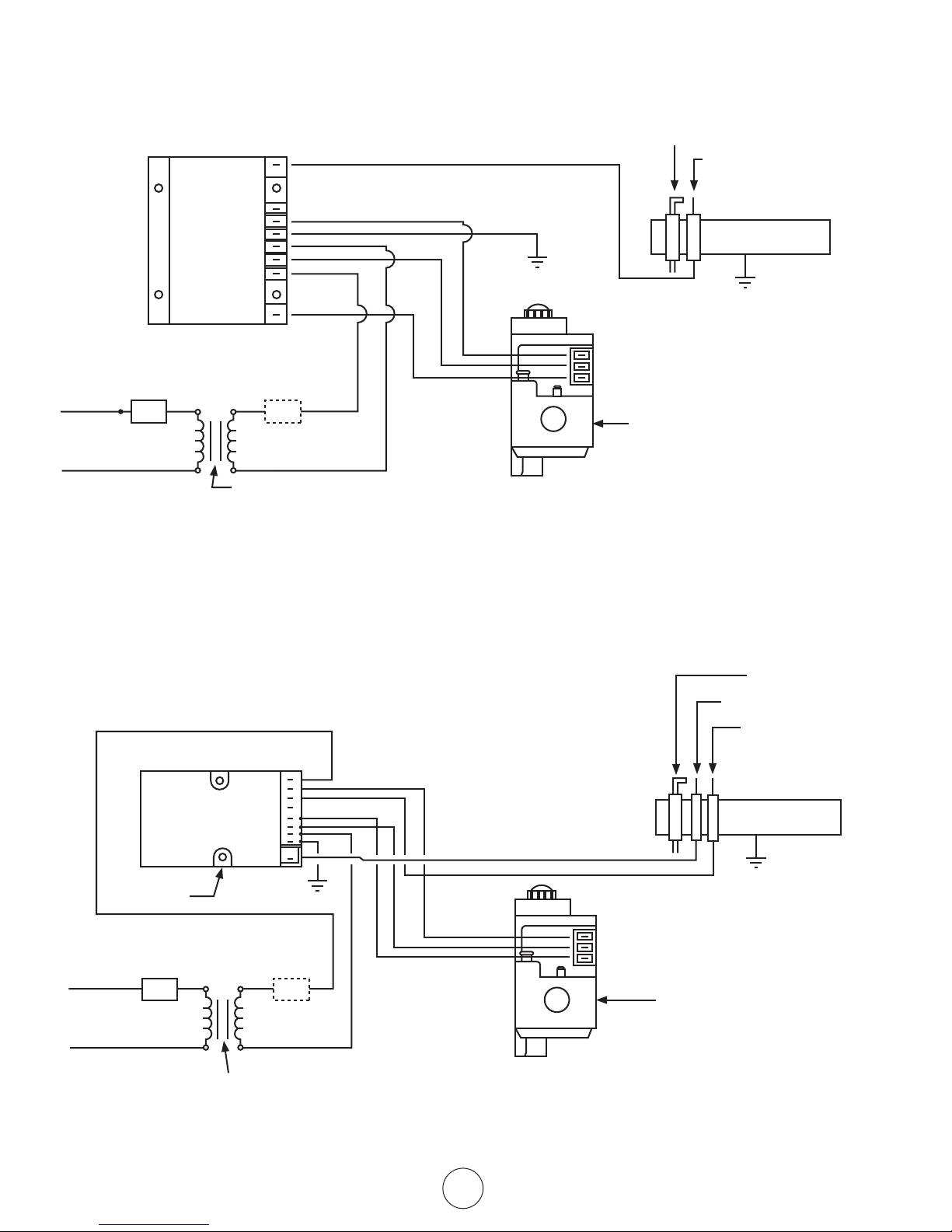

CONNECTION DIAGRAM FOR FLAME ROD CURRENT

FOR FLAME RECTIFICATION SYSTEMS (DSP-5, A5)

MEANS OF PROVING ADEQUATE GROUNDING AREA

The proper flame-rod-to-ground-area ratio cannot

alwaysbedeterminedbyvisualexaminationorphysical

measurement. A positive means of checking the instal-

lation is the measurement of the flame rod current

underactualringconditions.Itisdenitelyrecom-

mended that the installer measure the current flow be-

tween the lead of the flame rod unit and the terminal

inthecontrolterminalboard(seeFigure3).Measure

the current with a DC Microammeter or equal. We

recommend a steady output of .9 microamperes or

more. A steady flow of current in this amount under

actualringconditionswillgenerallyindicateadequate

grounding of the pilot flame.

NOTE:

1. Read all control data sheet supplied with this heater.

2. Check flame rod for any contact to heater parts. Flame

rod must be free of any contact to heater. Contact with

heater will short circuit flame rod.

3. Cracked porcelain on flame rod will short circuit sensor.

Replace flame rod.

Figure 3 – Using a microammeter to prove adequate grounding area.

Gas

Flame Flame

Rod

Flame

Rod Assy.

Microammeter Control

Terminal For

Flame Rod

Loadwire

G

THERMOSTAT

Thermostat Powerpile Thermocouple

Honeywell Q313A

Factory wired

Powerpile Gas Valve – Honeywell VS820

WIRE

SIZES

MAXIMUM

LENGTH

OF WIRE

CABLE

NO 18 15 FEET

NO 16 30 FEET

NO 14 50 FEET

CAUTION TO INSTALLER

NEVER CONNECT POWERPILE

GAS VALVE OR THERMOSTAT

TO LINE VOLTAGE OR A

TRANSFORMER.

NOTE Donotexceedthe

maximumlengthslistedinthe

table when wiring between the

Thermostat and Gas Valve with

cable not supplied by HEAT STAR.

CONNECTION DIAGRAM

6

Enerco Group, Inc. |Gas-Fired Infra-Red Space Heaters OperatingInstructionsandOwner’sManual

SP715A

IGN

SP745

PV

GND

TR

PV/MV

TH

MV

LOGIC BOX

THERMOSTAT NOT

BY HEAT STAR

120 VAC

24 VOLT

THERMOSTAT

OPTIONAL

24 VAC

TRANSFORMER(SHIPPEDLOOSE)

COMBINED LOAD: 1.5 AMP. PILOT BURNER

SPARK ELECTRODE /

FLAME SENSOR

MAIN BURNER

PV

PV/MV

MV

GAS VALVE

VR8204 A5 CONNECTION

DIAGRAM

REF. B2984-1

TH

PV

SENSE

EJ

MV

MV/PV

TR

GND

IGN

LOGIC BOX

THERMOSTAT NOT

BY HEAT STAR

120 VAC

24 VOLT

THERMOSTAT

OPTIONAL

24 VAC

TRANSFORMER(SHIPPEDLOOSE)

COMBINED LOAD: 1.5 AMP PILOT BURNER

SPARK ELECTRODE

FLAME SENSOR

MAIN BURNER

PV

PV/MV

MV

GAS VALVE

VR8204

NDSP-5 CONNECTION

DIAGRAM

REF. A2983-1

7OperatingInstructionsandOwner’sManualEnerco Group, Inc. | Gas-Fired Infra-Red Space Heaters

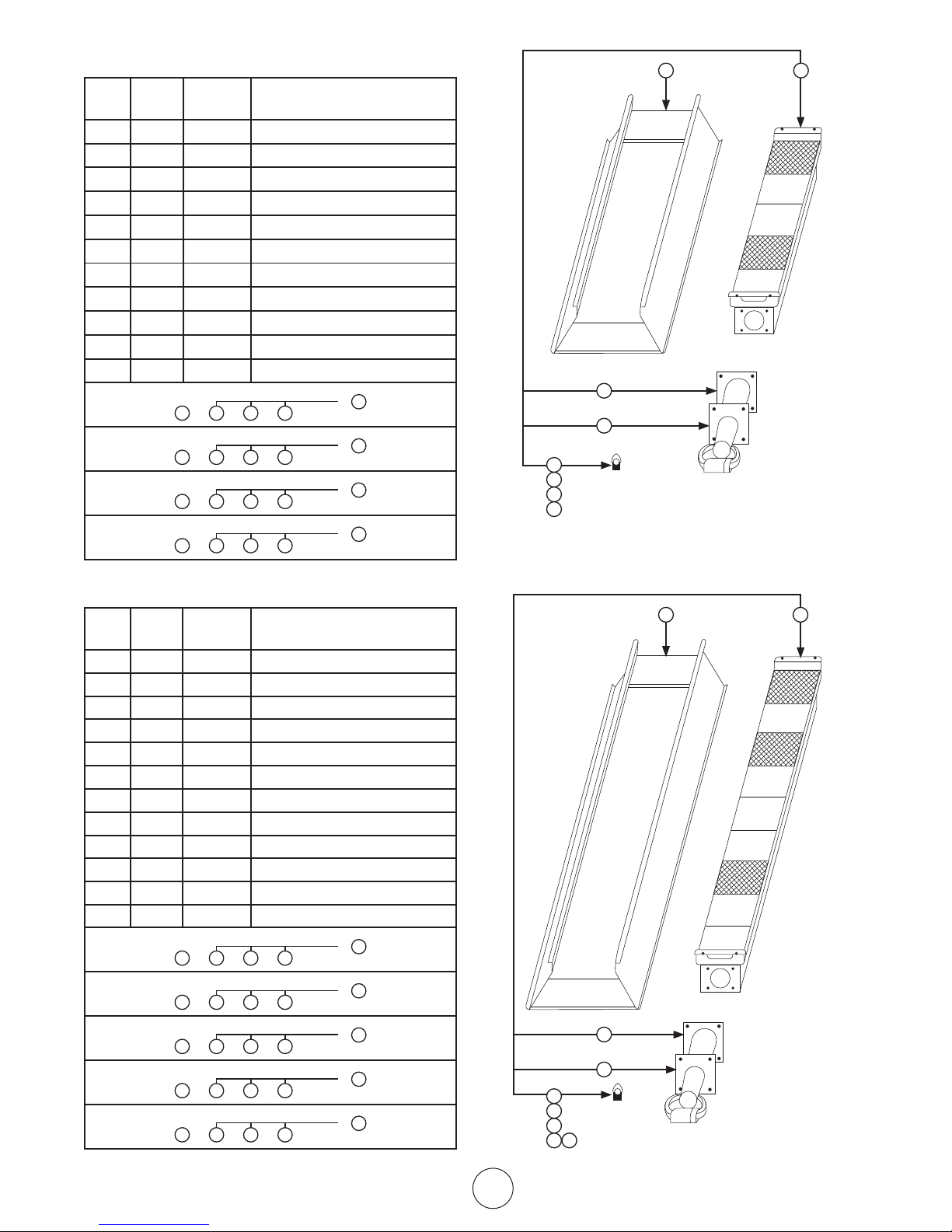

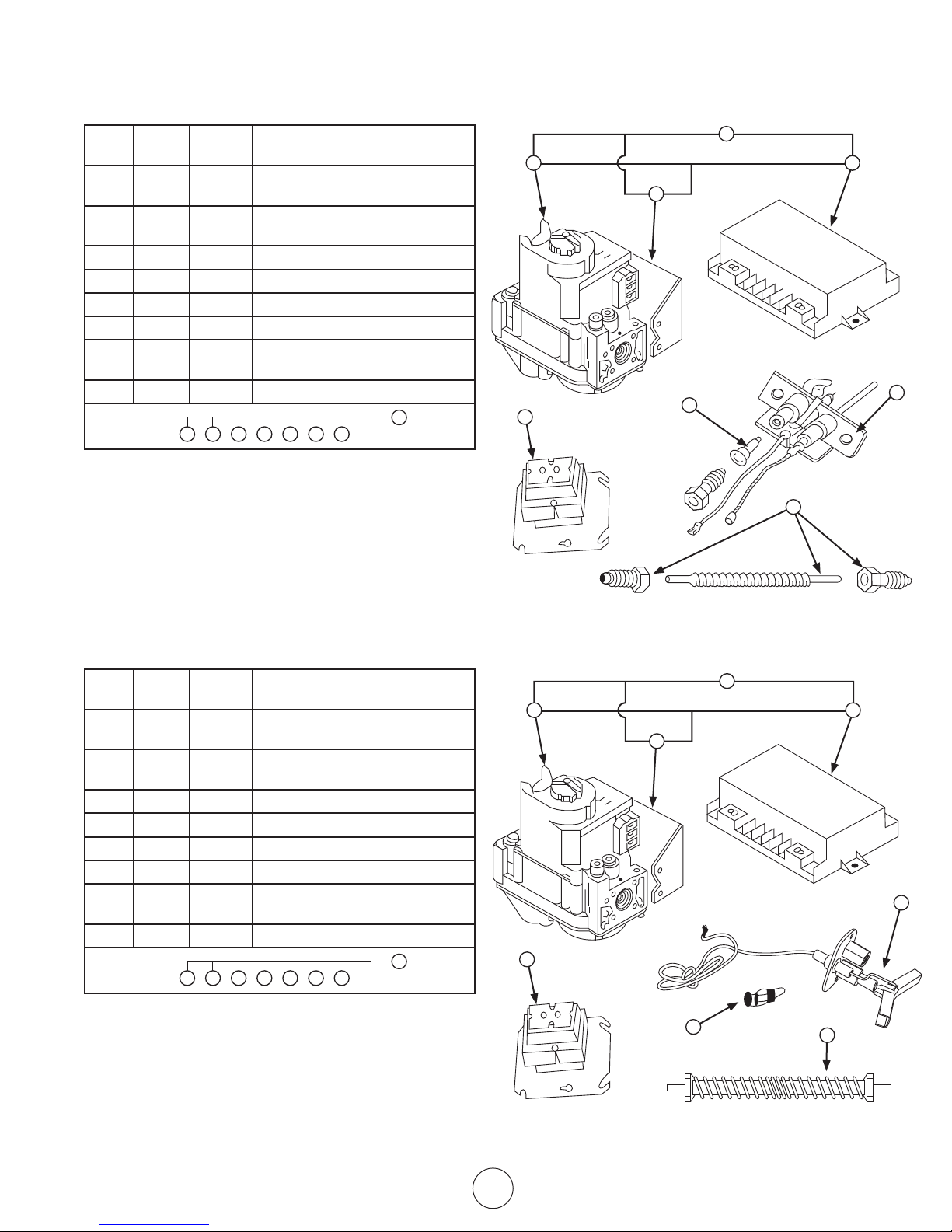

Replacement Parts List For Heaters

4000 Series Models / Less Control

Item

No.

No.

Req’d.

Stock

No. Description

1 1 00435 A Reflector Assembly

2 1 02523 A Burner Assembly

3 1 03397 P Venturi

4

5 1 05437 Orice–Br.N.G.4040

6 1 05443 Orice–Br.N.G.4030

7 1 05449 Orice–Br.L.P.4040

8 1 05452 Orice–Br.L.P.4030

9 1 12366 Gasket – Venturi

10

11

1359

4040 Nat. Gas 2

or

1369

4040 Nat. Gas 2

or

1379

4040 Propane 2

or

1389

4040 Propane 2

or

Replacement Parts List For Heaters

8000 Series Models / Less Control

Item

No.

No.

Req’d. Stock No. Description

1 1 00442 A Reflector Assembly

2 1 02524 A Burner Assembly

3 1 03421 P Venturi

4

5 1 05428 Orice–Br.N.G.8070

6 1 05429 Orice–Br.N.G.8060

7 1 05430 Orice–Br.N.G.8050

8 1 05443 Orice–Br.L.P.8060

9 1 05445 Orice–Br.L.P.8050

10 1 12366 Gasket – Venturi

11

12

13510

8070 Nat. Gas 2

or

13610

8060 Nat. Gas 2

or

13710

8050 Nat. Gas 2

or

13810

8060 Propane 2

or

13910

8050 Propane 2

or

5

6

7

8

1 2

9

3

5

6

7

8 9

1 2

10

3

8

Enerco Group, Inc. |Gas-Fired Infra-Red Space Heaters OperatingInstructionsandOwner’sManual

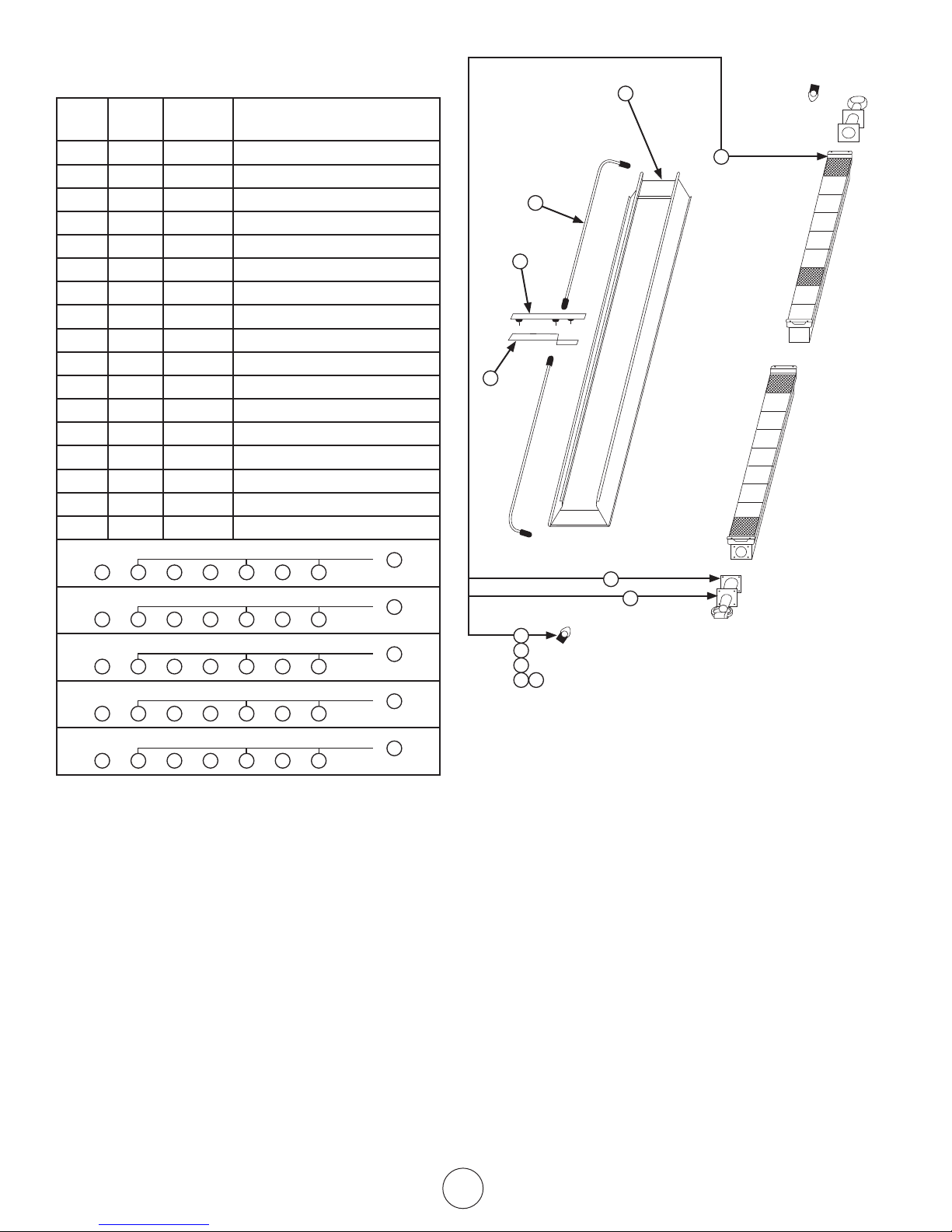

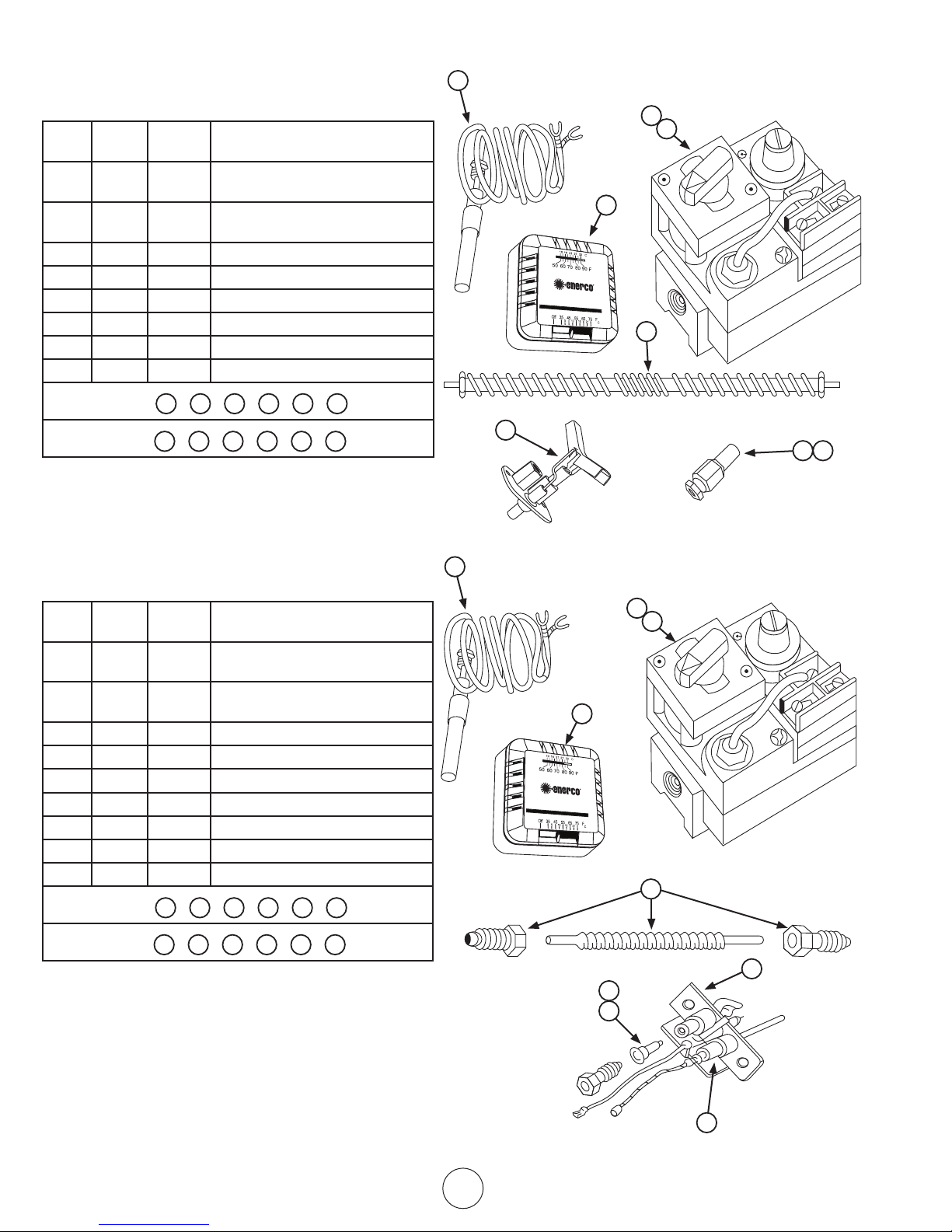

Replacement Parts List For Heaters

9000 Series Models / Less Control

Item

No.

No.

Req’d. Stock No. Description

1 1 00444 A Reflector Assembly

2 2 02694 Burner Assembly

3 2 03421 P Venturi

4

5

6 2 05428 Orice–Br.N.G.9140

7 2 05429 Orice–Br.N.G.9120

8 2 05430 Orice–Br.N.G.9100

9 2 05443 Orice–Br.L.P.9120

10 2 05445 Orice–Br.L.P.9100

11 2 06396 Manifold Assembly

12 2 12366 Gasket – Venturi

13

14 1 14639 Center Saddle Bracket

15 1113 81 CenterSupportAss’y

16

17

9140 Nat. Gas

1 3 12

61411 15

2

or

9120 Nat. Gas

1 3 12

71411 15

2

or

9100 Nat. Gas

1 3 12

81411 15

2

or

9120 Propane

1 3 12

91411 15

2

or

9100 Propane

1 3 12

10 1411 15

2

or

1

11

15

14

7

8

910

12

6

3

2

9OperatingInstructionsandOwner’sManualEnerco Group, Inc. | Gas-Fired Infra-Red Space Heaters

Replacement Parts List For Heaters

9100S Series Models / Less Control

Item No. No.

Req’d. Stock No. Description

1 1 00443 A Reflector Assembly

2 2 02508 A Burner Assembly

3 2 03421 P Venturi

4

5

6 2 05431 Orice–Br.N.G.9100S

7 2 05432 Orice–Br.N.G.9090

8 2 05437 Orice–Br.N.G.9080

9 2 05446 Orice–Br.L.P.9100S

10 2 05447 Orice–Br.L.P.9090

11 2 05449 Orice–Br.L.P.9080

12 2 06398 Manifold Assembly

13 2 12366 Gasket – Venturi

14

15 1 14639 Center Saddle Bracket

16 1113 81 Center Support Assembly

9100S Nat. Gas

1 3 13

61512 16

2

or

9090 Nat. Gas

1 3 13

71512 16

2

or

9080 Nat. Gas

1 3 13

81512 16

2

or

9100S Propane

1 3 13

91512 16

2

or

9090 Propane

1 3 13

10 1512 16

2

or

9080 Propane

1 3 13

11 1512 16

2

or

15

12

1

6 7

8 9

10 11

2

16

3

13

10

Enerco Group, Inc. |Gas-Fired Infra-Red Space Heaters OperatingInstructionsandOwner’sManual

1

3

2

5

1

3

2

or

48

6

7

10

9

9

5

4

8

6

7

10

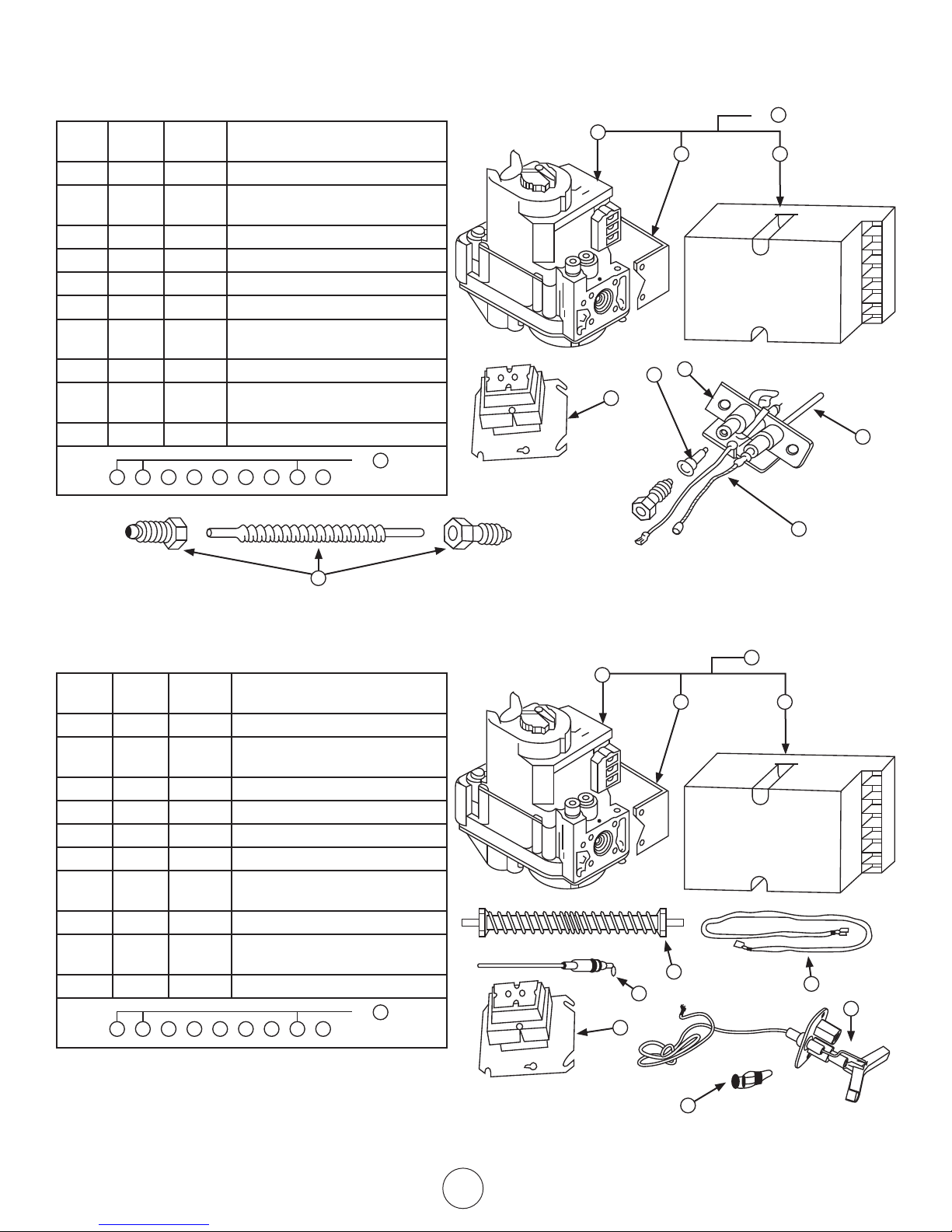

FOR HEAT STAR SERIES 4000, 8000

REPLACEMENT PARTS LIST FOR CONTROL

SYSTEM SUFFIX NDSP-5

ITEM

NO.

NO.

REQ’D

STOCK

NO. DESCRIPTION

1 1 00028 IGNITIONCONTROL#SP715A

2 1 00037 GAS VALVE DSP-5/VR8204A2001/

SWC

3 1 00228 CONTROL ASSY. NDSP-5

4 1 05573 ORIFICE PILOT NG.

5 1 08353 TRANSFORMER 40VA

6 1 09374 PROBE T/C 1 5/32” LONG

7 1 09375 PROBE LEAD 4000, 8000, 9000

HTRS.

8 1 11403 PILOT BURNER ASSY.

9 1 14606 BRACKET MTG. SP715A RS.L. &

HON.V.

10 1 16425 FLEX PILOT TUBE W/FITTINGS

NDSP-5 2

or

1245678910

FOR HEAT STAR SERIES 9000, 9000S

REPLACEMENT PARTS LIST FOR CONTROL

SYSTEM SUFFIX NDSP-5

ITEM

NO.

NO.

REQ’D

STOCK

NO. DESCRIPTION

1 1 00028 IGNITIONCONTROL#SP715A

2 1 00037 GAS VALVE DSP-5/VR8204A2001/

SWC

3 1 00228 CONTROL ASSY. NDSP-5

4105383 ORIFICE PILOT – NG

5 1 08353 TRANSFORMER 40VA

6 1 09374 PROBE T/C 1 5/32” LONG

7 1 09375 PROBE LEAD 4000, 8000, 9000

HTRS.

81113 8 5 PILOT BURNER ASSY.

9 1 14606 BRACKET MTG. SP715A RS.L. &

HON.V.

10 1 16425 FLEX PILOT TUBE W/FITTINGS

NDSP-5 2

or

1245678910

11 OperatingInstructionsandOwner’sManualEnerco Group, Inc. | Gas-Fired Infra-Red Space Heaters

FOR HEAT STAR SERIES 9000, 9000S

REPLACEMENT PARTS LIST FOR CONTROL

SYSTEM SUFFIX LA5

ITEM

NO.

NO.

REQ’D

STOCK

NO. DESCRIPTION

1 1 00036 GAS VALVE A5/VR8204A2092/11”

WC

2 1 00039 CONTROL LOGIC /A5/

#SP745NL36005

3 1 00329 CONTROL ASSY. LA5

4 1 05384 ORIFICE PILOT – LP

5 1 08353 TRANSFORMER 40VA

6 1 113 8 5 PILOT BURNER ASSY.

7 1 14615 BRACKET MTG. A5, 745RS.L. &

HON.V.

8 1 16425 FLEX PILOT TUBE W/FITTINGS

LA5

3

or

1245678

FOR HEAT STAR SERIES 4000, 8000

REPLACEMENT PARTS LIST FOR CONTROL

SYSTEM SUFFIX LA5

ITEM

NO.

NO.

REQ’D

STOCK

NO. DESCRIPTION

1 1 00036 GAS VALVE A5/VR8204A2092/11”

WC

2 1 00039 CONTROL LOGIC /A5/

#SP745NL36005

3 1 00329 CONTROL ASSY. LA5

4 1 05577 ORIFICE PILOT – LP

5 1 08353 TRANSFORMER 40VA

6 1 11407 PILOT BURNER ASSY.

7 1 14615 BRACKET MTG. A5, 745RS.L. &

HON.V.

8 1 16425 FLEX PILOT TUBE W/FITTINGS

LA5

3

or

1245678

1 2

3

7

48

5

6

8

5

6

12

3

7

4

12

Enerco Group, Inc. |Gas-Fired Infra-Red Space Heaters OperatingInstructionsandOwner’sManual

FOR HEAT STAR SERIES 9000, 9000S

REPLACEMENT PARTS LIST FOR

CONTROL SYSTEM SUFFIX NPP, LPP

ITEM

NO.

NO.

REQ’D

STOCK

NO. DESCRIPTION

1 1 00024 COMB.GASVALVE(PP)NG.

1/2x1/2NPT

2 1 00025 COMB.GASVALVE(PP)LP.1/2x1/2

NPT

3 1 05384 ORIFICE PILOT LP

4 1 05383 ORIFICE PILOT NG

5 1 09360 THERMOCOUPLE PP HONEYWELL

6 1 10367 THERMOSTAT “PP” HEAT STAR

7 1 113 8 5 PILOT BURNER-9000HTR

8 1 16425 FLEX PILOT TUBE WITH FITTINGS

NPP 145678

LPP 235678

FOR HEAT STAR SERIES 4000, 8000

REPLACEMENT PARTS LIST FOR

CONTROL SYSTEM SUFFIX NPP, LPP

ITEM

NO.

NO.

REQ’D

STOCK

NO. DESCRIPTION

1 1 00024 COMB.GASVALVE(PP)NG.

1/2x1/2NPT

2 1 00025 COMB.GASVALVE(PP)LP.1/2x1/2

NPT

3 1 05577 ORIFICE PILOT LP

4 1 05573 ORIFICE PILOT NG

5 1 09360 THERMOCOUPLE PP HONEYWELL

6 1 10367 THERMOSTAT “PP” HEAT STAR

7 1 11405 PILOT-PP-4K, 8K HTR NG

7 1 11408 PILOT-PP-4K, 8K HTR LP

8 1 16425 FLEX PILOT TUBE WITH FITTINGS

NPP 145678

LPP 235678

NOTE: 1 – WHEN ORDERING SPARE PARTS ALWAYS GIVE HEATER

MODEL NO., STOCK NO., SERIAL NO., AND TYPE OR

GAS USED.

2 – WHEN DISASSEMBLING PARTS FROM HEATER FOR RE-

PAIR, CAREFULLY NOTE ORIENTATION OF PARTS, AND

THEN REVERSE PROCEDURE WHEN ASSEMBLING.

1

4

5

6

7

8

2

3

1

5

3

6

2

8

4

5

7

13 OperatingInstructionsandOwner’sManualEnerco Group, Inc. | Gas-Fired Infra-Red Space Heaters

SUGGESTED HANGING METHOD

MODEL: 4000, 8000, 9000, MH40

TYPICAL BEAM MOUNT

FIGURE 4

CEILING

SIDE

WALL

FLOOR

HORIZONTAL MOUNT

BACK

SEE INSTALLATION INSTRUCTIONS FOR

DETAILED CLEARANCES INFORMATION

CLEARANCES TO COMBUSTIBLES

BELOW

TOP

BEAM CLAMP

THREADED ROD

WHEN ANGLE MOUNTING

ELEVATE ONLY DESIGNATED

SIDE OF HEATER

FIGURE 5

ANGLE IRON

SEE CHAIN KIT

#17374OR

THREADED ROD

FROM

HORIZONTAL

MAXIMUM

45°

TYPICAL WALL MOUNT

HEATER SIDE REFLECTOR MUST

BE PARALLEL TO THE FLOOR

MOUNTING

SEE CHAIN

KIT#17374

OR THREAD-

ED ROD

F114581 HANGING

BRACKET KIT

F114581 HANGING

BRACKET KIT

OR CHAIN

KIT 17374

RECOMMEND USING

HEATER HANGING

BRACKET F114581

14

Enerco Group, Inc. |Gas-Fired Infra-Red Space Heaters OperatingInstructionsandOwner’sManual

FIGURE 6

LOW PRESSURE, MAIN GAS LINE

SEE FIGURE 2 FOR PROPER INLET PRESSURES

FOR HIGHER PRESSURES THAN SHOWN ABOVE

CONTACT FACTORY FOR PROPER REGULATOR

ON THREADED PIPES USE A PIPE COMPOUND WHICH

IS RESISTANT TO THE ACTION OF ALL GASES

MUST BE RESISTANT TO PROPANE

TYPICAL LOW PRESSURE

STANDARD INSTALLATION

HEATER

MOUNTING HOLES-4 REQ’D

SIDE VIEW

½ PSI MAX.

SHUT-OFF VALVE

TEE

DRIP LEG

CAP

HIGH ALTITUDE OPERATION

Please contact the factory for a detailed High Altitude1.

ConversionKittosuityourspecicneed.

1.1 Be prepared to answer factory questions regard-

ing: Type of fuel for the proposed appliance con-

version,gaspressureavailableatsite,andspecic

altitude at site.

“The conversion shall be carried out by a manufac-2.

turer’sauthorizedrepresentative,inaccordancewith

the requirements of the manufacturer, provincial or

territorial authorities having jurisdiction and in accor-

dance with their requirements.”

High Altitude Conversion Kits will include high3.

altitude rating plate with stamped data, necessary

oricesorburnerasrequiredforspecicneedand

additional installation instructions.

In Canada, Heater installations at High Altitudes shall4.

comply with the applicable construction provisions of

thecurrentstandardCAN1-2.17,gasredappliances

for use at high altitudes.

RIGID OR FLEXIBLE GAS

LINE TO HEATER

PIPE NIPPLE

15 OperatingInstructionsandOwner’sManualEnerco Group, Inc. | Gas-Fired Infra-Red Space Heaters

THIS PAGE INTENTIONALLY

LEFT BLANK

16

Enerco Group, Inc. |Gas-Fired Infra-Red Space Heaters OperatingInstructionsandOwner’sManual

WARNING: USEONLYMANUFACTURER’SREPLACEMENTPARTS.USE

OF ANY OTHER PARTS COULD CAUSE INJURY OR DEATH. REPLACEMENT PARTS

ARE ONLY AVAILABLE DIRECT FROM THE FACTORY AND MUST BE INSTALLED BY

A QUALIFIED SERVICE AGENCY.

PARTS ORDERING INFORMATION:

PURCHASING: Accessories may be purchased at any Mr. Heater/HeatStar local dealer

or direct from the factory

FOR INFORMATION REGARDING SERVICE

PleasecallToll-Free800-251-0001•www.enerco-mrheater.com

Ourofcehoursare8:30AM–5:00PM,EST,MondaythroughFriday.

Email to: techservice@enerco-mrheater.com

Please include the model number, date of purchase, and description of problem in all

communication.

LIMITED WARRANTY

The company warrants this product to be free from imperfections in material or workmanship,

under normal and proper use in accordance with instructions of The Company, for a period of

one year from the date of delivery to the buyer. The Company, at its option, will repair or replace

products returned by the buyer to the factory, transportation prepaid within said one year period

and found by the Company to have imperfections in material or workmanship.

Pro-rated 10-year warranty on the burner assembly only.

If a part is damaged or missing, call our Technical Support Department at 800-251-0001.

Address any Warranty Claims to the Service Department, Enerco Group, Inc., 4560 W. 160th St.,

Cleveland, Ohio 44135. Include your name, address and telephone number and include details

concerning the claim. Also, supply us with the purchase date and the name and address of the

dealer from whom you purchased our product.

TheforegoingisthefullextentoftheresponsibilityoftheCompany.Therearenoother

warranties,expressorimplied.Specicallythereisnowarrantyoftnessforaparticularpurpose

and there is no warranty of merchantability. In no event shall the Company be liable for delay

causedbyimperfections,forconsequentialdamages,orforanychargesoftheexpenseof

any nature incurred without its written consent. The cost of repair or replacement shall be the

exclusiveremedyforanybreachofwarranty.Thereisnowarrantyagainstinfringementofthe

like and no implied warranty arising from course of dealing or usage of trade. This warranty will

not apply to any product which has been repaired or altered outside of the factory in any respect

which in our judgment affects its condition or operation.

Somestatesdonotallowtheexclusionorlimitationofincidentalorconsequentialdamages,so

theabovelimitationorexclusionmaynotapplytoyou.ThisWarrantygivesyouspeciclegal

rights, and you may have other rights which vary from state to state.

Enerco Group, Inc., reserves the right to make changes at any time, without notice or

obligation,incolors,specications,accessories,materialsandmodels.

ENERCOGROUP,INC.,4560W.160THST.,CLEVELAND,OHIO44135•216-881-5500

Mr. Heater is a registered trademarks of Enerco Group, Inc.

© 2008, Enerco Group, Inc. All rights reserved

ANSI Z83.19b-2008/CSA 2.35-2007

®

®

18650 Rev. A 06/08

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all

instructions. Place instructions in a safe place for future

reference. Do not allow anyone who has not read these

instructions to assemble, light, adjust or operate the heater.

HEATSTAR High-Intensity Infrared Heaters

HS4030 HS8070 HS9100

HS4040 HS9080 HS9120

HS8050 HS9090 HS9140

HS8060 HS9100S

MODELS

16

Enerco Group, Inc. | Appareils de chauffage à gaz infrarouge Guide d'utilisation et instructions de fonctionnement

AVERTISSEMENT : N'UTILISEZ QUE LES PIÈCES DE

REMPLACEMENT DU FABRICANT. L'UTILISATION D'AUTRES PIÈCES RISQUE DE

CAUSER DES BLESSURES ET LA MORT. LES PIÈCES DE REMPLACEMENT NE SONT

OFFERTES QUE PAR LE FABRICANT ET DOIVENT ÊTRE INSTALLÉES PAR UNE

ENTREPRISE SPÉCIALISÉE.

INFORMATIONS SUR LA COMMANDE DE PIÈCES :

ACHAT : on peut se procurer des accessoires auprès de tous les détaillants locaux Mr. Heater/

HeatStar ou directement du fabricant

POUR OBTENIR DES INFORMATIONS SUR LE SERVICE

Appelezsansfraisau1800251-0001•www.enerco-mrheater.com

Nos heures d'ouverture sont de 8 h 30 à 17 h HE, du lundi au vendredi.

Adressezvoscourrielsà:techservice@enerco-mrheater.com

Veuillez indiquer le numéro du modèle, la date d'achat et la description du problème dans toutes

vos communications avec nous.

GARANTIE LIMITÉE

L'entreprisegarantitceproduitcontretoutdéfautdematérieloudemain-d'œuvre,dansdes

conditions d'utilisation normales et adéquates, conformément aux instructions de l'entreprise,

pour une période de un an à compter de la date de livraison à l'acheteur. L'entreprise réparera

ou remplacera, à sa discrétion, les produits retournés port payé par l'acheteur au fabricant dans

lapériodedeunanetjugésparl'entreprisecommeprésentantdesdéfautsdematérieloude

main-d'œuvre.

Garantie au prorata de 10 ans sur le brûleur seulement.

Si une pièce est endommagée ou manquante, téléphonez à notre service de soutien technique

au1800251-0001.

Adressez toute réclamation relative à la garantie à Service Department, Enerco Group, Inc.,

4560W.160thSt.,Cleveland,Ohio44135États-Unis.Indiquezvosnom,adresseetnumérode

téléphoneainsiquelesdétailsdelaréclamation.Indiquez-nouségalementladated'achatetle

nom et l'adresse du détaillant auprès duquel vous avez acheté le produit.

Cequiesténoncéci-dessusconstituelaresponsabilitétotaledel'entreprise.Iln'existeaucune

autre garantie, expresse ou tacite. Plus précisément, il n'y a aucune garantie concernant

l'adéquation à un usage particulier ni aucune garantie concernant la qualité marchande.

En aucun cas l'entreprise ne sera tenue responsable des retards causés par des défectuosités,

ni des dommages indirects, ni des dépenses encourues sans son consentement écrit, quelle que

soit leur nature. Le coût de la réparation ou du remplacement sera le seul recours possible en

cas de violation de garantie. Il n'y a aucune garantie contre une transgression de ce genre ni

aucune garantie tacite découlant des usages du commerce ou de la façon habituelle d'échanger.

La présente garantie ne s'applique à aucun produit qui a été réparé ou modifié par d'autres

que le fabricant si cela influe de quelque façon que ce soit sur l'état de l'appareil ou son

fonctionnement,selonnotrejugement.

Certains États ou provinces ne permettent pas d'exclure ou de limiter les dommages indirects

ousubséquents.Parconséquent,leslimitationsouexclusionsci-dessusmentionnéesnevous

concernentpeut-êtrepas.Laprésentegarantievousaccordedesdroitsjuridiquesprécis,mais

vous pourriez avoir d'autres droits qui varient selon la province ou l'État.

Enerco Group Inc. se réserve le droit d'effectuer des modifications en tout temps, sans préavis

ni obligation, aux couleurs, aux spécifications, aux accessoires, aux matériaux et aux modèles.

ENERCOGROUP,INC.,4560W.160THST.,CLEVELAND,OHIO44135USA•(216)881-5500

Mr. Heater est une marque de commerce déposée d'Enerco Group Inc.

© 2008, Enerco Group, Inc. Tous droits réservés

ANSI Z83.19b-2008/CSA 2.35-2007

®

®

18650 Rév. A 06/08

GUIDE D'UTILISATION ET INSTRUCTIONS DE FONCTIONNEMENT

LISEZ SOIGNEUSEMENT LES INSTRUCTIONS. Lisez et observez

toutes les instructions. Conservez les instructions pour vous y référer

ultérieurement. Interdisez à quiconque n'ayant pas lu les présentes

instructions d'assembler, d'allumer, de régler ou de faire fonctionner

cet appareil de chauffage.

Appareils de chauffage infrarouge haute intensité HEATSTAR

HS4030 HS8070 HS9100

HS4040 HS9080 HS9120

HS8050 HS9090 HS9140

HS8060 HS9100S

MODÈLES

15 Guide d'utilisation et instructions de fonctionnementEnerco Group, Inc. | Appareils de chauffage à gaz infrarouge

CETTE PAGE EST LAISSÉE

BLANCHE INTENTIONNELLEMENT

14

Enerco Group, Inc. | Appareils de chauffage à gaz infrarouge Guide d'utilisation et instructions de fonctionnement

FIGURE 6

CONDUITE DE GAZ PRINCIPALE, BASSE PRESSION

CONSULTEZLAFIGURE2POURCONNAÎTRELESPRESSIONSD'ENTRÉEADÉQUATES

ENCASDEPRESSIONSUPÉRIEUREÀLAVALEURINDIQUÉECI-DESSUS,

COMMUNIQUEZ AVEC LE FABRICANT POUR OBTENIR LE RÉGULATEUR APPROPRIÉ

SUR LES CONDUITES FILETÉES, UTILISEZ UN COMPOSÉ À

CONDUITE RÉSISTANT À L'ACTION DE TOUS LES GAZ

DOIT ÊTRE RÉSISTANT AU PROPANE

INSTALLATION

STANDARD BASSE PRESSION

APPAREIL DE CHAUFFAGE

TROUSDEFIXATION-QUANTITÉ4

VUE DE CÔTÉ

½ PSI MAX.

ROBINET D'ARRÊT

TÉ

COLLECTEUR DE CONDENSATS

CAPUCHON

UTILISATION À HAUTE ALTITUDE

Veuillez communiquer avec le fabricant pour obtenir1.

des renseignements détaillés sur l'ensemble de

conversion haute altitude qui convient précisément

à vos besoins.

1.1 Soyez prêt à répondre aux questions du fabricant

concernant le type de combustible utilisé avec

l'appareil converti, la pression de gaz dont on dispose

sur les lieux et l'altitude des lieux.

«Laconversiondoitêtreeffectuéeparun2.

représentant autorisé du fabricant, conformément

aux exigences du fabricant ainsi que des autorités

provincialesouterritorialesayantjuridiction.»

Les ensembles de conversion haute altitude3.

comprennent une plaque signalétique haute altitude

portantdesdonnéesestampillées,lesajutagesoule

brûleur nécessaires selon les besoins, ainsi que des

instructions d'installation supplémentaires.

Au Canada, les installations d'appareils de chauffage4.

à haute altitude doivent être conformes aux

dispositions pertinentes concernant la construction

qui sont données par la version en vigueur de la

normeCAN1-2.17surlesappareilsàgazpour

utilisation à haute altitude.

CONDUITE DE GAZ

RIGIDE OU FLEXIBLE

VERS L'APPAREIL DE

CHAUFFAGE

RACCORD DE

CONDUITE

13 Guide d'utilisation et instructions de fonctionnementEnerco Group, Inc. | Appareils de chauffage à gaz infrarouge

MÉTHODE DE SUSPENSION SUGGÉRÉE

MODÈLE : 4000, 8000, 9000, MH40

FIXATION TYPE À UNE POUTRE

FIGURE 4

PLAFOND

CÔTÉ

MUR

PLANCHER

FIXATION HORIZONTALE

ARRIÈRE

CONSULTEZ LES INSTRUCTIONS D'INSTALLATION POUR OBTENIR

DES RENSEIGNEMENTS DÉTAILLÉS SUR LES DISTANCES DE SÉCURITÉ

DISTANCES DES MATÉRIAUX COMBUSTIBLES

DESSOUS

DESSUS

COLLIER DE

POUTRE

TIGE FILETÉE

LORS D'UNE FIXATION EN ANGLE,

ÉLEVEZ SEULEMENT LE CÔTÉ DÉSI-

GNÉ DE L'APPAREIL DE CHAUFFAGE

FIGURE 5

CORNIÈRE

VOIR L'ENSEM-

BLEDECHAÎNE

Nº 17374 OU LA

TIGE FILETÉE

DEPUIS LE

MAXIMUM

HORIZONTAL

45 °

FIXATION MURALE TYPE

LE RÉFLECTEUR DU CÔTÉ APPAREIL

DE CHAUFFAGE DOIT ÊTRE

PARALLÈLE AU PLANCHER

FIXATION

VOIRL'ENSEMBLE

DECHAÎNE

Nº 17374

OU TIGE

FILETÉE

F114581 ENSEMBLE DE

FERRURE DE SUSPENSION

F114581 ENSEMBLE

DE FERRURE DE

SUSPENSION

OU ENSEMBLE

DECHAÎNE

17374

IL EST RECOMMAN-

DÉ D'UTILISER LA

FERRURE DE SUSPEN-

SION D'APPAREIL DE

CHAUFFAGE F114581

This manual suits for next models

3

Table of contents

Other ENERCORP Electric Heater manuals

Popular Electric Heater manuals by other brands

DeLonghi

DeLonghi ELECTRIC CONVECTOR HEATER Instructions for use

Nufer Medical

Nufer Medical CERATHERM 600-3 instruction manual

DELTACALOR

DELTACALOR VALET Operation and installation manual

Valor Fires

Valor Fires 823 Installer and owner guide

LG

LG LKAEH052 installation instructions

Wärme

Wärme ZC-02 Installation and operating instructions