Table of contents

CONDITIONS FOR SAFE AND RELIABLE OPERATION............................................................................................. 4

CHARACTERISTICS OF PRESSURE EQUIPMENT..................................................................................................... 5

Tank construction 200 ZC-02................................................................................................................................ 6

Tank dimensions 200 ZC-02.................................................................................................................................. 7

Construction TankA 250 ZC-025........................................................................................................................... 8

Tank dimensions 250 ZC-025................................................................................................................................ 9

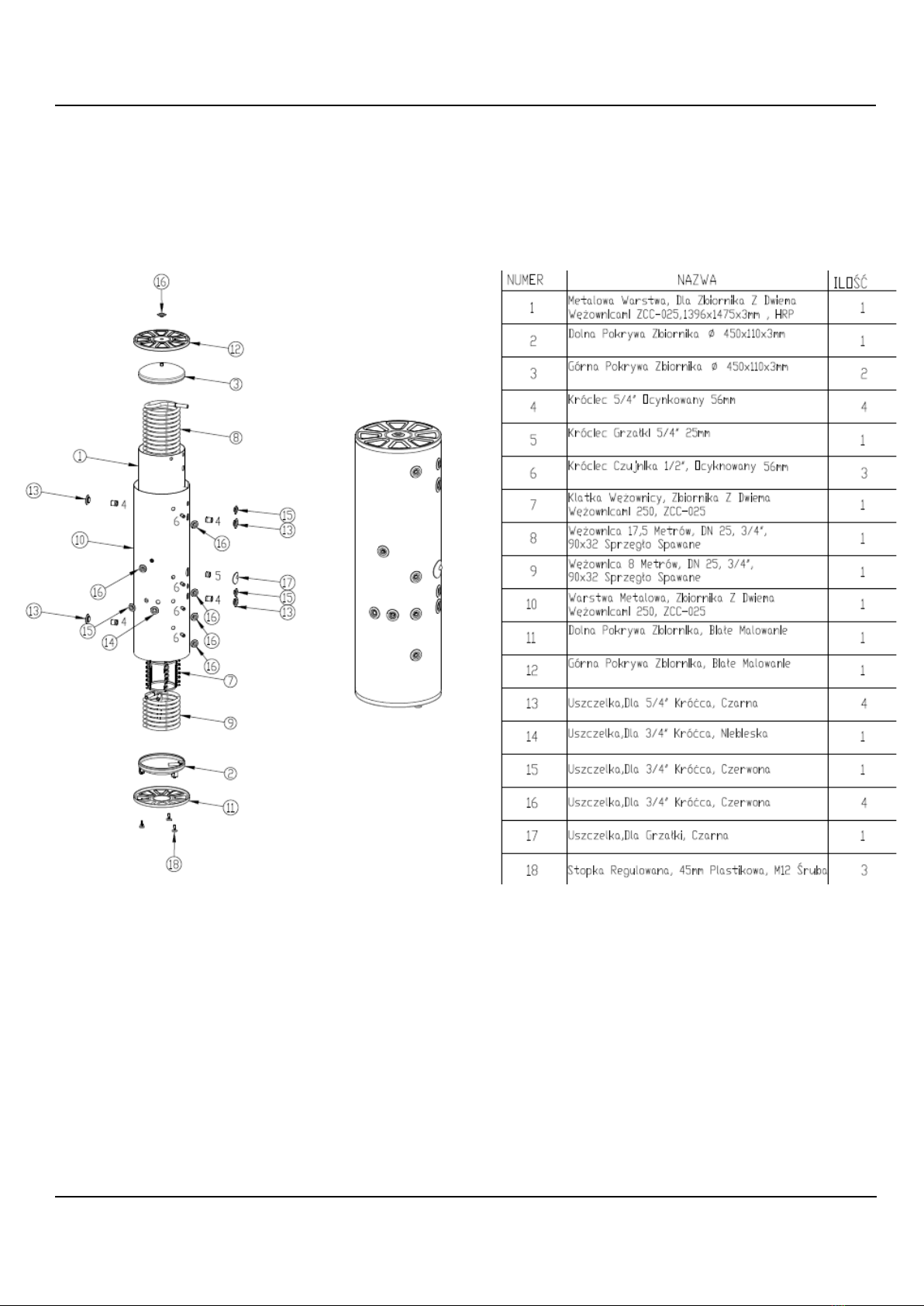

Construction of tank 250 with two coils ZCC-0 25 ............................................................................................. 10

Tank dimensions 250 with two coils ZCC-025 .................................................................................................... 11

Tank construction 500 ZC-05.............................................................................................................................. 12

Tank dimensions 500 ZC-05................................................................................................................................ 13

Tank dimensions 500 with two coils ZCC-05 ...................................................................................................... 14

Construction of Tank 500 with two coils ZCC-05................................................................................................ 15

Dimensions and construction of the tank 1000 ZC-10....................................................................................... 16

CONNECTION TO THE PLUMBING SYSTEM ........................................................................................................ 17

CONNECTION TO CENTRAL HEATING AND PLUMBING...................................................................................... 18

RUN..................................................................................................................................................................... 19

TANK EMPTYING................................................................................................................................................. 19

OPERATION......................................................................................................................................................... 20

TECHNICAL SPECIFICATIONS............................................................................................................................... 20

WHAT TO DO IN CASE OF DAMAGE OR IRREGULARITIES

....................................................................................... 21

RECYCLING AND DISPOSAL OF WASTE

.................................................................................................................. 21

DECOMMISSIONING........................................................................................................................................... 21