En-Eco Enecom HF20-5-16 User manual

MANUAL ISSUED BY:

Headquarters

ENECOM s.r.l.

Via Odorico da Pordenone, 28

FLORENCE - Italy

Version:

Title Version Date

MODULES HF - Instruction Manual 2 10/2017

CONTENTS

Introduction 2

The manual 2

The HF photovoltaic module 3

Front surface 3

Back surface 4

Identification 5

Technical specifications 6

Instructions for use 8

Installation 9

General rules for installation 9

Orientation 9

Mounting 10

Electrical connections 11

Maintenance 15

Warranty 16

Contacts 16

2

INTRODUCTION

This manual provides an overview of Enecom HF photovoltaic modules and their use. It

covers the following Enecom modules:

Module Code Description

HF20-5-16 Flexible m-si module: 620 mm × 292 mm

HFp20-5-16 Pliable flexible m-Si module: 320 mm × 280 mm (closed)

HF40-5-16 Flexible m-Si module: 604 mm × 536 mm

HFp40-5-16 Pliable flexible m-Si module: 560 mm × 280 mm (closed)

HFs40-5-16 Flexible m-Si module: 1120 mm × 282 mm

HF65-6-16 Flexible m-Si module: 728 mm × 660 mm

HFs65-6-16 Flexible m-Si module: 1370 mm × 344 mm

HF80-5-16 Flexible m-Si module: 1104 mm × 536 mm

HF90-5-18 Flexible m-Si module: 1230 mm × 536 mm

HF135-6-16 Flexible m-Si module: 1350 mm × 660 mm

HFpy120-6-16 Flexible p-Si module: 1350 mm × 660 mm

HFsp 90-5-16 Flexible m-Si module: 970mm × 536 mm

HFsp120-5-21 Flexible m-Si module: 1250mm × 536 mm

This manual also applies to modules which have been custom designed to the

customer’s specifications.

3

THE HF PHOTOVOLTAIC MODULE

Introduction

A photovoltaic module is a device that converts solar energy into electrical energy, thanks to

the presence of silicon cells within which the physical phenomenon known as the

“photovoltaic effect” takes place. The greater is the number of silicon cells in the photovoltaic

module, the more electrical energy is produced.

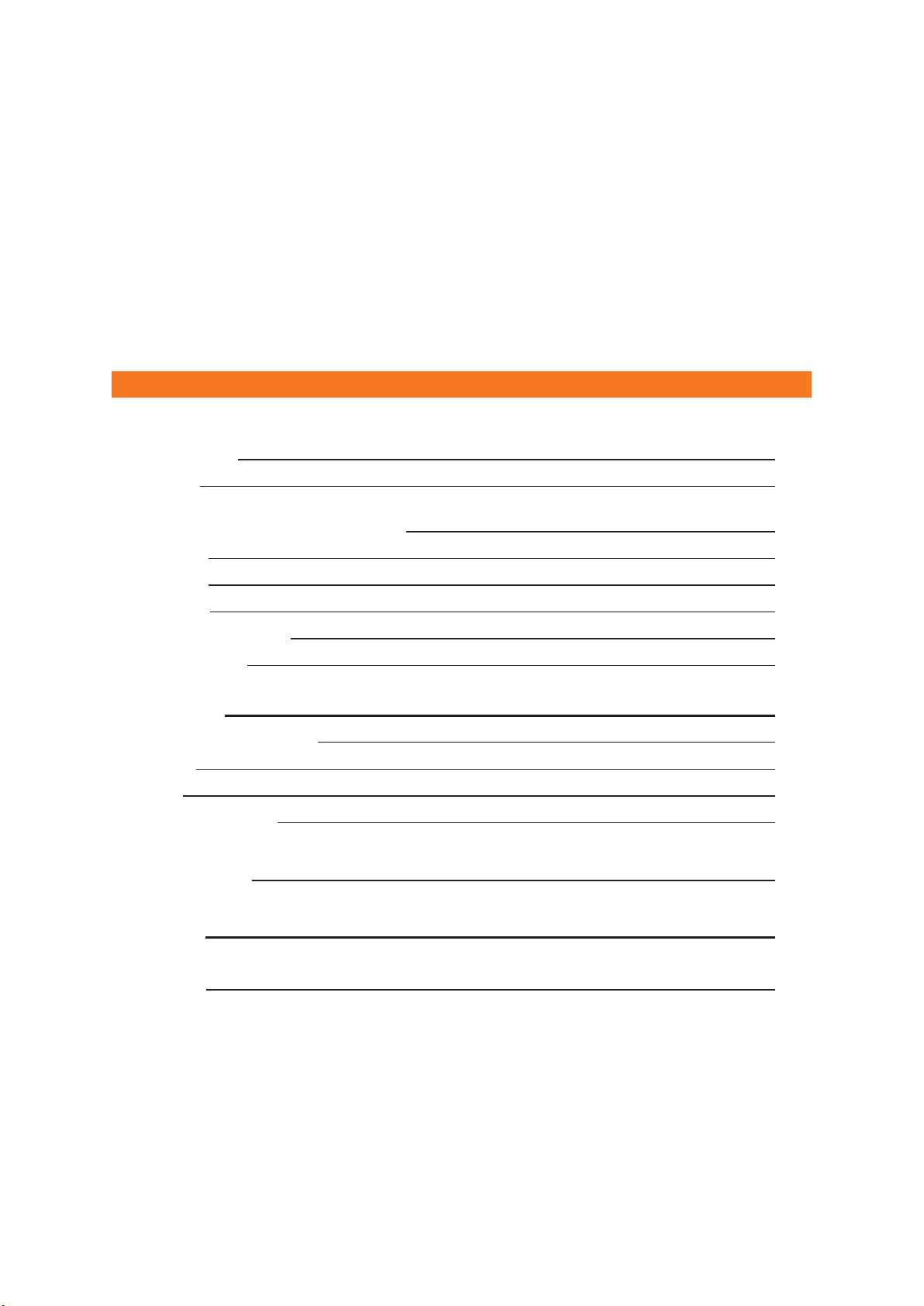

The front surface of the photovoltaic module

The front surface of the module must be exposed to direct sunlight.

Connectors

Cables

Junction box

Cells

The junction box, at the request of the customer, can be placed on the back surface.

4

Back surface of the photovoltaic module

Bipolar cable

Connector

Junction box

Cells

In HFp modules the junction box is positioned on the back surface.

In HF and HFs modules the back surface of the module has no components; it provides only the

identification label bearing the serial number of the module and the electrical data plate

(unless the junction box has been positioned on the back surface, in which case the junction

box will also be present).

Serial number and

module data

5

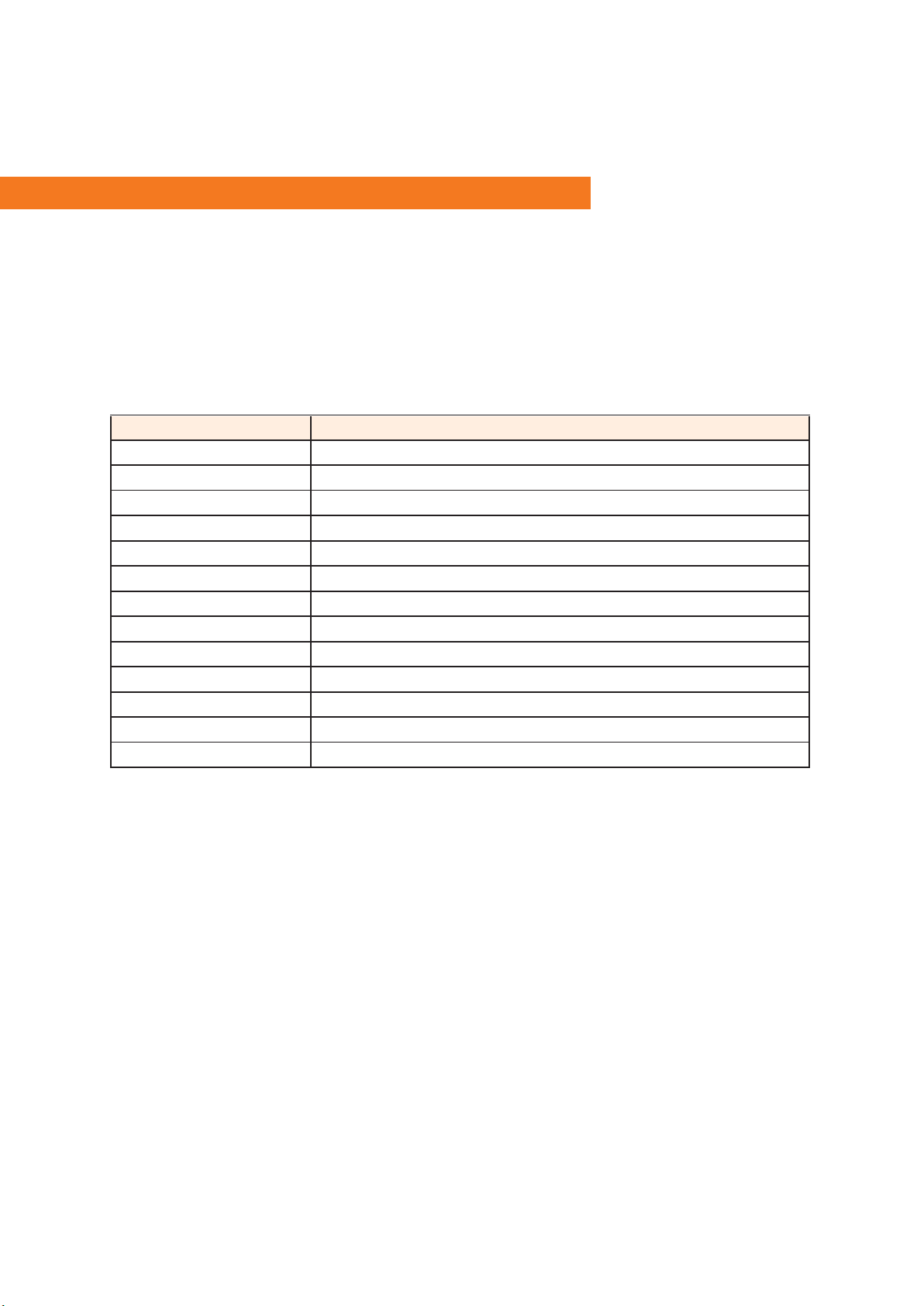

Identification

Every Enecom module is identified by a label on the back surface with the following

information.

ENECOM s.r.l. gruppo EN-ECO S.p.A.

Via Emilia, 6 10099 San Mauro Torinese (TO) - ITALY 1. Panel type

2. Serial number of the

module,year and place

of production (SMT =

San Mauro Torinese, MM

=Montemurlo)

3. Date of production

4. Maximum power

5. Open circuit voltage

6. Short circuit voltage

7. Voltage at maximum

power

8. Current at maximum

power

9. Maximum system

voltage

10. Nominal power

measured at Standard

Test Conditions (STC)

Do not remove or tamper with the label.

MODULE TYPE:

1)

Serial Number

2)

Data produzione

3) gg/mm/aa

Maximum power (Pmax)

4)

Wp

Open circuit voltage (Vca)

5)

V

Short circuit current (Isc)

6)

A

Voltage at max power (Vmp)

7)

V

Current at max power (Imp)

8)

A

Maximum system voltage

9)

V

10) Nominal power misured at standard test condition (STC):

l = 1000 W/m² Tamb = 25°C AM = 1.5

6

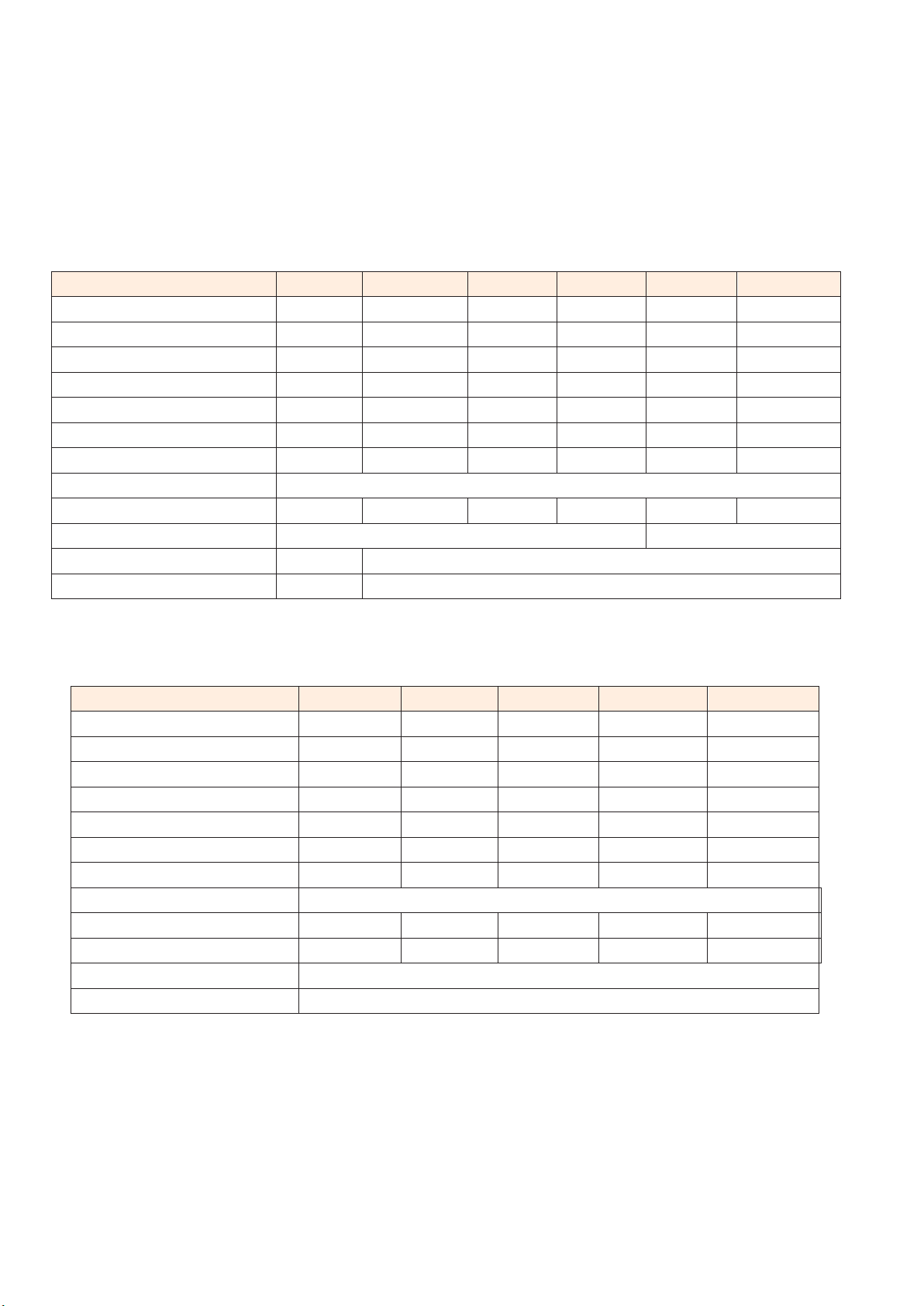

Technical specifications

Technical specifications of the HF line

HF20-5-16

HF40-6-16

HF80-5-16

HF90-5-18

HF65-6-16

HF 135-6-16

Max power Pmax(Wp) ± 3%

20

40

80

90

65

135

Open circuit voltage Voc (V)

19,63

19,63

19,63

22,42

20,2

20,2

Short circuit current Isc (A)

1,40

2,80

5,61

5,61

4,36

8,61

Voltage at Pmax Vmp (V)

16,23

16,23

16,23

18,54

16,4

16,4

Current at Pmax Imp (A)

1,33

2,65

5,31

5,15

4,07

8,14

Number of cells

32

32

32

36

32

32

Size (w x h) in mm

620 x 292

604 x 536

1104 x 536

1230 x 536

660x728

1351 x 660

Thickness in mm

1,8-2 mm

Weight (kg)

0,5

0,8

1,3

1,5

1,3

2,2

Cell efficiency

18,6%

18,6%

Output terminals

MC4 connectors

Maximum system voltage

600 V

Technical specifications of the HFs-HFsp-HFpy line

HFs40-5-16

HFs65-5-16

HFsp90-5-16

HFsp120-5-21

HFpy120-6-16

Maximum power Pmax(Wp)

40

65

90

120

120

Open circuit voltage Voc (V)

19,63

20,2

19,9

25,66

19,68

Short circuit current Isc (A)

2,80

4,36

6,01

6,01

8,56

Voltage at Pmax Vmp (V)

16,23

16,4

17,1

22,1

16,3

Current at Pmax Imp (A)

2,65

4,07

5,65

5,65

8,05

Number of cells

32

32

28

36

32

Size (w x h) in mm

1120 x 282

1370 x 344

977x536

1230x536

1350x660

Thickness in mm

1,8-2 mm

Weight (kg)

0,8

1,2

1,5

1,8

2,2

Cell efficiency

18,6%

18,6%

22,3 %

22,3%

17,8%

Output terminals

MC4 connectors

Maximum system voltage

600 V

7

Technical specifications of the HFp line

HFp20-5-16

HFp40-6-16

Maximum power Pmax(Wp) ± 3%

20

40

Open circuit voltage Voc (V)

19,63

19,63

Short circuit current Isc (A)

1,40

2,80

Voltage at Pmax Vmp (V)

16,23

16,23

Current at Pmax Imp (A)

1,33

2,65

Number of cells

32

32

Size (w x h) in mm

320 × 280 (closed)

560 x 280 (closed)

Thickness in mm

1,8-2 mm

Weight (kg)

0,6

0,9

Cell efficiency

18,6%

Output terminals

Cigarette lighter style socket / MC4 connectors

Maximum system voltage

600V

Technical specifications of the wired junction box

Junction Box Size

82 x 64 x 13 mm

Diode

one-two bypass diodes

IF

12 A

VDC

45V

Temperature range

-40 ÷ 80 °C

Protection class

IP67

Technical characteristics of the connectors

HF20-5-16

HFp20-5-16

HFp40-5-16

HF40-5-16

HFs40-5-16

HFs65-6-16

HF80-5-16

HF90-5-18

HF130-6-16

HF20-5-16

HFp20-5-16

HFp40-5-16

Connector type

Standard cigarette

lighter style socket

Standard MC4

Protection class

IP22

IP67

8

Warnings

Please read and follow these general instructions and warnings carefully; failure to comply with these

instructions will void the warranty.

•

Leave the photovoltaic module in the packaging until it is installed.

•

Check the physical integrity of the module before installation.

•

Contact with electrically active parts of the module can generate sparks and

electrical discharges at low voltage: please use caution.

•

The photovoltaic module produces electricity when the front part is exposed to

sunlight. Please use caution.

•

When modules are connected “in series” the voltage is cumulative, whereas

when connected “in parallel” the current is cumulative. For this reason, a system

with multiple modules connected to each other can produce high voltages and

currents that can be a source of danger and can cause serious injury or death.

Use caution.

•

The photovoltaic module must be handled with care, without excessive

bending. The minimum suggested curvature radius is 1meter, if lesser curvature

radius is needed contact the technical support that will provide you a response

about the feasibility of the installation.

•

Do not move the panel taking it by the connection cables.

•

Do not put localized pressure on the cells.

•

Avoid prolonged partial shade on the module.

•

Do not use the photovoltaic module for purposes other than those for which it

was designed and built.

•

Do not place the module near sources of heat.

•

Do not disassemble or modify the module components (junction box, cables

and connectors).

•

Do not pierce the module, even in areas that are far away from the cells.

•

Do not use paint on the front or the back.

•

Do not walk on the module.

•

Do not concentrate sunlight or artificial light sources on the module.

•

Do not short-circuit the module connectors (do not connect them together).

RISKS FROM MECHANICAL DAMAGE

9

INSTALLATION

General rules for installation

For correct installation of the photovoltaic module, it is necessary to follow these guidelines.

•

A photovoltaic module generates electricity when exposed to sunlight; it is

advisable to fully cover the surface of the front side with a dark opaque material

to block sunlight during installation or removal.

•

During operation, the module tends to heat up (because of both the effect of

solar radiation and the physical phenomenon of photovoltaic action). To improve

the performance of the module, it is therefore important to facilitate the dispersal

of heat. Fastening the module to thermally insulating materials is not

recommended because it would impede the dispersal of heat.

•

If the support chosen for the installation site is metallic (and therefore conducts

electricity), when installing, be careful to avoid any contact between the metallic

material and the electrical terminals of the module.

•

During installation, be careful to comply with safety regulations and general

instructions.

•

Installation should only be undertaken in dry conditions, keeping the photovoltaic

module and all tools dry and adequately insulated.

•

Do not install the photovoltaic module in the vicinity of flammable gases or vapors.

•

Choose an installation location which is exposed to direct sunlight as much as

possible; avoid shaded areas.

•

In the event that the cables need to be extended (e.g., to connect the module to

a charge regulator), the electrical conductor section of the extension cord should

be large enough to avoid excessive voltage drops with relative loss of power.

Orientation

In general the best energy performance of the module can be approximately obtained by

installing the device:

•

facing south;

•

at an inclination equal to the latitude from the horizontal.

Installing the module at non-optimal inclination and orientation lead to reduce the module’s

power output.

12

Mounting

The photovoltaic module can be mounted in the following ways:

•

mechanically with eyelets

•

bonding it using double sided adhesive

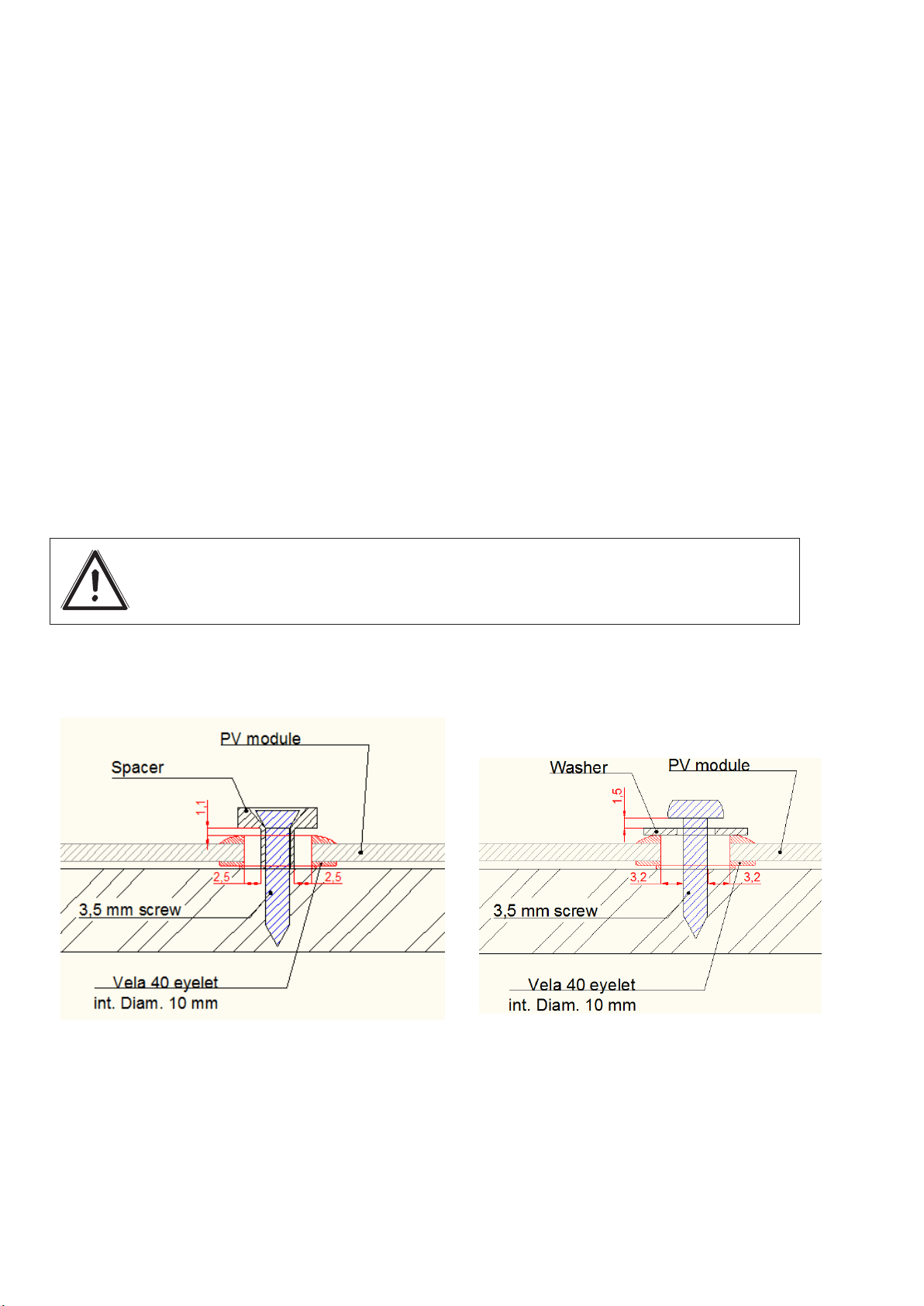

Mounting the panel by means of eyelets

Mounting by means of eyelets is performed using screw or bushing that leave space between

the eyelet and the screw or spacer used for the installation.

The space allows thermal dilation between the module and the fixing system and for a

correct installation this space has to be at least:

1 mm from the top of the eyelet and the fixing system.

2 mm from the internal diameter of the eyelet and the screw

See below an example of a mechanical fixing system using a washer or a spacer and a

screw:

During mounting, avoid applying pressure on the cells or overbidding the panel.

Eyebrow fixing is also suitable for support on non-rigid surfaces (awnings, camper verandas,

camping tents, etc.) using elastic or corded joints for example.

Block the module without leave space for thermal dilation void the guarantee

13

Bonding the panel using double sided adhesive

Bonding using double sided adhesive is indicated when the material of the module and that

of the surface, on which the panel has to be fixed, have similar thermal expansion

coefficients.

Enecom can provide the module with already attached to the back double sided adhesive

stripes or send to you the quantity you need for the installation.

You can fix the panel also with a kind of Velcro called Dual Lock. This system allows you to

remove the panel if necessary, but it is not recommended where high adherence is required.

The following instructions should be followed when using this method:

•

clean the installation surface thoroughly with isopropyl alcohol

•

make sure the surfaces are completely dry after cleaning

•

attach the modules, making sure there are no air bubbles between the

adhesive and the surfaces

•

do not subject the cells of the module to localized pressure during

mounting: this can cause serious damage to the solar cells

Fastening with double-sided adhesive makes it difficult to remove the module

from the surface on which it is glued without damaging it due to the high

adhesion strength that is created between the surfaces. It is therefore

advisable to use this installation method if you do not want to move the

module later and if the installation is final while you are advised to fasten with

dual lock when you need to move the module after installation.

Other installation option

If it is not possible to fix the module as in the two previously-mentioned cases,

please contact Enecom Technical Support who will provide you support

giving instructions on how to proceed with the installation.

Install the panel in a different way than the two descripted without

contacting the technical office and having its permission void the warranty

14

Electrical connections

Connecting several modules together

Several PV modules can be connected to each other in the following ways:

•

in-series connection

•

parallel connection

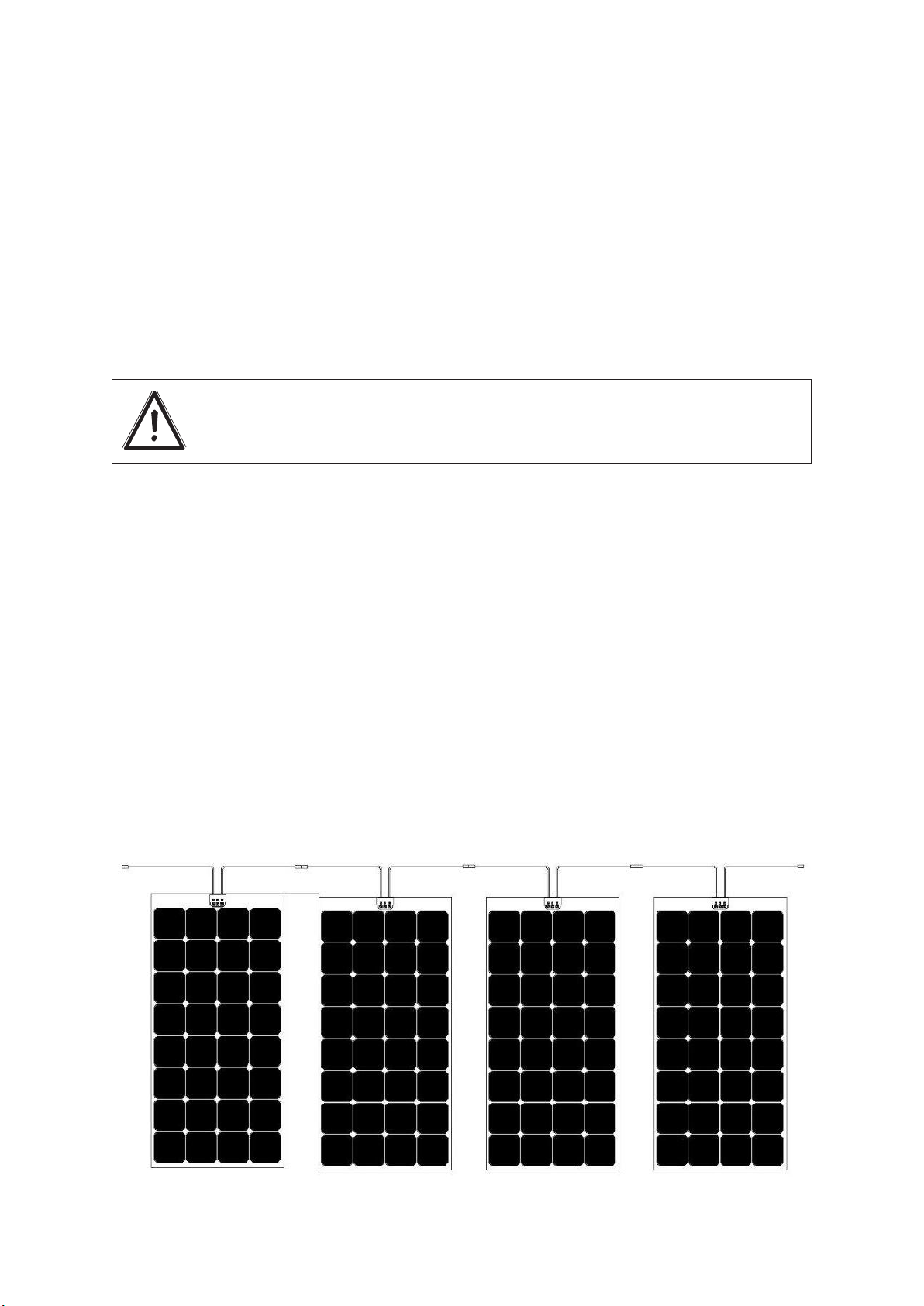

Connection of several modules in-series

For in-series connection, the positive connector (+) of one module must be connected to the

negative connector (-) of the one next to it: in this way, a voltage corresponding to the sum of

the electrical voltages of each individual module will be present between the free connector

of the first module and the free connector of the last module.

∑ VOLTAGE

= CURRENT

This option is not applicable to modules HF20-5-16, HFp20-5-16, HFp40-5-16

with cigarette lighter style socket

15

Modules of the same type can be always connected in series. The connection in series between

different types of modules can be done only after Enecom technician’s authorization.

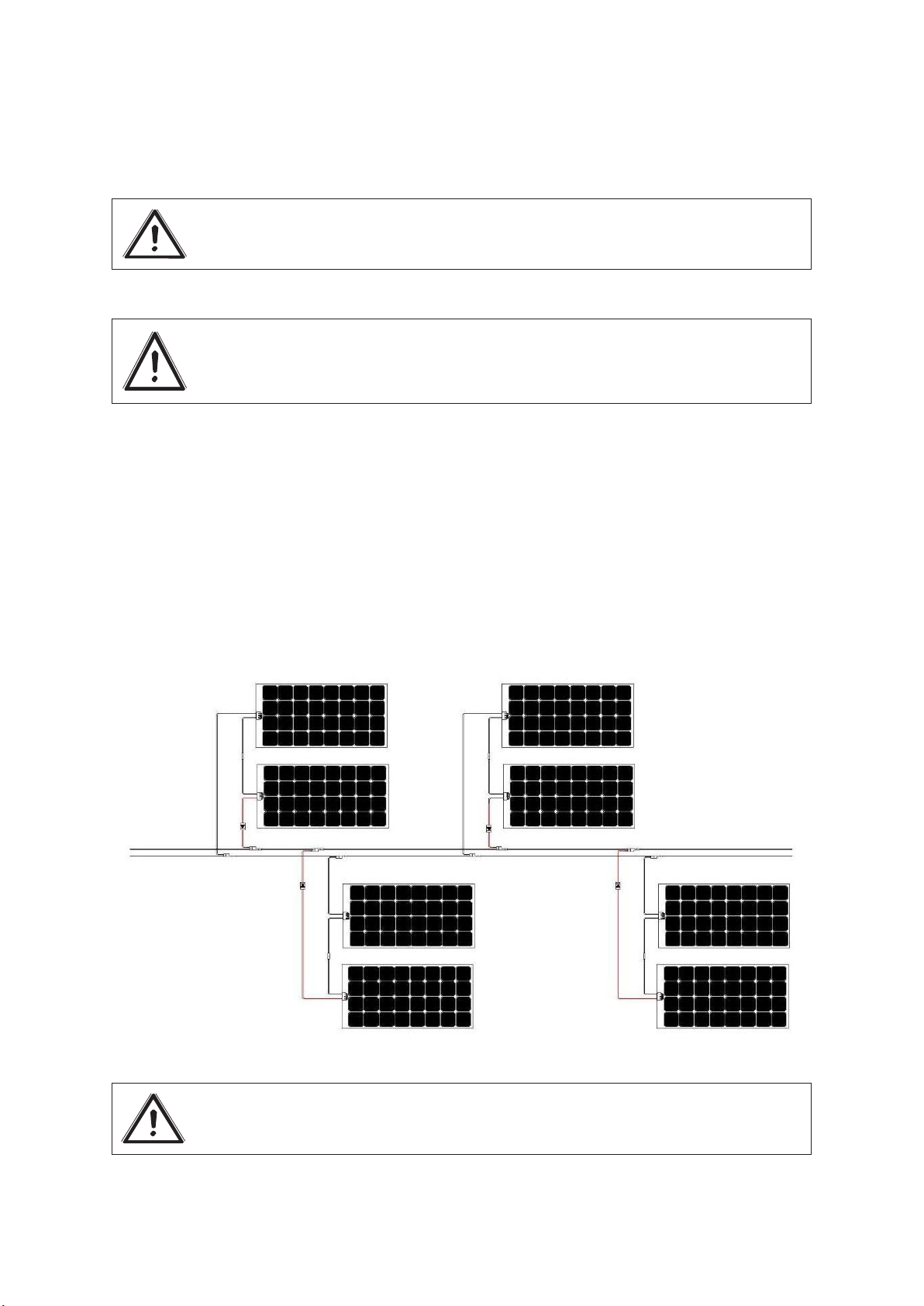

Connection of several modules in parallel

In parallel connection an electrical current is obtained which is the sum of the electrical currents

generated by the individual modules. Establishing a parallel connection requires the use of

additional connectors (parallel connectors) which can be ordered separately from our

accessory range.

VOLTAGE =

∑ CURRENT

Warning! This type of connection is indicated when all modules are

exposed to the sun in the same way. We suggest that the installation of

more than two modules should be performed by a qualified technician.

Warning! All the modules connected in parallel must be identical. It is

also necessary to protect the panels by using blocking diodes placed on

the positive cable of each panel group.

Warning! Wrong connections between the modules void the guarantee.

16

Extension

cables

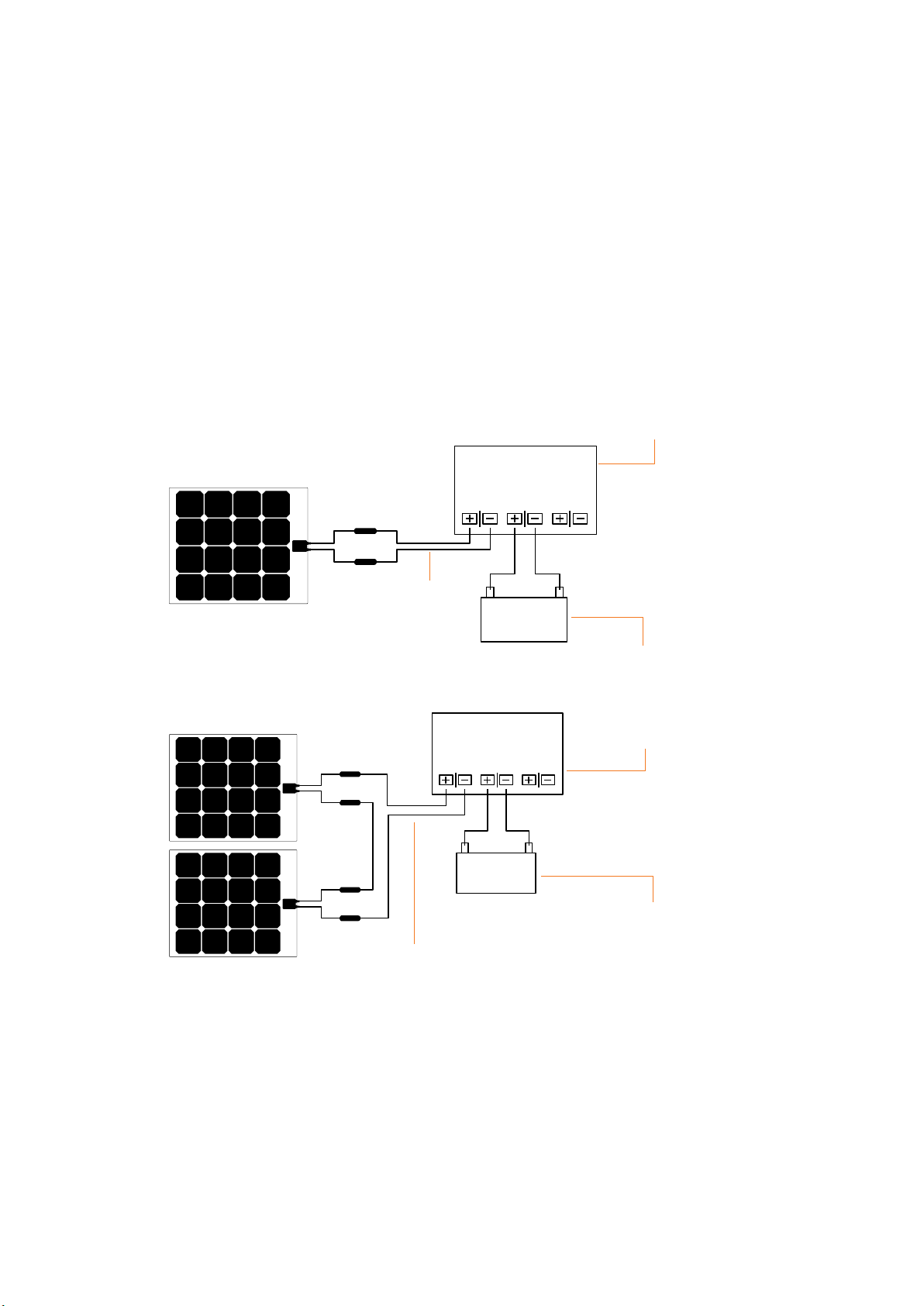

Connecting to an accumulator (battery)

The connection of one or more modules to an accumulator must always be performed by means

of a charge regulator.

The module (or the string of modules) must be connected to the charge regulator and the

accumulator by means of two extension cables.

The charge controller must be chosen according the instruction of its user manual; if the

compatibility is not certain contact Enecom’s technical office. Any erroneous connections to

the solar charger will cause the void of the guarantee and may be a source of malfunction of

the system.

See below some example of connection to an accumulator.

Charge regulator

Accumulator

Charge regulator

Extension

cables

Accumulator

Direct connection is possible only with usage devices that have a built-in battery and charge

regulator.

Modules HF20-5-16, HFp20-5-16 and HFp40-5-16 are suitable for this type of connection by

means of an automobile transformer specific to its device. The transformer is equipped with a

cigarette lighter style plug which is inserted into the module’s socket.

17

Connecting to the electrical network

The connection of one or more modules to the electrical network is not described in this

manual, as it must be performed by a qualified technician because small electrical systems are

subject to specific regulatory constraints and safety regulations.

MAINTENANCE

Photovoltaic modules require very little maintenance because of the absence of moving parts.

Maintenance includes the following:

•

regular cleaning of the module;

•

periodic inspection;

•

electrical performance checks.

Cleaning the module

Dirt accumulated on the upper surface reduces performance and can cause adverse effects

similar to those caused by shade. The problem is more pronounced in areas with high smog

levels or the presence of birds or trees.

The intensity of the effect depends on the opacity of the accumulations (grime, soot, leaves,

bird droppings, etc.). In many cases, rain may reduce or eliminate the accumulation of

impurities on the modules.

Cleaning involves simply washing the module with fresh water or isopropyl alcohol using non-

abrasive sponges. Do not use pressurized water jets.

Inspection

It is a good rule to inspect the photovoltaic system periodically in order to check the condition of

the solar panels and the connections between the devices.

Electrical performance checks

Periodic electrical performance checks help to ensure the proper functioning of the

photovoltaic module: for example, a reduction of the electrical power generated may

indicate an isolated shady area on one or more cells, which can then be rectified to obtain

optimal performance.

18

WARRANTY

The warranty against defects in material and workmanship and the warranty of proper

functioning of the product are given in the document “Enecom Warranty” provided

together with this manual.

CONTACTS

Headquarters

Via Odorico da Pordenone, 28 - 50127 FIRENZE Tel.

+39 055 333017

Fax +39 055 3217162

Prato Operational Unit

Via Siena, 16 - 59013 MONTEMURLO (PO)

Tel. +39 0574 653085

Fax +39 0574 658000

Turin Operational Unit

Via Emilia, 6 - 10099 SAN MAURO TORINESE (TO) Tel.

+39 011 2979165

Tel. +39 011 2976623

Fax +39 011 2742438

Sales department:

info@enecompower.com

CONTATTI

This manual suits for next models

12

Table of contents

Popular Solar Panel manuals by other brands

Ansult

Ansult 019394 operating instructions

Viessmann

Viessmann Vitosol-F Series installation instructions

PHOTOWATT

PHOTOWATT PW72LHT-CB-XF installation manual

iwerkz

iwerkz SolRX instruction manual

EINHELL

EINHELL SO 6-M operating instructions

Photonic Universe

Photonic Universe SWD-FWP-60M instruction manual