Energie Solar Block 4 Guide

CentralHeating

SwimmingPoolHeating

HighVolumeHotWater

InstallationandUseManualfor

SolarBlocks4to40

Eco500to6000

ROV3

1

EUROPEAN CERTIFICATION

EN60335‐1

EN60335‐2‐21

Directives:

73/23/CEE93/68/CEE

Congratulations on your excellent choice in acquiring a system that will reduce your

energy consumption and benefit the environment.

Please read the manual carefully before installing your thermodynamic solar system.

This manual does not intend to replace, in any way, the thermodynamic solar systems

installation course.

ATTENTION

The use of a power circuit with inadequate voltage and frequency will result in the

damage of the unit and potentially cause a fire incident.

Pulling the power cable may cause damage or electric shock. Don't use the power

cable incorrectly.

Always use a fuse with the proper amperage.

As for the feeding cables, please comply with the local rules and regulations. The

improper connection may result in the overheating of the feeding cable, the connector

or the electric socket and cause a fire.

For your safety, turn off the circuit breaker or disconnect the power cable when you do

not intend to use the equipment for a long period of time.

In case the cable needs replacement, use only the network power cable specified by

the manufacturer.

Any and all intervention should be performed by a certified technician.

Any repairing or maintenance operation that is not performed by a certified technician

will result in the loss of warranty.

2

Contents

1.0Functioning……………………..……………………………………………………………………………………………………3

1.1TechnicalSpecifications…………………………………………………………………………………………………………4

2.0Systemcomponents.……………………………………………………………………………………………………………4

2.1ThermodynamicBlock…………………………………………………………………………………………….…….........5

2.2SolarPanel………..........…………………..………………………………………………………………………….……......5

2.3FluidDistributor.....………………………………………………………………………………………………………………..5

2.4Fluid………………………………………………………………………………………………………………………………………6

2.5Tubing....................................................……………………………….………..........................................6

3.0PanelInstallation..……………………………………………………………………………………………………………….6

3.1MaximumDistance……………………………………..………..………….....................……………………………...6

3.2Unevenness…………………………………………………...........................................................................7

3.3SolarPanelsOrientation........................……………………………………………......................................7

3.4TiltAngle...............………………………………………………………………………………………………………………...7

3.5TypeofThermodynamicSolarPanels...…………………………………………………………………………………8

3.6StandardDistancebetweenthePanels....……………………………………………...................................8

3.7PanelLayout……………….………………………….............…………………………………………………………………9

3.8SolarPanelFixing……………………………………………………………………………………………………………………10

4.0ThermodynamicBlockInstallation…………………………………….………....….........…………………………10

4.1ChoiceofLocation..........................................................………………………………………………………..10

5.0ConnectionbetweenthePanelsandtheThermodynamicBlock………………………………………….11

5.1Welding………….………………………………......................................................…………………………………11

5.2DistributorsandCollector'sConnectiontothePanel's Tubing………………………………………………12

5.3Suctioncollector..................................……………………………………………………………………………………12

5.4ConnectionstotheThermodynamicBlock......……………………………………....................................13

6.0HydraulicConnections.............................……………………………….................................................13

7.0FluidLoad..................………………..………………………………………………………………………………………...14

7.1Leak‐tightnessTesting……………………………………......................……….…………………………..…………...14

7.2Vacuum......................................................................................………..…………………………………...14

7.3LoadofR407c...............................................………......…………………………………………………..………..14

8.0ControlPanel......................................................................…………………………………………………...16

9.0ElectricalWiring...........................…………………………………………………………….……………………........16

10.0Troubleshooting..................………………………………………………………………………….…………………..18

11.0InstallationSchemes…………………………………………………………………..........................................

Guarantee…………………………………………………………………………………………………………………………………….

21

30

3

1.0Functioning

TheENERGIEsolarsystemsarethermodynamicsolarsystems.

Thesolarpanellocatedoutsideensuresthecaptureofenergythrough:

oDirectanddiffuseradiation

oExteriorairbynaturalconvection

oWindeffect(usuallypresent)

oRainwater

Thetemperaturegradientcausedbytheabovefactorsensuresthatthefluidpassestothe

gaseousstateinsidethepanel.

Thecompressorextractsthecoolingfluid(vapour)fromthepanelbyrisingitspressureand

temperature,whichisthentransmittedtothewatercircuitthroughaheatexchanger.

Theexchangerisplacedinsidethecabinet(ThermodynamicBlock)providingheattothewater

ithasinside.

Whenthecoolantreachestheexpansionvalveitisintheliquidphase,andthelossofloaddue

tostrangulationreducesthepressure,whichleavesthefluidreadytore‐enterthepanels.

Sun

Wind

Rain

ThermodynamicGroup

Solar

Panels

4

1.1TechnicalSpecifications

TheSolarBlocksandtheEcomodelsforhighvolumewaterheating(HVWH)ENERGIEareon

themarketinarangewith4,6,8,12,16,24,32or40solarpanelsaccordingtothefollowing:

CentralHeating/SwimmingPoolHeating

ModelNrofPanelsAbsorbedPowerSuppliedPowerFlow(m3/h)

SolarBlock44960W7,290W0.5

SolarBlock661,230W9,680W0.7

SolarBlock681,440W11,240W0.8

SolarBlock12122,010W16,580W1.0

SolarBlock16163,210W24,210W1.5

SolarBlock24244,140W31,430W2.8

SolarBlock32325,690W42,600W4

SolarBlock40407,630W52,970W5

HVWH

Model

Capacity

(L)

NrofPanels

Dim.HotWaterCylinderAbsorbed

Power

Thermal

Power

Height

(mm)Diameter(mm)

ECO50050021830650595W2,800W

ECO75075042135750960W7,290W

ECO1000100042185850960W7,290W

ECO15001500624609501,230W9,680W

ECO200020008252011001,440W11,240W

ECO3000300012290012502,010W16,580W

ECO3000E300016290012503,210W24,210W

ECO4000400024296014504,140W31,430W

ECO5000500032303016005,690W42,600W

ECO60006000402x29002x12507,630W52,970W

2.0SystemComponents

TheThermodynamicSolarSystemsarecomposedbythefollowingelements:

oThermodynamicBlock

oThermodynamicSolarPanels

oLiquidDistributor

5

2.1ThermodynamicBlock

TheThermodynamicBlockiscomposedofseveralelementssuchas:

oCabinet

oHermeticcompressorScrolltype

oHeatexchanger*

oExpansionvalve

oOilseparator

oFluidtank

oFilter

oFluiddisplay

oPressuregauge

oDigitalthermostat

oElectricalequipment

*‐titaniumheatexchangersgoapartfromthethermodynamicblock.

2.2SolarPanel

Thesolarpanelismadeofanodized

aluminiumofdualrailwithpostpressing

anodicoxidationforhighsolarabsorption.

Thedimensionsofthepanelare2000mmx

800mmx20mm,anditfeaturesafluidflux

inandoutmadeofacopper/aluminiumtube

withinnerdiameterof¼’’.Itweights

approximately8kg.

Whiletransportingthecollectorprotectedit

againstimpactandmechanicalactions,thereforeproperpackagingupontransportationis

recommended.

2.3FluidDistributor

Toensurethatthefluidreachesthepanelin

aseamlessmanner,it'snecessarytoinstalla

fluiddistributor.Thisdistributorfeaturesas

manydistributiontubesasthenumberof

panelsintheinstallation.

Thedistributorisplacedbetweenthepanels.

Theconnectiontubestothepanelsmust

havetheexactsamelengthanditsendsare

directlyconnectedtothepanels.

Dimensions[mm]ABC

ThermodynamicBlockfrom4to16panels880630430

ThermodynamicBlockfrom24to40panels880750500

SolarPanel

Serpentinedetail

6

2.4Fluid

TheR407cisazeotropicmixture(afluidwithmorethanonecomponent).Itischemically

stable,possessesgoodthermodynamicproprietiesanditpresentsitselfasacoolantwithlow

impactontheenvironmentandreducedtoxicity.

2.5Tubing

Itisessentialthatthetubinghavecoolingqualities,bothinthesuctionandinthefluidline

(feeding).Itisalsorecommendableforallthetubingtohaveahighqualitythermalisolationto

avoidpotentialcondensation.

Thetubingdiametervariesaccordingtothesystemmodel,asshownonthefollowingtable.

TubingDimensions

ModelSuctionLineFluidLine

SolarBlock4/Eco750/Eco10005/8’’1/2’’

SolarBlock6/Eco15003/4’’1/2’’

SolarBlock8/Eco2003/4’’1/2’’

SolarBlock12/Eco30007/8’’1/2’’

SolarBlock16/Eco1500 7/8’’3/4’’

SolarBlock24/Eco40001’’1/83/4’’

SolarBlock32/Eco50001’’1/87/8’’

SolarBlock40/Eco60001’’3/87/8’’

3.0PanelInstallation

3.1Maximumdistance

Themaximumdistancebetween

panelsandtheThermodynamicBlock

is20meters,howeverifshouldthere

beabiggerdistancetheeventual

lossesgeneratedbythelengthofthe

tubingcanbereducedwiththecorrect

calculationofthethermalisolation

usedandbyadjustingthetubes

diameters.

FluidR407c

MolecularMassKg/Kmol86.2

Boilingtemperatureat1.013barºC ‐43.28

CriticaltemperatureºC86.2

Latentheatuponevaporationat25ºCkJ/kg250

Criticalpressurebar54.5

Fireresistant

Max.H=15

7

3.2Unevenness

Innormalsituationsthemaximumunevennessshouldalwaysbelessthan15meters.

However,therearesituationswhereitisnotpossibletorespectthatmeasurement.Insuch

casesyoupleasecontactourtechnicaldepartment.

Thesuctiontubingandthedistributionrodsshouldriseabovethepanellevel,inordertoavoid

theeffectofquicksiphonofthefluidwhenthecompressorstops.

3.3SolarPanelsOrientation

TheENERGIEsolarpanelsshallbe,

preferablyorientedtowardsSouth,but

theycanalsohaveadislocated

orientationtoNortheastorNorthwest.

3.4TiltAngle

Thetiltingangleofthesun

beamsinrelationtothe

horizontalpositiondependson

theseason.Inthewinter,in

Zenith,thesunbeamshavean

angleof20ºto40ºinrelationto

thehorizon.Inthesummer,the

angleisbetween60ºand80º.

Tobenefitthemostfromthesunbeamsitispreferabletochooseatiltbetween45ºand90º.

Youmayhoweverinstallthepanelswithadifferenttiltincertainsituations.

North

WestEast

SouthOptimalOrientation

OrientationLimits

Bad

Good

Summer

Winter

Horizont

Zenith

8

3.5TypeofThermodynamicSolarPanels

Therearetwotypesofpanels:

oLeftSolarPanels

oRightSolarPanels

Thedirectionofthepanelsisdefinedbythedownwardtubingexitsandbytheviewofthe

frontpartofthepanels.Theyshouldalwaysbeplacedwithalongerhorizontallengthandthe

connectionsfacingdown.

Left:Aleftpanelisinstalledontheright(frontview);forthatpurposeitsconnectionsareon

theleftside.

Right:Arightpanelisinstalledontheleft(frontview),forthatpurposeitsconnectionsareon

therightside.

3.6StandardDistancebetweenSolarPanels

Thepositionofthepanelsandthechoiceoftheconnectionsidesshallbedonesuchastolimit

thelengthofthetubingandsimplifytheconnections.

Asforthedistancebetweenthepanels,itischoseninordertofacilitateitsplacementandthe

connectionbetweenthetubing.

‐Minimumspacebetweenpanelsontheconnectionsside:200mm(idealspacing:500mm)

‐ Spacingbetweenthepanelsontheoppositesideoftheconnections:theyshouldnotbein

contactwithoneanother(preferably>10mm)

SteamLine(Out)

LiquidLine(In)

SteamLine(Out)

LiquidLine(In)

9

3.7PanelLayout

TherelativePositionofthepanelsdependsonwhichsystemisinstalled,ontheavailable

installationarea,onthearchitectonicintegration,amongothervariablesthatmayhavelocal

impact.

Someofthepossiblelayoutsforthepanelsarerepresentedinthefollowingscheme.The

installationtechnicianmayoptforadifferentlayoutaslongasitcomplieswithalltherelevant

criteriaforanadequateinstallation.

SolarBlock4orEco750/1000

a)b)

SolarBlock6orEco1500

a) b)

SolarBlock12orEco3000

a)

b)

ENERGIEENERGIE

ENERGIE ENERGIE

ENERGIE

ENERGIE

ENERGIE

ENERGIE

ENERGIE

ENERGIEENERGIEENERGIE

ENERGIE ENERGIE

ENERGIE ENERGIEENERGIE ENERGIE ENERGIEENERGIE

ENERGIE

ENERGIE

ENERGIE

ENERGIE ENERGIEENERGIE

ENERGIE ENERGIE

ENERGIE ENERGIE

ENERGIE ENERGIE

ENERGIE

ENERGIE ENERGIEENERGIE

ENERGIE ENERGIE ENERGIEENERGIE

ENERGIE ENERGIEENERGIE

ENERGIE

10

3.8SolarPanelsFixing

Thefixingofthepanelsdependsontheinstallationsite.Themethodandtypeoffixing

dependsentirelyontheinstaller'sdecision.Thereare,however,severalfactorsthatshouldbe

takenintoconsideration(previouslydescribed,suchasthedistanceandtheorientation)for

thecorrectpanelsfixing.Asforthephysicalpartofthefixingstands,theyshouldhavea

resistantstructureaccordingtothecircumstancesofthesite.Eachandeverypanelmustbe

fixedin6points(atleast).

Thefollowingpictureisanexampleofthefixingused.The

fixingofthepanelsisensuredbyaluminiumstands.

Thestandisfoldedintoan"L"shapewithtwoM8bushing

holes.Thestandbaseisfixedtotheroof(ifthatisthe

case)withaM6screwandaplasticsleeveorbya

threadedfemale(dependingonthesituation).

TheotherharmofthestandisfixedwithgalvanizedM6

screwstopreventcorrosion.

NOTE:Thepanelsshouldhaveaminimum

spacingof50cm(inrelationtothepreviousand/ornextpanel)

4.0ThermodynamicBlockInstallation

4.1ChoiceofLocation

Thechoiceofthelocationwherethethermodynamicblockisgoingtobeplacedhasamajor

importance,andshouldbechosentakingintoconsiderationacertainnumberofimportant

criteria,suchas:

oAccessibility

o(incaseofreplacement)

oPossibilityofvibrationtransmission

oPositionofthetubingcomingoutofthepanels

Itisessentialthatthethermodynamicblockstaysinadryventilatedplace

protectedfromallweatherconditions.

Thelocationshouldbechosensoastofacilitatethesettingandconnectionofalltubes,and

itshouldalsoalloweasyaccesstomaintenanceoperations.

Note:Avoidinstallingthethermodynamicblocknearbedroomssincetheymaytransmit

vibrationand/ornoise.

Itmaybeplacedinthefloororonacantilevered(upagainstawall).

Youshouldplaceanti‐vibratingstandsbetweeneachapplianceandthefloor.

Inthecaseitiscantilevered,itshouldbefixedtothegroundandtothewall,andseparatedby

anti‐vibratingstandsbetweenthecabinetandthewalls.Ifyouputtheblockintheatticyou

shouldpayspecialattentiontothevibrationstransmittedtothebuilding(madeofwood).You

11

shallalsoplaceatrayunderneaththeappliancesoitmayretrievewaterincaseofapotential

leakageontheequipment.

Duringtransportandinstallationneverholdormanipulatethethermodynamic

blockbytheit’stubes.

5.0ConnectionbetweenthePanelsandtheThermodynamicBlock

Whentheinstallationofthesolarpanelsandthethermodynamicblockiscompletedthenext

stepisinstallingtwotubingconnections:

oFluidTubing(feeding)

oSuctionCollector

Beforeyouperformtheabovementionedconnectionsitisadvisabletoexecutethe

connectionsofthetubesofthepanelstothe:

oLiquiddistributor(s)

oSuctioncollector(s)

Establishingtheconnectionsisoneofthemostdelicatestepsofthewholeinstallationanditis

veryimportantthattheweldingisdoneaccordingtoallkeycriteriaforaqualitywelding

process.

5.1Welding

Thetypeofweldingrecommendedforperformingthetubingconnectionistheoxy‐acetylene

welding(oxygen/acetylene).Anothertypeofgasmaybeused,like,forinstance,propane.

Theconnectiontubingisweldedtotheinandoutwithasilverrod(at40%).Before

startingtheweldingprocess,youshouldperformsomepreventiveactionssothat

the"retractilejoint"isnotdamaged.

Withapieceofdampclothyoushouldenvelopthe"retractile

joint"sothatitisproperlyprotectedfromthehightemperatures

causedbytheweldingflame,asitisshowninthefollowing

picture.

Nowheatupthemetal:thecopper,untilitbecomesdarkred.

Drawtheweldingrodcloser,slightlytilted,withoutexposingitto

theflame.Generally,theamounttoapplyequalsoneandhalf

timesthediameterofthetube.Assoonasthealloyexpands,

stopheatingandletitcooldown.Removethesurplus.

Whentheweldingiscompletedandafterensuringthatitisnolongerintheliquidstate,you

shouldquicklycooldowntheentiresurroundingareaoftheweldingwithawetcloth.

Theweldingnearthethermodynamicblockshouldalsobedonewithasilverrodandattention

shouldbegivensoasnottoburnanycomponentoftheblock.

Afteralloperationsarecompleted,thesystemisreadytoperformaleaktightnessproofand

alltheloadprocessofcoolant.

12

5.2DistributorsandCollector'sConnectiontothePanel'sTubing

Forconveniencereason,theplacementofthedistributorandthecollectormaybedoneprior

totheinstallationofthepanels(nuisance,passageofthetubingbehindthepanels)

Removetheprotectionlidsofthetubingonlywhenyouconnectthefeedingandthesuction

rodstopreventtheentranceofimpurities.

Installthedistributor(s)verticallyheaddown(neverhorizontally!)thusensuringthatthefluid

getstothepanelshomogeneously.

ENERGIEENERGIE

ENERGIEENERGIE

ENERGIEENERGIE

ENERGIE ENERGIE

Linha de Líquido

Lira Principal

Cu 1/2"

Itisimperativethatallfeedingrods(

∅

1/4’’)havethesamelength.Thesame

appliestotherodsofthemaindistributor.

Ifoneoftherodsistoolongforthelengthitneedstocover,youshouldrollitupandnevercut

it.Shouldyouwanttoshortenorextendaroditisalwaysnecessarytoperformthisprocess

onalltherodswiththesamediameter.

Alloftherodswith∅1/4’’mustbeweldedtothelowerconnectionsofthepanels(fluidin).

Therodswith∅1/2’’ofthemaindistributormustbeweldedtothesecondarydistributors.

5.3Suctioncollector

AccordingtotheThermodynamicBlock'smodelandthepositionofthepanels,itisnecessary

tomakeoneormoreSuctioncollectors.

Thesuctioncollectorthatenablesretrievingthecoolantinthegaseousstatemustregroupall

suctionexits(∅3/8’’)fromthepanelstothecollector.

Allrodsshallbeweldedtothetopexitsofthepanels.

Itisimportantthattheconnectionsinthecollectorsareassimpleaspossibleandthatthe

instructionsarefollowedincasethereisaramp.

ENERGIEENERGIE

ENERGIE ENERGIE

ENERGIEENERGIE

ENERGIEENERGIE

Cu 5/8"

Cu 5/8"

Cu 3/4"

Linha de Aspiração

Liquid Line

Suctionline

13

5.4ConnectionstotheThermodynamicBlock

Thethermodynamicblockhasseveraldifferentconnectionsas

describedbelow.

Theconnectionsofthethermodynamicblock(cabinet)tothe

panelsaredulysealedsoastoavoidtheentranceofimpurities

inthecoolingcircuitandtoprovideinsulationfromthe

humidity.

Beforeproceedingwiththepanelsconnectionsitisnecessarytoemptythenitrogen

loadthroughtheloadpipe(allequipmentleavesthefactorywithanitrogenloadat

30bar).

6.0HydraulicConnections

Theconnectionofthethermodynamicblock(cabinet)totheheatingcircuitisdoneaccording

tothetypeofinstallation:

oNewstructure

oExistingstructure(whenreplacinganothersystem)

Incaseofanewstructure,thelayoutofthewatercircuitmustbecarefullystudied,takinginto

considerationthebestlocationfortheblock(cabinet).Incaseofanexistingstructure,the

thermodynamicblockmust,imperatively,beplacedinparallelwiththeothersystem(ifthatis

thecase)andchoosethebestplacetoinstalltheBlockstudied,whilerespectingtheexisting

watercircuit.

Itismandatorytoapplyananticorrosionadditive(stabilizingfluid)tothehydraulic

circuittopreventclogging,electrolyzephenomenaandnoiseinthecircuit.

First,preferablychooseheatemittersoflargeexchangesurface(under‐floor

heating,radiators,convectors,fanconvectors),sincetheyenabledistributionatlow

temperatureandachievebetterperformances.

Thecirculationpumpmustbeplacedtakingintoaccounttheloadlostandtheminimumflow

ofthecondenser(heatexchanger).Thenexttablepresentstheminimumflowforeachofthe

systems:

SolarBlock 4681216243240

Minimumwaterflowinthecondenser(m3/h)0.50.70.81.01.52.845

NrDescription

1SuctionLine

2FluidLine

3ConnectiontotheHeatExchanger(DHW/SwimmingPool)

4Exit(watercircuit)

5Return(watercircuit)

6ElectricalWiring

14

7.0Fluidload

7.1Leak‐tightnessTesting

Aloadofnitrogenatapressureof12bar(max.15bar)willbeoptimaltoensurethatthereare

noleaksinthewelding.Whentheequipmentisdulycharged,envelopalltheweldingwith

soapfoamandchecktheexistenceofnitrogenleaks.

Thepanelsshouldbe2to3dayswithaloadofnitrogentoensureinexistenceofleaks.Once

thisoperationiscompleted,removeallnitrogenfromtheequipment.

7.2Vacuum

Beforeloadingthecoolant,youmustcreatevacuumintheequipment.Thepurpose

ofvacuumisremovingallairandhumiditypresentinthecircuit.Theamountof

vacuumtimedependsonthefollowingfactors:

oVolumeofthevacuumpumpinm3/h

oVolumeofthetubes

oVolumeofthesystem

oAmountofwaterinthesystem

Thisoperationisdonefromtwoloadpipes,placed,oneinthesuctionline(nearthe

compressor)andtheotherinthefluidline.

Oncethevacuumprocessisover,closethefaucetsofthevacuumpump.Thevacuumgauge

shouldalwayspresentthesamereadingafterstoppingthepump,thusensuringthatthe

equipmentmaintainsthevacuumandisreadyforthecoolantload.

SolarBlock4681216243240

Minimumtimeofvacuum(Hours)45689101112

7.3LoadofR407c

Whendealingwithazeotropicfluid,suchastheR407c,itisnecessarytohavesomecaution

whenloadingtheequipment.Ifyouloadtheequipmentwithazeotropiccoolantinthe

gaseousstate,thereistheriskthatoneofthecomponentswillvaporizebeforeallothersand,

therefore,theequipmentwillhaveahigherproportionofthatcomponent.Forthatreason,

youshouldloadtheequipmentwiththecoolantintheliquidstate.Mostoftherecipientsof

theR407chaveasystemthatallowsloadingintheliquidstate,asshowninthefollowing

picture.

Loadingprocess

fromatankwith

asiphon

Loadingprocess

fromatank

withoutasiphon

ValveValve

15

Beforestartingtheloadingprocessyoushouldmakesurethatthecompressoristurnedoff.

Thefluidloadisdonethroughthecompressionpipe.Theamountoffluidthatwillbeloaded

intothesystemdependsessentiallyontwofactors:

oThemodelofthesolarsystem

oDistancebetweentheblockandthepanels

ToensurethefunctioningofthethermodynamicsystemyoushouldperformafluidPre‐load

(fluidminimumload).Thepre‐loadisdonethroughthehighpressurecompressionpipewith

thecompressorturnedoff.Pleasefindthepre‐loadvaluesonthefollowingtable:

Whenthepressureisequalonthegaugesthesystemisreadyforstarting‐upthecompressor.

Thetuning(remainingload)ofthesystemisdoneveryslowlythroughthelowpressure

suctionpipewiththecompressorturnedon.Forthatyoushouldperformtheloadslowly

throughthesuctionlineuntilyoureachadifferenceof20ºCbetweenoutsideairtemperature

andsuctiontemperature(forlowgaugeswithSTEAMreadings!).

Or,youshouldgetascloseaspossibleofthefollowingsuctionpressurefiguresforthe

respectiveexteriortemperature(airtemperaturenearthesolarpanels).

*Forreturnwatertemperaturesbetween25to30ºC

Note:Youmaynotbeabletoobtaintheexactdesiredpressure,sinceitdependsonfactors

suchas:

oDirectsolarradiationonthepanels

oVentilation

oRelativehumidityoftheair

oDistancevariations(unevennessandhorizontal)

Whenthesolarsystemisusedforswimming‐poolheatingyoushouldalwaysapply

atitaniumheatexchangerorothermadeofamaterialthatwillresistthe

aggressivenessofsuchwaters.Neveruseastainlesssteelheatexchangerdirectly!

ModelPre‐Load

SolarBlock4/Eco750/Eco10001.5kg

SolarBlock6/Eco15001.6kg

SolarBlock8/Eco20001.8kg

SolarBlock12/Eco30002.0Kg

SolarBlock16/Eco15002.5kg

SolarBlock24/Eco40003.0kg

SolarBlock32/Eco50003.5kg

SolarBlock40/Eco60004.0kg

ExteriorTemp.SuctionPressure

(ºC)(bar)

01.2

51.6

102.2

152.9

203.6

254.5

305.5

16

8.0ControlPanel

Itpresentsitselfasanelectronicdevicewhichisthecontrol/commandinstrumentofthe

ENERGIEsystem.Throughityoucanconfigureseveralfunctioningparameterssuchas:return

temperature,temperaturedifferentialandtimers,amongothers.(seeattachedelectronic

manualSY255)

9.0ElectricalWiring

Donotpowertheelectriccompressorbeforeallcoolingconnectionsarecompleted,makesure

thatthecircuitisloadingandthatthehydrauliccircuitisproperlyfilledwithwater.

Theelectricpowerofthesystemsmustbecompliantwithfactoryfeaturesasshowninthe

followingtable:

ModelPowerInput

Eco500230/400V(50Hz)

SolarBlock4/Eco750/Eco1000230/400V(50Hz)

SolarBlock6/Eco1500230/400V(50Hz)

SolarBlock8/Eco2000230/400V(50Hz)

SolarBlock12/Eco3000230/400V(50Hz)

SolarBlock16/Eco1500400V(50Hz)

SolarBlock24/Eco4000400V(50Hz)

SolarBlock32/Eco5000400V(50Hz)

SolarBlock40/Eco6000400V(50Hz)

Theterminalsconnectingtheblocktotheelectricalswitchboardareontheinnerpartofthe

thermodynamicblock'sdoor.

Theelectricpoweringofthesystemshallbeensuredfromtheexistingelectricalswitchboard

byacablewiththeappropriatesection(asseeninthetablebelow).Thepoweringofthe

circulatorpump(s)shallbeensuredbyacableof3x1.5mm2(minimum).

Youshouldhowevermakesurethattheelectricalcurrentissufficientforthesystemsyouare

installing.

Priortosettinguptheelectricalconnectionsofthesystemyoushouldinstalladevicethat

ensurespeople'sprotectionagainstpossibledirectand/orindirectcontactswiththeelectric

circuit.ThosedevicesarecalledDifferentials.

Selection Button (+)

Compressor Led

Esc Button

Pump 1

Pump 2

Menu/Set Button

Room Temperature

Thermostat Led

Selection Button (-)

ViewingButtonProbe1

RUNLed

ON/OFFButton

DailyChronoLed

WeekendChronoLed

ChronoDisplayButton

WeeklyChronoLed

ViewingButtonProbe2

17

Youshouldalsoprotectthecircuitfrompossibleoverloadsandshort‐circuitsbyinstallinga

magneto‐thermalcut‐outswitchwiththefollowingintensities:

Asthisismandatory,allequipmentmustbeaccompaniedbyanelectrical

switchboardwiththeabovementionedprotectionfeatures!

ModelElectriccable(mm2)Magneto‐Thermal

230V400V230V400V

Eco5002.5‐ ‐ ‐

SolarBlock4/Eco750/Eco10002.52.516A 6A

SolarBlock6/Eco15002.52.516A 6A

SolarBlock8/Eco200042.520A 10A

SolarBlock12/Eco300042.525A 10A

SolarBlock16/Eco1500‐2.5‐16A

SolarBlock24/Eco4000‐4‐16A

SolarBlock32/Eco5000‐4‐20A

SolarBlock40/Eco6000‐6‐25A

Theelectricalconnectionsintheblockmustrespecttheconnectionsshowninthefollowing

pictures.

Three‐PhasePowerInput:

NrDescription

1Phase(L1)

2Phase(L2)

3Phase(L3)

4Neutral

5BCirculating2(Phase)

6BCirculating2(Neutral)

7BCirculating1(Phase)

8BCirculating1(Neutral)

9VContact

10

11Ambient

Thermostat

12

TGround

SinglePhasePowerInput:

NrDescription

1Phase

2Neutral

3BCirculating2(Phase)

4BCirculating2(Neutral)

5BCirculating1(Phase)

6BCirculating1(Neutral)

7VContact

8

9Ambient

Thermostat

10

11Ground

Contact V

Ambient

Thermostat

Earth

Contact V

Ambient

Thermostat

Earth

18

10.0Troubleshooting

Whenthesystempresentsanyfailure/malfunction,theupperdisplayoftheelectronicdevice

shouldshowthe"message"forthatmalfunction.Thecausesforeachpossiblemalfunction

are:

“LP”error(systemdoesnotwork)

‐Possibleshortageofcoolantpotentiallycausedby:

oCoolantleakage

oInadequateload

“LP”error(systemturnsoffcyclically)

oExteriortemperatureistoolow.

oShortageofcoolant.

oCloggingofcoolingcircuit.

oHumidityinthecoolingcircuit.

“HP”error(systemdoesnotwork)

oCoolantexcess.

oShortageofwaterinthehydrauliccircuitorexcessofair.

oFailureinthecirculationofthehydrauliccircuit.

“TS”error(systemdoesnotwork)

oShortageofcirculationofthewaterorpumpstoppagewhichrisesthetemperatureof

theprobe1or2andtheelectronicdevicecutsthecircuit.

“Tn”error(systemdoesnotwork)

oPerformanceofthethermalrelayforsituationsofexcessiveconsumptionbythe

compressorand/orproblemsinthenetworktension.

19

This manual suits for next models

16

Table of contents

Other Energie Solar Panel manuals

Popular Solar Panel manuals by other brands

Sharp

Sharp ND-AF C Series installation manual

Thrane&Thrane

Thrane&Thrane EXPLORER 700 quick start guide

Comnet

Comnet netwave NWKSP3 Installation and operation manual

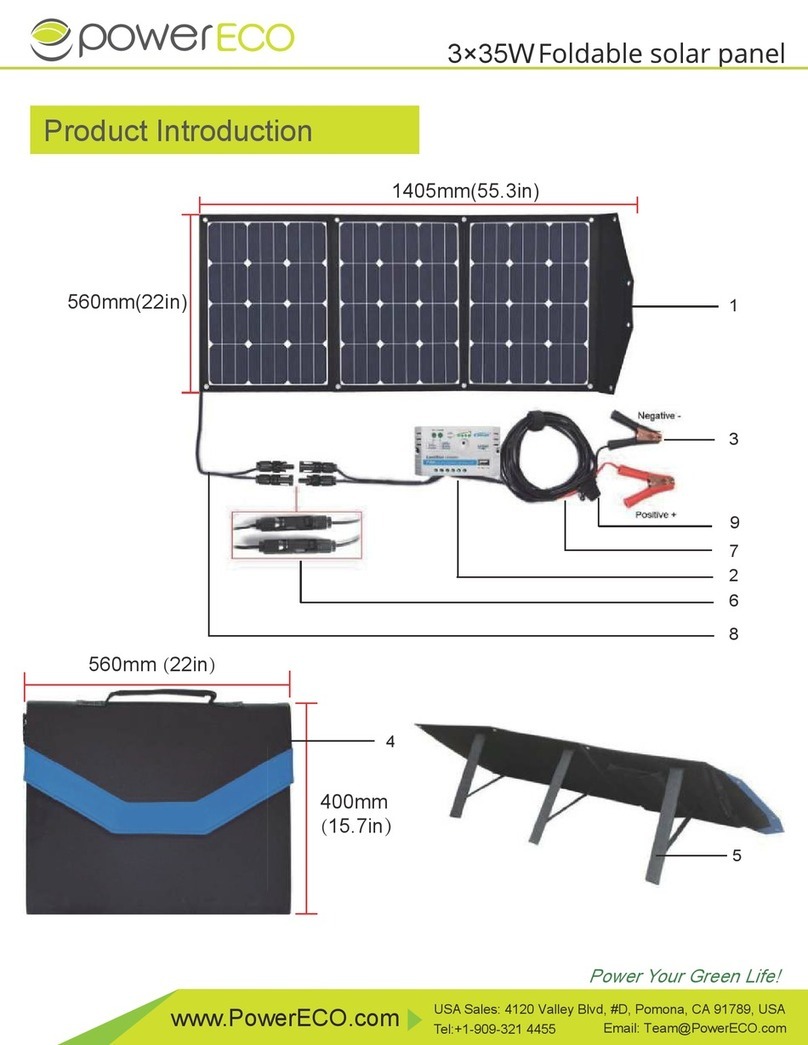

Powereco

Powereco PE-LTK-3x35W manual

Schumacher Electric

Schumacher Electric SP-5400 owner's manual

Sunny Scout

Sunny Scout VISION operating manual

PION POWER

PION POWER PVSolver GS-03 installation manual

Chicago Electric

Chicago Electric 96350 25W Operation instructions

Lippert

Lippert GS-STAR-200W user manual

Scheuten

Scheuten Solar Fusion P6-60 U Safety and installation guide

Viessman

Viessman VITOSOL 100-F installation instructions

Solimpeks

Solimpeks Wunder CLS 2510 instruction manual