Energie SOLAR BOX Operating manual

TECHNICAL MANUAL SOLAR BOX

1

USER AND INSTALLATION

EN

SOLAR BOX

Directives:

2014/35/UE

2014/30/UE

Revision:1

Date: 11/10/2021

TECHNICAL MANUAL SOLAR BOX

3

Esteemed Client,

We would like to thank you for your choice when you acquired an equipment for

sanitary water heating.

The thermodynamic solar system Solar Box will surely meet all your expectations

and provide many years of comfort with maximum power saving.

Our organization dedicates much time, energy and economic resources in order

to develop innovations that will promote power saving in our products.

Your choice has demonstrated your good sense and concern with pow-

er consumption, a matter that affects the environment.

We have taken on a permanent commitment to conceive innovative and efficient

products so that this rational use of energy can actively contribute to the

preservation of the environment and natural resources of the planet.

Keep this manual whose objective is to inform, alert and advise about the use and

maintenance of this equipment.

Our services are always at your disposal. Feel free to call upon us!

TECHNICAL MANUAL SOLAR BOX

4

INDEX

1. SYMBOLS...........................................................................................................................5

2. PRE- INSTALLATION ....................................................................................................5

3. SAFETY ..............................................................................................................................5

4. OPERATING PRINCIPLE ..............................................................................................6

5. COMPONENTS.................................................................................................................6

6. TECHNICAL FEATURES ...............................................................................................7

7. ASSEMBLY SCHEME......................................................................................................7

8. ASSEMBLY SCHEME......................................................................................................8

8.1 Thermodynamic solar panel................................................................................8

8.2 Solar Box....................................................................................................................8

9. PLACING EQUIPMENT..................................................................................................8

9.1 Thermodynamic solar panel................................................................................8

9.2 Fixing Solar Box on horizontal surface .........................................................10

9.3 Refrigerant connections – Thermodynamic panel (1 panel) ..................10

9.4 Refrigerant connections – Thermodynamic panel (2 panels) ............... 12

9.5 Refrigerant connections – Solar Box.............................................................. 13

10. NITROGEN LOADING.............................................................................................. 14

11. VACUUM ...................................................................................................................... 14

12. WATER QUALITY ..................................................................................................... 15

13. HYDRAULIC CONNECTIONS................................................................................ 15

13.1 Vented installation................................................................................................ 16

13.2 Tank with two connections ............................................................................... 16

13.3 Tank with more than two connections.......................................................... 17

13.4 Tank with backup connections ........................................................................ 17

14. FILTER .......................................................................................................................... 18

15. AIR PURGE.................................................................................................................. 18

16. ELECTRICAL CONNECTIONS .............................................................................. 19

17. ELECTRONIC CONTROLLER............................................................................... 20

18. INSTALLER MENU ................................................................................................... 22

19. WIRING DIAGRAM.................................................................................................. 23

20. TROUBLE SHOOTING ............................................................................................ 23

21. ERRORS ...................................................................................................................... 25

22. WARRANTY............................................................................................................... 26

TECHNICAL MANUAL SOLAR BOX

5

1. SYMBOLS

WARNING

The entire process the supplier believes may imply danger of personal injury

and/or material damage shall be marked with a DANGER SIGN.

As a means of further classifying the danger, the symbol will be accompanied by

one of the following words:

•

DANGER: when the operator and/or people in the vicinity of the

equipment are subject to personal injury.

• WARNING: when the equipment and/or nearby materials are subject to

material damage.

INFO

All the information the supplier believes may contribute to the enhanced

performance and conservation of the equipment shall be marked with the

information sign.

2. PRE- INSTALLATION

WARNING

•The electrical installation of the equipment should comply with national

regulations on electrical installations in force.

•Solar Box will only work after receiving the respective cooling load.

•The maximum admissible water pressure at the input to the hydraulic

circuit is 300 kPa.

•Electrical power: 230V, 50 Hz

•

If the power cable is damaged, it should be replaced by the

manufacturer, the post-sales service or similar qualified personnel in

order to avoid danger.

•Solar Box will only work if the tank has been filled with water.

•This appliance should not be used by persons (including children) with

physical, sensorial or mental disabilities, or with a lack of experience or

expertise, unless supervised by someone liable for their safety, or in the

event the same have been trained in relation to how the equipment

works.

3. SAFETY

The installer should notify the customer of how the equipment works, the inherent dangers, and

the rights and obligations of the customer.

•The installation of thermodynamic equipment geared to heating sanitary water should

be performed by personnel who are qualified and skilled in relation to the same;

•The appliance should not be installed in locations subject to the risk of impact or ex-

plosion;

•Keep the equipment in its packaging until the time of installation;

•Ensure all hydraulic connections are duly watertight prior to turning on the electrical

power;

•The gas used in the entire process is R134a, free of CFCs, noninflammable and harmless

to the ozone layer. Thus, the gas present when this equipment is used may not be re-

leased into the atmosphere by law.

•The gas present when this equipment is used should be handled by a qualified techni-

cian.

TECHNICAL MANUAL SOLAR BOX

6

•Maintenance of the equipment should be carried out by the support service, performing

the general and continuous cleaning operations, which may/should be executed by the

users themselves;

•The electrical power of the equipment should always be turned off during maintenance

operations;

•The supplier recommends the equipment be inspected at least once a year by a qualified

technician;

•The operating principles of this equipment are directly associated with high

temperatures and pressures, thus all the processes involved with the equipment should

be designed to avoid the risk of burns and explosion.

4. OPERATING PRINCIPLE

The Solar Box Thermodynamic Solar System is a piece of equipment based on the principle of

cooling by compression – the Carnot principle – which we have named Thermodynamic Solar

Systems: Solar Panel and a Heat Pump. The solar panel, which is the main component, placed

outdoors, ensures the capture of energy from:

•Direct and diffuse solar radiation;

•Outdoor air, via natural convection;

•The effect of the wind (almost always existent);

•Rainwater.

The temperature difference caused by the aforementioned external agents ensures the

refrigerant fluid evaporates inside the solar panel.

The absence of glass in the panel ensures increased heat exchange via convection.

After passing through the panel, the refrigerant fluid is sucked in by the mechanical com- ponent

of the system, the compressor, raising the temperature and pressure of the same; which in turn

is transferred to the water circuit by means of the panel heat exchanger.

Before the refrigerant fluid returns to the solar panel the pressure needs to be reduced to

guarantee it attains its liquid state once again, there by completing the cycle.

The ease with which we combine technology and the laws of nature (alteration of the state of a

fluid), demonstrates the veracity and potential of Solar Box.

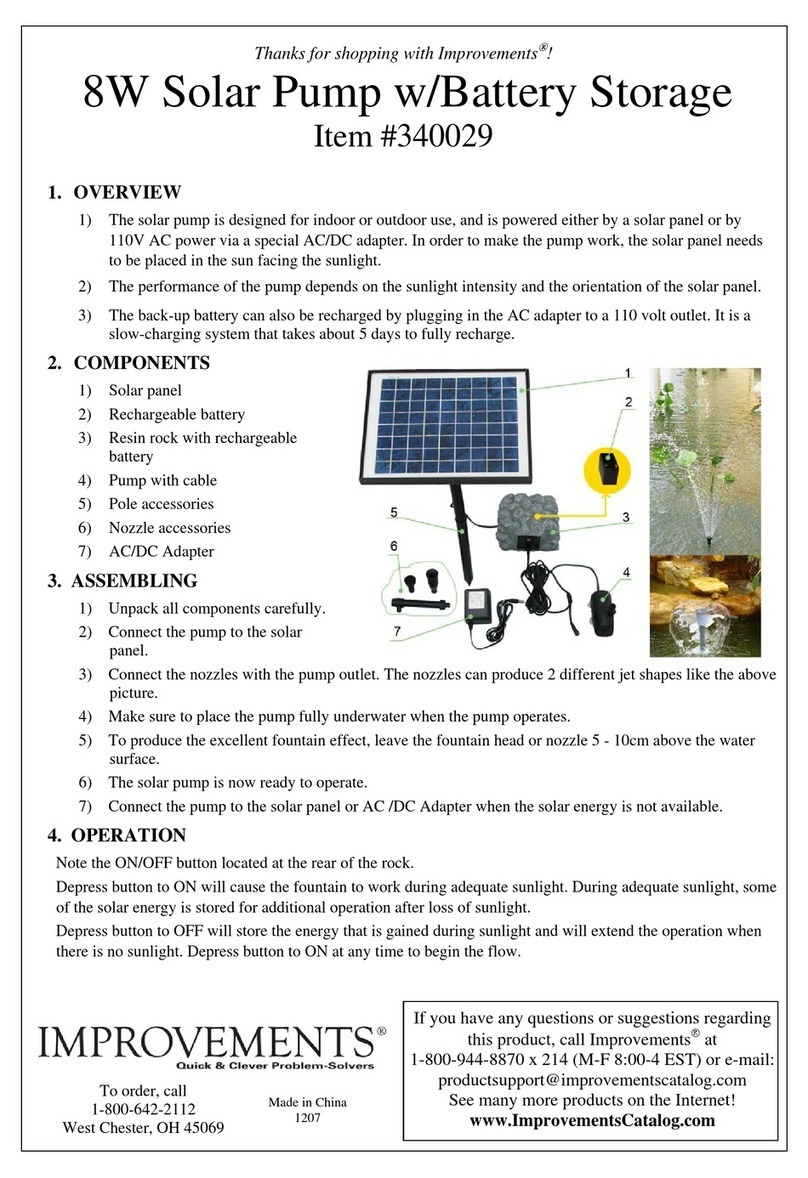

5. COMPONENTS

•Thermodynamic Solar Panel

•1 SolarBox

•4 Silent block M6

•1 “Y” filter

•Solar Box setting 4 Screw + 4 rawlplug

•6 brackets + 10 screws M6.3x40 + 10 plugs ø8+ 6 screws M6x20 + 6 nut M6 + 12 washers

M6

TECHNICAL MANUAL SOLAR BOX

7

6. TECHNICAL FEATURES

Solar Box

Unit

1 Panel

2 Panels

Thermal power supplied (med-max)

W

1690 - 2900

2800 - 4550

Power absorbed (med-max)

W

390 - 550

595 - 890

Electrical power

V/HZ

230/50

Operating temperature

°C

-2 to 42

Cooling fluid / Load

-/Kg

R134a / 0,8

R134a / 1,0

Maximum water temperature

°C

55

Maximum operating pressure (water)

bar

7

Weight

Kg

23,5

Size of the packaging (a x l x p)

-

470 x 400 x 400

Hydraulic connections (input|output)

Inches

1/2” | 1/2”

Refrigerant connections (input|output)

Inches

3/8” | 1/4”

1/2” | 3/8”

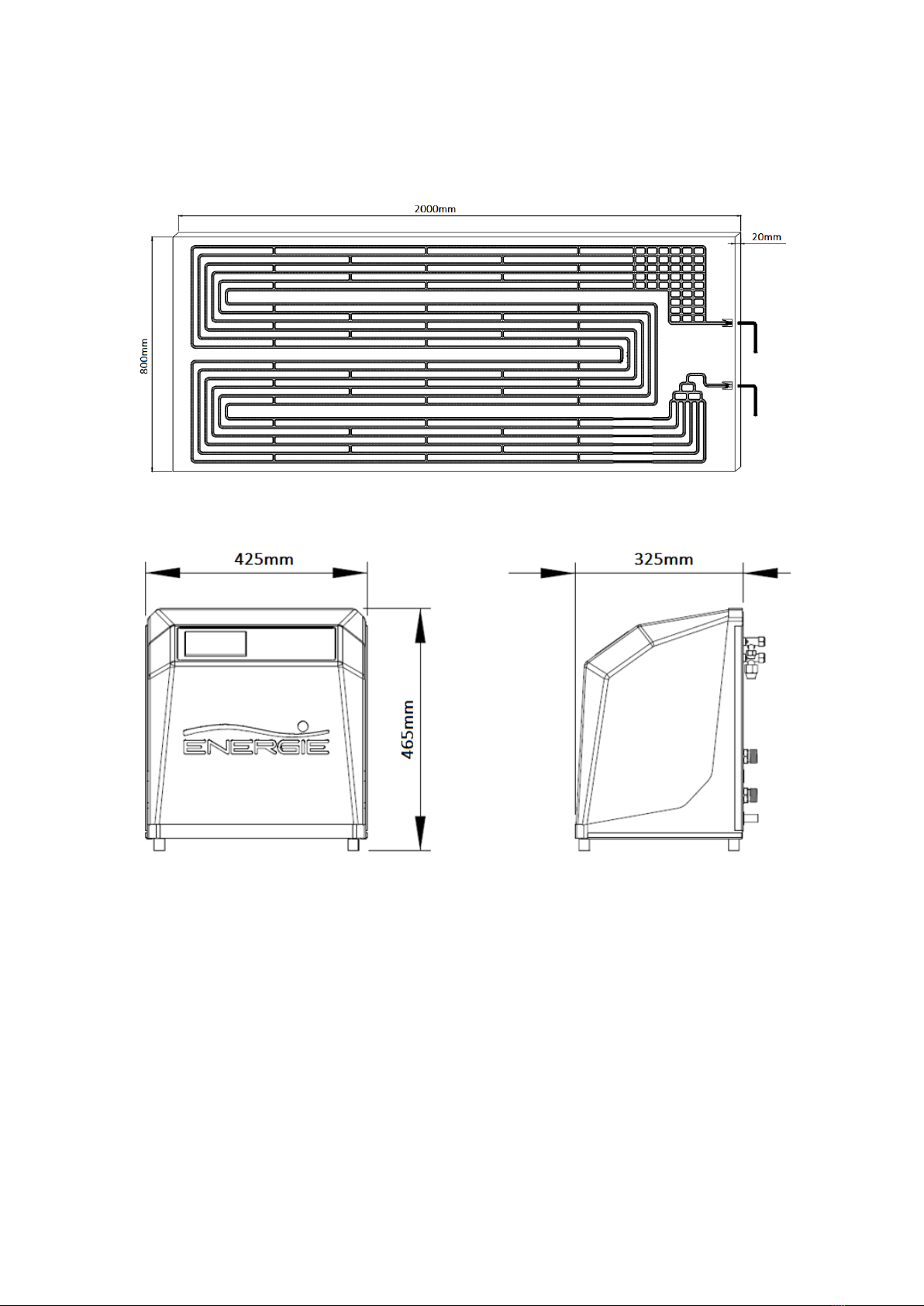

Thermodynamic Solar Panel

Weight

Kg

8

(2x) 8

Size of the packaging (a x l x p)

-

2000 x 800 x 20

(2x) 2000 x 800 x 20

Refrigerant fluid connections (in | Out)

Pol.

1/4” | 3/8”

Tank Requirements

Maximum Tank Capacity

lts

300

Minimum Coil Area (when using back-

up connections)

m2 1,5

7. ASSEMBLY SCHEME

1

Thermodynamic solar panel

4

Suction line

2

SolarBox

5

Liquid line

3

Cylinder

6

Temperature probe

TECHNICAL MANUAL SOLAR BOX

8

8. ASSEMBLY SCHEME

8.1 Thermodynamic solar panel

8.2 Solar Box

9. PLACING EQUIPMENT

9.1 Thermodynamic solar panel

The location and the angle at which the panels are installed must be taken into

account. In order to take full advantage of the solar radiation in question, the

panels should be set at an angle of between 10° - 85° to the ground, and

preferably pointing south.

The panel comes with six M8 holes on the side flaps. The distance between the

holes at the location where the panel is to be placed should coincide with the

holes in the panel.

TECHNICAL MANUAL SOLAR BOX

9

The panel has 3 small profiles (side A) and 3 large profiles (side B) which shall

be fixed according stipulations in the diagram, giving the panel the desired

level of inclination.

The profile shall be fixed to a base (e.g. a roof) via the provided plastic wall plugs and the self-

tapping M6 screws. The M6 screws and the respective nuts and washers shall make the panel

fixing to the profiles.

Panel profile fixing process

1

Aluminum profile

2 Plastic wall plug

3

Self-tapping screw (M6x40)

4

Washer M6

5

Screw (M6x20)

6

Nut M6

7

Panel

TECHNICAL MANUAL SOLAR BOX

10

The solar panel shall always be installed with the connections facing downwards.

The right or left panel shall always be installed horizontally, not vertically.

A – Panel input | B – Panel Output

WARNING

The panel should always be installed downwards, with the connections facing

down and shall be installed horizontally

9.2 Fixing Solar Box on horizontal surface

9.3 Refrigerant connections – Thermodynamic panel (1 panel)

WARNING

The refrigerant connections should be dealt with by a qualified technician holder

of a professional skills certificate for the purpose.

INFO

The thermodynamic unit holds a pre-load of R134a fluid.

WARNING

The refrigerant connections should be thermally insulated in order to avoid

burns and to ensure the maximum performance of the equipment.

•A lay the structure on a level and stable surface,

checking the four anti-vibratory brackets have

been duly mounted;

•Remove the half holes from the rear of the

structure by twisting the metal part you wish to

remove;

•Secure the connections on the rear of the structure.

TECHNICAL MANUAL SOLAR BOX

11

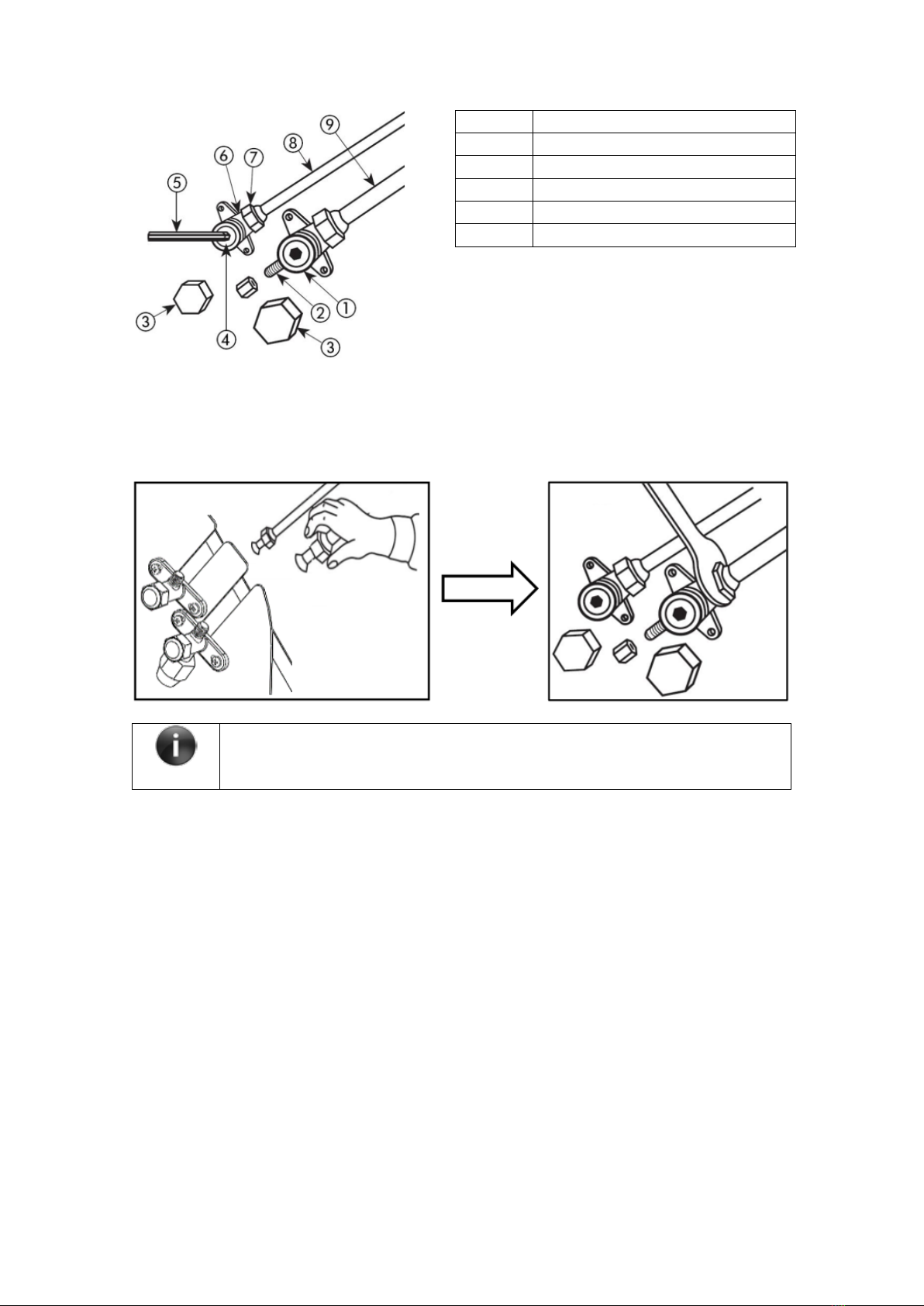

Pipe diameter

Number of panels

Vapour

(Suction line)

Liquid

(Line to the panel)

1 3/8’’ (9,52mm) 1/4’’ (6,35mm)

2 1/2’’ (12,7mm) 3/8’’ (9,52mm)

a) Prepare the copper pipe, removing the protective caps from the ends;

b) Place the end of the pipe face-down, cut the pipe at the desired distance and clean any

frayed edges;

c) Remove the nuts from the connections and place them on the side of the pipe;

d) Flange the pipe with an appropriate tool, forming a cone, ensuring there are no frayed

edges or imperfections and the lengths of the walls are the same;

e) Tighten the nut a few turns with your hand, and then execute the final tightening by

twisting in accordance with the values illustrated in the table.

INFO

TECHNICAL MANUAL SOLAR BOX

12

Pipe Diameter (inch) Applied Torque (Nm) Wrench nº

1/4” 14 a 16 19

3/8” 33 a 42 21

9.4 Refrigerant connections – Thermodynamic panel (2 panels)

Remove the protecting caps from the ends of the copper piping.

Place the end of the tube so that it is pointing downwards, cutting the pipe at the intended point,

making sure to clean off any burrs (e.g. with a reamer).

Next, remove the covers from the panel connections, and with the aid of a cutting tool such as

a penknife, remove 5 cm of the thermo-retractable sleeve.

A 3/8” piping expansion area must be made, with the aid of an appropriate tool, for proper

connection to the panel.

Line up the liquid and suction tubes, but before commencing the welding operation, make sure

to protect the thermo-retractable sleeve by using a damp cloth.

The type of solder recommended for welding the pipes is type oxyacetylene

(Oxygen/Acetylene). Other types of gases can also be used, such as propane for example.

After carrying out the panel connection welding operations, but before installing the

Thermodynamic Block, make sure the apparatus has been cleaned with nitrogen.

For installations with two or more panels, it is essential that the fluid is homogeneously

distributed (panel entry). The equipment already comes installed with a liquid distributor so that

this process can be accurately put into effect.

Removal of thermo-retractable

sleeve

Piping expansion (3/8”)

TECHNICAL MANUAL SOLAR BOX

13

This distributor is placed between the two panels. The panel connecting pipes (1/4”) must be

exactly the same length, their extremities connecting directly to the panels.

Liquid distributor (liquid line)

The same level of pipe symmetry exactness is not required in relation to the suction

connections (Panel exit). This must be done by “denting” or with a “T” connection (in

accordance with the following image), being properly insulated.

Suction line

9.5 Refrigerant connections – Solar Box

Some of the steps involved here are exactly the same as the procedures followed to connect the

panel.

•Cut the pipe at the desired point with the end facing down. Clean any frayed edges.

•Flange the pipe not forgetting to place the nut on the side of the pipe.

Legenda:

1

3-way valve

2

Pressure tap

3

Valve sleeve

Liquid distributor

TECHNICAL MANUAL SOLAR BOX

14

•Tighten the nut a few turns with your hand and then use an appropriate spanner to fully

tighten the same as described above

INFO

ALL THE PIPES SHOULD BE INSULATED!

10. NITROGEN LOADING

Once the connections have been concluded the user needs to check there are

no leaks. To this end, a load of nitrogen at a pressure of 10 bar should be

injected via the pressure tap (3-way valve).

Cover all the connections in soap foam and check if the pressure on the gauges is constant.

11.VACUUM

a) Always use connections, vacuum pump and gauges duly adapted for R134a fluid;

b) Only use a vacuum pump to remove the air and moisture existing in the pipe;

c) Never use the system refrigerant to purge the pipes;

d) Keep the stop valves completely closed;

e) Connect the hose from the vacuum pump to the 3-way valve;

f) Create a vacuum with the pump connected to the pressure tap to the 3-way valve (for

4

Valve needle

5

Hexagonal spanner

6

2-way valve

7

Conical nut

8

Liquid line

9

Gas line

TECHNICAL MANUAL SOLAR BOX

15

30 minutes);

g) Once the vacuum process has been concluded (30 minutes), turn off the pump and the

gauge should always display the same value;

h) Turn off the gauge taps;

i) After this vacuum process has been concluded, the two valves should be opened to

enable the coolant to circulate throughout the system.

INFO

After creating the vacuum, do not remove the hoses until the system has been

fully pressurized by the coolant.

After creating the vacuum, do not remove the hoses until the system has been

fully pressurized by the coolant.

12.WATER QUALITY

INFO

The water you use may contain impurities and/or substances damaging to the system and

even harmful to your health. Make sure you use water with quality fitting for home

consumption. The following table indicates some parameters according to which water must

be subjected to chemical treatment.

Hardness (ºdH)

pH

Treatment

3,0 to 20,0

6,5 to 8,5

NO

3,0 to 20,0

<6,5 or >8,5

YES

<3,0 or >20,0

YES

13.HYDRAULIC CONNECTIONS

To assemble the couplings of the hydraulic circuit you must:

a) Connect the water inlet and outlet of the equipment with tubing or joints capable of

supporting a combined temperature/pressure of a constant 75°C / 7 bar. For such we

recommend the use of tubing which is resistant to high temperatures and pressures, such as

PEX, PPR, among others.

b) A safety valve needs to be installed at the cold water line of the equipment. The safety

device should comply with standard EN 1487:2002, discharge pressure of 7 bar (0.7 MPa).

c) In addition to this device other components need to be installed to guarantee the

interruption of the hydraulic load, in the following order:

• One way valve

• Pressure reducing valve (3 bar)

• Safety discharge group

• Expansion vessel

The safety discharge group should be connected by tubing with a diameter which is never less

TECHNICAL MANUAL SOLAR BOX

16

than the cold water inflow connection.

The part of the exhaust should be connected to an interceptor, or, in the event this is inviable,

raised at least 20mm above the floor to allow for visual inspection.

All the above recommendations are to guarantee the safety of people, animals and others. Solar

Box may be installed in tanks with two or more connections.

The diagrams below illustrate types of connection to a tank:

13.1 Vented installation

13.2 Tank with two connections

TECHNICAL MANUAL SOLAR BOX

17

13.3 Tank with more than two connections

13.4 Tank with backup connections

TECHNICAL MANUAL SOLAR BOX

18

Legend

1

Open/closed Valve

7

Drain

2

Non return Valve

A

Mains Water

3

Pressure Reducing Valve

B

Hot Water Outlet

4

Security Group

C

Solar Box

5

Expansion Vessel

D

Thermodynamic Panel

6

Filter

S1

Temperature Probe

14.FILTER

The filter allows block any impurities present in the hydraulic circuits. Residue left in the heater

pipes will damage the heat exchangers and cause the Solar Box to malfunction. It is

recommended install the filter in the heater return line. It is indispensable in order to prevent

serious damage to the heat exchanger.

15.AIR PURGE

After doing the correct installation of the system, the installer must purge all the hydraulic circuit

before turning on the Solar Box.

a) Ensure that the valve 1a is closed;

WARNING

The equipment is supplied with a “y” filter placed

on the Solar

Box hydraulic return line, at the

entrance of the heat exchanger.

TECHNICAL MANUAL SOLAR BOX

19

b) Close de valve 1b;

c) Open the purge valve inside the Solar Box;

d) Open the discharge valve (drain) 7;

e) Open valve 1a;

f) Close the bleed valve inside the Solar Box (only when there is water with no bubbles

leaving the valve);

g) Close the valve 1c (only when there is water with no bubbles leaving the valve);

h) Open the valve 1b;

i) Turn-on the Solar Box;

16.ELECTRICAL CONNECTIONS

Check the following conditions before implementing the electrical connections:

a) The thermodynamic equipment should only be powered electrically after the tank has

been filled.

b) The thermodynamic equipment should be connected to monophasic voltage (230 VAC /

50 or 60Hz).

c) Connections should always comply with the installation regulations in force in the

country in which the thermodynamic equipment is installed.

d) The equipment must be connected to an electrical grounded socket.

NOTE: The Solar Box equipment have a relay to allow the connection of a backup electric

resistance with maximum power of 3kW.

TECHNICAL MANUAL SOLAR BOX

20

17.ELECTRONIC CONTROLLER

CODE CONNECTO

RS

DEVICE CHARACTERISTICS

INPUTS

S1

S1

Water Probe

Sensor NTC10K@25°C, functioning

temperature 0÷120°C, Reading Range

0÷99°C

LP LP Low Pressure

Contact

Contact Open/Closed

HP

11

High Pressure

Contact

Contact Open/Closed

12

OUTPUTS

3

N

Pump Power 230 Vac Max 3A

230Vac

4

FON

5

N

Electrical

Heater

Power 230 Vac Max 3A

230Vac

6

FOFF

7

FON

8

COM

Compressor

Free contact Max 8A

230Vac

9

N.C.

10

N.O.

LINE

1

F

Input Line 230 Vac +/-10% 50 Hz;

Protection Fuse T3,15 A

2

N

Absorbed Power:

2VA

Applied rules:

EN 60730-1 50081-1 EN 60730-1 A1 50081-2

1 – ON/OFF

The ON/OFF of the controller is performed by the extended pressure of the button K4

•The OFF state is signaled by OFF of the display and all leds;

•

The ON state is signaled by the led L9 ON.

2 – START/STOP operations in ON state

•Fill the tank with water and expel any existing air, opening a hot water tap;

•The START/STOP of the operations is through the extended pressure of the button K3

(CP);

•

The STOP is signaled by the led L9 blinking.

Table of contents

Other Energie Solar Panel manuals